Escolar Documentos

Profissional Documentos

Cultura Documentos

Lift Truck Safety Inspection Checklist

Enviado por

Balgo Balgobin0 notas0% acharam este documento útil (0 voto)

442 visualizações22 páginasThis document contains daily safety inspection checklists for electric lift trucks, electric transtackers, and indoor propane tow tractors. The checklists include procedures to inspect equipment under key off and key on conditions, including visual checks of components and functional tests of equipment like steering, brakes and lights. Inspectors are instructed to report any problems found to their supervisor immediately to avoid using faulty equipment.

Descrição original:

checklist

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoThis document contains daily safety inspection checklists for electric lift trucks, electric transtackers, and indoor propane tow tractors. The checklists include procedures to inspect equipment under key off and key on conditions, including visual checks of components and functional tests of equipment like steering, brakes and lights. Inspectors are instructed to report any problems found to their supervisor immediately to avoid using faulty equipment.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

442 visualizações22 páginasLift Truck Safety Inspection Checklist

Enviado por

Balgo BalgobinThis document contains daily safety inspection checklists for electric lift trucks, electric transtackers, and indoor propane tow tractors. The checklists include procedures to inspect equipment under key off and key on conditions, including visual checks of components and functional tests of equipment like steering, brakes and lights. Inspectors are instructed to report any problems found to their supervisor immediately to avoid using faulty equipment.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 22

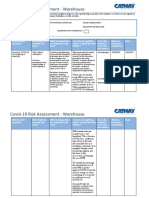

DAILY LIFT TRUCK SAFETY INSPECTION CHECKLIST

ELECTRIC LIFT TRUCK

Week of:______________ to ______________ Department:_______________________

Location:_________________________ Area Supervisor:_________________________

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Overhead guard

Hydraulic cylinders

Mast assembly

Lift chains and rollers

Forks

Tires

o Examine the battery*

o Check the hydraulic

fluid level*

* Can be done once every 10

uses or monthly, as needed.

KEY ON Procedures:

o Visual inspection of gauges

Hour meter

Battery discharge indicator

o Test standard equipment

Steering

Brakes

Front/tail/brake lights

Horn

Safety seat (if applic.)

o Check the operation of load-

handling attachments

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Overhead guard

Hydraulic cylinders

Mast assembly

Lift chains and rollers

Forks

Tires

o Examine the battery*

o Check the hydraulic

fluid level*

* Can be done once every 10

uses or monthly, as needed.

KEY ON Procedures:

o Visual inspection of gauges

Hour meter

Battery discharge indicator

o Test standard equipment

Steering

Brakes

Front/tail/brake lights

Horn

Safety seat (if applic.)

o Check the operation of load-

handling attachments

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Overhead guard

Hydraulic cylinders

Mast assembly

Lift chains and rollers

Forks

Tires

o Examine the battery*

o Check the hydraulic

fluid level*

* Can be done once every 10

uses or monthly, as needed.

KEY ON Procedures:

o Visual inspection of gauges

Hour meter

Battery discharge indicator

o Test standard equipment

Steering

Brakes

Front/tail/brake lights

Horn

Safety seat (if applic.)

o Check the operation of load-

handling attachments

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Overhead guard

Hydraulic cylinders

Mast assembly

Lift chains and rollers

Forks

Tires

o Examine the battery*

o Check the hydraulic

fluid level*

* Can be done once every 10

uses or monthly, as needed.

KEY ON Procedures:

o Visual inspection of gauges

Hour meter

Battery discharge indicator

o Test standard equipment

Steering

Brakes

Front/tail/brake lights

Horn

Safety seat (if applic.)

o Check the operation of load-

handling attachments

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Overhead guard

Hydraulic cylinders

Mast assembly

Lift chains and rollers

Forks

Tires

o Examine the battery*

o Check the hydraulic

fluid level*

* Can be done once every 10

uses or monthly, as needed.

KEY ON Procedures:

o Visual inspection of gauges

Hour meter

Battery discharge indicator

o Test standard equipment

Steering

Brakes

Front/tail/brake lights

Horn

Safety seat (if applic.)

o Check the operation of load-

handling attachments

IF YOU DISCOVER ANY PROBLEMS, REPORT TO YOUR SUPERVISOR

IMMEDIATELY AND DO NOT USE THE LIFT TRUCK!

DAILY LIFT TRUCK SAFETY INSPECTION CHECKLIST

ELECTRIC TRANSTACKER

Week of: ________________ to __________________ Department:_________________

Location:________________________ Area Supervisor:__________________________

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Overhead guard

Hydraulic cylinders

Mast assembly

Lift chains/rollers

Forks

Tires

Battery cables

Safety door

KEY ON Procedures:

o Visual inspection of gauges

Battery discharge indicator

Hour meter

o Test standard equipment

Steering

Brakes

Lights

Horn

o Test control lever

o Check operation of load-handling

attachments

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Overhead guard

Hydraulic cylinders

Mast assembly

Lift chains/rollers

Forks

Tires

Battery cables

Safety door

KEY ON Procedures:

o Visual inspection of gauges

Battery discharge indicator

Hour meter

o Test standard equipment

Steering

Brakes

Lights

Horn

o Test control lever

o Check operation of load-handling

attachments

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Overhead guard

Hydraulic cylinders

Mast assembly

Lift chains/rollers

Forks

Tires

Battery cables

Safety door

KEY ON Procedures:

o Visual inspection of gauges

Battery discharge indicator

Hour meter

o Test standard equipment

Steering

Brakes

Lights

Horn

o Test control lever

o Check operation of load-handling

attachments

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Overhead guard

Hydraulic cylinders

Mast assembly

Lift chains/rollers

Forks

Tires

Battery cables

Safety door

KEY ON Procedures:

o Visual inspection of gauges

Battery discharge indicator

Hour meter

o Test standard equipment

Steering

Brakes

Lights

Horn

o Test control lever

o Check operation of load-handling

attachments

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Overhead guard

Hydraulic cylinders

Mast assembly

Lift chains/rollers

Forks

Tires

Battery cables

Safety door

KEY ON Procedures:

o Visual inspection of gauges

Battery discharge indicator

Hour meter

o Test standard equipment

Steering

Brakes

Lights

Horn

o Test control lever

o Check operation of load-handling

attachments

IF YOU DISCOVER ANY PROBLEMS, REPORT TO YOUR SUPERVISOR

IMMEDIATELY AND DO NOT USE THE LIFT TRUCK!

