Escolar Documentos

Profissional Documentos

Cultura Documentos

Filtros Ros

Enviado por

thiagobonamigoDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Filtros Ros

Enviado por

thiagobonamigoDireitos autorais:

Formatos disponíveis

Industrial Filters Accumulators Industrial Filters Accumulators

Quality assured!

K. & H. Eppensteiner GmbH & Co. KG

Hardtwaldstrae 43 D-68775 Ketsch/Rh.

Postfach 1120 D-68768 Ketsch/Rh.

Telefon: 06202 / 603-0

Telefax: 06202 / 603-199

E-Mail: Eppensteiner@compuserve.com

Internet: www.Eppensteiner.de Technical modifications reserved! 20A/01/10.99/6000

Spare Parts

Filter head

Filter cover

Filter element

Profile seal

Profile seal

O-ring

Plug

Maintenance Indicator

Seal

Reduction for

M 070

Duplex fitting

for I...

Pressing with

valve

Part No. 785 Part No. 770

Part No. 1372

Part No. 1371

Buna N/Viton

Buna N/Viton

5.8

Various

Fibre

Steel

Steel

Various

plastic

Aluminium cast

Various

Various

Quality and Standardisation

The development, manufacturing and assembly of EPE Industrial filters and filter elements is performed within the guidelines

of a certified quality management system according to DIN EN ISO 9001. The calculation of strength and the filter tests are

done in compliance to actual pressure vessel regulations and national & international standards.

A filter inspection by accredited certification bodies ( e.g. TV, GL, LRS, LRIS, ABS, BV, DNV, DRIRE, UDT etc. ) is possible

on request.

please indicate ordering information "Filter Assembly"

please indicate ordering information "Filter Assembly"

please indicate ordering information "Filter Assembly"

please indicate ordering information "Filter Element"

please indicate ordering information "Seal Kit"

please indicate ordering information "Seal Kit"

please indicate ordering information "Seal Kit"

please indicate ordering information "Seal Kit"

Size 56 90 140 225 360 460 560

Part Qty. Designation Material

1 1

2 1

3 1

4 1

5 1

6 1

7 1

8 1 refer section "Maintenance Indicator"

9 1

10 1

11 1

12 1

Installation, Starting and Maintenance

Filter Installation

Screw suction filter type S8-455 direct on pump suction line.

Type SE 56- 560: remove dust protection plug from filter inlet.

Mount filter assembly at tank using mounting device on the head

(Part 2) considering and servicing length required for cleaning /

replacing elements (Part 3 ).

Connection of Electrical Maintenance Indicator

Type: SE 56- 560:

Connect indicator using the two wired cable.

Please verify electrical ratings on the indicators name plate.

Starting

Switch on system pump.

Pay attention to pump noise, dismount filter assembly if necessary and

check filtration grade and seals.

Maintenance

The filter element is clogged and needs to be replaced or cleaned if the

vacuum gauge indicator moves into red alert range or the electrical

switch is activated.

Filter Element Service

S8-455: switch off system , drain tank , disconnect suction filter from

suction line.

SE 56-560: switch off system pump. Unscrew filter cover (Part 1), return

flow blockage closes automatically, remove filter element from filter

housing. Check filter housing inside and clean if necessary.

Replace filter element H..-SL , P ... and VS... .

The filter element with G... media is cleanable. The efficiency of the

cleaning process depends on the characteristics of contamination and

the final pressure drop prior to servicing / cleaning the element.

Install cleaned or replaced filter element.

Check O-ring (Part 6 ) on filter head , replace in case of damage or wear.

Screw filter cover (Part 1) and tighten it at hexagon bolt using a suitable

tool.

Operate filter as described above.

Suction Filters

S8 - 455

SE56- 560

Nominal flow rate: 15 - 1000 l/min

Connection up to SAE 4

Filters for installation in

suction pipes

Suctions filters with housing for

tank mounting

Suction filters with housing

including automatic shut off valve.

