Escolar Documentos

Profissional Documentos

Cultura Documentos

Krilna Rexroth 1pv2v3

Enviado por

ado_22Descrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Krilna Rexroth 1pv2v3

Enviado por

ado_22Direitos autorais:

Formatos disponíveis

RE 10 436/08.

94

1/8

Further details

in clear text

1 = Bleed valve

Volume flow adjustment

A = Setting screw

Zero stroke range

25 = 12 to 25 bar

40 = 20 to 40 bar

63 = 30 to 63 bar

100 = 50 to 100 bar

Pressure adjustment

C = Setting screw

S = Setting screw, lockable

Seals

M = NBR - seals, suitable for

Mineral oil HLP to DIN 51 524 part 2

V = Viton seals, suitable for

Phosphate ester (HFD-R)

RE

10 436/08.94

Replaces: 07.86

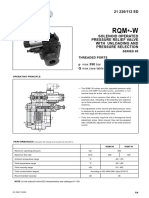

Direct controlled vane pump ,

with variable stroke volume

Type V3 - Series 3X and 4X

up to 100 bar

Size 12 to 63

from 8.5 cm

3

to 47 cm

3

Series

Sizes 40 and 63 = 3X

Series 30 to 39

Sizes 12 and 25 = 4X

Series 40 to 49

(30 to 39 installation and connection dim. unchanged)

(40 to 49 installation and connection dim. unchanged)

Size (size)

8,5 cm

3

= size 12 = 12

19 cm

3

= size 25 = 25

32 cm

3

= size 40 = 40

47 cm

3

= size 63 = 63

Rotation direction

clockwise (view onto drive shaft) = R

Shaft end, cone-shaped

Single pump = A

Combination pump, front = E

Combination pump, back (gear-toothed) = G

Connection ports

Suction and pressure port = 01

Pipe thread to ISO 228/1

Ordering examples:1PV2 V3-4X/12 RA01 MS 63 A1 or

1PV2 V3-3X/63 RA01 MC 100 A1

Ordering Code

1 PV 2 V3 R 01 A 1

*

K 3460/7

Type 1 PV2 V3-3X/40 RA01 MC100 A1

Very short control times

Low operating noise level

Good degree of effectiveness

Long life

May be used as combination pump

RE 10 436/08.94

2/8

Symbol

Double pump

Single pump

S

P

1 7 6 4 5 3 2

Section, Function Description

Hydraulic pumps type V3 are direct operated variable

displacement vane pumps

The main components are the housing (1), cover (2), rotor (3),

vanes (4), stator ring (5), pressure spring (6), setting screw (7),

control plate (8).

To limit the maximum volume flow the pump is equipped with a

setting screw (9).

The rotor (3) rotates within the stator ring (5). The vanes inside

the rotor are pressed against the inside of the stator ring (5) by

the centrifugal force.

Suction and pumping process

The chambers (10) required for the transport of the fluid are

formed by the vanes (4), the rotor (3), the stator ring (5), the

control plate (8) and the cover (2).

The chamber volume (10) increases through the rotation of the

rotor (3) and fill with oil when passing the suction side (S). On

reaching maximum volume the chambers (10) are separated

from the suction side. As the rotor (3) continues to rotate they

connect to the pressure side, become smaller and pump the oil

into the system via the pressure port (P) .

Pressure control

The stator ring (5) is held in the eccentric starting position by the

spring (6). The maximum operating pressure required in the

system is set at the setting screw (7) via the spring (6).

The pressure produced by the operating resistance pushes onto

the inside of the stator at the pressure side against the force of

the spring (6).

When the pressure corresponding to the set spring force has

been reached the stator ring (5) is moved from its eccentricity

towards the zero position. The volume flow sets itself to the value

which is just been taken. If the maximum pressure set at the

spring (6) has been reached the pump controls almost zero at

the volume flow. The operating pressure is kept and only the

leakage oil is replaced. Loss and the heating up of the oil is

therefore kept to a minimum.