DAILY LIFT TRUCK SAFETY INSPECTION CHECKLIST

INDOOR PROPANE TOW TRACTOR

Week of: _______________ to _________________ Department:___________________

Location:___________________________ Area Supervisor:_______________________

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Fluid leakage

Tires

Tow hook

Windshield (if applic.)

Overhead guard (if applic.)

LPG tank/locator pin

LPG tank hose

Gas gauge

o Check engine oil & coolant levels*

o Examine the battery*

* Can be done once every 10 uses or

monthly, as needed.

KEY ON Procedures:

o Test front, tail and brake lights

o Visual inspection of gauges

Oil pressure gauge

Ammeter

Water temperature gauge

Hour meter

ENGINE RUNNING Procedures:

o Inspect standard equipment

Steering

Brakes

Horn

Safety seat (if applic.)

o Check transmission fluid level*

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Fluid leakage

Tires

Tow hook

Windshield (if applic.)

Overhead guard (if applic.)

LPG tank/locator pin

LPG tank hose

Gas gauge

o Check engine oil & coolant levels*

o Examine the battery*

* Can be done once every 10 uses or

monthly, as needed.

KEY ON Procedures:

o Test front, tail and brake lights

o Visual inspection of gauges

Oil pressure gauge

Ammeter

Water temperature gauge

Hour meter

ENGINE RUNNING Procedures:

o Inspect standard equipment

Steering

Brakes

Horn

Safety seat (if applic.)

o Check transmission fluid level*

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Fluid leakage

Tires

Tow hook

Windshield (if applic.)

Overhead guard (if applic.)

LPG tank/locator pin

LPG tank hose

Gas gauge

o Check engine oil & coolant levels*

o Examine the battery*

* Can be done once every 10 uses or

monthly, as needed.

KEY ON Procedures:

o Test front, tail and brake lights

o Visual inspection of gauges

Oil pressure gauge

Ammeter

Water temperature gauge

Hour meter

ENGINE RUNNING Procedures:

o Inspect standard equipment

Steering

Brakes

Horn

Safety seat (if applic.)

o Check transmission fluid level*

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Fluid leakage

Tires

Tow hook

Windshield (if applic.)

Overhead guard (if applic.)

LPG tank/locator pin

LPG tank hose

Gas gauge

o Check engine oil & coolant levels*

o Examine the battery*

* Can be done once every 10 uses or

monthly, as needed.

KEY ON Procedures:

o Test front, tail and brake lights

o Visual inspection of gauges

Oil pressure gauge

Ammeter

Water temperature gauge

Hour meter

ENGINE RUNNING Procedures:

o Inspect standard equipment

Steering

Brakes

Horn

Safety seat (if applic.)

o Check transmission fluid level*

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Fluid leakage

Tires

Tow hook

Windshield (if applic.)

Overhead guard (if applic.)

LPG tank/locator pin

LPG tank hose

Gas gauge

o Check engine oil & coolant levels*

o Examine the battery*

* Can be done once every 10 uses or

monthly, as needed.

KEY ON Procedures:

o Test front, tail and brake lights

o Visual inspection of gauges

Oil pressure gauge

Ammeter

Water temperature gauge

Hour meter

ENGINE RUNNING Procedures:

o Inspect standard equipment

Steering

Brakes

Horn

Safety seat (if applic.)

o Check transmission fluid level*

IF YOU DISCOVER ANY PROBLEMS, REPORT TO YOUR SUPERVISOR

IMMEDIATELY AND DO NOT USE THE LIFT TRUCK!

DAILY LIFT TRUCK SAFETY INSPECTION CHECKLIST

INDUSTRIAL TOW TRACTOR

Week of: ________________ to __________________ Department:_________________

Location:________________________ Area Supervisor:__________________________

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Windshield

Tires

Three-point hitch

assembly

o Check engine oil and

engine coolant levels*

* Can be done once every 10 uses

or monthly, as needed.

KEY ON Procedures:

o Visual inspection of gauges

Oil and battery lights

Temperature

Hour meter

o Inspect standard equipment

Steering

Front, tail and brake lights

Horn

ENGINE RUNNING Procedures:

o Inspect standard equipment

Windshield wiper

Brakes

Hoist operation

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Windshield

Tires

Three-point hitch

assembly

o Check engine oil and

engine coolant levels*

* Can be done once every 10 uses

or monthly, as needed.

KEY ON Procedures:

o Visual inspection of gauges

Oil and battery lights

Temperature

Hour meter

o Inspect standard equipment

Steering

Front, tail and brake lights

Horn

ENGINE RUNNING Procedures:

o Inspect standard equipment

Windshield wiper

Brakes

Hoist operation

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Windshield

Tires

Three-point hitch

assembly

o Check engine oil and

engine coolant levels*

* Can be done once every 10 uses

or monthly, as needed.

KEY ON Procedures:

o Visual inspection of gauges

Oil and battery lights

Temperature

Hour meter

o Inspect standard equipment

Steering

Front, tail and brake lights

Horn

ENGINE RUNNING Procedures:

o Inspect standard equipment

Windshield wiper

Brakes

Hoist operation

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Windshield

Tires

Three-point hitch

assembly

o Check engine oil and

engine coolant levels*

* Can be done once every 10 uses

or monthly, as needed.

KEY ON Procedures:

o Visual inspection of gauges

Oil and battery lights

Temperature

Hour meter

o Inspect standard equipment

Steering

Front, tail and brake lights

Horn

ENGINE RUNNING Procedures:

o Inspect standard equipment

Windshield wiper

Brakes

Hoist operation

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Windshield

Tires

Three-point hitch

assembly

o Check engine oil and

engine coolant levels*

* Can be done once every 10 uses

or monthly, as needed.