Low pressure drop

Various filter media available

Dimensions Performance Characteristics

Pressure drop curves for wire mesh G 100

2

Oil viscosity 30,200 mm /sec

3

specific gravity < 0,9 kg/dm

Maintenance Indicator

Maintenance Indicator

Filter Type

Filter Type

SE = Suction Filter

with housing

S = Suction Filter

Connection

Connection

00 =

pipe thread

S0 =

SAE flange

F0 =

square flange

00 = standard

Material

Material

Filter Element 6. 90 G 25 S 00 0 0

Filtration Grade

Filtration Grade

Differential

Pressure

Differential

Pressure

S = standard

S = standard

56

90

140

225

360

460

560

8, 16, 28,

45, 75, 115,

175, 280, 455

Nominal Size

Nominal Size

Filter Element

Type:

6.

Filter Element Design

Filter Element Design

Bypass Valve

Bypass Valve

Seal

Seal

Add. Info

Add. Info

Filter Assembly

Filter Assembly

Seal Kit H10SL

SE

S

D SE

90

45

90

G 25

G 130

S

S

00

00

0

0

1

0

A

0

0O

0O

P

0

0

0

0

0

A 0O P 0

Magnet

Magnet

0 = without

0 = without

Avisual Bvisual/electrical

normally closed 42 V

Cvisual/electrical

normally open 42 V

Ordering information

A = M 070

Ordering information

B 0,2 = l 0,2 HS 32 00P*

Ordering information

C 0.2 = l 0,2 HA 32 00P*

Switching symbol

Switching symbol

Ordering

Information

Selection of filter size:

using the computer program

"EPE - FILTERSELECT

or performance characteristics

in this brochure.

Special designs available on request.

0 = without

A = vacuum gauge

B 0,2 = vacuum switch

normally closed 42 V

C 0,2 = vacuum switch

normally open 42 V

0 = without

0 = standard

0 = standard

Nominal filtration grade in m

G = stainless steel wire mesh, cleanable

G10 G25 G40 G60 G80 G100

VS = nonwoven media, not cleanable

VS 25 VS 40 VS 80

P = paper, not cleanable

P5 P10 P25

Absolute filtration grade

(ISO4572)in m

H...SL = micro glass-fibre, not cleanable

H1SL H3SL H6SL H10SL

H20SL

AS = micro glass-fibre, water

absorbing, not cleanable

AS1 AS3 AS6 AS10 AS20

Nominal filtration grade in m

G = stainless steel wire mesh, cleanable

G25 G40 G 130

G 200 G 250 G 300

G 350 G 450 G 550

G 600 G 800 G 1000

G 1500 G 2000

0... = standard adhesive

T = 100C

...0 = standard material

0... = standard adhesive

T = 100C

1 = 0,3 bar

for

Filter Element

always 0

0 = without

1 = 0,3 bar

0 =

without

P =

Buna N

V =

Viton

for Filter

Element

always 0

0 =

without

0= without

5= silicon free

Y= with add.

strainer only

for SE 360 to

SE 560

on request

Z= inspection

certificate

5= silicon free

Z= inspection

certificate

0= without

V= non return

valve 0,02 bar

Z= inspection

certificate

Maintenance Indicator Filter Switching Symbol

*P = Buna N, V = Viton also possible

SE 56-560 S 8-455

Size Volume

in ltrs.

Weight

1)

in kg

A1 A2

2)

A3 A4 B1 B2 B3 B4 B5 B6 B7 B8 C1 C2

Tank-Bore Connection

S 8 0,05 45 12 24 40 G

3

/8

S 16

0,2

60

13 35 36 57

G

1

/2

S 28 90 G

3

/4

S 45 0,4 95

17 60 55 77

G 1

S 75 0,5 130 G 1

1

/4

S 115 0,6 135

21 54 75 108

G 1

1

/2

S 175 0,7 180 G 2

S 280

1,7

170

28 85 105 150

G 2

1

/2

S 455 250 G 3

SE 560 0,5 1,0 125

96 220 32 115 70 65 137 74 G 1

SE 900 0,8 1,2 180

SE 140 1,9 3,0 266 119 310 42 142 85 78 95,5 G 1

1

/2

SE 225

3,7 7,5 281 155

G 2

1

/2

SE 360

280

58 85

77

166

130

DN 80

SE 460 4,0 8,7 301

188 80 120

104

170

146

77,8 154 130,2

SAE4

SE560 4,8 9,1 361 3000 psi

1)

