Escolar Documentos

Profissional Documentos

Cultura Documentos

Saudi Arabia Qurayyah: Functional Description and Logic Diagram For Block Load Control

Enviado por

anbesivam87Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Saudi Arabia Qurayyah: Functional Description and Logic Diagram For Block Load Control

Enviado por

anbesivam87Direitos autorais:

Formatos disponíveis

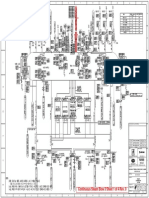

11/21/11 J .H.Kim P.H.

Kim

11/08/10 J .H.Kim P.H.Kim

DATE CHKD. CERT.

Project Title

Client

Consultant

in association with

Contractor

Document Title

J H Kim CREATEDBY:

REV.

NO.

001

000

APPD.

D.J .Kim

D.J .Kim

DESCRIPTION BY:

Issued for Approval (Revised as per discussion) J .H.Kim

J .H.Kim Issued for Approval

J H Kim

CONVERSION OF QURAYYAH OPEN CYCLE POWER

PLANT TO COMBINED CYCLE POWER PLANT

PROJECT C

Functional Description and Logic Diagram for

Block Load Control

CHECKEDBY:

EE-01824 30621127 000 3BD

DATE COMPLETED:

J OB NO.

PROJ ECT

SUBDIVISION

DOCUMENT NUMBER DOCUMENT TYPE CODE

DOC. NO.

SAUDI ARABIA

DATE STARTED:

REV. NO.

THIS DOCUMENT IS NOT TO BE USED FOR

CONSTRUCTION OR FOR ORDERING

MATERIAL UNTIL CERTIFIED AND DATED

J .H.Kim

OPR'G. DEPT.:

CREATED BY: J .H.Kim

J OB ORDER NO.

001

CHECKED BY:

ENG. DEPT.:

REV. NO.

APPROVAL/CERTIFICATION INFORMATION

QURAYYAH

1-0923053.01

30621127-000-3BD-EE-01824 PAGE 1 OF 20

Project : QURAYYAH CCPP

Subject : Functional Description and Logic Diagram for Block Load Control

Doc. No. : 30621127-000-3BD-EE-01824

1

CONTENTS

1. General

2. Block Load Control (Station Load Control) Philosophy

3. Conceptual Operation Block Diagram

Appendix:

-. DCS Graphic for Block Load Control

-. Logic Diagrams for Block Load Control System

-. AGC Control Logic in Existing DCS

1

1

1

1

30621127-000-3BD-EE-01824 PAGE 2 OF 20

Project : QURAYYAH CCPP

Subject : Functional Description and Logic Diagram for Block Load Control

Doc. No. : 30621127-000-3BD-EE-01824

1. General

The Block Load Control will be implemented in the Qurayyah Combined Cycle Power

Plant DCS control system. It will co-ordinate the electrical loading of the Gas Turbine

Generators (GTGs) and Steam Turbine Generators (STGs) and will provide setpoints to

GTG control systems to achieve Block (Station) MW Control.

2. Block Load Control (Station Load Control) Philosophy

The block (individual power block) total power demand (target) will be selected by an

operator selectable setpoint or load demand from LDC (Load Dispatch Center) and is

calculated by the DCS, which adjusts the individual load setpoints for each of the

operational GTGs.

Control of the power output from the individual GTGs will also be possible from their local

control panels using a local setpoint. Selection of the point of control will be from the

respective local control panel (remote for DCS control). All the setpoints for local and

remote operation are contained within the GTG respective local control panels. The

transfer from local to remote control and vice versa shall be bumpless.

STG MW OUTPUT

STGs MW output will be controlled separately. They will operate either on a speed/load

control or IPC (Inlet Pressure Control) the load will vary with the process conditions.

Therefore the DCS station load controller will only consider the MW production from the

steam turbines as part of the generating calculations, and adjust the GTGs load control to

compensate.

GTG MW OUTPUT MODES OF OPERATION

Each GTG can be run in the following modes of operation:

Manual Speed/Load Control (Existing in Open Cycle)

1

1

1

1

30621127-000-3BD-EE-01824 PAGE 3 OF 20

Project : QURAYYAH CCPP

Subject : Functional Description and Logic Diagram for Block Load Control

Doc. No. : 30621127-000-3BD-EE-01824

Pre-select Load (Existing in Open Cycle)

Station Load Control

Base Load (Existing in Open Cycle)

When a GTG control panel is selected to remote operation, the DCS accepts the current

mode of operation which could be Pre-select load, Base load or Manual Raise/Lower.

Station Load Control mode is available only from the DCS. In this mode the DCS

determines the operational setpoint for each GTG based on an operator entered export

requirement. Whilst in any of the local panel modes of operation, the DCS Pre-select load

setpoint will track the GTG MW output.

The DCS receives status signals from the GTG for the current mode of operation and

whether the local control panel is in local or remote. The GTG local control panel is the

master for mode selection.

The DCS has the following analogue output to each GTG local control panel;

Pre-select load

The Pre-select load signal to each GTG controller is used both for the Pre-select load and

the Station load control. For Pre-select load the operator selects the setpoint and for

Station load control the DCS determines the setpoint based on the station export

requirement. When neither of these modes are in use, the DCS tracks the GTG MW

output to ensure bumpless transfer on mode change.

Manual Speed/Load Control (Existing in Open Cycle)

The DCS operator has the facility to manually raise / lower the GTG MW output. This is

achieved by the DCS sending a series of raise/lower commands to GTG control

sysem.The raise/lower facility is disabled whilst the GTG is in local or Station load control.

Whilst in manual control the Pre-select load setpoint will track the GTG MW output.

Pre-select load Control (Existing in Open Cycle)

1

30621127-000-3BD-EE-01824 PAGE 4 OF 20

Project : QURAYYAH CCPP

Subject : Functional Description and Logic Diagram for Block Load Control

Doc. No. : 30621127-000-3BD-EE-01824

In Pre-select load mode the operator enters a setpoint for each GTG MW output. The

GTG local control panel must be set to remote before an operator can enter a setpoint.

Once the desired setpoint has been entered a confirmation will be required from the

operator before the setpoint is accepted. Only a valid setpoint will be accepted. If the

setpoint is not valid, or the conditions are not correct for the setpoint to be accepted then

the last value will be retained. The GTG local control panel uses the setpoint in a closed

loop control system to maintain the desired output.