KEY ON Procedures:

o Visual inspection of gauges

Oil and battery lights

Temperature

Hour meter

o Inspect standard equipment

Steering

Front, tail and brake lights

Horn

ENGINE RUNNING Procedures:

o Inspect standard equipment

Windshield wiper

Brakes

Hoist operation

IF YOU DISCOVER ANY PROBLEMS, REPORT TO YOUR SUPERVISOR

IMMEDIATELY AND DO NOT USE THE LIFT TRUCK!

DAILY LIFT TRUCK SAFETY INSPECTION CHECKLIST

ORDER PICKER

Week of: ________________ to __________________ Department:_________________

Location:_________________________ Area Supervisor:_________________________

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Hoist lines, cables

and chains

Hour meter

Tires

Battery cables

Limiting device

KEY ON Procedures:

o Check battery discharge

indicator

o Test standard equipment

Safety interlock

Steering

Brakes

Lights

Horn

o Visual inspection of

Gripper jaws

Work platform

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Hoist lines, cables

and chains

Hour meter

Tires

Battery cables

Limiting device

KEY ON Procedures:

o Check battery discharge

indicator

o Test standard equipment

Safety interlock

Steering

Brakes

Lights

Horn

o Visual inspection of

Gripper jaws

Work platform

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Hoist lines, cables

and chains

Hour meter

Tires

Battery cables

Limiting device

KEY ON Procedures:

o Check battery discharge

indicator

o Test standard equipment

Safety interlock

Steering

Brakes

Lights

Horn

o Visual inspection of

Gripper jaws

Work platform

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Hoist lines, cables

and chains

Hour meter

Tires

Battery cables

Limiting device

KEY ON Procedures:

o Check battery discharge

indicator

o Test standard equipment

Safety interlock

Steering

Brakes

Lights

Horn

o Visual inspection of

Gripper jaws

Work platform

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Hoist lines, cables

and chains

Hour meter

Tires

Battery cables

Limiting device

KEY ON Procedures:

o Check battery discharge

indicator

o Test standard equipment

Safety interlock

Steering

Brakes

Lights

Horn

o Visual inspection of

Gripper jaws

Work platform

IF YOU DISCOVER ANY PROBLEMS, REPORT TO YOUR SUPERVISOR

IMMEDIATELY AND DO NOT USE THE LIFT TRUCK!

DAILY LIFT TRUCK SAFETY INSPECTION CHECKLIST

PROPANE LIFT TRUCK

Week of: ________________ to __________________ Department:_________________

Location:________________________ Area Supervisor:__________________________

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Overhead guard

Hydraulic cylinders

Mast assembly

Lift chains/rollers

Forks

Tires

LPG tank hose

Gas gauge

o Examine the battery*

o Check engine oil, hydraulic

fluid and engine coolant

levels*

* Can be done once every 10 uses

or monthly, as needed.

ENGINE RUNNING Procedures:

o Visual inspection of gauges

Oil pressure indicator lamp

Ammeter indicator lamp

Hour meter

Water temperature gauge

o Test standard equipment

Steering

Front, tail and brake lights

Brakes

Horn

Safety seat (if applic.)

o Check operation of load-

handling attachments

o Check transmission fluid level*

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Overhead guard

Hydraulic cylinders

Mast assembly

Lift chains/rollers

Forks

Tires

LPG tank hose

Gas gauge

o Examine the battery*

o Check engine oil, hydraulic

fluid and engine coolant

levels*

* Can be done once every 10 uses

or monthly, as needed.

ENGINE RUNNING Procedures:

o Visual inspection of gauges

Oil pressure indicator lamp

Ammeter indicator lamp

Hour meter

Water temperature gauge

o Test standard equipment

Steering

Front, tail and brake lights

Brakes

Horn

Safety seat (if applic.)

o Check operation of load-

handling attachments

o Check transmission fluid level*

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Overhead guard

Hydraulic cylinders

Mast assembly

Lift chains/rollers

Forks

Tires

LPG tank hose

Gas gauge

o Examine the battery*

o Check engine oil, hydraulic

fluid and engine coolant

levels*

* Can be done once every 10 uses

or monthly, as needed.

ENGINE RUNNING Procedures:

o Visual inspection of gauges

Oil pressure indicator lamp

Ammeter indicator lamp

Hour meter

Water temperature gauge

o Test standard equipment

Steering

Front, tail and brake lights

Brakes

Horn

Safety seat (if applic.)

o Check operation of load-

handling attachments

o Check transmission fluid level*

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Overhead guard

Hydraulic cylinders

Mast assembly

Lift chains/rollers

Forks

Tires

LPG tank hose

Gas gauge

o Examine the battery*

o Check engine oil, hydraulic

fluid and engine coolant

levels*

* Can be done once every 10 uses

or monthly, as needed.

ENGINE RUNNING Procedures:

o Visual inspection of gauges

Oil pressure indicator lamp

Ammeter indicator lamp

Hour meter

Water temperature gauge

o Test standard equipment

Steering

Front, tail and brake lights

Brakes

Horn

Safety seat (if applic.)

o Check operation of load-

handling attachments

o Check transmission fluid level*

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Overhead guard

Hydraulic cylinders

Mast assembly

Lift chains/rollers

Forks

Tires

LPG tank hose

Gas gauge

o Examine the battery*

o Check engine oil, hydraulic

fluid and engine coolant

levels*

* Can be done once every 10 uses

or monthly, as needed.

ENGINE RUNNING Procedures:

o Visual inspection of gauges

Oil pressure indicator lamp

Ammeter indicator lamp

Hour meter

Water temperature gauge

o Test standard equipment

Steering

Front, tail and brake lights

Brakes

Horn

Safety seat (if applic.)

o Check operation of load-

handling attachments

o Check transmission fluid level*

IF YOU DISCOVER ANY PROBLEMS, REPORT TO YOUR SUPERVISOR

IMMEDIATELY AND DO NOT USE THE LIFT TRUCK!

