Escolar Documentos

Profissional Documentos

Cultura Documentos

DC Electrification Supply System Design

Enviado por

曾乙申Descrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

DC Electrification Supply System Design

Enviado por

曾乙申Direitos autorais:

Formatos disponíveis

Roger D White - 1 - 26/04/2011

Atkins Rail

DC ELECTRIFICATION SUPPLY SYSTEM DESIGN

Dr Roger D White

Professional Head of Electrification

ATKINS United Kingdom

roger.white@atkinsglobal.com

INTRODUCTION

Railway electrification has in the past been dominated by

overhead contact wire and DC third/ fourth conductor rail

electrification systems. The historical reasons for this

have been the success of the DC traction motor and the

necessity of a DC supply. Mercury arc rectifiers were

originally used to provide rectification at substations with

the DC power being transmitted to the traction equipment

by the conductor rail or overhead wire. Success in

producing mercury arc rectifiers capable of being

operated on board the railway vehicle, enabled railway

AC electrification systems to become a reality in the

1950/60's.

It should be noted that DC is still the most common form

of railway electrification system in the world.

HIGH VOLTAGE SUPPLY FEEDING

ARRANGEMENT

The Local Grid Network

The HV AC incoming supplies from a National Grid or

Regional Electricity Companies (REC), or Railway

Generators provide the feed for the DC traction power

substations. The local supplies for stations, tunnel-

cooling fans, auxiliary circuits including batteries,

chargers and uninterruptible power supplies (UPS) for

computers and signalling circuits are also provided by the

REC.

The electrical supply is fed to the railway at typically

132kV, 66kV or 33kV and the electrical power is then

(on larger systems) distributed through a separate AC

network at a medium voltage of 33kV, 22kV or 11kV by

the railway/metro. This supply is used to provide traction

power at regular intervals around the railway network.

With light rail/super tram applications it is usually only

necessary to provide the supply at a couple of points and

is therefore obtained directly from the electricity supply

utility.

Positioning of HV Supply Points

The number of feed points to the railway network will

depend upon the size of the railway system and the

capacity required at any particular point. On urban mass

transit systems EHV supplies may not be available and

space for substations and feeders are difficult to obtain

and expensive. It is sometimes necessary therefore to

provide the supply from local 33/66kV supplies. This is

convenient from the supply authority viewpoint and

provides a high degree of supply integrity; however it

does raise two problems, control of the traction voltage

regulation and HV voltage harmonics.

Incoming Feeding Arrangement

The AC switchboard will have in addition to the

incoming breakers, local supply breakers and feeder

breakers to other substations. The local supply breakers

provide the supply to traction transformer-rectifier units,

and auxiliary step down transformers, which are required

in the immediate vicinity.

The incoming supplies from the electrical utility will

have its own protection provided by the Supply

Company. The protection of supply cables require the co-

operate with the Supply Company to agree on the relay

settings necessary to achieve stability and discrimination.

Power is supplied into the railway network at several

points, and it is necessary to ensure that the incoming

feeds are not paralleled. An interlocking scheme enables

the system to be fed from all power sources but ensures

that an electrical break prevents paralleling taking place.

This arrangement gives the most reliable delivery of

power to the railway even if one supply source fails

completely.

39

Roger D White - 2 - 26/04/2011

Atkins Rail

Railway LV Feeding Arrangement and Switchboard

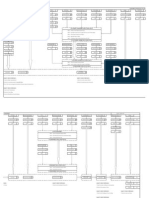

A typical LV supply arrangement is given in Fig 1 where

one circuit breaker is connected to each side of the Bus

Coupler Breaker which feeds step down transformers

(33kV/11kV) and the 11 kV switchboard, these circuit

breakers are equipped with the protection relays to

protect the step down transformer.

A typical 11kV distribution network is provided

throughout this system where all the passenger stations

have 11kV switchboards. At each passenger station the

11kV would be transformed to 415V 3 phase for

domestic supplies. To give a high level of security of

these supplies, duplication is provided at each location.

Providing the supply capacity for mass transit railways is

more complex as there can be up to 10 trains on a

particular substation, some of which are motoring,

coasting, braking or regenerating. The worst scenario

occurs when all the trains are accelerating or regenerating

simultaneously. The design of the electrical supply

system must be such that it can cope with worst case

scenario. The limitation of the number of trains in any

particular section is the responsibility of the Operation

Control Room.

On DC intercity lines, or freight routes, the positioning of

incoming supply feeders and substations do not pose such

a problem. Land is easier to come by and space is not at

a premium. Since each substation only supplies one or

two trains and the acceleration/deceleration is slower, the

positioning of supply points, substations, and the

specification of their capacity is relatively easy.

Figure 1 Typical feeding Arrangement for DC Electrification Systems

40

Roger D White - 3 - 26/04/2011

Atkins Rail

DISTRIBUTION OF THE DC TRACTION

SUPPLY

One of the main drawbacks when using DC traction

systems is the fact that electrical energy is universally

generated by supply authorities in the form of

alternating current. This means that for a DC traction

system the railway authority has to provide its own

converting plant. Due to the high levels of current that

are drawn in the conductor rail or overhead catenary, the

system voltage can experience severe regulations. To

overcome this, substations are spaced at regular

intervals. This normally results in the operation of a

high voltage AC distribution network linking the

lineside substations. Obviously this increases the

capital expenditure when the various systems are

compared.

Conductor Rail and Overhead Line

The conductor rail or overhead power supply is

designed to operate within specified voltage limits and it

is necessary that the traction unit is capable of handling

the voltage provided. The traction motors and control

gear are required to be adequately insulated to the

maximum operating voltage of the supply network.

Traction motors for DC systems are normally wound for

600/750 V and connected permanently in parallel for

600/750 V DC supplies, or connected in series parallel

pairs for 1500 V DC operation. On 3000 V DC supplies

the traction motors are normally wound for 1500V

operation and connected two in series on full voltage

and as a result they are larger in diameter and more

difficult to install under the low floors of multiple unit

stock. The establishment of DC supply voltages have

traditionally been chosen to meet the needs of the DC

traction motor control.

In the past the main advantage of the DC supply system

compared to the AC supply system is that a less

complex traction control system is required, however

with the advent of high power GTO (gate turn off

thyristor), IGBT (insulated gate bipolar transistors) and

the microprocessor, 3 phase drives are becoming more

common on both AC and DC electrification systems.

With the advent of 3 phase drives the DC voltage is not

a design requirement for the traction engineer due to the

ability of the traction input converter to set the DC link

voltage to the inverter drive, it is likely therefore with

new schemes using three phase drives that other system

voltages could be used.

Positions of the Lineside Traction Sub-Stations

A detailed analysis is needed to establish the correct

positions of sub-stations on the railway system, a simple

mathematical approach has been included. (Calculation

of voltage regulation and short circuit situation). Having

established the working voltage 600V, 750V, 1500V or

3000V the exact position of the substation has to be

decided. This decision is made on the technical

performance of the power system. It is also necessary to

take into account other factors which will determine the

final choice; availability of land, position of junctions

and crossovers, provision of road access up to the main

door of the substation building in order to facilitate the

transport of spare items of plant and any necessary

maintenance test equipment.

The most economic distance between substations is for

600V DC 3-4km; 750 V DC 5-6km; 1500V DC 8 -

13km and 3000V DC 20 - 30km.