9 8 10

S

P

L S L

P

S L

P

RE 10 436/08.94

3/8

Model Vane pump, variable

Type V3

Mounting type Flange mounting

Connection type Thread

Installation position optional (horizontal preferred)

Shaft loading Radial and axial forces cannot be transferred

Rotation direction clockwise (view on shaft end)

Pressure fluid

1

) HLP - Mineral oil to DIN 51524, Phosphate ester (HFD-R)

Temperature range pressure fluid T C 10 to 70

Viscosity range v mm

2

/s 16 to 160 at operating temperature and zero stroke pressure < 63 bar

25 to 160 at operating temperature and zero stroke pressure > 63 bar

max. 800 when starting under flow condition

max. 200 when starting at zero flow

Fluid cleanliness Maximum permissible degree of contamination of the fluid

to NAS 1638 Class 9. Therefore we recommend a filter

with a minimum retention rate of

20

100.

To secure long life we recommend Class 8 to NAS 1638. For this

we recommend a filter with a minium retention rate of of

10

100.

Size size 12 25 40 63

Weight m kg 6,25 11,1 26,5 29,5

Drive speed min n min

-1

1000 1000 1000 1000

max n min

-1

1800 1800 1800 1800

Max. perm. torque T Nm 54 61,8 235 353

Displacement volume min V cm

3

5 8,5 19 32

max V cm

3

8,5 19 32 47

Volume flow

2

)

(at 1450 min

-1

; 5 bar) Q l/min 13 27,5 47 67

Nominal pressure p bar 100

Operating pressure, absolute

Input p bar 0.8 to 2.5

Leakage output p bar 2

Output, zero pressure range p bar to 100

with spring type C25 p bar 12 to 25

with spring type C40 p bar 20 to 40

with spring type C63 p bar 30 to 63

with spring type C100 p bar 50 to 100

1

) Please consult data sheet RE 07 075, other fluids on request

2

) The volume flow can increase by up to +9% because of manufacturing tolerances

Technical Data (For application outside these parameters please consult us!)