DAILY LIFT TRUCK SAFETY INSPECTION CHECKLIST

REACH TRUCK

Week of: ________________ to __________________ Department:_________________

Location:________________________ Area Supervisor:__________________________

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Overhead guard

Hydraulic cylinders

Mast assembly

Lift chains/rollers

Forks

Tires

Battery cables

Safety door

Hydraulic fluid

KEY ON Procedures:

o Visual inspection of gauges

Battery discharge indicator

Hour meter

o Test standard equipment

Steering

Brakes

Lights

Horn

o Test control lever

o Check operation of load-

handling attachments

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Overhead guard

Hydraulic cylinders

Mast assembly

Lift chains/rollers

Forks

Tires

Battery cables

Safety door

Hydraulic fluid

KEY ON Procedures:

o Visual inspection of gauges

Battery discharge indicator

Hour meter

o Test standard equipment

Steering

Brakes

Lights

Horn

o Test control lever

o Check operation of load-

handling attachments

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Overhead guard

Hydraulic cylinders

Mast assembly

Lift chains/rollers

Forks

Tires

Battery cables

Safety door

Hydraulic fluid

KEY ON Procedures:

o Visual inspection of gauges

Battery discharge indicator

Hour meter

o Test standard equipment

Steering

Brakes

Lights

Horn

o Test control lever

o Check operation of load-

handling attachments

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Overhead guard

Hydraulic cylinders

Mast assembly

Lift chains/rollers

Forks

Tires

Battery cables

Safety door

Hydraulic fluid

KEY ON Procedures:

o Visual inspection of gauges

Battery discharge indicator

Hour meter

o Test standard equipment

Steering

Brakes

Lights

Horn

o Test control lever

o Check operation of load-

handling attachments

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Overhead guard

Hydraulic cylinders

Mast assembly

Lift chains/rollers

Forks

Tires

Battery cables

Safety door

Hydraulic fluid

KEY ON Procedures:

o Visual inspection of gauges

Battery discharge indicator

Hour meter

o Test standard equipment

Steering

Brakes

Lights

Horn

o Test control lever

o Check operation of load-

handling attachments

IF YOU DISCOVER ANY PROBLEMS, REPORT TO YOUR SUPERVISOR

IMMEDIATELY AND DO NOT USE THE LIFT TRUCK!

DAILY LIFT TRUCK SAFETY INSPECTION CHECKLIST

RIDING GRIP TOW TRACTOR

Week of: ________________ to __________________ Department:_________________

Location:________________________ Area Supervisor:__________________________

Date: Inspector:

o Visual inspection of

Lines and hoses

Battery

Safety switch

Hand guards

o Operations inspection

Test brakes

Check drive operations

Test horn

Check grip coupling

Date: Inspector:

o Visual inspection of

Lines and hoses

Battery

Safety switch

Hand guards

o Operations inspection

Test brakes

Check drive operations

Test horn

Check grip coupling

Date: Inspector:

o Visual inspection of

Lines and hoses

Battery

Safety switch

Hand guards

o Operations inspection

Test brakes

Check drive operations

Test horn

Check grip coupling

Date: Inspector:

o Visual inspection of

Lines and hoses

Battery

Safety switch

Hand guards

o Operations inspection

Test brakes

Check drive operations

Test horn

Check grip coupling

Date: Inspector:

o Visual inspection of

Lines and hoses

Battery

Safety switch

Hand guards

o Operations inspection

Test brakes

Check drive operations

Test horn

Check grip coupling

IF YOU DISCOVER ANY PROBLEMS, REPORT TO YOUR SUPERVISOR

IMMEDIATELY AND DO NOT USE THE LIFT TRUCK!

DAILY LIFT TRUCK SAFETY INSPECTION CHECKLIST

STAND-UP RIDING TOW TRACTOR

Week of: ________________ to __________________ Department:_________________

Location:________________________ Area Supervisor:__________________________

Date: Inspector:

o Visual inspection of

Lines and hoses

Battery

Safety switch

Hand guards

o Operations inspection

Test brakes

Check drive operations

Test horn

Check tow hook and safety

catch

Date: Inspector:

o Visual inspection of

Lines and hoses

Battery

Safety switch

Hand guards

o Operations inspection

Test brakes

Check drive operations

Test horn

Check tow hook and safety

catch

Date: Inspector:

o Visual inspection of

Lines and hoses

Battery

Safety switch

Hand guards

o Operations inspection

Test brakes

Check drive operations

Test horn

Check tow hook and safety

catch

Date: Inspector:

o Visual inspection of

Lines and hoses

Battery

Safety switch

Hand guards

o Operations inspection

Test brakes

Check drive operations

Test horn

Check tow hook and safety

catch

Date: Inspector:

o Visual inspection of

Lines and hoses

Battery

Safety switch

Hand guards

o Operations inspection

Test brakes

Check drive operations

Test horn

Check tow hook and safety

catch

I

F

Y

O

U

D

I

S

C

O

V

E

R

A

N

Y

P

R

O

B

L

E

M

S

,

R

E

P

O

R

T

T

O

Y

O

U

R

S

U

P

E

R

V

I

S

O

R

I

M

M

E

D

I

A

T

E

L

Y

A

N

D

D

O

N

O

T

U

S

E

T

H

E

L

I

F

T

T

R

U

C

K

!