The distribution voltage for heavy metro and freight is

1500V, 3000V DC overhead, and therefore requires less

isolation and clearance than for AC electrification. The

mechanical strength of the overhead line conductor

becomes the main factor in overhead design, making the

conductor sizes not dissimilar between 1500 V DC and

25 kV AC Where the power requirements exceed the

capability of the overhead catenary it is necessary to

include parallel feeds along the overhead masts.

Connections are made at regular intervals to the

catenary to ensure good current sharing.

The 3000 V system is applied almost entirely to the

main line in order to maximise substation spacing, with

750 V for tram and 1500 V DC supplies predominantly

chosen for urban mass transit or light rail systems. It

should be noted that London Underground use a fourth

rail system with -210V and +420V conductor rails.

Factors Influencing Substation Spacing

The substation spacing is determined by the traction

loads and the maximum permissible voltage drop in the

conductor system, i.e. including both outgoing and

return conductors that can be reasonably tolerated

without too seriously affecting either the system

efficiency or the train operation. With DC systems a

voltage drop in the order of 15 to 30% has usually been

allowed, although the lower percentage value is to be

advocated.

In considering maximum voltage drop that can be

allowed in the system, the following factors should be

borne in mind so far as running rail return systems are

used.

The greater the feeding length, the greater will be the

rail potential above earth. This should be limited on

account of the danger of risk to passengers and railway

personnel. On 660 Vdc third rail systems, rail potentials

are typically 30V with respect to earth, while on 1500

Vdc overhead systems rail potentials are typically 60-

120V. Voltages in excess of this will be obtained under

41

Roger D White - 4 - 26/04/2011

Atkins Rail

more severe operational and feeding modes. The greater

the rail potential the greater the risk of electrolysis.

Factors affecting the Length of the DC Feeding

i. System Loading

The system loading can be obtained from

analysis of train operating schedules or from the

output of a multi train simulator. This will enable

the optimum number of rectifier substations to be

selected; also the substation plant capacity.

ii. Conductor Section

The greater the cross section area of the

conductor system the less the electrical resistance

and hence the greater the distance for a given

voltage drop with a specified load. The capital

cost of the conductor system however increases

directly as the conductor cross section area;

furthermore the greater the cross section area, the

greater the weight and resultant load on the

supporting structures in overhead systems. With

ground collection systems the conductor rail

cross section is usually approximately equal to

that of a running rail, though in certain busy

sections of the line, at junctions, a larger cross

section is employed. With DC overhead systems

the limiting factor for the cross section area is the

load on each supporting insulator, hence the

conductor cross section is usually determined by

mechanical considerations though its electrical

conductivity in DC systems is the governing

characteristic. Where the line current exceeds the

current rating of the overhead catenary separate

feeder cables have to be provided on the

supporting structures.

iii. Circuit Breaker Tripping Current

The length of section fed by one substation must

be such that its electrical resistance, including

both outgoing and return conductors, does not

exceed the minimum system voltage divided by

the circuit breaker tripping current. With a 1500

V DC overhead system, the loop resistance is in

the order of 0.0375 ohm per km. Assuming a

10% volt drop at the far end and a breaker setting

of 4000 amps, then loop resistance must not

exceed:

90% x 1500 = 0.3375 ohms

4000

(which is equivalent to approximately 9 km of

track.)

Normally the substations are situated at

approximately 8 km intervals so that the loop

resistance for a fault at the end of the section with

one substation out of service would be 0.3 ohms;

this gives a margin of 0.3375 - 0.3 = .0375 ohms,

which could be included in the fault resistance

and breaker operation would still take place.

iv. Inter- tripping

With both substations feeding into a track

section, then inter-tripping of feeder breakers is

commonly used. If a fault occurs within a section

of overhead line then the breaker nearest to the

fault would trip first and by means of pilot wires

the corresponding section breaker in the

substation at the end of the section remote from

the fault could be made to trip. This would have

the benefit of allowing longer feeding sections.

DC FEEDING ARRANGEMENTS

The normal feeding arrangement is with the substations

all connected in parallel. There is a DC circuit breaker

at each end of the feeding section to provide protection

under fault conditions. Each substation feeds from a

common DC busbar through DC circuit breakers in both

directions. The feed is separated by a bypass isolator;

this is normally open and closed only when it is

necessary to bypass the substation.

Normal Feeding Arrangement

This is where all of the feeder DC circuit breakers are

closed, providing double end feeding of the section of

traction supply. The isolator at each substation is

normally open, providing an isolated feeding section of

traction supply, and ease of protection of the feeding

section. Where regeneration is applied, the isolator at

each S/S is normally closed.

Tee Feeding Arrangement

This is implemented at a substation when a DC feeder

circuit breaker at one end of the feeding section is open.

The tee feeding arrangement is achieved by closing

the bypass isolator, allowing the remaining DC circuit

breaker at the substation to feed the traction supply in

both directions.

Single End Feeding Arrangement

Single end feeding arrangement on double end fed

sections is a temporary feeding arrangement following

the loss of the feed from a track feeder DC circuit

breaker. This mode of feeding is normally only

temporary and if the feed cannot be restored within a

reasonable period of time, the traction supply would

normally revert to tee feeding.

Bypass Feeding Arrangement

42

Roger D White - 5 - 26/04/2011

Atkins Rail

This occurs when there is a loss of supply at the

substation or failure of the feeder DC circuit breakers in

both directions. Under this condition the associated

isolator is closed. The traction supply is provided from

the feeder DC circuit breakers at the adjacent

substations. In the case of single end fed sections, it is

necessary to close only the appropriate by pass isolator.

Loss of Supply from Transformer Rectifier Units:

The supply system is designed with more than one

transformer rectifier unit at a location. The traction

supply is normally designed to operate with one

transformer rectifier unit out of service at any location.

If the complete substation is lost, the substation should

operate as a track paralleling hut.

TRACKSIDE DC SUBSTATION

Most silicon rectifiers on traction systems use a three

phase 50 Hz national or railway supply intake. Three

phase rectification arrangement is used to reduce

harmonic distortion at the point of common coupling

and to reduce harmonic content in the DC supply.

Where the mercury arc rectifier have been replaced by a

silicon rectifier the double star transformer with inter

phase transformer is employed. The advance of the

silicon rectifier makes more simple arrangements of

design.

The advent of high reverse repetitive peak voltage

withstand of the diodes in excess of 4500V makes the

series connection of diodes in rectifier design

unnecessary, for three phase bridges and for traction

line voltage of up to 1800V. Where higher system

voltage of 3000V DC is required, two three phase

bridges can be connected in series. A low ripple on the

DC system voltage can be achieved with the connection

of one bridge in star and the other in delta.

Rectifier Design

The function of the rectifier is to convert the three-phase

current into direct current. In the past, mercury arc

rectifiers have been used, however it is now normal to

install naturally ventilated silicon rectifiers. This has

become possible with the increase in area of the silicon

wafer and has created what is practically a short circuit

proof rectifier.

Natural ventilation of the rectifier means that there are

no moving parts and therefore an increase in reliability,

economic benefits and minimum maintenance. Silicon

diode rectifiers are very robust, efficient (low on state

losses) and able to sustain large fluctuations in

temperature, high over current and over voltage rating

(reverse).

The use of capsule/disc construction permits a wide

range of the mean forward current and allows a

minimum number of devices to be connected in parallel

in each arm.