The limitation of maximum rate of GTG output increase or decrease is set within the GTG

local control panel. This prevents damage to the GTG due to the analogue either ramping

too fast or jumping.

Station load control

In Station load control mode, the operator sets a station Export MW output and the DCS

determines the Pre-select setpoint for each of the GTGs in this mode. The Export MW

value can also be set via grid control, but only if the operator has selected this mode of

operation. Station load control mode for a GTG can only be selected when the respective

local control panel is in remote and the circuit breaker is closed. A GTG has to be in

Station load control mode before an export setpoint can be entered. On selecting a GTG

to Station load control mode the current export MW will become the initial setpoint. If the

GTGs switched to this mode of operation are running at different MW outputs then the

setpoint to each will be adjusted by the DCS until the load is equally shared.

An operator will only be able to enter a valid export MW setpoint. This valid value could

be constantly changing depending on the number of GTGs in Station load control mode,

In house loading and the output of the units in other modes which are supplying load to

the grid. As the In house load or STGs output changes, the setpoint to the GTGs will

change to compensate so that the station desired export MW is always maintained.

The following conditions are required to select Station load control:

GTG remote mode

GTG circuit breaker closed

GTG Station load control Pushbutton ON Initiated

30621127-000-3BD-EE-01824 PAGE 5 OF 20

Project : QURAYYAH CCPP

Subject : Functional Description and Logic Diagram for Block Load Control

Doc. No. : 30621127-000-3BD-EE-01824

GTG in Droop mode

APS ON is Not Initiated

The GTG will exit from Station load control under the following conditions:

GTG not remote mode

GTG circuit breaker not closed

GTG Station load control Pushbutton OFF Initiated

GTG not in Droop mode

APS ON is Initiated

GTG not pre-select mode

GTG base load

GTG Load Runback Initiated

Base load (Existing in Open Cycle)

In Base load mode, a GTG is run at its maximum output. The GTG can be set to Base

Load either locally at the control panel, or if the control panel has been set to remote from

the DCS. The GTG is ramped to its maximum output with various parameters (i.e.

temperature) constantly monitored. In the event of the temperature rising above a pre-set

value the output is ramped back to a pre-set point. This mode is configured in the GTG

local control panel. The DCS sends a signal to the GTG local control panel to switch to

Base load and monitors the operation. The GTGs will remain in this mode of operation

until a new mode is selected for each GTG.

3. Conceptual Operation Block Diagram

Refer to next page;

30621127-000-3BD-EE-01824 PAGE 6 OF 20

Project : QURAYYAH CCPP

Subject : Functional Description and Logic Diagram for Block Load Control

Doc. No. : 30621127-000-3BD-EE-01824

1

Block Load Control is Highest Control Loop of APC

(Automatic Plant Control System) in Combined Cycle

Power Plant.

This Control Loop will decide Total Power Demand

and Station Export Power Demand as per Power

Plant Operation Condition or Power Demand from

LDC (Load Dispatch Center) and Control each

Turbine Generator Power.

What is Non STN (Station) Power ?

For GTG, Total MW in Operation Mode in PRESEL

(Fixed Load), not in Operation in Station Load Mode.

For STG, Actual Power (MW) because this is always

Non STN Mode.

What is No of STN Mode ?

Number of GTG in Station Mode

What is In House Load ?

Power Consumption in the Qurayyah Power Plant

What is STG Load Control Concept?

STG Power Output will be Controlled under IPC (Inlet

Pressure Control) Mode (Like as Turbine Follow Mode

in Thermal Power Plant).

1

1

30621127-000-3BD-EE-01824 PAGE 7 OF 20

Project : QURAYYAH CCPP

Subject : Functional Description and Logic Diagram for Block Load Control

Doc. No. : 30621127-000-3BD-EE-01824

Index for Block Diagram

30621127-000-3BD-EE-01824 PAGE 8 OF 20

Project : QURAYYAH CCPP

Subject : Functional Description and Logic Diagram for Block Load Control

Doc. No. : 30621127-000-3BD-EE-01824

1

Appendix:

-. DCS Graphic for Block Load Control

-. Logic Diagrams for Block Load Control System

-. AGC Control Logic in Existing DCS

1

1

1

30621127-000-3BD-EE-01824 PAGE 9 OF 20

30621127-000-3BD-EE-01824 PAGE 10 OF 20

Appendix-1

- DCS Graphic for Block Load Control

30621127-000-3BD-EE-01824 PAGE 11 OF 20

Appendix-2

- Logic Diagram for Block Control

30621127-000-3BD-EE-01824 PAGE 12 OF 20

30621127-000-3BD-EE-01824 PAGE 13 OF 20

30621127-000-3BD-EE-01824 PAGE 14 OF 20

30621127-000-3BD-EE-01824 PAGE 15 OF 20

A

A

B

B

C

C

D

D

E

E

F

F

G

G

H

H

I

I

J

J

K

K

L

L

M

M

N

N

O

O

P

P

Q

Q

R

R

S

S

T

T

U

U

V

V

W

W

X

X

Y

Y

Z

Z

00 00

01 01

02 02

03 03

04 04

05 05

06 06

07 07

08 08

09 09

10 10

11 11

12 12

13 13

14 14

15 15

16 16

17 17

18 18

19 19

20 20

21 21

22 22

23 23

24 24

25 25

26 26

27 27

28 28

29 29

7/28/200911:40:51AM

LastModified

V01.00.00A

ModuleRevision Customer

AGCINwillbeprocessedonlywhenPER1&PER2aresatisfied.PER1&PER2willbespecifiedatsitebycustomer.

Title

ELECTRICAL.AGC_1

SoftwarePath

5/26/200918:35:53

BuildMajorRevision

ELEC1

DeviceName Site DMNumber Requisition

V03.03.27C

ToolboxSTVersion DWG Engineer

00000:00:00

BuildMinorRevision

8/21/200910:13:31AM

PrintDate ProcessApplication SerialNumber ShopOrderNumber MachineSize

0001

Cont.onSh.

0000

Sh.No.