DAILY LIFT TRUCK SAFETY INSPECTION CHECKLIST

WALKING PALLET TRUCK

Week of: ________________ to __________________ Department:_________________

Location:________________________ Area Supervisor:__________________________

Date: Inspector:

o Visual inspection of

Forks

Battery

Hand guards

o Operations inspection

Check drive operations

Test brakes

Check horn

Inspect load-handling

attachment operations

Date: Inspector:

o Visual inspection of

Forks

Battery

Hand guards

o Operations inspection

Check drive operations

Test brakes

Check horn

Inspect load-handling

attachment operations

Date: Inspector:

o Visual inspection of

Forks

Battery

Hand guards

o Operations inspection

Check drive operations

Test brakes

Check horn

Inspect load-handling

attachment operations

Date: Inspector:

o Visual inspection of

Forks

Battery

Hand guards

o Operations inspection

Check drive operations

Test brakes

Check horn

Inspect load-handling

attachment operations

Date: Inspector:

o Visual inspection of

Forks

Battery

Hand guards

o Operations inspection

Check drive operations

Test brakes

Check horn

Inspect load-handling

attachment operations

I

F

Y

O

U

D

I

S

C

O

V

E

R

A

N

Y

P

R

O

B

L

E

M

S

,

R

E

P

O

R

T

T

O

Y

O

U

R

S

U

P

E

R

V

I

S

O

R

I

M

M

E

D

I

A

T

E

L

Y

A

N

D

D

O

N

O

T

U

S

E

T

H

E

L

I

F

T

T

R

U

C

K

!

DAILY LIFT TRUCK SAFETY INSPECTION CHECKLIST

WALKING TRANSTACKER

Week of: ________________ to __________________ Department:_________________

Location:________________________ Area Supervisor:__________________________

Date: Inspector:

o Visual inspection of

Forks

Battery

Hand guards

o Operations inspection

Check drive operations

Test brakes

Check horn

Inspect load-handling

attachment operations

Date: Inspector:

o Visual inspection of

Forks

Battery

Hand guards

o Operations inspection

Check drive operations

Test brakes

Check horn

Inspect load-handling

attachment operations

Date: Inspector:

o Visual inspection of

Forks

Battery

Hand guards

o Operations inspection

Check drive operations

Test brakes

Check horn

Inspect load-handling

attachment operations

Date: Inspector:

o Visual inspection of

Forks

Battery

Hand guards

o Operations inspection

Check drive operations

Test brakes

Check horn

Inspect load-handling

attachment operations

Date: Inspector:

o Visual inspection of

Forks

Battery

Hand guards

o Operations inspection

Check drive operations

Test brakes

Check horn

Inspect load-handling

attachment operations

I

F

Y

O

U

D

I

S

C

O

V

E

R

A

N

Y

P

R

O

B

L

E

M

S

,

R

E

P

O

R

T

T

O

Y

O

U

R

S

U

P

E

R

V

I

S

O

R

I

M

M

E

D

I

A

T

E

L

Y

A

N

D

D

O

N

O

T

U

S

E

T

H

E

L

I

F

T

T

R

U

C

K

!

DAILY LIFT TRUCK SAFETY INSPECTION CHECKLIST

YARD LIFT TRUCK

Week of: ________________ to __________________ Department:_________________

Location:________________________ Area Supervisor:__________________________

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Overhead guard

Hydraulic cylinders

Mast assembly

Lift chains/rollers

Forks

Tires

LPG tank/locator pin

LPG tank hose

Gas gauge

o Examine the battery*

o Check engine oil,

hydraulic fluid and engine

coolant levels*

* Can be done once every 10

uses or monthly, as needed.

KEY ON Procedures:

o Test standard equipment

Front, tail and brake lights

Fuel gauge (if diesel)

Windshield wiper and heater*

ENGINE RUNNING Procedures:

o Visual inspection of gauges

Oil pressure indicator lamp

Ammeter indicator lamp

Ammeter

Hour meter

Water temperature gauge

o Test standard equipment

Steering

Brakes

Horn

Safety seat (if applic.)

o Check operation of load-

handling attachments

o Check transmission fluid level*

* Can be done once every 10 uses or

monthly, as needed.

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Overhead guard

Hydraulic cylinders

Mast assembly

Lift chains/rollers

Forks

Tires

LPG tank/locator pin

LPG tank hose

Gas gauge

o Examine the battery*

o Check engine oil,

hydraulic fluid and engine

coolant levels*

* Can be done once every 10

uses or monthly, as needed.

KEY ON Procedures:

o Test standard equipment

Front, tail and brake lights

Fuel gauge (if diesel)

Windshield wiper and heater*

ENGINE RUNNING Procedures:

o Visual inspection of gauges

Oil pressure indicator lamp

Ammeter indicator lamp

Ammeter

Hour meter

Water temperature gauge

o Test standard equipment

Steering

Brakes

Horn

Safety seat (if applic.)

o Check operation of load-

handling attachments

o Check transmission fluid level*

* Can be done once every 10 uses or

monthly, as needed.

I

F

Y

O

U

D

I

S

C

O

V

E

R

A

N

Y

P

R

O

B

L

E

M

S

,

R

E

P

O

R

T

T

O

Y

O

U

R

S

U

P

E

R

V

I

S

O

R

I

M

M

E

D

I

A

T

E

L

Y

A

N

D

D

O

N

O

T

U

S

E

T

H

E

L

I

F

T

T

R

U

C

K

!

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Overhead guard

Hydraulic cylinders

Mast assembly

Lift chains/rollers

Forks

Tires

LPG tank/locator pin

LPG tank hose

Gas gauge

o Examine the battery*

o Check engine oil,

hydraulic fluid and engine

coolant levels*

* Can be done once every 10

uses or monthly, as needed.

KEY ON Procedures:

o Test standard equipment

Front, tail and brake lights

Fuel gauge (if diesel)

Windshield wiper and heater*

ENGINE RUNNING Procedures:

o Visual inspection of gauges

Oil pressure indicator lamp

Ammeter indicator lamp

Ammeter

Hour meter

Water temperature gauge

o Test standard equipment

Steering

Brakes

Horn

Safety seat (if applic.)

o Check operation of load-

handling attachments

o Check transmission fluid level*

* Can be done once every 10 uses or

monthly, as needed.

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Overhead guard

Hydraulic cylinders

Mast assembly

Lift chains/rollers

Forks

Tires

LPG tank/locator pin

LPG tank hose

Gas gauge

o Examine the battery*

o Check engine oil,

hydraulic fluid and engine

coolant levels*

* Can be done once every 10

uses or monthly, as needed.