RE 10 436/08.94

4/8

0 10 20 30 40 50 60 70

0 20 40 60 80 100

0 10 20 30 40

28

24

20

16

12

8

4

28

24

20

16

12

8

4

0 5 10 15 20 25

28

24

20

16

12

8

4

28

24

20

16

12

8

4

4

3

2

1

4

3

2

1

6

5

4

3

2

1

6

5

4

3

2

1

0 10 20 30 40 50 60 70

0 20 40 60 80 100

0 10 20 30 40 0 5 10 15 20 25

14

12

10

8

6

4

2

14

12

10

8

6

4

2

14

12

10

8

6

4

2

14

12

10

8

6

4

2

1

0,8

0,6

0,4

0,2

1,6

1,2

0,8

0,4

2,4

2,0

1,6

1,2

0,8

0,4

1,2

0,8

0,4

Size 25

Operating pressure p in bar

Operating pressure p in bar

Operating pressure p in bar Operating pressure p in bar

V

o

l

u

m

e

f

l

o

w

Q

i

n

L

/

m

i

n

D

r

i

v

e

p

o

w

e

r

P

i

n

K

W

V

o

l

u

m

e

f

l

o

w

Q

i

n

L

/

m

i

n

V

o

l

u

m

e

f

l

o

w

Q

i

n

L

/

m

i

n

V

o

l

u

m

e

f

l

o

w

Q

i

n

L

/

m

i

n

V

o

l

u

m

e

f

l

o

w

Q

i

n

L

/

m

i

n

D

r

i

v

e

p

o

w

e

r

P

i

n

K

W

D

r

i

v

e

p

o

w

e

r

P

i

n

K

W

D

r

i

v

e

p

o

w

e

r

P

i

n

K

W

Size 12

Operating pressure p in bar

C 25

C 40

C 63

C 40

C 25

C 63

C 100

C 100

D

r

i

v

e

p

o

w

e

r

P

i

n

K

W

D

r

i

v

e

p

o

w

e

r

P

i

n

K

W

P

ze

ro

stro

ke

P

ze

ro

stro

ke

P

d

e

liv

e

rin

g

P

zero stroke

P

d

e

liv

e

r

in

g

P

d

e

liv

e

rin

g

Operating pressure p in bar

Performance Curves (medium values) measured at n = 1450 min

-1

, v = 41mm

2

/s and t = 50C

P

zero stroke

P

d

e

liv

e

rin

g

P zero stroke

D

r

i

v

e

p

o

w

e

r

P

i

n

K

W

P

d

e

liv

e

r

in

g

P zero stroke

P zero stroke

V

o

l

u

m

e

f

l

o

w

Q

i

n

L

/

m

i

n

P

zero stroke

P

d

e

l

i

v

e

r

i

n

g

P

d

e

liv

e

r

in

g

P

d

e

liv

e

r

in

g

Curve with

spring type C 40

Curve with

spring type C 63

Curve with

spring type C 25

V

o

l

u

m

e

f

l

o

w

Q

i

n

L

/

m

i

n

V

o

l

u

m

e

f

l

o

w

Q

i

n

L

/

m

i

n

D

r

i

v

e

p

o

w

e

r

P

i

n

K

W

Operating pressure p in bar

Curve with

spring type C 25

Operating pressure p in bar

Curve with

spring type C 40

Curve with

spring type C 63

RE 10 436/08.94

5/8

70

60

50

40

30

20

10

0 10 20 30 40 50 60 70

0 10 20 30

12

11

10

9

8

7

6

5

4

3

2

1

4

3

2

1

0 10 20 30 40

70

60

50

40

30

20

10

7

6

5

4

3

2

1

10

9

8

7

6

5

4

3

2

1

70

60

50

40

30

20

10

70

60

50

40

30

20

10

0 20 40 60 80 100

Size 63

Performance Curves (medium values) measured at n = 1450 min

-1

, v = 41mm

2

/s and t = 50C

Size 40

C 25

C 40

P

d

e

liv

e

rin

g

V

o

l

u

m

e

f

l

o

w

Q

i

n

L

/

m

i

n

Operating pressure p in bar

D

r

i

v

e

p

o

w

e

r

P

i

n

K

W

V

o

l

u

m

e

f

l

o

w

Q

i

n

L

/

m

i

n

P

zero stroke

C 63

Operating pressure p in bar

D

r

i

v

e

p

o

w

e

r

P

i

n

K

W

V

o

l

u

m

e

f

l

o

w

Q

i

n

L

/

m

i

n

C 100

P

d

e

l

i

v

e

r

i

n

g

P

d

e

liv

e

r

in

g

P

zero stroke

Curve with

spring type C 25

P

z

e

ro

s

tro

k

e

48

40

32

24

16

8

0 10 20 30 40 50 60 70

0 10 20 30 40

48

40

32

24

16

8

0 10 20 30

48

40

32

24

16

8

4

3

2

1

4

3

2

1

8

7

6

5

4

3

2

1

8

7

6

5

4

3

2

1

48

40

32

24

16

8

0 20 40 60 80 100

C 25

Operating pressure p in bar

D

r

i

v

e

p

o

w

e

r

P

i

n

K

W

V

o

l

u

m

e

f

l

o

w

Q

i

n

L

/

m

i

n

V

o

l

u

m

e

f

l

o

w

Q

i

n

L

/

m

i

n

C 40

Operating pressure p in bar

D

r

i

v

e

p

o

w

e

r

P

i

n

K

W

D

r

i

v

e

p

o

w

e

r

P

i

n

K

W

D

r

i

v

e

p

o

w

e

r

P

i

n

K

W

C 100

Operating pressure p in bar

V

o

l

u

m

e

f

l

o

w

Q

i

n

L

/

m

i

n

Operating pressure p in bar

C 63

V

o

l

u

m

e

f

l

o

w

Q

i

n

L

/

m

i

n

Curve with

spring type C 25

P

d

e

liv

e

rin

g

P

zero stroke

P zero stroke

P

d

e

liv

e

r

in

g

Curve with

spring type C 63

Curve with

spring type C 40

P

d

e

liv

e

r

in

g

P zero stroke

P

d

e

liv

e

r

in

g

P

ze

ro

stro

ke

P

d

e

liv

e

rin

g

Operating pressure p in bar

Curve with

spring type C 63

Curve with

spring type C 40

Operating pressure p in bar

D

r

i

v

e

p

o

w

e

r

P

i

n

K

W

D

r

i

v

e

p

o

w

e

r

P

i

n

K

W

V

o

l

u

m

e

f

l

o

w

Q

i

n

L

/

m

i

n

P zero stroke

RE 10 436/08.94

6/8

72

70

68

66

64

62

60

58

56

54

0 20 40 60 80 100

6

5

4

3

2

1

0 20 40 60 80 100

Noise level when pump is delivering

Noise level with zero stroke

Operating pressure p in bar

s

i

z

e

6

3

s

i

z

e

4

0

s

iz

e

2

5

s

iz

e

1

2

Noise level L

p

Leakage volume flow Q

L

N

o

i

s

e

l

e

v

e

l

L

p

i

n

d

B

(

A

)

Measured in a noise measuring chamber to DIN 45 635, Part 28

Distance microphone - pumps =1m

EMotor + pump carrier + coupling + pump

Suggestion for pipe layout

Warning!