LATCH_1 1

S

R

AND_1 2

OR_1 3

SWITCH_1 4

SEL

T

F T

AND_2 5

NOT_1 6

SELECTOR_1 7

SELA

SELB

CASC

INA1

INB1

OUT1

G

R

P

A

G

R

P

B

O

U

T

C

O

N

T

R

O

LSELECTOR

CASC

AND_3 8

B1.P11MYB75GH001XT13

NOT_2 9

OR_2 10

MOVE_1 11

ENABLE

MOVE_2 12

ENABLE

13 AGC_BLOCK1:SETPOINT_ST

SELECTOR_2 14

SELA

SELB

CASC

INA1

INB1

OUT1

G

R

P

A

G

R

P

B

O

U

T

C

O

N

T

R

O

LSELECTOR

CASC

NOT_3 15

AND_4 16

MOVE_3 17

ENABLE

OR_3 18

P_B_1 26

NOT_6 27

P_B_2 28

P_B_3 29

LATCH_3 30

S

R

NOT_7 31

CLAMP_1 33

MAX

MIN

CLAMP_2 34

MAX

MIN

CLAMP_3 35

MAX

MIN

AND_6 37

NOT_8 44

NOT_9 45

P_B_10 47

COMPARE_1 48

COMPARE_2 49

COMPARE_3 50

COMPARE_4 51

COMPARE_5 52

COMPARE_6 53

AGC IN will be processed only when PER1 & PER2

are satisfied.PER1 & PER2 will be specified at site

by customer.

Block wise control selection or

Unit wise control selection.

Low Load limit and High Loah

limit reached alarm generation.

When AGC IN, GT in auto, but

external load control setpoint DI

from MarkVI not present, MW

feedback from MarkVI will be

processsed,

When AGC IN, external load

control setpoint DI from MarkVI

present, but GT taken in manual,

operator entered setpoint will be

processed by taking care of

bumpless transfer.

With AGC IN, external load setpoint control DI energised, GT in auto,

AGC_stpt for block will be processed and divided amongst 3 GT's

depending upon G1, G2, G3 settings. (% settings).