= weight including standard filter element

2)

= servicing height for filter element replacement

C3 C4 C5 C6 D1

11

11,5

11

M 12

120

22

M 16 100

S 8, S 16, S 28, S 45, S 75, S 115

S 175, S 280, S 455

SE 56, SE 90, SE 140 SE 225, SE 360, SE 460,

SE 560

51 89

112

Suction Filters

S8 - 455

SE56 -560

Nominal flow rate:

15 - 1000 l/min

Operating temperature:

-10C up to +100C

Connection up to SAE 4

Application

Filtration of liquids and lubricants.

Filtration of liquids and gases.

Filtration of industrial liquids.

Direct installation in suction lines or tank

mounting installation.

Design

S8-455 with pleated filter element an pipe thread

connection.

SE56 - 560: filter head with screwable cover,

bypass valve and outlet.

Filter housing with filter element locator , filter

inlet and return flow blockage for element service.

Material: as per spare parts list in this brochure.

Filter Element

Pleated design with optimised pleat density and

various filter media.

The filter element is the most important

component of the filter in view of prolonged life

and wear protection of the system.

Oil cleanliness, the initial pressure drop and the

dirt holding capacity are the most important

criteria for selection.

For further detailed information please refer our

"Filter Elements" brochure.

A proper filter selection is enabled by our

"EPE - FILTERSELECT" software.

Accessories

Maintenance Indicators

For monitoring the filter element's contamination

status, visual and visual/electrical indicators, with

one or two switching points are available.

Bypass Valve

S8-455: bypass valve available

SE56-560: standard bypass valve with opening

pressure of 0,3 bar included.

To protect the pump against cavitation during

start up and over pressurisation due to clogging.

Dimensions Performance Characteristics

Pressure drop curves for wire mesh G 100

2

Oil viscosity 30,200 mm /sec

3

specific gravity < 0,9 kg/dm

Maintenance Indicator

Maintenance Indicator

Filter Type

Filter Type

SE = Suction Filter

with housing

S = Suction Filter

Connection

Connection

00 =

pipe thread

S0 =

SAE flange

F0 =

square flange

00 = standard

Material

Material

Filter Element 6. 90 G 25 S 00 0 0

Filtration Grade

Filtration Grade

Differential

Pressure

Differential

Pressure

S = standard

S = standard

56

90

140

225

360

460

560

8, 16, 28,

45, 75, 115,

175, 280, 455

Nominal Size

Nominal Size

Filter Element

Type:

6.

Filter Element Design

Filter Element Design

Bypass Valve

Bypass Valve

Seal

Seal

Add. Info

Add. Info

Filter Assembly

Filter Assembly

Seal Kit H10SL

SE

S

D SE

90

45

90

G 25

G 130

S

S

00

00

0

0

1

0

A

0

0O

0O

P

0

0

0

0

0

A 0O P 0

Magnet

Magnet

0 = without

0 = without

Avisual Bvisual/electrical

normally closed 42 V

Cvisual/electrical

normally open 42 V

Ordering information

A = M 070

Ordering information

B 0,2 = l 0,2 HS 32 00P*

Ordering information

C 0.2 = l 0,2 HA 32 00P*

Switching symbol

Switching symbol

Ordering

Information

Selection of filter size:

using the computer program

"EPE - FILTERSELECT

or performance characteristics

in this brochure.

Special designs available on request.