The voltage level of the supply system and the

transformer rectifier arrangement will give the

characteristic DC voltage. The DC system voltage

should be such that it complies with the train operating

requirements whether 650V/1500V or 3000V DC

Rectifier Protection

Short Circuit Protection

The rectifiers are protected against short circuit and

overloading by a thermal relay and over current time

relay. These relays will trip the rectifier AC supply,

removing the system driving force.

Internal Short Circuits

Internal short circuit of the rectifier will occur due to the

failure of one of the rectifier arms. This will produce a

two-phase transformer fault current and reverse current

flowing in the faulted rectifier arm. The fault is

interrupted by the diode fuse on the line side which

isolates the faulted diode, a micro switch on the diode

fuse indicates that the fuse has ruptured.

Where the diode is of sufficient rating it is sometimes

considered suitable not to include a separate fuse.

Over voltages

Over voltages originating from the AC supply or the

traction DC supply are normally attributed to switching

or interruption of the power system. These over voltage

are attenuated with a resistor capacitor network

provided on the DC side of the rectifier.

Commutation Protection

Commutation hole storage protection circuits are

applied to each diode. These protect the devices from

high voltages that are generated during the commutation

of the diode.

The use of these over voltage devices can be dispensed

with as the reverse voltage ratings of the devices is

increased.

Mechanical Construction Rectifier

The semiconductor diodes are mounted on aluminum

extruded heat sinks. These are required to ensure that

the device does not operate outside its normal junction

operating temperature. The diodes are normally

connected in parallel in a bridge and are hermetically

sealed against the ingression of dust and moisture etc.

The diode fuses and micro switches are mounted

adjacent to the diodes, the diode units are then mounted

43

Roger D White - 6 - 26/04/2011

Atkins Rail

so that the heat sink fins can circulate air freely. The AC

and DC busbars are arranged at either the top or bottom

of the cubicle. The rectifier arm can then be connected

to provide any arrangement that is required.

Substation Performance

Ref. Figure 4 on Page 9

The detailed electrical performance of the substation has

to be designed into the electrification system at the

outset The performance is dependent upon the traction

load specified by the operating business, and the level of

supply redundancy required. Provision for future

extension of the system, the increase in train loads, and

the change of type of vehicles to be operated must also

be considered.

In the design of a traction substation it is necessary to

take into consideration the following aspects:-

i. Traction sub station rating

ii. Traction supply and converter arrangements

iii. DC Traction supply voltage

iv. The regulation of the DC traction voltage

v. The characteristic DC short circuit fault current

vi. The power factor of the traction rectifier unit

vii. The production of harmonics in the input AC

supply current, and the distortion to the input

supply voltage.

1 Typical Traction Substation Rating: Design

specification for Greenwich Traction Substation

(Jubilee Line Extension)

+ Rated capacity 2400kW

+ Rated DC traction voltage 600VDC

+ Rated DC traction current 4000A

+ Short circuit protection 40 kA 0.25 sec

+ Transformer 22kV/415V

+ Rated Capacity 2 MVA

+ Short circuit protection 40 kA 0.25 Sec

A typical design specification for a 750V supply

system:-

+ Rated capacity 3000 kW

+ Rated DC traction voltage 750 V DC

+ Rated DC traction current 4000 A

+ Overload capabilities 150% 300% 450% of the

rated load current for permitted overload

periods.

150% 6000 A for 1 hr

300% 12000 A for 1 min

450% 18000 A for 10 secs

Typically the voltage regulation will vary by up to 6%

at full load current over the linear portion of the

characteristic, with a specified maximum and minimum

values of supply voltage over the operating range

2 Transformer and Rectifier Circuit

Arrangement

Ref. Figure 2 and 3

The pulse characteristic of the supply system is

primarily defined by the transformer winding and

converter arrangement. A number of simple

arrangements of the transformer windings may be

chosen with a 3 phase AC supply system to provide 6,

12, 18, and 24 pulse DC output voltage. Other ripple

frequencies may be achieved using two converters and

windings, which are phase displaced or wound in an

alternative star/delta configuration.

A 12 pulse rectifier therefore can be obtained by

connecting two separately fed phase displaced, 6 pulse

systems in series or parallel. The arrangement will

provide the necessary 30

o

displacement of the supply to

provide a twelve pulse ripple when the respective

bridges are connected in series or parallel.

The arrangement of the windings during the design and

construction of the transformer determine the short

circuit reactance, commutating reactance and the

operating load loss due to winding resistance. These

design parameters are responsible for dominating the

DC short circuit fault current level, the operating DC

voltage regulation level, transformer efficiency,

transformer and converter power factor and the level of

harmonics produced in the supply side.

44

Roger D White - 7 - 26/04/2011

Atkins Rail

Figure 2 12-Pulse Parallel Bridge Converter

Figure 3 12-Pulse Series Bridge Converter

45

Roger D White - 8 - 26/04/2011

Atkins Rail

3 DC Traction Supply Voltage

European regulation EN 50163 (Supply Voltage of

Traction Systems)

Table 1 DC Traction System Voltages

Definition of

operating DC

System Voltages

600

*

750 150

0

300

0

lowest non permanent

voltage duration

10min,

lowest permanent

voltage duration

indefinitely,

400 500 100

0

200

0

nominal voltage

designed system value,

600 750 150

0

300

0

highest permanent

voltage duration

indefinitely

720 900 180

0

360

0

highest non permanent

voltage duration 5

min.

770

+

950

^

195

0

390

0

*Future DC traction systems for tramways and local

railways should conform with system nominal voltage of

750, 1500, 3000V

+In case of regenerative braking a voltage of 800 may be

admissible

^In case of regenerative braking a voltage of 1000

may be admissible

4 The Regulation of DC Traction Voltage

Regulation of the substation is a vital characteristic of

the DC electrification system. If the regulation is too

steep then the train will not have sufficient volts to

maintain train timetables. Raising the voltage at the

substation will provide a higher voltage on the load but

may produce excessive voltages under no load

conditions. A lower regulation is achieved by reducing

the impedance of the supply transformer. This however

will increase the short circuit fault current which will

require a higher rating for the circuit breakers and

converters. The optimum design is therefore a

compromise between regulation of the substation and

the level of short circuit fault current.

Advanced transformer designs using coupled secondary

allow low regulation over the normal load range and yet

limit the short circuit current. This is achieved by using

secondary windings which are coupled to achieve the

correct short circuit to regulation relationship.

Calculation of Voltage Drop in the Feeding Network

For accurate calculation of remote DC faults computer

modelling is necessary utilising the following data:

+ substation is modelled as a transformer of known

impedance,

+ a rectifier whose characteristics include overlap;

+ power rail and return conductor being

represented by a resistance and inductance both

of which may vary with the frequencies of the

load current.

The following calculations are simplified to show the

principles involved. The supply is assumed to be a

constant voltage supply with zero source impedance and

the power rail and return conductor purely resistive.

One train in a double track section without

track-sectioning equipment (Ref Figure 5 on page

10)

Let the distance between the substations be L metres,

the resistance of the conductor be R

c

O/m and the

resistance of each rail be R

t

O/m. If both substations

have the same voltage at their busbars then the

maximum voltage drop will occur when the train is at

the mid section.

The maximum voltage drop

Vd

max

= R

c

L I + R

t

L I (V)

or Vd

max

= I L(R

c

+ R

t

) (V)

assumptions:-

+ where L is the distance in metres between

substations;

+ where I is the maximum current taken per train;

+ one running rail is available for traction return

circuit;

+ IR - current per rail;

+ IR -I (if one rail available per track).