No radial and axial forces on the pump shaft are

permitted!

> Motor and pump must be exactly aligned!

> Use flexible coupling

Oil tank:

The usable volume of the tank must meet requirements

Warning! The permissible fluid temperature must not

be exceeded

> If required install cooler!

Lines and connections

Cut at an angle of 45

Min. distance of 50 mm to bottom of tank

> Dirt is not sucked up or otherwise disturbed

Min. 50 mm immersion depth, even at lowest

permissible fluid level

> Foaming is avoided

case drain and return fluids must not be sucked up again

immediately!

> Fluid temperature is kept low

Performance Curves (medium values) measured at n = 1450min

-1

,

v = 41mm

2

/s and t = 50C

m

i

n

5

0

m

i

n

5

0

min 200

m

i

n

1

0

0

lowest permissible

fluid level

Installation positions

horizontal preferred

Permissible installation position

1

) Lay drain line in such a way that pump cannot run empty

Commissioning - Instructions

Observe / check direction of rotation

All V3 - pumps are self-aspirating

When starting up for the first time we recommed filling the

housing via the leakage port. Observe fineness of filter! This

increases the operation safety and prevents wear and tear

in unfavourable installation conditions.

L

e

a

k

a

g

e

v

o

l

u

m

e

f

l

o

w

Q

L

i

n

L

/

m

i

n

size 40

size 25

size 12

size 63

Drain line

1

)

Suction line

Installation Instructions

Operating pressure p in bar

RE 10 436/08.94

7/8

Unit Dimensions V3/12, V3/25, V3/40, V3/63 (Dimensions in mm)

1 Volume flow adjustment

Adjustment instructions with clockwise

rotation:

Decrease of volume flow

with anti-clockwise rotation:

Increase of volume flow

B1

max

B5

B3

B4

h9

B2

max

L1

L3 L2

L6

L5

L7

L8

D1

D2

S

H

4

L4

D3

L

L9

P

H

1

0

,

2

D6

H13

D

4

0

,2

D

7

h

8

D

5

j

6

H

3

H

2

0

,

2

2 Pressure adjustment

Adjustment instructions for clockwise

rotation:

Increase of operating pressure

with anti-clockwise rotation:

Decrease of operating pressure

3 Pressure port

4 Suction port

5 Leakage port

6 Drive shaft

1

) Up to 70 bar zero stroke pressure

2

) Up to 100 bar zero stroke pressure

3

6

4

5

1

2

Size B3 B4

h9

B5 D1 D2 D3 D40,2 D5

k6

D6 D7

h8

H10,2 H20,2 H3 H4

12 68,5 156 93 6 56,5 G3/8 G1/2 G1/4 100 18 9 80 56,5 56,5 113 20,5

25 78 164 115 6 56,5 G1/2 G3/4 G1/4 125 19 11 100 65 65 130 21,5

40 95 201 148 8 76 G3/4 G1 1/4 G3/8 160 28 14 125 94 94 188 31

63 95 201 148 10 76 G1 G1 1/2 G3/8 160 32 14 125 97 94 191 35,3

Size L1

1

) L1

2

) L2

1

) L2

2

) L3 L4 L5 L6 L7 L8 L9

12 136,5 136,5 102 102 34,5 4 50,5 17 15,5 20,5 28

25 158,5 168,5 124 134 34,5 4 65 25 20 25 28

40 211 218 159 166 52 4 81 32 27 32 42

63 242 249 174 181 68 4 91 34 27 38 58

B1

max.

B2

max.

RE 10 436/08.94

8/8

All rights reserved - Subject to revision

Mannesmann Rexroth GmbH

D-97813 Lohr am Main

Jahnstrae 35 D-97816 Lohr am Main

Telefon 0 93 52 / 18-0 Telefax 0 93 52 / 18-10 40

Telex 6 89 418

Project Instructions

Extensive instructions and ideas can be found in the Hydraulic

Trainer, Volume 3, RE 00 281 " Planning and Design of Hydraulic

Power Systems".

When using vane pumps we especially recommend the following

instructions:

Specifications

All values mentioned are dependent on

manufacturing tolerances and are valid with certain

conditions. Some variations in actual values must therefore

be expected due to the manufacturing tolerances and

changes in ambient and operating conditions (e.g. viscosity).