KEY ON Procedures:

o Test standard equipment

Front, tail and brake lights

Fuel gauge (if diesel)

Windshield wiper and heater*

ENGINE RUNNING Procedures:

o Visual inspection of gauges

Oil pressure indicator lamp

Ammeter indicator lamp

Ammeter

Hour meter

Water temperature gauge

o Test standard equipment

Steering

Brakes

Horn

Safety seat (if applic.)

o Check operation of load-

handling attachments

o Check transmission fluid level*

* Can be done once every 10 uses or

monthly, as needed.

Date: Inspector:

KEY OFF Procedures:

o Visual inspection of

Overhead guard

Hydraulic cylinders

Mast assembly

Lift chains/rollers

Forks

Tires

LPG tank/locator pin

LPG tank hose

Gas gauge

o Examine the battery*

o Check engine oil,

hydraulic fluid and engine

coolant levels*

* Can be done once every 10

uses or monthly, as needed.

KEY ON Procedures:

o Test standard equipment

Front, tail and brake lights

Fuel gauge (if diesel)

Windshield wiper and heater*

ENGINE RUNNING Procedures:

o Visual inspection of gauges

Oil pressure indicator lamp

Ammeter indicator lamp

Ammeter

Hour meter

Water temperature gauge

o Test standard equipment

Steering

Brakes

Horn

Safety seat (if applic.)

o Check operation of load-

handling attachments

o Check transmission fluid level*

* Can be done once every 10 uses or

monthly, as needed.

I

F

Y

O

U

D

I

S

C

O

V

E

R

A

N

Y

P

R

O

B

L

E

M

S

,

R

E

P

O

R

T

T

O

Y

O

U

R

S

U

P

E

R

V

I

S

O

R

I

M

M

E

D

I

A

T

E

L

Y

A

N

D

D

O

N

O

T

U

S

E

T

H

E

L

I

F

T

T

R

U

C

K

!

Você também pode gostar

- Cert - Mobile Crane 30T - LOLER - Model Rok300Documento2 páginasCert - Mobile Crane 30T - LOLER - Model Rok300Rafael Lecu100% (1)

- Luffing Tower Crane Preshift InspectionDocumento1 páginaLuffing Tower Crane Preshift InspectionEdmond KeraAinda não há avaliações

- Suspended Personnel Platform Check List PDFDocumento1 páginaSuspended Personnel Platform Check List PDFmark lester caluzaAinda não há avaliações

- Aluminium LadderDocumento1 páginaAluminium LadderVinay PandeyAinda não há avaliações

- Lifting ChecklistDocumento13 páginasLifting ChecklistEric T100% (1)

- Lifting Equipements Checklist-1Documento59 páginasLifting Equipements Checklist-1Mahmud ShalehudinAinda não há avaliações

- (After Installation) : Tikaria Expansion Project, ACC Checklist For Tower CraneDocumento2 páginas(After Installation) : Tikaria Expansion Project, ACC Checklist For Tower CraneRajuAinda não há avaliações

- Tandem Lifting Container SWGDocumento1 páginaTandem Lifting Container SWGarifAinda não há avaliações

- Side Boom Crane Daily Inspection ChecklistDocumento1 páginaSide Boom Crane Daily Inspection ChecklistBorislav VulićAinda não há avaliações

- 2014 Hoisting Rigging Plan 10-6-14 Final Posted To WebsiteDocumento23 páginas2014 Hoisting Rigging Plan 10-6-14 Final Posted To WebsiteSudiatmoko Supangkat100% (1)

- 19-F12 Mobile Crane Daily Inspection ChecklistDocumento2 páginas19-F12 Mobile Crane Daily Inspection ChecklistSn AhsanAinda não há avaliações

- Tower Crane Inspection ChecklistDocumento4 páginasTower Crane Inspection Checklistmailme_viju100% (1)

- B Lifting Plan Using LorryDocumento1 páginaB Lifting Plan Using LorrySyed Fawad ShahAinda não há avaliações

- Check List of Mobil CraneDocumento3 páginasCheck List of Mobil CraneZulhaidy Salim100% (1)

- Presentation For RiggingDocumento18 páginasPresentation For RiggingRameese MuhammedAinda não há avaliações

- Checklist Inspection For CraneDocumento1 páginaChecklist Inspection For CraneMohammed Rashid Al-kalbaniAinda não há avaliações

- Lorry Loader Crane ChecklistDocumento1 páginaLorry Loader Crane ChecklistSameer ParambathAinda não há avaliações

- F-49 Full Body Harness Inspection ChecklistDocumento1 páginaF-49 Full Body Harness Inspection ChecklistSKH Culture100% (1)

- Mobile Crane Inspection ChecklistDocumento1 páginaMobile Crane Inspection ChecklistSaumya Siddhantha Choudhury100% (1)

- Crane Jib Check ListDocumento1 páginaCrane Jib Check ListsawkariqbalAinda não há avaliações

- Risk Assessment Man Cage and Telehandler Pklands July 2022Documento4 páginasRisk Assessment Man Cage and Telehandler Pklands July 2022Dáithí O'LaoghaireAinda não há avaliações

- Qcs 2010 Section 11 Part 2.3.10 She Procedures - The Safe Use of CranDocumento26 páginasQcs 2010 Section 11 Part 2.3.10 She Procedures - The Safe Use of Cranbryanpastor106100% (7)

- PE001-Environment ManagementDocumento14 páginasPE001-Environment ManagementOgunwa EmmanuelAinda não há avaliações

- New Mobile Crawler Crane ChecklistDocumento2 páginasNew Mobile Crawler Crane ChecklistsunilAinda não há avaliações

- Rigging Plan Worksheet: 4.0/3b07e011.pdf 1 (11/2006)Documento3 páginasRigging Plan Worksheet: 4.0/3b07e011.pdf 1 (11/2006)Cleiciane FrancoAinda não há avaliações

- 010 Pre-Job Safety Checklist (Rivision 2) - UPDATEDDocumento1 página010 Pre-Job Safety Checklist (Rivision 2) - UPDATEDLijo John100% (1)