RefScreen:AGC_1

SELECTOR_4 54

SELA

SELB

CASC

INA1

INB1

OUT1

G

R

P

A

G

R

P

B

O

U

T

C

O

N

T

R

O

LSELECTOR

CASC

SELECTOR_5 55

SELA

SELB

CASC

INA1

INB1

OUT1

G

R

P

A

G

R

P

B

O

U

T

C

O

N

T

R

O

LSELECTOR

CASC

SELECTOR_6 56

SELA

SELB

CASC

INA1

INB1

OUT1

G

R

P

A

G

R

P

B

O

U

T

C

O

N

T

R

O

LSELECTOR

CASC

AGC_IN_VAR

EGD

AGC_IN_PER1

EGD

AGC_IN_PER2

EGD

AGC_OUT_VAR

EGD

AGC_OUT_1

EGD

AGC_OUT_2

EGD

BLOCK_SEL

EGD

UNIT_SEL

EGD

P11MYB75GH001YQ66_F1

ELECTRICAL.AGC1_4.SELECTOR_1.OUT1

EGD

SELECTOR_3.OUT1

SELECTOR_3.OUT10001

AGC1.AGC_STPT

AGC_IN

LATCH_1.OUT0000

EGD

G1_MANUAL_LATCH

LATCH_2.OUT0001

EGD

B1.P11MYB75GH001XT13

AGC_TRK3

OR_4.OUT0001

B1.P11MYB75GH001XZ61

B2.P12MYB75GH001XT13

G2_MANUAL_LATCH

LATCH_4.OUT0001

EGD

B2.P12MYB75GH001XZ61

P12MYB75GH001YQ66_F1

ELECTRICAL.AGC1_2.SELECTOR_1.OUT1

EGD

P13MYB75GH001YQ66_F1

ELECTRICAL.AGC1_3.SELECTOR_1.OUT1

EGD

B1.P11MYB75GH001YT31

AGC_IN

ELECTRICAL.AGC1_2.AND_1.IN1

EGD

AGC_OUT

EGD

BLOCK_SEL_1

NOT_7.A0000

EGD

UNIT_SEL_1

ELECTRICAL.AGC1_2.AND_1.IN2

ELECTRICAL.AGC1_3.AND_1.IN2

EGD

P11MYB75GH001YQ66_HI

EGD

P11MYB75GH001YQ66_FF

EGD

P11MYB75GH001YQ66_LO

EGD

P12MYB75GH001YQ66_HI

EGD

P12MYB75GH001YQ66_FF

EGD

P12MYB75GH001YQ66_LO

EGD

P13MYB75GH001YQ66_HI

EGD

P13MYB75GH001YQ66_FF

EGD

P13MYB75GH001YQ66_LO

EGD

SP

SH

SL

PV1

TK1

B1

G1

PV2

TK2

B2

G2

PV3

TK3

B3

G3

SP_OUT

N

OUT1

OUT2

OUT3

AND_1.OUT

OR_1.OUT

AGC_IN

EGD ELECTRICAL.AGC1_2.AND_1.IN1

P_B_1.OUT

AGC_IN_PER1

AGC_IN_PER2

P_B_2.OUT

AGC_OUT_1

AGC_OUT_2

AND_6.OUT

AGC1.AGC_STPT

0

P_B_3.OUT

AGC_IN

B1.P11MYB75GH001XT13

NOT_1.NOT_A

AND_3.OUT

0

B1.P11MYB75GH001XZ61

MOVE_2.DEST

B1.P11MYB75GH001XT13

G1_MANUAL_LATCH

AGC_IN

NOT_2.NOT_A

G1_MANUAL_LATCH

NOT_1.NOT_A

LATCH_1.OUT B1.P11MYB75GH001YT31

B1.P11MYB75GH001XZ61

NOT_8.NOT_A

GT1_STPT

EGD ELECTRICAL.AGC1_4.SELECTOR_1.INB1

SP SWITCH_1.OUT

SH 250

SL 20

PV1 SELECTOR_1.OUT1

TK1 OR_2.OUT

B1 0

G1 33

PV2 SELECTOR_2.OUT1

TK2 OR_3.OUT

B2 0

G2 34

PV3 SELECTOR_3.OUT1

TK3 AGC_TRK3

B3 0

G3 33

SP_OUT EGD

N EGD

OUT1 P11MYB75GH001YQ66_F

EGD

OUT2 P12MYB75GH001YQ66_F

EGD

OUT3 P13MYB75GH001YQ66_F

EGD

NOT_3.NOT_A

AND_4.OUT

0

B2.P12MYB75GH001XZ61

MOVE_3.DEST

B2.P12MYB75GH001XT13

B2.P12MYB75GH001XT13

G2_MANUAL_LATCH

B2.P12MYB75GH001XZ61

NOT_9.NOT_A

GT2_STPT

EGD ELECTRICAL.AGC1_2.SELECTOR_1.INB1

NOT_2.NOT_A

G2_MANUAL_LATCH

NOT_3.NOT_A

AGC_IN_VAR

WIDTH=1000

LATCH_1.OUT AGC_OUT

EGD

AGC_OUT_VAR

WIDTH=1000

BLOCK_SEL

WIDTH=1000

AND_2.OUT

P_B_10.OUT

BLOCK_SEL_1

EGD SELECTOR_5.SELA0000

LATCH_3.OUT UNIT_SEL_1

EGD ELECTRICAL.AGC1_2.AND_1.IN2

SELECTOR_4.OUT1

G1_HGHSTPT

G1_LWSTPT

P11MYB75GH001YQ66_FF

EGD

SELECTOR_5.OUT1

G2_HGHSTPT

G2_LWSTPT

P12MYB75GH001YQ66_FF

EGD

SELECTOR_6.OUT1

G3_HGHSTPT

G3_LWSTPT

P13MYB75GH001YQ66_FF

EGD

AGC_IN

BLOCK_SEL_1

G1_MANUAL_LATCH

G2_MANUAL_LATCH

UNIT_SEL

WIDTH=1000

SELECTOR_4.OUT1

G1_LWSTPT

P11MYB75GH001YQ66_LO

A EGD

SELECTOR_4.OUT1

G1_HGHSTPT

P11MYB75GH001YQ66_HI

A EGD

SELECTOR_5.OUT1

G2_LWSTPT

P12MYB75GH001YQ66_LO

A EGD

SELECTOR_5.OUT1

G2_HGHSTPT

P12MYB75GH001YQ66_HI

A EGD

SELECTOR_6.OUT1

G3_LWSTPT

P13MYB75GH001YQ66_LO

A EGD

SELECTOR_6.OUT1

G3_HGHSTPT

P13MYB75GH001YQ66_HI

A EGD

BLOCK_SEL_1

UNIT_SEL_1

0

P11MYB75GH001YQ66_F

P11MYB75GH001YQ66_F1

BLOCK_SEL_1

UNIT_SEL_1

0

P12MYB75GH001YQ66_F

P12MYB75GH001YQ66_F1

BLOCK_SEL_1

UNIT_SEL_1

0

P13MYB75GH001YQ66_F

P13MYB75GH001YQ66_F1

30621127-000-3BD-EE-01824 PAGE 16 OF 20

Appendix-3

- AGC Control Logic in Existing DCS

A

A

B

B

C

C

D

D

E

E

F

F

G

G

H

H

I

I

J

J

K

K

L

L

M

M

N

N

O

O

P

P

Q

Q

R

R

S

S

T

T

U

U

V

V

W

W

X

X

Y

Y

Z

Z

00 00

01 01

02 02

03 03

04 04

05 05

06 06

07 07

08 08

09 09

10 10

11 11

12 12

13 13

14 14

15 15

16 16

17 17

18 18

19 19

20 20

21 21

22 22

23 23

24 24

25 25

26 26

27 27

28 28

29 29

7/28/200911:40:51AM

LastModified

V01.00.00A

ModuleRevision Customer

AGCINwillbeprocessedonlywhenPER1&PER2aresatisfied.PER1&PER2willbespecifiedatsitebycustomer.

Title

ELECTRICAL.AGC_1

SoftwarePath

5/26/200918:35:53

BuildMajorRevision

ELEC1

DeviceName Site DMNumber Requisition

V03.03.27C

ToolboxSTVersion DWG Engineer

00000:00:00

BuildMinorRevision

8/21/200910:13:32AM

PrintDate ProcessApplication SerialNumber ShopOrderNumber MachineSize Cont.onSh.

0001

Sh.No.

SELECTOR_3 19

SELA

SELB

CASC

INA1

INB1

OUT1

G

R

P

A

G

R

P

B

O

U

T

C

O

N

T

R

O

LSELECTOR

CASC

NOT_4 20

AND_5 21

MOVE_4 22

ENABLE

OR_4 23

NOT_5 24

LATCH_2 25

S

R

LATCH_4 32

S

R

LATCH_5 36

S

R

P_B_4 38

P_B_5 39

P_B_6 40

P_B_7 41

P_B_8 42

P_B_9 43

NOT_10 46

Same conditions as discussed

above for other GT's.

Latching of Auto and Manual

signals.