+ IR -I/8 (if two rails available per track).

One train in a double track section with

track-sectioning equipment (Ref Figure 6 on page

10)

Again the maximum volt drop occurs when the train is

at the midsection. However, the track section cabin

provides a means of paralleling the conductors, hence

Voltage Drop = R

c

L I + R

t

L I (V)

= (IR

c

+ IR

t

)L /8 (V)

Assume one running rail is available for traction return

current.

.

46

R

o

g

e

r

D

W

h

i

t

e

-

9

-

2

6

/

0

4

/

2

0

1

1

A

t

k

i

n

s

R

a

i

l

F

i

g

u

r

e

4

T

r

a

c

t

i

o

n

S

u

b

s

t

a

t

i

o

n

T

r

a

n

s

f

o

r

m

e

r

a

n

d

R

e

c

t

i

f

i

e

r

P

e

r

f

o

r

m

a

n

c

e

C

h

a

r

a

c

t

e

r

i

s

t

i

c

4

7

Roger D White - 10 - 26/04/2011

Atkins Rail

.

Figure 5 Voltage Regulation of Train in Double Track Section without Track Sectioning Equipment

Figure 6 Voltage Regulation of Train in Double Track Section with Track Sectioning Equipment

48

Roger D White - 11 - 26/04/2011

Atkins Rail

5 Characteristic DC Short Circuit fault Current

The DC short circuit level is an important design

characteristic of the power supply system. The fault

level must be such that it does not interfere with normal

train operation. The level must be also be such that the

short circuit rating of the rectifier devices is not

exceeded. The short circuit rating of the rectifier

devices is specified by the surge rating of the device

under a fault condition. It is also necessary to ensure

that the transformer windings are adequately braced

against stress brought about by short circuit forces.

Finally, the DC track circuit breakers must be capable

of successfully interrupting any short circuit.

A short circuit at the output of the rectifier terminals

applies a balanced three phase short circuit to the AC

system. Normal circuit theory can be applied to

establish the fault current which flows. The secondary

circuit of the transformer and rectifier can be

represented as a source e.m.f., supply reactance and

supply resistance per phase. This produces a DC fault

current that rises to 40-80kA in 10-20mS. The di/dt of

the fault current is dependant on the inductance of the

supply system and the inductance of the overhead line

the return current system.

(t) = V

m

sin (et + ) source emf

the AC current which flows can be calculated as

ShortCircuit

ac

e L E e

r t

L

R

2

e

2

L

2

+

|

\

|

.

(

(

(

(

(

E

R

2

e

2

L

2.

+

|

\

|

|

|

.

sin e t atan

e L

R

|

\

|

|

.

+ u +

|

\

|

|

.

|

\

|

|

.

(

(

(

+ :=

ac

L = supply and line inductance

R = supply and line resistance

e= angular velocity of the supply rad/sec

The analysis can be used to establish the instantaneous

fault current obtained from faults remote from the

substation itself, provided that a value of line

inductance and resistance can be established.

The value of the DC fault current can be achieved by

adding each of the secondary line currents point by

point during the DC short circuit. With a 6-pulse

system this will include the inverse of the line currents

shown. The DC fault current obtained will be the

typical fault current. Alternatively the current can be

approximated to

I

dc

= I

m

(1- e

-(R/L)t

)

Calculations of Short Circuit Currents The circuit

breaker setting must be low enough to enable the

circuit breaker to trip when a short circuit occurs, yet

the setting must be sufficiently high to cover the

maximum current likely to result from normal

operation of the schedules. When calculating fault

currents precise details of the track bonding and

conductor supply arrangements are necessary.

(a) Single unit substation without track-sectioning

equipment (figure 7)

The circuit breaker, shown open, immediately trips, but

current can still flow to the fault from the next

substation as shown. The short circuit current I

sc

is

approximated to the current flow from substation B,

this is to a first approximation only:

I

sc

= V (A)

L (R

c

+ R

t

)

where V is the voltage at the substation busbars and

only one running rail is available for traction return

current.

If there are two tracks and all the running rails are

bonded together at each substation for connection to the

negative busbar, then the resistance of the return

conductors is halved increasing the current to:

I

sc

= V (A)

L (R

c

+ R

t

)

(b) Single-unit substation with track-sectioning

equipment (figure 8)

This is most easily solved by applying Kirchhoff's

second law, i.e. in a closed loop the sum of the applied

e.m.f.s is equal to the sum of the products of current

and resistance. Hence :

V

A

= I

a

R

c

L + (I

a

+ I

b

)R

c

L (V)

V

B

= I

b

R

c

L + (I

a

+ I

b

)R

c

L + I R

t

(V)

Assuming the voltage at the substations remains

constant, these two equations can be solved for I

A

and

I

B

, and one running rail is available for traction return

current.

If there are four running rails able to return fault current

is as shown:

V

A

= I

A

R

c

L + (I

A

+ I

B

)R

c

L (V)

V

B

= I

B

R

c

L + (I

A

+ I

B

)R

c

L + I

B

R

t

(V)

49

Roger D White - 12 - 26/04/2011

Atkins Rail

.

Figure 7 Short Circuit Fault Current Double Track Section without Track Sectioning Equipment

Figure 8 Short Circuit Fault Current Double Track Section with Track Sectioning Equipment

50

Roger D White - 13 - 26/04/2011

Atkins Rail

6 Power Factor of the Transformer Rectifier Unit

The overall power factor of the rectifier unit and the

traction supply transformer are normally specified to be

better than 0.9 pu (including distortion factor).

Power Factor = I

rms

(fundamental) x cos

I

rms

(total)

cos (phase angle of fundamental)

The distortion factor needs to be included within the

power factor equation to take into consideration the

effect of the line current harmonics.

Distortion factor = I

rms

(fundamental)

I

rms

(total)

7 The production of harmonics in the DC and

input AC supply current.

Any complex wave can be resolved into its Fourier

Series; that is a series of sinusoidal waves of specific

amplitude, frequency, and phase. Complex waveforms

are therefore, the summation of a specific set of even

and odd harmonics as indicated below.

(t) = 0.5

0

+

1

sin(

1

t-

1

) +

2

sin(

2

t+

2

) + .

The rectifier circuit is a major source of harmonics in

the AC supply and the DC traction supply. This effect is

due to a number of system parameters including:

Rectifier pulse number

Balance of the firing circuits

Supply voltage symmetry

Transformer tolerances

The rectifier switches the load current from one phase to

the next; this is necessary to keep the polarity of the DC

voltage positive. This process is called 'commutation'.

The line current cannot switch instantaneously due to

the effect of the leakage reactance; this process is called

'overlap'. During the overlap period all devices are

conducting in the outgoing and incoming arms of the

rectifier. This produces a short circuit on the input and

the output to the rectifier.

The input supply voltage waveform and the output DC

waveform will therefore be interrupted, producing a

notch and oscillation due to the RLC characteristic of

the voltage waveform supply system. This has the effect

of distorting the AC supply waveform at the point of

common coupling.

The input current to the rectifier produces line current

with a stepped waveform due to the switching strategy of

the rectifier converter.