- SOP-015 - Inspection, Tagging & Color Coding - ReviewedDocumento4 páginasSOP-015 - Inspection, Tagging & Color Coding - ReviewedShahulAinda não há avaliações

- Onshore Critical Lift Plan FormDocumento2 páginasOnshore Critical Lift Plan FormSyaiful Akhmad100% (1)

- 10 - Cherry Picker Inspection ChecklistDocumento1 página10 - Cherry Picker Inspection Checklistsanjeev kumarAinda não há avaliações

- Machinery Inspection ChecklistDocumento4 páginasMachinery Inspection ChecklistCynthia ChuaAinda não há avaliações

- Crane InspectionDocumento1 páginaCrane InspectionMKhairulMD100% (1)

- Tower Light Inspection ChecklistDocumento1 páginaTower Light Inspection ChecklistHabib ur rahmanAinda não há avaliações

- Crane Lift Work PlatformDocumento13 páginasCrane Lift Work PlatformsheqarayzanAinda não há avaliações

- SOP - ForkliftDocumento4 páginasSOP - ForkliftGyanendra Narayan Nayak100% (1)

- Crane Hoist Sling Safety ProgramDocumento14 páginasCrane Hoist Sling Safety Programomar sadiqAinda não há avaliações

- 1a. Crawler CraneDocumento2 páginas1a. Crawler CraneSHARAFUDHEEN TKAinda não há avaliações

- SOP 4 - Coal Bed Leveling in PGPDocumento18 páginasSOP 4 - Coal Bed Leveling in PGPfaraz ahmedAinda não há avaliações

- Critical Lift ChecklistDocumento5 páginasCritical Lift ChecklistMohamed HadjkacemAinda não há avaliações

- CCU Cargo ChecklistDocumento1 páginaCCU Cargo ChecklistCostin100% (1)

- Safety in Manual Handling of Loads PDFDocumento20 páginasSafety in Manual Handling of Loads PDFhoboslayer97100% (1)

- Crane and Lifting TrainingDocumento1 páginaCrane and Lifting TrainingLeonardo RoncettiAinda não há avaliações

- Telehandler Forklift Pre-Use Inspection ChecklistDocumento1 páginaTelehandler Forklift Pre-Use Inspection ChecklistMalika Baboo100% (1)

- Lifting Plan and FarmDocumento7 páginasLifting Plan and FarmAbid RehmanAinda não há avaliações

- 021 Crane Operator ChecklistDocumento1 página021 Crane Operator ChecklistJunard Lu HapAinda não há avaliações

- 10 Frequently Asked Questions About The Machinery DirectiveDocumento5 páginas10 Frequently Asked Questions About The Machinery Directivesujal_aminAinda não há avaliações

- Site:FSW - Major Overhaul GTG#1: Alstom Zero Deviation Plan Audit ReportDocumento26 páginasSite:FSW - Major Overhaul GTG#1: Alstom Zero Deviation Plan Audit ReportRoy MangaraAinda não há avaliações

- ForkliftDocumento2 páginasForkliftSHARAFUDHEEN TKAinda não há avaliações

- Crane Checklist PDFDocumento2 páginasCrane Checklist PDFWaqar IftikharAinda não há avaliações

- Load ChartDocumento1 páginaLoad Chartdavid chusnul100% (1)

- Lifting PlanDocumento2 páginasLifting PlanMidhunRameshThuvasseryAinda não há avaliações

- 1 WAH ChecklistDocumento2 páginas1 WAH Checklistvirendra kumar singhAinda não há avaliações

- ForkliftDocumento3 páginasForkliftJamesss BlackAinda não há avaliações

- 59-1 Man BasketDocumento3 páginas59-1 Man BasketAkhil100% (1)

- 39-98 - Safe Use of Lifting Machines and Lifting Tackle - 0Documento59 páginas39-98 - Safe Use of Lifting Machines and Lifting Tackle - 0JakesAinda não há avaliações

- Safe Work Procedure (Air Compressor)Documento2 páginasSafe Work Procedure (Air Compressor)SURJIT SINGH100% (1)

- Critical Lift Plan Mobile Cranes PDFDocumento10 páginasCritical Lift Plan Mobile Cranes PDFAndre MarsAinda não há avaliações

- 7.wheel Loader Daily Checklist - OkDocumento7 páginas7.wheel Loader Daily Checklist - Okmuhammad.younisAinda não há avaliações

- Emergency Generator MaintenanceDocumento8 páginasEmergency Generator MaintenanceGerardo Rubio100% (1)

- Backhoe-Rock Breaker Inspection ChecklistDocumento1 páginaBackhoe-Rock Breaker Inspection ChecklistAlok Singh100% (1)

- Crane Inspection Check ListDocumento2 páginasCrane Inspection Check Listmuhammad.younisAinda não há avaliações

- Pit Dimensions: Standard Dock LevellerDocumento1 páginaPit Dimensions: Standard Dock LevellerBalgo BalgobinAinda não há avaliações

- Assa Abloy Door Installation ManualDocumento40 páginasAssa Abloy Door Installation ManualBalgo BalgobinAinda não há avaliações

- A Spreadsheet Template With Scaled Graph Options Useful For Engineering ClassesDocumento8 páginasA Spreadsheet Template With Scaled Graph Options Useful For Engineering ClassesBalgo BalgobinAinda não há avaliações

- BSI Standards Publication: Water Meters For Cold Potable Water and Hot WaterDocumento13 páginasBSI Standards Publication: Water Meters For Cold Potable Water and Hot WaterBalgo BalgobinAinda não há avaliações

- 180 AtjDocumento6 páginas180 AtjBalgo BalgobinAinda não há avaliações

- Assessment Sheet For Registration Stage 2 - Step 2Documento8 páginasAssessment Sheet For Registration Stage 2 - Step 2Balgo BalgobinAinda não há avaliações

- Foot Operated PedalDocumento1 páginaFoot Operated PedalBalgo BalgobinAinda não há avaliações

- Content of Mauritius Fire Code Newa PDFDocumento3 páginasContent of Mauritius Fire Code Newa PDFBalgo BalgobinAinda não há avaliações