B3.P13MYB75GH001XT13

G3_MANUAL_LATCH

LATCH_5.OUT0001

EGD

B3.P13MYB75GH001XZ61

AGC_IN

LATCH_1.OUT0000

EGD

G1_MANUAL

EGD

G1_AUTO

EGD

G2_MANUAL

EGD

G2_AUTO

EGD

G3_MANUAL

EGD

G3_AUTO

EGD

SELECTOR_3.OUT1

AGC_BLOCK1.PV30000

AGC_TRK3

AGC_BLOCK1.TK30000

G1_MANUAL_LATCH

ELECTRICAL.AGC1_4.OR_1.IN2

ELECTRICAL.AGC1_4.NOT_3.A

AND_3.IN20000

OR_2.IN20000

NOT_8.A0000

EGD

G2_MANUAL_LATCH

ELECTRICAL.AGC1_2.OR_1.IN2

ELECTRICAL.AGC1_2.NOT_3.A

AND_4.IN20000

OR_3.IN20000

NOT_9.A0000

EGD

G3_MANUAL_LATCH

ELECTRICAL.AGC1_3.OR_1.IN2

EGD

NOT_4.NOT_A

AND_5.OUT

0

B3.P13MYB75GH001XZ61

MOVE_4.DEST

AGC_BLOCK1.PV30000

B3.P13MYB75GH001XT13

B3.P13MYB75GH001XT13

G3_MANUAL_LATCH

B3.P13MYB75GH001XZ61

NOT_10.NOT_A

GT3_STPT

EGD ELECTRICAL.AGC1_3.SELECTOR_1.INB1

NOT_5.NOT_A

G3_MANUAL_LATCH

NOT_4.NOT_A

AGC_TRK3

AGC_BLOCK1.TK30000

AGC_IN

P_B_4.OUT

P_B_5.OUT

G1_MANUAL_LATCH

EGD ELECTRICAL.AGC1_4.OR_1.IN2

P_B_6.OUT

P_B_7.OUT

G2_MANUAL_LATCH

EGD ELECTRICAL.AGC1_2.OR_1.IN2

P_B_8.OUT

P_B_9.OUT

G3_MANUAL_LATCH

EGD ELECTRICAL.AGC1_3.OR_1.IN2

G1_MANUAL

G1_AUTO

G2_MANUAL

G2_AUTO

G3_MANUAL

G3_AUTO

G3_MANUAL_LATCH

30621127-000-3BD-EE-01824 PAGE 17 OF 20

A

A

B

B

C

C

D

D

E

E

F

F

G

G

H

H

I

I

J

J

K

K

L

L

M

M

N

N

O

O

P

P

Q

Q

R

R

S

S

T

T

U

U

V

V

W

W

X

X

Y

Y

Z

Z

00 00

01 01

02 02

03 03

04 04

05 05

06 06

07 07

08 08

09 09

10 10

11 11

12 12

13 13

14 14

15 15

16 16

17 17

18 18

19 19

20 20

21 21

22 22

23 23

24 24

25 25

26 26

27 27

28 28

29 29

7/28/200911:40:51AM

LastModified

V01.00.00A

ModuleRevision Customer

LogicforUnitwiseoperation.

Title

ELECTRICAL.AGC1_2

SoftwarePath

5/26/200918:35:53

BuildMajorRevision

ELEC1

DeviceName Site DMNumber Requisition

V03.03.27C

ToolboxSTVersion DWG Engineer

00000:00:00

BuildMinorRevision

8/21/200910:14:04AM

PrintDate ProcessApplication SerialNumber ShopOrderNumber MachineSize Cont.onSh.

0000

Sh.No.

AND_1 3

SELECTOR_1 1

SELA

SELB

CASC

INA1

INB1

OUT1

G

R

P

A

G

R

P

B

O

U

T

C

O

N

T

R

O

LSELECTOR

CASC

OR_1 2

NOT_1 4

NOT_2 5

MOVE_1 6

ENABLE

NOT_3 7

Logic for Unit wise operation.

Once unit wise control selected, AGC_Unit wise

setpoint will be processed for individual GT.If GT

taken into manual, operator can enter the

setpoint with bumpless transfer taken into

consideration.If external load setpoint control DI

not received from MarkVI, then MW feedback

from Mark VI will be processed.

RefScreen:P12-MYA-01.cim

AGC_IN

ELECTRICAL.AGC_1.LATCH_1.OUT

EGD

UNIT_SEL_1

ELECTRICAL.AGC_1.NOT_7.NOT_A

EGD

G2_MANUAL_LATCH

ELECTRICAL.AGC_1.LATCH_4.OUT

EGD

B2.P12MYB75GH001XT13

AGC1.AGC_GT2

B2.P12MYB75GH001XZ61

AGC_IN

UNIT_SEL_1

NOT_3.NOT_A

B2.P12MYB75GH001XT13

AND_1.OUT

OR_1.OUT

SELECTOR_1.OUT1

AGC1.AGC_GT2

GT2_STPT

P12MYB75GH001YQ66_F1

EGD ELECTRICAL.AGC_1.SELECTOR_5.INB1

NOT_1.NOT_A

G2_MANUAL_LATCH

NOT_2.NOT_A

AGC_IN

B2.P12MYB75GH001XT13

B2.P12MYB75GH001XZ61

NOT_3.NOT_A

GT2_STPT

EGD ELECTRICAL.AGC_1.MOVE_3.DEST

G2_MANUAL_LATCH

30621127-000-3BD-EE-01824 PAGE 18 OF 20

A

A

B

B

C

C

D

D

E

E

F

F

G

G

H

H

I

I

J

J

K

K

L

L

M

M

N

N

O

O

P

P

Q

Q

R

R

S

S

T

T

U

U

V

V

W

W

X

X

Y

Y

Z

Z

00 00

01 01

02 02

03 03

04 04

05 05

06 06

07 07

08 08

09 09

10 10

11 11

12 12

13 13

14 14

15 15

16 16

17 17

18 18

19 19

20 20

21 21

22 22

23 23

24 24

25 25

26 26

27 27

28 28

29 29

7/28/200911:40:51AM

LastModified

V01.00.00A

ModuleRevision Customer

LogicforUnitwiseoperation.

Title

ELECTRICAL.AGC1_3

SoftwarePath

5/26/200918:35:53

BuildMajorRevision

ELEC1

DeviceName Site DMNumber Requisition

V03.03.27C

ToolboxSTVersion DWG Engineer

00000:00:00

BuildMinorRevision

8/21/200910:14:28AM

PrintDate ProcessApplication SerialNumber ShopOrderNumber MachineSize Cont.onSh.

0000

Sh.No.

AND_1 3

SELECTOR_1 1

SELA

SELB

CASC

INA1

INB1

OUT1

G

R

P

A

G

R

P

B

O

U

T

C

O

N

T

R

O

LSELECTOR

CASC

OR_1 2

NOT_1 4

NOT_2 5

MOVE_1 6

ENABLE

NOT_3 7

Logic for Unit wise operation.

Once unit wise control selected, AGC_Unit wise

setpoint will be processed for individual GT.If GT

taken into manual, operator can enter the

setpoint with bumpless transfer taken into

consideration.If external load setpoint control DI

not received from MarkVI, then MW feedback

from Mark VI will be processed.

RefScreen:P13-MYA-01.cim

AGC_IN

ELECTRICAL.AGC_1.LATCH_1.OUT

EGD

UNIT_SEL_1

ELECTRICAL.AGC_1.NOT_7.NOT_A

EGD

G3_MANUAL_LATCH

ELECTRICAL.AGC_1.LATCH_5.OUT

EGD

B3.P13MYB75GH001XT13

AGC1.AGC_GT3

B3.P13MYB75GH001XZ61

AGC_IN

UNIT_SEL_1

NOT_3.NOT_A

B3.P13MYB75GH001XT13

AND_1.OUT

OR_1.OUT

SELECTOR_1.OUT1

AGC1.AGC_GT3

GT3_STPT

P13MYB75GH001YQ66_F1

EGD ELECTRICAL.AGC_1.SELECTOR_6.INB1

NOT_1.NOT_A

G3_MANUAL_LATCH

NOT_2.NOT_A

AGC_IN

B3.P13MYB75GH001XT13

B3.P13MYB75GH001XZ61

NOT_3.NOT_A

GT3_STPT

EGD ELECTRICAL.AGC_1.MOVE_4.DEST

G3_MANUAL_LATCH

30621127-000-3BD-EE-01824 PAGE 19 OF 20

A

A

B

B

C

C

D

D

E

E

F

F

G

G

H

H

I

I

J

J

K

K

L

L

M

M

N

N

O

O

P

P

Q

Q

R

R

S

S

T

T

U

U

V

V

W

W

X

X

Y

Y

Z

Z

00 00

01 01

02 02

03 03

04 04

05 05

06 06

07 07

08 08

09 09

10 10

11 11

12 12

13 13

14 14

15 15

16 16

17 17

18 18

19 19

20 20

21 21

22 22

23 23

24 24

25 25

26 26

27 27

28 28

29 29

8/21/20094:44:52AM

LastModified

V01.00.00A

ModuleRevision Customer

LogicforUnitwiseoperation.