Performance curves

Performance curves for volume flow and input power.

Please observe the maximum possible input data when

designing the installation of the drive motor.

Noise level

The values for the noise level shown on page 6 are measured

to DIN 45 635 part 26. That means that only the noise

emission of the pump is shown. Ambient conditions (as e.g.

installation site, piping, etc.) are not taken into

consideration. These values are only valid for one pump.

If, for example, two pumps of the same size are operated

under the same load the noise level increases according to

the formula

L

= 10lg (10

0,1L1

+10

0,1L2

)

L

= total level

L

1

...L

2

= noise level of the single pumps

Example:

Warning: The construction of the unit and the influences of the

site where the pump is eventually placed can cause the noise

level to be, as a rule, 5 to 10 dB (A) higher than the value of the

pump alone.

Leakage oil

The avaerage external leakage oil of the pumps is shown on

page 6. Please note that these values are only to be used as a

project aid for the design of the cooling sizes and the pipe cross

sections. During the off stroke the quantity of the leakage oil is

shortly increased due to the control oil of the controller. Caused

by cross section narrowings but also through the leakage oil

coolers it is possible that unduly high pressure peaks are

produced in the leakage oil line. The relevant size for the

dimensioning of the tanks is the zero stroke power (see pages 4

and 5).

Zero stroke

During the stroke onto zero stroke variably high pressure peaks

can occur according to design. For the illustrated measuring

design the following values were measured:

Pressure peak

Zero stroke pressure size 12 size 25 size 40 size 63

100 bar 175 bar 180 bar 190 bar 210 bar

63 bar 135 bar 140 bar 150 bar 170 bar

40 bar 115 bar 120 bar 130 bar 150 bar

25 bar 100 bar 105 bar 115 bar 135 bar

Please observe the possible effects on the units during

projecting.

Measuring layout:

V3/16 + V3/16, delivering

p = 80 bar

L

1

= 64 dB(A)

L

2

= 64 dB(A)

L

= 10lg(10

0,164

+10

0,164

)

= 67,01dB(A)

G.L. Rexroth Ltd.

Cromwell Road

St Neots Cambs PE19 2ES

Telephone 0 480 / 47 60 41 Telefax 0 480 / 21 09 52

Telex 3 21 61 rex g 3 23 71 rex ser - Service Department

Você também pode gostar

- Saet Work AnsDocumento5 páginasSaet Work AnsSeanLejeeBajan89% (27)

- WB93R-5 M Weam006000 WB93R-5Documento284 páginasWB93R-5 M Weam006000 WB93R-5ado_2280% (5)

- WH609-716 SDocumento516 páginasWH609-716 Sado_22100% (1)

- Walmart, Amazon, EbayDocumento2 páginasWalmart, Amazon, EbayRELAKU GMAILAinda não há avaliações

- Hägglunds - Choice of Hydraulic Fluid PDFDocumento2 páginasHägglunds - Choice of Hydraulic Fluid PDFAnibal RiosAinda não há avaliações

- Moog G122-829A DS A4 v2Documento4 páginasMoog G122-829A DS A4 v2Hammad AshrafAinda não há avaliações

- Bomba Pv7 Bosch RexrothDocumento9 páginasBomba Pv7 Bosch RexrothHIDRAFLUIDAinda não há avaliações

- Hagglunds Viking MK 64 163000 Bo LN 0100 PDFDocumento26 páginasHagglunds Viking MK 64 163000 Bo LN 0100 PDFKOSTAS100% (1)

- PW160-7K S 0411Documento890 páginasPW160-7K S 0411ado_22100% (3)

- Micron Interview Questions Summary # Question 1 Parsing The HTML WebpagesDocumento2 páginasMicron Interview Questions Summary # Question 1 Parsing The HTML WebpagesKartik SharmaAinda não há avaliações

- A17FODocumento16 páginasA17FOJose SalvadorAinda não há avaliações

- Re91401 A2foDocumento20 páginasRe91401 A2foTaz Juan GAinda não há avaliações

- 4/3 and 4/2 Directional Control Valves With Hand Lever Type WMMDocumento8 páginas4/3 and 4/2 Directional Control Valves With Hand Lever Type WMMAhmed Abd ElhakeemAinda não há avaliações

- 4wre 6-10 Sew1xDocumento12 páginas4wre 6-10 Sew1x2267airportAinda não há avaliações