Harmonic distortion levels are specified by the Electricity

Council recommendation G5/4. This lays down the limits

of harmonic current which may be generated back in the

supply network. As a result of design predictions it is

possible to decide whether 6, 12 or 24 pulse will meet the

supply authorities regulations. In urban areas with

systems supplied at 33/66/132 kV it is normal to use 12 or

24 pulse rectifiers to ensure compliance with G5/4 AC

Side Harmonics.

Characteristic harmonics: the DC output voltage

waveform produces a ripple that is related to the pulse

number of the converter. This will produce harmonics in

the load current waveform that are typically related to

300Hz, 600Hz, 900Hz etc. depending on the rectifier

pulse number. The characteristic DC side harmonics are

therefore related to the pulse number.

AC side harmonics can be characterised by the Fourier

Analysis of the quasi square waveform. This produces

harmonics that are related to V

hn

= n pulse 1.

Pulse

Number

DC side AC Side

p np np 1

6 0,6,12,18,2

4

1,5,7,11,13,17,19,23,

25

12 0, 12,

24

1, 11,13,

23,25

The harmonics are responsible for undesirable effects

including

Overheating capacitors

Overheating generators and induction motors

Instability in converter control systems

Interference with control systems

Noise on telephone lines

Interference with signaling systems

The main mechanism of reducing harmonics on DC

electrification systems

Increase of the converter pulse number

Installation of filters

Uncharacteristic harmonics

The uncharacteristic harmonics are produced by :

unbalance in three phase systems positive,

negative and zero phase sequence

51

Roger D White - 14 - 26/04/2011

Atkins Rail

voltage waveform distortion

unbalance in phase impedances

inaccuracy in the converter delay angles

supply frequency variation

The harmonics of low uncharacteristic orders are

normally much smaller than those of adjacent

characteristic harmonics in the converter itself, however

on the ac side the uncharacteristic harmonic may be of

about the same magnitude as those of the characteristic

harmonics that are produced.

Under normal conditions the frequency of the National

Grid transmission system is required to be within 1% of

the nominal frequency i.e. from 49.5- 50.5 Hz. The

design of a users plant and apparatus must enable

operation within this range within this range also

complying with.

47.5 - 52.5 Hz continuous

47 - 47.5 Hz operation for a period of at least

20s is required whenever the frequency falls

below 47.5 Hz.

Permitted Harmonics and the Engineering

recommendation G5/4

Stage 3 assessment is applicable to connection of non

linear equipment with supply systems having a Point of

Common Coupling (PCC) at 33kV and higher voltages.

Requirements of the Railway Company

i. The railway system is required to provide the

characteristics of the load to be installed, when this

is a non linear equipment,

ii. Prediction of the Total Harmonic Distortion (THD)

is required to assess all harmonics up to and

including the 50

th

harmonic.

Requirements of the NOC (Network Operating

Company)

iii. NOC is required to provide the system harmonic

impedance values at the PCC which will enable the

customer to evaluate his system harmonic

performance.

iv. The existing distortion that already exists on the

system is required to be measured.

v. The prediction of the total harmonic levels by the

addition of the results of existing and new

harmonics.

Calculations

i. For unbalanced harmonic conditions, the phase

with the highest THD should be used.

ii. For individual harmonics which have the summated

magnitude and hence the greatest THD, the

measured and calculated values of distortion are

assumed to peak at the same time and to be in phase.

V

hp

= V

hm

+ V

hc

(Total = Measured + Calculated)

For other harmonics an average phase difference of 90

o

is

assumed at the time of maximum THD

_______

V

hp

= V

hm

+V

hc

Total = Measured + Calculated

The THD is then given by

THD

2

50

h

V

hp

( )

2

_

=

:=

Planning and Compatibility Levels

Planning Levels are the levels for public supply system

harmonics and are specified in the IEC Basic Standards

IEC 61000-3-3, these levels are used in the design study

to ensure that any increase in load on the system does not

cause adverse reduction of performance.

Compatibility Levels for public supply system harmonics

are specified in the IEC Basic Standards 61000-2-2 and

61000-2-12. The immunity test levels for equipment are

higher levels based on the specified compatibility levels.

If the network distortion exceeds the relevant

compatibility level, experience has shown that there will

be a sudden increase in equipment failure and customer

complaints.

System Planning Levels

(IEC 61000-3-

6)

Compatibility

Levels

400V 5% 8% (IEC 61000-

2-2)

6.6, 11,

22 kV

4% 8% (IEC 61000-

2-12)

>20kV

and

<145kV

3% 5% (UK)

275 and

400kV

3% 3.5% (UK)

Stage 3 Limits

The values of V

hp

for all harmonic orders and the THD

which have been assessed at the PCC should not exceed

52

Roger D White - 15 - 26/04/2011

Atkins Rail

the individual and the THD harmonic voltage planning

levels for the relevant supply network.

Where existing harmonic voltage levels are more than the

planning levels, the risk of disturbance to other customers

is increased.

Compatibility levels for 66,132,275 and 400kV systems

have not been specified internationally. The margins for

the THD in the UK are 4% for 6.6, 11 kV, 5% 22,33kV,

2% 66 and 132 kV and 0.5% for 275 and 400kV.

Note The planning and compatibility levels quoted in

G5/4 are the required limits at the point of common

coupling.

Supplies that are derived from traction supplies cannot be

expected to comply with these

53

Roger D White - 16 - 26/04/2011

Atkins Rail

Figure 9 Transformer Primary and Secondary Voltage

54

Roger D White - 17 - 26/04/2011

Atkins Rail

TRACTION RETURN CURRENT SYSTEMS

There are typically four earthing strategies for DC

railways and these are detailed below:

Fourth Rail Systems:

problem relating to leakage currents is

overcome by the insulation of the fourth rail

(London Underground UK)

Running Rails as the return conductor:

Rail Nominally Insulated (Network Rail UK)

Diode Earthed (Hong Kong MTRC, Sheffield

Super Tram)

Floating Negative Earth with Rail Potential

Control Devices ( Singapore MRT, Hong

Kong LRT)

Rail Insulation

The railway normally uses the train wheels and running

rails as the traction current return path to the DC

substation, (except fourth rail systems). Where the rails

are not insulated from the sleepers, the earth return is

considerably more complex since the current may flow

out of the rails and return at some other point (stray

current). Most modern rail systems use high insulated

rails to prevent the current from leaving the rails and

corroding metallic structures

A very important aim when designing a DC electrified

railway is to control return DC traction current and

avoid passing these currents through the reinforcement

of concrete structures, and in particular highly stressed

concrete structures to avoid causing damage to the

reinforcement through electrolytic corrosion.

The Running Rail is normally insulated from the sleeper

/ concrete pad by the use of insulation pads placed under

the rails with an insulation value in line with the

European Standard EN 50122-2. (Table 1 Page 6; No

added rail insulation 0.5 S/km for open formation and

2.5 S/km for closed formation). This level can be

improved with the application of track insulation

mounting pads or polymeric insulation. This value of

insulation however will reduce over time, due to

degradation of the track insulation. For closed

formation, improved levels of insulation can be

achieved where the rail is to be embedded in the road.

The level of insulation is determined not only by the

installation but the maintenance of the track bed. Every

effort should be made to minimise the risk of ballast

coming into contact with the rails, since ballast,

especially when wet will reduce the insulation value of

the rails to earth.

Hazards Associated with Rail Potentials

The track is insulated from ground to minimise leakage.