Title

ELECTRICAL.AGC1_4

SoftwarePath

5/26/200918:35:53

BuildMajorRevision

ELEC1

DeviceName Site DMNumber Requisition

V03.03.27C

ToolboxSTVersion DWG Engineer

00000:00:00

BuildMinorRevision

8/21/200910:15:05AM

PrintDate ProcessApplication SerialNumber ShopOrderNumber MachineSize Cont.onSh.

0000

Sh.No.

AND_1 3

SELECTOR_1 1

SELA

SELB

CASC

INA1

INB1

OUT1

G

R

P

A

G

R

P

B

O

U

T

C

O

N

T

R

O

LSELECTOR

CASC

OR_1 2

NOT_1 4

NOT_2 5

MOVE_1 6

ENABLE

NOT_3 7

Logic for Unit wise operation.

Once unit wise control selected, AGC_Unit wise

setpoint will be processed for individual GT.If GT

taken into manual, operator can enter the

setpoint with bumpless transfer taken into

consideration.If external load setpoint control DI

not received from MarkVI, then MW feedback

from Mark VI will be processed.

RefScreen:P11-MYA-01.cim

AGC_IN

ELECTRICAL.AGC_1.LATCH_1.OUT

EGD

UNIT_SEL_1

ELECTRICAL.AGC_1.NOT_7.NOT_A

EGD

G1_MANUAL_LATCH

ELECTRICAL.AGC_1.LATCH_2.OUT

EGD

B1.P11MYB75GH001XT13

AGC1.AGC_GT1

B1.P11MYB75GH001XZ61

AGC_IN

UNIT_SEL_1

NOT_3.NOT_A

B1.P11MYB75GH001XT13

AND_1.OUT

OR_1.OUT

SELECTOR_1.OUT1

AGC1.AGC_GT1

GT1_STPT

P11MYB75GH001YQ66_F1

EGD ELECTRICAL.AGC_1.SELECTOR_4.INB1

NOT_1.NOT_A

G1_MANUAL_LATCH

NOT_2.NOT_A

AGC_IN

B1.P11MYB75GH001XT13

B1.P11MYB75GH001XZ61

NOT_3.NOT_A

GT1_STPT

EGD ELECTRICAL.AGC_1.MOVE_2.DEST

G1_MANUAL_LATCH

30621127-000-3BD-EE-01824 PAGE 20 OF 20

Você também pode gostar

- Co2 Ee-00100-Co2-002Documento56 páginasCo2 Ee-00100-Co2-002anbarasusivaprakasam100% (2)

- DG SynchronizationDocumento5 páginasDG SynchronizationParag RekhiAinda não há avaliações

- Legislation Statutory Inspection ChecklistDocumento2 páginasLegislation Statutory Inspection ChecklistAry PutraAinda não há avaliações

- LPBFP - Sizing Calculation LP HRSG Feed Pump - Doc PG DC 292 100 d603 - R 1Documento8 páginasLPBFP - Sizing Calculation LP HRSG Feed Pump - Doc PG DC 292 100 d603 - R 1anbesivam87_49857255Ainda não há avaliações

- Aux Steam Ee 00100 Axs 002Documento15 páginasAux Steam Ee 00100 Axs 002anbarasusivaprakasam100% (1)

- 000 3BD Ee 01509 006Documento93 páginas000 3BD Ee 01509 006Samir Zaghlool100% (1)

- Control Logic Diagram of HRSG: Conversion of Qurayyah Open Cycle Power Plant To Combined Cycle Power Plant Project CDocumento65 páginasControl Logic Diagram of HRSG: Conversion of Qurayyah Open Cycle Power Plant To Combined Cycle Power Plant Project CanbarasusivaprakasamAinda não há avaliações

- PP10CC 0009 6mal Yr Abc 001Documento30 páginasPP10CC 0009 6mal Yr Abc 001anbesivam87Ainda não há avaliações

- For Information: West Offaly PowerDocumento33 páginasFor Information: West Offaly PowerParlindungan Sihombing100% (1)

- Operation Philosophy of 209HA CCPP BhikkiDocumento34 páginasOperation Philosophy of 209HA CCPP BhikkiMunibAinda não há avaliações

- 000-Performance Test Procedure (General)Documento10 páginas000-Performance Test Procedure (General)K R Kumar RanjanAinda não há avaliações

- Uong Bi 300 MW Extension Power Plant: OwnerDocumento32 páginasUong Bi 300 MW Extension Power Plant: OwnerAmEnPro100% (1)

- CMI Energy Reference ListDocumento24 páginasCMI Energy Reference Listthanhtbk2000Ainda não há avaliações

- PB02-LPS-001 Low Pressure Steam System: Saudi Arabian Oil CompanyDocumento1 páginaPB02-LPS-001 Low Pressure Steam System: Saudi Arabian Oil CompanyzhangAinda não há avaliações

- JO003-10-MAL-MDD-IDM-001 P&ID ST Drains SystemDocumento2 páginasJO003-10-MAL-MDD-IDM-001 P&ID ST Drains SystemHasan MustafaAinda não há avaliações

- 000 3BD Ee 00100 FPS 00Documento17 páginas000 3BD Ee 00100 FPS 00anbesivam87_49857255100% (1)

- HMBD Review Check ListDocumento4 páginasHMBD Review Check Listctraminst_81Ainda não há avaliações

- Lara Super Thermal Power Project (2X800 MW) Comment Reply SheetDocumento34 páginasLara Super Thermal Power Project (2X800 MW) Comment Reply SheetA N MadhavanAinda não há avaliações

- N2 Purging Demand Calculation Shutdown - Flare SystemDocumento54 páginasN2 Purging Demand Calculation Shutdown - Flare SystemMoch FaridAinda não há avaliações