- M4 Spool Replacement PDFDocumento11 páginasM4 Spool Replacement PDFMira RedaAinda não há avaliações

- Ronald Luis Quisurco PDFDocumento5 páginasRonald Luis Quisurco PDFmoisesAinda não há avaliações

- RA 90 220 Rexroth Hydraulic Fluids On A Petroleum Oil Basis PDFDocumento8 páginasRA 90 220 Rexroth Hydraulic Fluids On A Petroleum Oil Basis PDFeng13Ainda não há avaliações

- Rcoa1806 03 03Documento36 páginasRcoa1806 03 03Fernando Sabino100% (1)

- Pet RainingDocumento57 páginasPet Rainingeddie2166100% (1)

- Webex Nr12Documento35 páginasWebex Nr12Carlos VandréAinda não há avaliações

- Eaton EN-0201 ® Hydraulic MotorDocumento8 páginasEaton EN-0201 ® Hydraulic Motormemelo3Ainda não há avaliações

- A4VG - Data Sheet - Serie 40Documento68 páginasA4VG - Data Sheet - Serie 40Aurimas Bendinskas100% (1)

- PVB PVBQ A10vso PVHDocumento38 páginasPVB PVBQ A10vso PVHWilliam ValenciaAinda não há avaliações

- Ficha Técnica Control de Accionamiento de Traslación de Vehículos de Ruedas DRC Bosch Rexroth Inglés PDFDocumento36 páginasFicha Técnica Control de Accionamiento de Traslación de Vehículos de Ruedas DRC Bosch Rexroth Inglés PDFvivsAinda não há avaliações

- Spare Parts List: B1517222382 Drawing: Material NumberDocumento6 páginasSpare Parts List: B1517222382 Drawing: Material NumberAgus YulfizarAinda não há avaliações

- Re 15190Documento24 páginasRe 15190Ahmed Abd ElhakeemAinda não há avaliações

- Re92060 2014-04Documento28 páginasRe92060 2014-04Ibrahim GökmenAinda não há avaliações

- Cat Hy14 1600 Denison Products PDFDocumento438 páginasCat Hy14 1600 Denison Products PDFEmiliano MercadoAinda não há avaliações

- Moog G122-829-001 - Catalog1Documento2 páginasMoog G122-829-001 - Catalog1Jean-Roch JacquesAinda não há avaliações

- Adjusting Max Displacement HPR-02Documento3 páginasAdjusting Max Displacement HPR-02ArleyTrujillo1224Ainda não há avaliações

- Atos Servo Valve TFS330Documento10 páginasAtos Servo Valve TFS330back1949Ainda não há avaliações

- Motores HagglundsDocumento8 páginasMotores HagglundsThiago SilvaAinda não há avaliações

- 10 01 Breather Filters GBDocumento8 páginas10 01 Breather Filters GBosuengAinda não há avaliações

- Hight Quality Spare Parts: Bosch Rexroth (Rexroth Build) Series A4VGDocumento1 páginaHight Quality Spare Parts: Bosch Rexroth (Rexroth Build) Series A4VGINVESTIGACION Y DESARROLLOAinda não há avaliações

- Seals For Michelin Earthmover Tyres and Rims: Seals Description O-RingDocumento1 páginaSeals For Michelin Earthmover Tyres and Rims: Seals Description O-RingThiago Lisboa GuimarãesAinda não há avaliações

- Rexroth - HST - Shift On Fly GearboxDocumento9 páginasRexroth - HST - Shift On Fly Gearboxngk522Ainda não há avaliações

- TDV 100Documento6 páginasTDV 100林育豪Ainda não há avaliações

- Universo de Reposio MobilDocumento36 páginasUniverso de Reposio MobilAdrian MartinAinda não há avaliações

- A2FE + ID Br61Documento1 páginaA2FE + ID Br61muhammadAinda não há avaliações

- A10V Series 31 Eng DataDocumento32 páginasA10V Series 31 Eng DataMARCO HernándezAinda não há avaliações

- WP Cross ReferenceDocumento12 páginasWP Cross ReferenceCentral HydraulicsAinda não há avaliações

- Aa4v56 Series 1 Service Parts ListDocumento36 páginasAa4v56 Series 1 Service Parts Listhamza HamzaAinda não há avaliações

- Denison Calzoni Type MRT Mrte MRTFDocumento24 páginasDenison Calzoni Type MRT Mrte MRTFSilvio RomanAinda não há avaliações