Introducing insulation means that voltages between the

rails and ground will occur. These voltages are a

potential hazard to passengers and railway staff when

coming into contact with rail or anything connected to it

and the ground. Reduction of rail touch voltages can be

achieved by clamping the rail to ground if a dangerous

voltage is reached and resetting as soon as possible

afterwards. It is necessary to have quick detection of the

high voltage and then activate a "clamp", by a thyristor

device, GTO device or contactor, to short out the

voltage.

Diode Earthed System (Figure 10)

This arrangement includes a diode at the traction

substation which is connected to the substation local

earth. The inclusion of the diode will cause the rail

potentials to be either at zero (diode is conducting) or

above zero if the diode is reverse biased.

Characteristics of the diode earth system:

Stray current is minimal where there is no rail

leakage

Where there is rail leakage the diode returns

this to the substation

The diode acts as a unidirectional connection

to remote earth

Diode conducts with negative rail potentials

( typically at substations and regenerating

trains)

There are particular difficulties in operating a diode

earthed system in conjunction with regenerative trains,

which may produce negative rail potentials and hence

encourage diode conduction.

Floating Negative Return Current System (figure

11)

In this arrangement there is no intentional connection

between the traction substation negative and the

substation earth. The effect is to produce a system that

floats about the remote earth potentials.

55

Roger D White - 18 - 26/04/2011

Atkins Rail

Figure 10 Typical Rail Potentials in Diode Earthing System

Substation Rectifier

Vrail

Diode Earth

Traction Current

Traction Return Current

DC System Voltage

Catenary

Main Earth bar

Vrail Vrail

Vrail

Figure 11 Typical Earth Currents and Rail Potentials in DC Negative Floating Return System

56

Roger D White - 19 - 26/04/2011

Atkins Rail

System configuration and generation of High Rail

Potentials

High traction load can cause high rail potentials which

subsequently cause spurious trips of the Over Voltage

Detection Circuits.

High Rail potentials may occur under the following:

Multiple train loads

Substation outage

Single end feeding

Long feeding section; i.e. during substation

outage

Remote Regenerative Train

The likelihood of all these circumstances occurring

simultaneously is rare; however the concurrence of

some circumstances will happen on a regular basis.

Rail Potentials under Fault Conditions

The magnitude of the fault impedance is dependant

on a number of factors

Fault Impedance

Substation impedance

Impedance of the OLE rails and bonds

Feeding length i.e. emergency feeding

Earth Fault Path dependant on:

Traction return rails

Earth wire or fault current return wire

Remote earth

The magnitude of the rail potentials dependant on:

Magnitude of the fault current

Feeding length i.e. emergency feeding

Path of the fault back to the substation

Earthing Management Plan

Statutory documents

ISBN 0105437743 Health and Safety at Work

Act 1974

SI 1989 No. 635 Electricity at Work

Regulations1989.

Relevant Standards

UK and European

European Standard EN 50122 Part 1 electrical

safety and earthing

European Standard EN 50122 Part 2 provision

against stray currents

BS 7430 Code of Practice for Earthing

BS7671 17th Edition of the IEE Wiring

Regulations

G59/1 Electricity Association Engineering

Recommendation

LU Standards

MR-S-PO-0009-Part 1Earthing Code of

Practice

MR-S-PO-0008 Earthing management

1-106 Earthing and Bonding of LU Electrical

Networks

E7720 A3 Engineering Standard 25kV 50Hz

immunisation

SSL-SE-0858-A1 Earthing Practice 1985-

Signal Engineering.

Network Rail

NR/SP/ELP/21085 Network Rail Earthing and

bonding Standard

RT/E/21032 Network Rail Earthing Systems

57

Roger D White - 20 - 26/04/2011

Atkins Rail

Figure 12 Earthing and Bonding on DC Electrified Railways

NGC

Substation

Earth Wire

DC

Voltage

R D White 2004

Signall ingPSU

Track circuit

Telecoms.

Cable

Tunnel

Structure

Telecoms PSU

Rebars

Copper

Earth Mat

REC

Supply

Track Structures

Local

RECS

Station

Apparatus

Station

Metallic

Structures

Figure 13 Earthing and Bonding on DC Electrified Railways (LUL)

58

Roger D White - 21 - 26/04/2011

Atkins Rail

14 Typical Cross Section of Cables found in a DC Mass Transit Railway

59

Roger D White - 22 - 26/04/2011

Atkins Rail

REGENERATIVE TRACTION UNITS AND

SUPPLY POINTS

3- Phase Traction Drives

The development of 3 phase induction drives has

introduced higher power drives and the ability of

regenerative braking energy back into the supply

system. Three phase induction motors are attractive due

to the elimination of the DC commutator. This reduces

the chance of mechanical breakdown and eliminates the

need for maintenance. The induction motor is able to

develop more torque due to the control system, the

motor design and the fact that there is increased space

on the rotor. Size for size the induction motor is more

powerful than the equivalent DC motor; consequently it

has a higher power to weight and power to volume ratio.

The capital cost of introducing inverter drives on

traction equipment is close to DC drives, therefore AC

drives are financially viable and also able to produce a

superior performance. Careful analysis must therefore

be undertaken if 3 phase drives are to be introduced to

ensure that the supply network will operate

satisfactorily.

The development of traction inverters and choppers has

made the recovering of kinetic energy of the train and

returning it to the supply common place. The

introduction of microprocessor control for traction drive

enables reliable control of the traction drive and reduces

the likelihood of any interference with the low

frequency signalling circuits.

Other traction equipment can use energy that is

regenerated back into the DC electrification network. If

there is no traction unit available to use the regenerative

energy, the system voltage will rise. It is vital the supply

voltage does not exceed that specified for the DC

electrification network (reference section 3.4 Table 1).

It is necessary at times to cease regeneration or dissipate

the energy in dynamic brake resistors. The inclusion of

inverters at the substation along with the normal diode

rectifier equipment, enables the power to be returned

back to the supply system when other trains in the

feeding section cannot absorb it.

Currently there are a number of applications where

energy is being regenerated by traction units, with the

energy (allowing for receptivity) being returned to the

DC electrification network. This energy is then utilised

by other trains on the same network.

Technical Merits of Regenerative System

i. Reduction of heat produced in underground

metro systems.

ii. Elimination of brake resistors.

iii. Reduction of brake dust in tunnels.

iv. Reduction of maintenance in tunnels.

v. Improved efficiency of the Railway

Network and reduction in energy costs.

Disadvantages of Regenerative Systems

i. More capital investment in traction and supply

equipment.

ii. More harmonics in the medium voltage supply.

iii. Intelligent protection system is required on the

supply and traction equipment enabling it to

discriminate with regenerating units.

iv. Adverse effects on stray current management

Regenerative vehicles on a DC Electrified Railway.

The following are system performance issues that need

to be addressed by the traction and the electrification

engineers to achieve compatibility and are required

where appropriate to be written into the software code

for the train and the Supply Protection System.

Variation in System Voltage.

The system voltage limits will determine the operation

of the regenerate vehicle. As the system voltage drops

the following process is necessary for regenerative load

and should reduce commensurate with falling voltage.

i. Power is reduced

ii. Dont initiate regeneration

iii. Stop Regeneration

iv. Open traction unit circuit breaker

A local short circuit of the system will cause the

collapse of the voltage. Under a remote short circuit the

system voltage will not collapse as easily, therefore

there is a greater chance of the train operating into the

short circuit.

Interference between the train and the electrification

system

i. A train runs into an electrification system which is

isolated and earthed?