- Acc Vs Heller CTDocumento37 páginasAcc Vs Heller CTkiddjoe1470Ainda não há avaliações

- Yazd-System Description For Start Up & Blow Down SystemDocumento6 páginasYazd-System Description For Start Up & Blow Down Systemandri.motoGAinda não há avaliações

- 1aha054179 ADocumento56 páginas1aha054179 Adebu1985Ainda não há avaliações

- N2 Gas Bottle Outline DrawingDocumento2 páginasN2 Gas Bottle Outline DrawingMathivanan AnbazhaganAinda não há avaliações

- 1e V09 MPGB 00043Documento10 páginas1e V09 MPGB 00043mohamed abourayaAinda não há avaliações

- Continuous Steam Blow 3 Sheet 1 of 4 Rev. 0Documento4 páginasContinuous Steam Blow 3 Sheet 1 of 4 Rev. 0Anonymous JtYvKt5XEAinda não há avaliações

- CCPP Operating BehaviorDocumento32 páginasCCPP Operating BehaviorphamquanghieuAinda não há avaliações

- This Document Contains Proprietary Data and Shall Not Be Reproduced or Disclosed Without The Permission of ALSTOM Power IncDocumento3 páginasThis Document Contains Proprietary Data and Shall Not Be Reproduced or Disclosed Without The Permission of ALSTOM Power IncJKKAinda não há avaliações

- Lara Super Thermal Power Project (2X800 MW) Comment Reply SheetDocumento25 páginasLara Super Thermal Power Project (2X800 MW) Comment Reply SheetA N MadhavanAinda não há avaliações

- Data Sheet EjectorDocumento4 páginasData Sheet EjectorGunturMudaAliAkbarAinda não há avaliações

- PP10CC 00 6PGB Yr Abc 001 PDFDocumento20 páginasPP10CC 00 6PGB Yr Abc 001 PDFanbesivam87Ainda não há avaliações

- Approved: Pöyry EnergyDocumento3 páginasApproved: Pöyry Energytvpham123Ainda não há avaliações

- Cooling and Sealing P&IDDocumento2 páginasCooling and Sealing P&IDrahul_choubey_9Ainda não há avaliações

- T219AB-384A9554 Rev E Deaerating Condenser Functional SpecificationDocumento6 páginasT219AB-384A9554 Rev E Deaerating Condenser Functional SpecificationvankayalasuryaAinda não há avaliações

- Sur - Erection Boq - I&c - Rev ADocumento14 páginasSur - Erection Boq - I&c - Rev Ashaikhsajid242Ainda não há avaliações

- CCPP Plant Operating Procedures PDFDocumento123 páginasCCPP Plant Operating Procedures PDFReda Nari100% (1)

- CCPPDocumento34 páginasCCPPphanindra100% (1)

- Design Manual Volume IV - Reference Drawing Rev. ADocumento437 páginasDesign Manual Volume IV - Reference Drawing Rev. AdatAinda não há avaliações

- Cover Sheet: Signature Not VerifiedDocumento14 páginasCover Sheet: Signature Not VerifiedvdrizzilsAinda não há avaliações

- TT2 P&ID 2015.01.20 AllDocumento36 páginasTT2 P&ID 2015.01.20 AllCARLOS OLIVEROS100% (1)

- Va1 Dec 00100 I M1D Pid 8204 PDFDocumento1 páginaVa1 Dec 00100 I M1D Pid 8204 PDFAnonymous JtYvKt5XEAinda não há avaliações

- 2-1 Tech Spec Ashuganj R0Documento181 páginas2-1 Tech Spec Ashuganj R0Anup Mitra100% (1)

- MC-ST-I-31-F00100 - 2 (Inst Flow Diagram - Loop Diagram)Documento59 páginasMC-ST-I-31-F00100 - 2 (Inst Flow Diagram - Loop Diagram)Zillur RahmanAinda não há avaliações

- Stim-03.014 - en Piping Design Requirements Condensate LinesDocumento9 páginasStim-03.014 - en Piping Design Requirements Condensate LinesbikendiaguirreAinda não há avaliações

- Technical Specifications For Sugauli CogenDocumento558 páginasTechnical Specifications For Sugauli Cogenchaitanya_kumar_13Ainda não há avaliações

- PO6258 RFI+for+S60133-0504+ (GTG+PKG) PDFDocumento57 páginasPO6258 RFI+for+S60133-0504+ (GTG+PKG) PDFmyungkwan haAinda não há avaliações

- HAazopDocumento35 páginasHAazopSaravanan ElangovanAinda não há avaliações

- Vol - V of V - Gspl-DrawingsDocumento102 páginasVol - V of V - Gspl-Drawingsapi-36989960% (1)

- 20TPH Dump Condenser Datasheet 12-1-2022Documento4 páginas20TPH Dump Condenser Datasheet 12-1-2022Manoj BAinda não há avaliações

- Breakdown EngineeringDocumento11 páginasBreakdown EngineeringDwi Mulyanti DwimulyantishopAinda não há avaliações

- KG - 008 Write Up For Steam Blowing Scheme For Khargone Units PDFDocumento92 páginasKG - 008 Write Up For Steam Blowing Scheme For Khargone Units PDFHimanshu ChaturvediAinda não há avaliações

- 11V02 Acc SPC M 0001 V2 Part ADocumento182 páginas11V02 Acc SPC M 0001 V2 Part Asuparnabhose100% (1)

- PP10CC 00 6LBB Yr Abc 001 PDFDocumento26 páginasPP10CC 00 6LBB Yr Abc 001 PDFanbesivam87Ainda não há avaliações

- Design Calc - Cooling Tower Sizing - R1 - 15.10.2011Documento1 páginaDesign Calc - Cooling Tower Sizing - R1 - 15.10.2011AliAliAinda não há avaliações

- NAV-10-GM-BR-IEM-035 Rev1Documento10 páginasNAV-10-GM-BR-IEM-035 Rev1Korcan ÜnalAinda não há avaliações

- Bibiyana 300-450 MW CCPP Volume-II Part ADocumento304 páginasBibiyana 300-450 MW CCPP Volume-II Part AboiporaAinda não há avaliações

- Clause No. Exhaust Gas System, HRSG and Auxiliaries (M2) Exhaust Gas SystemDocumento19 páginasClause No. Exhaust Gas System, HRSG and Auxiliaries (M2) Exhaust Gas SystemSIVA50% (2)