- A (A) 10vso18-140 Series 3x PDFDocumento36 páginasA (A) 10vso18-140 Series 3x PDFR.Ranjan PradhanAinda não há avaliações

- Bargawan Attendence AugDocumento38 páginasBargawan Attendence Auggolu23_1988Ainda não há avaliações

- Accumulator Charging Valves: Single Charging Valves, Dual Charging Valves, and Load Sensing Charging ValvesDocumento27 páginasAccumulator Charging Valves: Single Charging Valves, Dual Charging Valves, and Load Sensing Charging ValvesPedro Mendoza100% (1)

- CP CatalogDocumento20 páginasCP CatalogCentral Hydraulics100% (1)

- Series 45 Frame F 74-90 Parts ManualDocumento160 páginasSeries 45 Frame F 74-90 Parts ManualArko RoosAinda não há avaliações

- HY11-3362 Press Control PPCC UKDocumento40 páginasHY11-3362 Press Control PPCC UKLucas Cardoso100% (1)

- Spare Parts List: R901352448 R961005926 Drawing: Material NumberDocumento4 páginasSpare Parts List: R901352448 R961005926 Drawing: Material NumberMohamed HusseinAinda não há avaliações

- Pressure Relief and Anti-Cavitation Valves (Cartridge Type) For Mobile ApplicationsDocumento12 páginasPressure Relief and Anti-Cavitation Valves (Cartridge Type) For Mobile ApplicationsOleg080Ainda não há avaliações

- Sacvanging ValveDocumento12 páginasSacvanging Valvemohammed sulaimanAinda não há avaliações

- Re92105 01 X b2 - 2017 08Documento56 páginasRe92105 01 X b2 - 2017 08cln100% (1)

- Re 91401Documento20 páginasRe 91401JozefAinda não há avaliações

- 3-5400 GB PDFDocumento16 páginas3-5400 GB PDFShijumon KpAinda não há avaliações

- A 2 FMDocumento4 páginasA 2 FMMadhu RajagopalanAinda não há avaliações

- Assembly Number: A10V (S) O45Documento4 páginasAssembly Number: A10V (S) O45Hashem AlbakriAinda não há avaliações

- METRUS Test Bench Overview 2017Documento8 páginasMETRUS Test Bench Overview 2017Ozawa MagooAinda não há avaliações

- Hydro TechnikDocumento80 páginasHydro Technikleon100% (1)

- Axial Piston Variable Motor A6VM: RE 91 604/05.06 1/76 Replaces: 06.03Documento76 páginasAxial Piston Variable Motor A6VM: RE 91 604/05.06 1/76 Replaces: 06.03Александр БулдыгинAinda não há avaliações

- Piston Pumps: VickersDocumento9 páginasPiston Pumps: VickersRodrigo Andrade ScarpaAinda não há avaliações

- Hagglunds CADocumento84 páginasHagglunds CAVINAY VISHWAKARMAAinda não há avaliações

- Bomba Pistao Variavel A4vg PDFDocumento72 páginasBomba Pistao Variavel A4vg PDFtawfeeqsylanAinda não há avaliações

- Spare Parts List: R902422155 R902420950 Drawing: Material NumberDocumento67 páginasSpare Parts List: R902422155 R902420950 Drawing: Material NumberJamin SmtpngAinda não há avaliações

- Rexroth 1PV2V3 PDFDocumento8 páginasRexroth 1PV2V3 PDFClaudio Sanchez100% (2)

- Nachi Vane PumpDocumento10 páginasNachi Vane PumpengineermarkAinda não há avaliações

- Pt6and8 Bu Eng 1372Documento2 páginasPt6and8 Bu Eng 1372ado_22Ainda não há avaliações

- DuplomatikDocumento4 páginasDuplomatikado_22Ainda não há avaliações

- TroubleshootingDocumento440 páginasTroubleshootingado_2298% (47)

- PC290 M Ueam004000 PC290LC NLC 7 0412Documento321 páginasPC290 M Ueam004000 PC290LC NLC 7 0412ado_22100% (1)

- TTDCD en 00 CircuitDocumento11 páginasTTDCD en 00 Circuitado_22100% (10)

- Fandrivesystem W SeriesDocumento3 páginasFandrivesystem W Seriesado_22Ainda não há avaliações