+ Train System must detect that there is no voltage

and not initiate regeneration

+ Train System should detect step change and

convert to rheostatic brake or friction brake.

ii. A train runs into an electrification system which is

isolated and not earthed? and with no load for the

regenerative energy:

+ System must detect that there is no system

voltage and not initiate regeneration

+ Train System should detect step change and

convert to rheostatic brake or friction brake.

60

Roger D White - 23 - 26/04/2011

Atkins Rail

iii. The train protection system should be designed

to trip with a short circuit and subsequently allow

the main track feeder breakers to also clear the

fault.

iv. The Electrification System opens the Supply

Circuit Breakers for whatever reason with a

regenerative train in section? The train may or

may not continue to regenerate.

v. On the reapplication of the Electrification Feeder

Circuit Breaker?

+ Auto-reclose may not be considered

appropriate in case a regenerative train is

operating within the system.

+ Closure of the circuit breaker onto a

regenerating train will produce a transient

effect on the train and the electrification

system.

+ Before the system can close the supply

circuit breaker should detect that there is no

existing voltage due to a regenerative

vehicle.

+ Alternatively the system could be locked out

for a set period to ensure that all regenerative

trains have come to a standstill.

MAGNETIC FIELDS ASSOCIATED WITH THE

OVERHEAD LINE

DC Magnetic Field ( ref. Figure 14)

The dc magnetic field created by the dc traction current

in the overhead line or third rail is significant within

and beyond the environment of the railway. The DC

field causes interference due to the change in load on

the system or under large di/dt during a short circuit.

The magnetic field will vary in magnitude due to the

passage of trains typically between 1-100A/m. The

limits for interference into electrical equipment are not

detailed for DC or power frequency harmonics in EN

50082-2 Generic Immunity Standard Industrial and BS

EN 50121.

The DC magnetic field during a short circuit will

typically be up to 600 A/m.

Harmonic Magnetic Fields

Harmonic fields attributed to the power frequency will

be significant within the environment of the railway.

There may be an effect on equipment within the

environment at these frequencies. The induction into

lineside cables of harmonic content of the power system

should also be considered.

CABLES AND CONDUCTORS

Applications ( ref. Figure 14)

Cabling and Conductors (copper, aluminum or steel) are

used extensively in the rail electrification system and

are used in:

+ 33kV & 11kV Distribution network, substation

feed

+ D.C, traction return cables

+ DC feeder cables.

+ Track bonding

+ Lineside cables

+ Overhead line conductors

National Regulations

Cable design is subject to stringent standards and

requirements for safety, safe installation and

serviceability. This is particularly so in the case of

tunnels where cable must comply with low smoke no

halogen specification. Also it is especially important

where the power supplies are subject to high

temperatures whether influenced by the environment or

internally by the current carrying capacity and load

demands.

Cables are manufactured to a range of specifications

including: BS 6853, BM/RT2120 and LUL/RSE/STD.

Cable Specification

Track Application

For the majority of track applications a combination of

copper and aluminum, concentric solid core and

stranded cables is used.

For solid core the insulation in many cases is PVC

applied to the cores when hot, then cooled and shrunk

onto the cores. Older cables use oil impregnated

insulated paper tapes. The outer core of the cable may

be protected by steel tape, or galvanized wire

armouring. This provides protection against abrasion

and gives strength and protection where the wire is

required to be drawn through cable ducts and laid on the

track.

HV Supply and Distribution

DC electrification uses solid, gas or oil-filled cables. In

ratings in excess 33kV. 33kV fluid filled and XLPE are

used for substation applications feeds. The most

common application of insulation for power cable feeds

now use XLPE (cross linked polyethylene) Polyethylene

is a good insulator, the main benefits of this being

greater stability at higher operating temperatures during

normal operation, degraded mode and short circuit.

61

Roger D White - 24 - 26/04/2011

Atkins Rail

DISTURBANCE EFFECTS INTO

TELECOMMUNICATIONS CIRCUITS

( ref. Figure 14)

Safety of Personnel, maintainers etc

The integrity for a railway network is dependent upon

the correct operation of the low voltage signalling

circuits. The circuits use the running rails as well as

cables which run parallel to the track and to the

overhead traction conductor, therefore it is possible for

the traction current to interfere with the low power

signalling circuits due to electromagnetic or conductive

mechanisms. It is necessary that the magnitude of this

interference must be reduced to levels which will not

threaten the safe operation of trains, nor the safety of

any personnel who are likely to come in contact with a

part of the signalling system.

The levels adopted are those specified in the

International Telegraph and Telephone Consultative

Committee (CCITT) directives concerning the

protection of telecommunication lines against harmful

effects of power lines.

With regard to signalling circuits, the longitudinally

induced emfs should not exceed the following levels:

+ Under normal conditions: 60 volts rms. In

situations where there is no exposure to other

than technical staff to any direct contact with

signalling lines circuits, the limitation of 60V is

normally raised to 110V, as this voltage is a

common supply voltage for signalling systems.

+ Maximum induced voltage occurring on lineside

cable conductors will be 430V, the fault duration

not exceeding 200mS.

Safety for humans Telecommunications Equipment

(Longitudinal Voltage)

This is a disturbance resulting in degradation of useful

signals and merely hampers the exchange of

communications. The rating of individual

manufacturers equipment will vary but should

nominally be about rated to about 1000V. (new

equipment)

The limit defined in the European Standard states that

equipment should be able to withstand as specified for a

50Hz Railway EN 50121 - 4:

+ 150V 50Hz for traction current

+ 650V rms 50Hz for short circuit

+ 100A/m Power frequency magnetic field

Existing equipment may be specified in the UK to 430

volts rms.

Interference into telecoms equipment Transverse

Voltage

Psophometrically weighted traction line current:

Psophometric current is defined as the r.m.s addition of

all the harmonic currents in the traction units primary

current wave-shape, each harmonic first being

attenuated in accordance with the appropriate CCITT

weighting curve. The psophometric current therefore is

an indication of the level of interference that will be

produced at that point in time for the traction unit. The

interference mechanism is by electromagnetic induction

from the traction high power into the low power

telecommunications networks. Conventional

telecommunications networks only are affected.

Digitised and optical links are inherently immune from

such interference.

I

pso

= _ \ (I

2

n

p

2

n

)

where n = harmonic number

p = psophometric weighting factor of the

nth harmonic

Immunity Concerns

The immunity concerns are related to high-energy surge

on the overhead line, due to connection to the high

voltage power system. The relative slow response of the

diodes will provide a good immunity to fast transient

effects including the effects of lightning strikes to the

overhead line.

Immunity to RF fields will be high where diode

rectification is used, extra consideration will be required

where thyristor or other controlled devices are used.