- Painampuram, Muthukurmandal, S.P.S.R. Nellore District, A.PDocumento53 páginasPainampuram, Muthukurmandal, S.P.S.R. Nellore District, A.Pkkumar_717405Ainda não há avaliações

- 1004 E GD 0010 X Electrical Load ListDocumento7 páginas1004 E GD 0010 X Electrical Load Listcherif yahyaoui100% (1)

- Method Statement For ACC BHELDocumento7 páginasMethod Statement For ACC BHELHsebepl NkAinda não há avaliações

- Synchronization PanelDocumento31 páginasSynchronization PanelHariom ChaurasiyaAinda não há avaliações

- Synchronization PanelsDocumento3 páginasSynchronization Panelsshivaram100% (1)

- PP10CC 00 Lab MR Abc 001Documento7 páginasPP10CC 00 Lab MR Abc 001anbesivam87Ainda não há avaliações

- PP10CC 00 6PGB Yr Abc 001 PDFDocumento20 páginasPP10CC 00 6PGB Yr Abc 001 PDFanbesivam87Ainda não há avaliações

- PP10CC 00 6lca Yr Abc 001 PDFDocumento20 páginasPP10CC 00 6lca Yr Abc 001 PDFanbesivam87100% (1)

- PP10CC 00 3mav MR Abc 001Documento9 páginasPP10CC 00 3mav MR Abc 001anbesivam87Ainda não há avaliações

- PP10CC 00 6LBB Yr Abc 001 PDFDocumento26 páginasPP10CC 00 6LBB Yr Abc 001 PDFanbesivam87Ainda não há avaliações

- FBC Operation II OperationDocumento21 páginasFBC Operation II Operationanbesivam87Ainda não há avaliações

- 000 3DT Ee 03584 000Documento135 páginas000 3DT Ee 03584 000anbarasusivaprakasam100% (4)

- 000 3DT 00005 000 - 2Documento116 páginas000 3DT 00005 000 - 2anbesivam87Ainda não há avaliações

- Commissioning Requirements For Generating Systems PDFDocumento17 páginasCommissioning Requirements For Generating Systems PDFanbesivam87Ainda não há avaliações

- Spectral Analysis of The ECG SignalDocumento2 páginasSpectral Analysis of The ECG SignalCamilo BenitezAinda não há avaliações

- 14 ComputoDocumento549 páginas14 ComputoEver Henry FloresAinda não há avaliações

- University of Central Punjab: Object Oriented ProgrammingDocumento3 páginasUniversity of Central Punjab: Object Oriented ProgrammingChoudhary MuneebAinda não há avaliações

- Eco-Friendly Fire Works CompositionDocumento4 páginasEco-Friendly Fire Works CompositionYog EshAinda não há avaliações

- Detector Demetales Manuel 103Documento6 páginasDetector Demetales Manuel 103wilfredoAinda não há avaliações

- APCO CSAA ANS2 101 1webfinalDocumento38 páginasAPCO CSAA ANS2 101 1webfinalJUAN CAMILO VALENCIA VALENCIAAinda não há avaliações

- Mds SM13CRM 110 enDocumento5 páginasMds SM13CRM 110 enColinAinda não há avaliações

- Super 6 Comprehension StrategiesDocumento1 páginaSuper 6 Comprehension StrategiesrosypatelAinda não há avaliações

- PCI Express Test Spec Platform 3.0 06182013 TSDocumento383 páginasPCI Express Test Spec Platform 3.0 06182013 TSDeng XinAinda não há avaliações

- Land SurveyingDocumento174 páginasLand SurveyingArifulmakrif Hailee100% (2)

- Energy Epp1924 WildlifeAndAssetProtection EnglishDocumento56 páginasEnergy Epp1924 WildlifeAndAssetProtection EnglishFalquian De EleniumAinda não há avaliações

- HPB Brochure 0708Documento12 páginasHPB Brochure 0708musaluddinAinda não há avaliações

- Section 02870 Site FurnishingsDocumento19 páginasSection 02870 Site FurnishingsMØhãmmed ØwięsAinda não há avaliações

- Ai R16 - Unit-6Documento36 páginasAi R16 - Unit-6RakeshAinda não há avaliações

- Adiba Final Activity CousellingDocumento29 páginasAdiba Final Activity Cousellingadiba KhanAinda não há avaliações

- Chapter Two Sector Analysis: (MBAM)Documento23 páginasChapter Two Sector Analysis: (MBAM)Ferlyn PelayoAinda não há avaliações

- Technical Bulletin: ConditionDocumento11 páginasTechnical Bulletin: ConditionFrancoAinda não há avaliações

- Chart and Compass (London Zetetic Society)Documento8 páginasChart and Compass (London Zetetic Society)tjmigoto@hotmail.comAinda não há avaliações

- Panasonic Sa Akx10ph PNDocumento114 páginasPanasonic Sa Akx10ph PNimmortalwombatAinda não há avaliações

- Open National Abacus Competition 2021 - Maats PVT LTDDocumento8 páginasOpen National Abacus Competition 2021 - Maats PVT LTDRanjana GalphadeAinda não há avaliações

- Financial Accounting Report (Partnership - Group 2)Documento20 páginasFinancial Accounting Report (Partnership - Group 2)syednaim0300Ainda não há avaliações

- CCR Control System Interface HandbookDocumento17 páginasCCR Control System Interface Handbooklcastrey23Ainda não há avaliações

- Internship Report PDFDocumento11 páginasInternship Report PDFASWIN KUMARAinda não há avaliações

- Chapter 10 - Process CostingDocumento83 páginasChapter 10 - Process CostingXyne FernandezAinda não há avaliações

- 1.vedantu - Class 3 To 5 - BrochureDocumento1 página1.vedantu - Class 3 To 5 - BrochureDeepak SharmaAinda não há avaliações

- DAC AnalysisDocumento19 páginasDAC Analysisమురళీధర్ ఆది ఆంధ్రుడుAinda não há avaliações

- EKONET CPRS Importer 26062014Documento6 páginasEKONET CPRS Importer 26062014anthony0216Ainda não há avaliações

- Chapter Vii. Damascius and Hyperignorance: Epublications@BondDocumento10 páginasChapter Vii. Damascius and Hyperignorance: Epublications@BondRami TouqanAinda não há avaliações

- Stelma & Cameron PDFDocumento35 páginasStelma & Cameron PDFCatarinaAinda não há avaliações