- Adjustment of Wheel Bearings: Series NMDocumento1 páginaAdjustment of Wheel Bearings: Series NMBalgo BalgobinAinda não há avaliações

- The New: Mark Ii Center In-Line 2Documento2 páginasThe New: Mark Ii Center In-Line 2Balgo BalgobinAinda não há avaliações

- Chapter 7 - Mechanical Ventillation and Smoke Control SystemsDocumento23 páginasChapter 7 - Mechanical Ventillation and Smoke Control SystemsBalgo BalgobinAinda não há avaliações

- Lindab Purlins: Technical InformationDocumento8 páginasLindab Purlins: Technical InformationBalgo BalgobinAinda não há avaliações

- Appendix D-4 Pump Selection GuideDocumento4 páginasAppendix D-4 Pump Selection GuideBalgo BalgobinAinda não há avaliações

- Mauritius Fire CodeDocumento3 páginasMauritius Fire CodeBalgo Balgobin100% (1)

- Covid-19 RiskAssessmentWarehouseDocumento11 páginasCovid-19 RiskAssessmentWarehouseBalgo BalgobinAinda não há avaliações

- Stats Review CH 1-6Documento15 páginasStats Review CH 1-6Megha BanerjeeAinda não há avaliações

- CHAPTER 3 Formwork Part 1Documento39 páginasCHAPTER 3 Formwork Part 1nasAinda não há avaliações

- Copd 9 027Documento13 páginasCopd 9 027Yussuf MuhammadAinda não há avaliações

- Web Script Ems Core 4 Hernandez - Gene Roy - 07!22!2020Documento30 páginasWeb Script Ems Core 4 Hernandez - Gene Roy - 07!22!2020gene roy hernandezAinda não há avaliações

- The Stony Brook Press - Volume 11, Issue 4Documento28 páginasThe Stony Brook Press - Volume 11, Issue 4The Stony Brook PressAinda não há avaliações

- CW Catalogue Cables and Wires A4 En-2Documento1.156 páginasCW Catalogue Cables and Wires A4 En-2Ovidiu PuieAinda não há avaliações

- CSF LeaksDocumento3 páginasCSF LeaksDrTarek Mahmoud Abo KammerAinda não há avaliações

- 01 Mono Channel BurnerDocumento1 página01 Mono Channel BurnerSelwyn MunatsiAinda não há avaliações

- The Nursing ShortageDocumento6 páginasThe Nursing Shortageapi-455495817Ainda não há avaliações

- TM1 PresentationDocumento33 páginasTM1 PresentationJas Sofia90% (10)

- Pakistan Hse Requirements and Guidlines For Drilling OperationsDocumento52 páginasPakistan Hse Requirements and Guidlines For Drilling OperationstyoAinda não há avaliações

- Io (Jupiter Moon)Documento2 páginasIo (Jupiter Moon)FatimaAinda não há avaliações

- PaperDocumento21 páginasPaperAnonymous N2TkzrAinda não há avaliações

- Marantz - dv-4200 DVD Player PDFDocumento60 páginasMarantz - dv-4200 DVD Player PDFH.V KayaAinda não há avaliações

- Child-Centered and Progressive EducationDocumento2 páginasChild-Centered and Progressive EducationDibyendu ChoudhuryAinda não há avaliações

- 006R5-WMS-JI-MI-MAU-ACS-II-23 Working Method - Pile CapDocumento20 páginas006R5-WMS-JI-MI-MAU-ACS-II-23 Working Method - Pile CapEko Budi HartantoAinda não há avaliações

- Muet Topic 10 City Life Suggested Answer and IdiomsDocumento3 páginasMuet Topic 10 City Life Suggested Answer and IdiomsMUHAMAD FAHMI BIN SHAMSUDDIN MoeAinda não há avaliações

- Neurovascular Assessment PDFDocumento5 páginasNeurovascular Assessment PDFNasrullah UllahAinda não há avaliações

- Stas Final ReviewerDocumento8 páginasStas Final ReviewerShane SaynoAinda não há avaliações

- Urinary Tract Infection (UTI) - 4 Nursing Diagnosis InterventionsDocumento4 páginasUrinary Tract Infection (UTI) - 4 Nursing Diagnosis InterventionsEricsonMitra0% (2)

- Adjectives Comparative and Superlative FormDocumento5 páginasAdjectives Comparative and Superlative FormOrlando MiguelAinda não há avaliações

- Materials Management in Hospital Industry Nandi ProjectDocumento27 páginasMaterials Management in Hospital Industry Nandi Projectkumaraswamy226Ainda não há avaliações

- 09B Mechanical Properties of CeramicsDocumento13 páginas09B Mechanical Properties of CeramicsAhmed AliAinda não há avaliações

- The Many Uses of Transmission Line ArrestersDocumento8 páginasThe Many Uses of Transmission Line ArrestersVK DharmikaAinda não há avaliações

- Carotenoids-Birkhäuser Basel (1971)Documento934 páginasCarotenoids-Birkhäuser Basel (1971)feghbalibAinda não há avaliações

- Zemoso - PM AssignmentDocumento3 páginasZemoso - PM AssignmentTushar Basakhtre (HBK)Ainda não há avaliações

- Recognizing Fractures and Dislocations: Corpuz, Rachella Nicole PDocumento46 páginasRecognizing Fractures and Dislocations: Corpuz, Rachella Nicole PRachella Nicole CorpuzAinda não há avaliações

- Ens TecDocumento28 páginasEns TecBorja CanalsAinda não há avaliações

- Governance, Business Ethics, Risk Management and Internal ControlDocumento4 páginasGovernance, Business Ethics, Risk Management and Internal ControlJosua PagcaliwaganAinda não há avaliações

- Air Pollution Emissions 2008-2018 From Australian Coal Mining: Implications For Public and Occupational HealthDocumento11 páginasAir Pollution Emissions 2008-2018 From Australian Coal Mining: Implications For Public and Occupational HealthMaria Stephany CalisayaAinda não há avaliações