Factors for Consideration with Induction

Calculations

Traction Power Disturbances

+ Change of traction load or fault current ( time

varying)

+ DC Ripple (rectifier supply)

+ Coupling increases with harmonics (j2..f.M)

+ Fast transients ( power supply)

+ Normal load Current Typically < 500A

+ Fault current typically < 10kA

Factors for DC System Design

+ Geometry of the line conductors

+ Inductance of the DC overhead line

+ Proximity of control system cables

62

Roger D White - 25 - 26/04/2011

Atkins Rail

Factors necessary for the Calculation of Induced

Voltage

+ Traction unit psophometrically weighted current

+ Power system cables HV 50 Hz ac power cables,

DC traction power cables

+ Receptor cables telecoms cables Signalling

cables

+ Parallelism of cables

+ mutual impedance as a function frequency

+ screening factors of the earthed conductors

Calculations required by Railway Company

+ induced touch potentials

+ equipment potentials

+ induced psophometric transverse voltage

Cable Management Systems

Extensive cabling for services for power, signalling,

communications, fire systems etc need to be routed

throughout the railway. Multi-compartment cable

management systems (cms) is used which allow for

ease of installation whilst providing mechanical

protection for cabling. Cms can run for very long

distances in underground stations and may place

sensitive telecoms and communications cabling in close

proximity to noisy power cabling. These power cables

may feed a variety of switching loads with associated

harmonics. The disturbance current induces a

longitudinal voltage in parallel signal/communications

cables which may present a touch voltage or accessible

voltage hazard. In addition, the longitudinal voltage will

result in a transverse voltage in the victim cable which

may cause interference to the victim circuit in question.

A typical cms will have many cables in each of its multi

compartments.

LIGHTNING AND LIGHTNING PROTECTION

Lightning strikes on or near railway equipment can

generate large voltage surges that can disturb or damage

railway operations. The various ways in which a

lightning strike can affect railways are:

i. Direct strike to the overhead lines

ii. Direct strike to the aerial earth wire or gantries

iii. Nearby strike to ground induced voltages

iv. Strike to ground further away rise of local

ground potential)

A direct strike to the lines can generate an overvoltage

surge of several million volts. This will cause a

flashover across the support insulators to the gantry.

The surge current will then find various routes to earth

depending on their surge impedance values. This will

also generate an overhead line earth fault.

A direct strike to the earth wire is unlikely to cause a

flashover across the support insulator, unless there is a

train at that point, as the lower impedance path will be

via the earth wire and support gantry. However, the

surge current will then find a similar path to earth as

before but with different current surge values.

A nearby strike to ground will cause induced surge

voltages of up to several 100kV to appear on the earth

wire and the lines. No flashovers are likely to occur as

most overhead wires will reach similar voltage levels.

However, the strike current will flow into the ground

and cause a local rise in ground potential (known as

earth potential rise EPR - or rise of earth potential -

ROEP). This may cause disturbance to electrical

equipment or signal cables on the railway.

A strike to ground from further away will not cause

damagingly high induced surge voltages but may still

cause problems due to ROEP.

Adequate surge protection is required to be included in

the system to protect lightning surges reaching the DC

switchboards. Surge protection must be fitted on the

incoming circuit of each DC track feeder circuit breaker,

in addition to surge protection of the OHL

Lightning Protection on Railway Lines

Specific designs for railways are not provided within

EN 50122-1; therefore guidance has been obtained from

BS 7354 Code of Practice for design of high- voltage

open terminal stations.

BS 7354 : 1990 Code of Practice "Design of high-

voltage open-terminal stations". Section 7.3 Earthing

see clause 7.3.9 states:

"An earth electrode, which may be part of the grid,

should be provided as near as practicable to each set of

surge arresters. The connections thereto should be as

direct as possible. Earth connections to surge arresters

should not pass through iron pipes which would

increase the surge impedance of the connections. The

earth connections of the arresters should be

interconnected with the main earthing system since, to

be effective in protecting the station equipment, a

definite connection of low impedance between the

equipment and the arresters is essential".

In terms of the railway, there is no copper earth mat as

exits in HV substations; there is however an earthed rail

returns system.

A copper bond (ideally flat in cross section) of the

shortest possible route shall be used. Ideally a

segregated earth for the lightning arrestors should be

used;

Where the lightning arrestor is also bonded to rail earth,

signalling, telecommunications and LV earth

connections should not be bonded to the rail within

close proximity of the connection from the surge

arrestor.

63

Roger D White - 26 - 26/04/2011

Atkins Rail

DISTURBANCE EFFECTS OF DC

ELECTRIFICATION SYSTEMS

Characteristic System Behaviour: DC Traction Systems

produce significant amount of ripple, which is present

within the DC supply, the ripple is related to the pulse

number of the rectifier. within the transformer rectifier

unit. (Figure 9)

Resonant frequency

Resonance is related to the system characteristics of the

power supply, rectification, dc electrification

distribution and traction loads. The frequencies can

occur from the resonant frequency of the input traction

filter to MHz. System parameters that are responsible

include: capacitance of the overhead line; leakage

inductance of the overhead line; rectifier switching;

inductance of supply transformer; traction input filters;

AC LV and HV Systems

i. AC side harmonics in 3 phase supply

ii. AC voltage distortion

iii. Power Factor

iv. 50Hz Disturbance to users on the

Railway LV/HV system

i. Power Harmonic to users on the railway LV/HV

system

DC and Power System Harmonics

i. DC Side Harmonics

ii. Resonant, overlap effect, system capacitance

iii. Traction line filter resonance

iv. Magnetic and Electric Fields

Inductive and Radiated Effects

i. High frequency radiated emissions

ii. Traction load traction to regeneration.

iii. Power arcs on the ramp end of the rails

iv. Disturbance changes supply & traction

v. Switching of the DC power (di/dt)

vi. Longitudinal Transverse voltages

Return Circuit and Stray Current

i. Stray DC current

ii. Magnetic field traction/electrification

iii. Harmonics in the return circuits

RFI from the Distribution System

i. current collection mechanism.

ii. operation with multiple contact wires.

iii. HV switching of the power system

iv. resonance of the power system at MHz

v. excessive voltage stress across insulators

vi. disturbances on the overhead line

RFI from the Traction Unit

i. transients due to raising the traction unit pantograph

ii. interaction of power system contacts earthing,

wheel rail, rail to rail

iii. operation of multiple pantographs

iv. switching of thyristors and semiconductors.

RFI from the Track Circuits

v. track circuit current producing arcing poor wheel to

rail,

vi. high voltage impulse track circuit.

64

Roger D White - 27 - 26/04/2011

Atkins Rail

Relevant UK and European Standards

i. IEC 60479-1 2005 Effects of current on human

beings and livestock.

ii. BS EN 50122-1, Railway applications - fixed

installations, Part 1: Protective provisions relating

to electrical safety and earthing,

iii. BS EN 50122-2, Railway applications - Fixed

installations - Electrical safety, earthing and the

return circuit - Part 2: Provisions against the

effects of stray currents caused by d.c.

iv. traction systems

v. BS EN 50122-3 Railway applications - Fixed

installations - Electrical safety, earthing and the

return circuit - Part 3: Mutual Interaction of a.c.

and d.c. traction systems

vi. BS EN 62305, Protection against Lightning, 2006.

vii. BS EN50388:2005 Railway applications Power

supply and rolling stock Technical criteria for

the coordination between power

supply(substation) and rolling stock to achieve

interoperability

viii. BS EN50119 Railway applications -Fixed

installations -Electric traction overhead contact

lines.

ix. BS 7671, Requirements for Electrical Installations.

IEE Wiring Regulations Seventeenth Edition, BSI,

2008.

x. BS 6651, Code of Practice for Protection of

Structures against Lightning, 1992.

xi. Guidelines for the Design Installation Testing and

Maintenance of Main Earthing Systems EATS 41-

24 1992.

xii. BS 7430, Code of Practice for Earthing, BSI,

1998.

xiii. Electricity Council Engineering S 5/1.

xiv. BS EN 32605 Protection against lightning.