- Salami Catalog Group3 Zupcaste PumpeDocumento32 páginasSalami Catalog Group3 Zupcaste Pumpeado_22Ainda não há avaliações

- Semperflex Hydraulics Catalogue 2013 05Documento24 páginasSemperflex Hydraulics Catalogue 2013 05ado_22Ainda não há avaliações

- CLRG 326e GBDocumento4 páginasCLRG 326e GBado_22Ainda não há avaliações

- Salami Catalog Group2Documento35 páginasSalami Catalog Group2ado_22Ainda não há avaliações

- Zupcastepumpe PZGDocumento4 páginasZupcastepumpe PZGado_22Ainda não há avaliações

- Binary File MCQ Question Bank For Class 12 - CBSE PythonDocumento51 páginasBinary File MCQ Question Bank For Class 12 - CBSE Python09whitedevil90Ainda não há avaliações

- Labstan 1Documento2 páginasLabstan 1Samuel WalshAinda não há avaliações

- Sophia Program For Sustainable FuturesDocumento128 páginasSophia Program For Sustainable FuturesfraspaAinda não há avaliações

- Delta AFC1212D-SP19Documento9 páginasDelta AFC1212D-SP19Brent SmithAinda não há avaliações

- Subqueries-and-JOINs-ExercisesDocumento7 páginasSubqueries-and-JOINs-ExerciseserlanAinda não há avaliações

- EnerconDocumento7 páginasEnerconAlex MarquezAinda não há avaliações

- CS321 Computer ArchitectureDocumento160 páginasCS321 Computer ArchitectureAnurag kumarAinda não há avaliações

- Brand Positioning of PepsiCoDocumento9 páginasBrand Positioning of PepsiCoAbhishek DhawanAinda não há avaliações

- Experiment On Heat Transfer Through Fins Having Different NotchesDocumento4 páginasExperiment On Heat Transfer Through Fins Having Different NotcheskrantiAinda não há avaliações

- A. The Machine's Final Recorded Value Was P1,558,000Documento7 páginasA. The Machine's Final Recorded Value Was P1,558,000Tawan VihokratanaAinda não há avaliações

- Cabling and Connection System PDFDocumento16 páginasCabling and Connection System PDFLyndryl ProvidoAinda não há avaliações

- Sustainable Urban Mobility Final ReportDocumento141 páginasSustainable Urban Mobility Final ReportMaria ClapaAinda não há avaliações

- Daraman vs. DENRDocumento2 páginasDaraman vs. DENRJeng GacalAinda não há avaliações

- Interruptions - 02.03.2023Documento2 páginasInterruptions - 02.03.2023Jeff JeffAinda não há avaliações

- A320 TakeoffDocumento17 páginasA320 Takeoffpp100% (1)

- Final ExamSOMFinal 2016 FinalDocumento11 páginasFinal ExamSOMFinal 2016 Finalkhalil alhatabAinda não há avaliações

- Unit Process 009Documento15 páginasUnit Process 009Talha ImtiazAinda não há avaliações

- 1.1. Evolution of Cloud ComputingDocumento31 páginas1.1. Evolution of Cloud Computing19epci022 Prem Kumaar RAinda não há avaliações

- Enerparc - India - Company Profile - September 23Documento15 páginasEnerparc - India - Company Profile - September 23AlokAinda não há avaliações

- Properties of Moist AirDocumento11 páginasProperties of Moist AirKarthik HarithAinda não há avaliações

- Difference Between Mountain Bike and BMXDocumento3 páginasDifference Between Mountain Bike and BMXShakirAinda não há avaliações

- Introduce Letter - CV IDS (Company Profile)Documento13 páginasIntroduce Letter - CV IDS (Company Profile)katnissAinda não há avaliações

- Seminar On Despute Resolution & IPR Protection in PRCDocumento4 páginasSeminar On Despute Resolution & IPR Protection in PRCrishi000071985100% (2)

- Draft Contract Agreement 08032018Documento6 páginasDraft Contract Agreement 08032018Xylo SolisAinda não há avaliações

- Agricultural Economics 1916Documento932 páginasAgricultural Economics 1916OceanAinda não há avaliações

- Wendi C. Lassiter, Raleigh NC ResumeDocumento2 páginasWendi C. Lassiter, Raleigh NC ResumewendilassiterAinda não há avaliações

- Rofi Operation and Maintenance ManualDocumento3 páginasRofi Operation and Maintenance ManualSteve NewmanAinda não há avaliações