0 = without

A = vacuum gauge

B 0,2 = vacuum switch

normally closed 42 V

C 0,2 = vacuum switch

normally open 42 V

0 = without

0 = standard

0 = standard

Nominal filtration grade in m

G = stainless steel wire mesh, cleanable

G10 G25 G40 G60 G80 G100

VS = nonwoven media, not cleanable

VS 25 VS 40 VS 80

P = paper, not cleanable

P5 P10 P25

Absolute filtration grade

(ISO4572)in m

H...SL = micro glass-fibre, not cleanable

H1SL H3SL H6SL H10SL

H20SL

AS = micro glass-fibre, water

absorbing, not cleanable

AS1 AS3 AS6 AS10 AS20

Nominal filtration grade in m

G = stainless steel wire mesh, cleanable

G25 G40 G 130

G 200 G 250 G 300

G 350 G 450 G 550

G 600 G 800 G 1000

G 1500 G 2000

0... = standard adhesive

T = 100C

...0 = standard material

0... = standard adhesive

T = 100C

1 = 0,3 bar

for

Filter Element

always 0

0 = without

1 = 0,3 bar

0 =

without

P =

Buna N

V =

Viton

for Filter

Element

always 0

0 =

without

0= without

5= silicon free

Y= with add.

strainer only

for SE 360 to

SE 560

on request

Z= inspection

certificate

5= silicon free

Z= inspection

certificate

0= without

V= non return

valve 0,02 bar

Z= inspection

certificate

Maintenance Indicator Filter Switching Symbol

*P = Buna N, V = Viton also possible

SE 56-560 S 8-455

Size Volume

in ltrs.

Weight

1)

in kg

A1 A2

2)

A3 A4 B1 B2 B3 B4 B5 B6 B7 B8 C1 C2

Tank-Bore Connection

S 8 0,05 45 12 24 40 G

3

/8

S 16

0,2

60

13 35 36 57

G

1

/2

S 28 90 G

3

/4

S 45 0,4 95

17 60 55 77

G 1

S 75 0,5 130 G 1

1

/4

S 115 0,6 135

21 54 75 108

G 1

1

/2

S 175 0,7 180 G 2

S 280

1,7

170

28 85 105 150

G 2

1

/2

S 455 250 G 3

SE 560 0,5 1,0 125

96 220 32 115 70 65 137 74 G 1

SE 900 0,8 1,2 180

SE 140 1,9 3,0 266 119 310 42 142 85 78 95,5 G 1

1

/2

SE 225

3,7 7,5 281 155

G 2

1

/2

SE 360

280

58 85

77

166

130

DN 80

SE 460 4,0 8,7 301

188 80 120

104

170

146

77,8 154 130,2

SAE4

SE560 4,8 9,1 361 3000 psi

1)

= weight including standard filter element

2)

= servicing height for filter element replacement

C3 C4 C5 C6 D1

11

11,5

11

M 12

120

22

M 16 100

S 8, S 16, S 28, S 45, S 75, S 115

S 175, S 280, S 455

SE 56, SE 90, SE 140 SE 225, SE 360, SE 460,

SE 560

51 89

112

Suction Filters

S8 - 455

SE56 -560

Nominal flow rate:

15 - 1000 l/min

Operating temperature:

-10C up to +100C

Connection up to SAE 4

Application

Filtration of liquids and lubricants.

Filtration of liquids and gases.

Filtration of industrial liquids.

Direct installation in suction lines or tank

mounting installation.

Design

S8-455 with pleated filter element an pipe thread

connection.

SE56 - 560: filter head with screwable cover,

bypass valve and outlet.

Filter housing with filter element locator , filter

inlet and return flow blockage for element service.

Material: as per spare parts list in this brochure.

Filter Element

Pleated design with optimised pleat density and

various filter media.

The filter element is the most important

component of the filter in view of prolonged life

and wear protection of the system.

Oil cleanliness, the initial pressure drop and the

dirt holding capacity are the most important

criteria for selection.

For further detailed information please refer our

"Filter Elements" brochure.

A proper filter selection is enabled by our

"EPE - FILTERSELECT" software.

Accessories

Maintenance Indicators

For monitoring the filter element's contamination

status, visual and visual/electrical indicators, with

one or two switching points are available.

Bypass Valve

S8-455: bypass valve available

SE56-560: standard bypass valve with opening

pressure of 0,3 bar included.

To protect the pump against cavitation during

start up and over pressurisation due to clogging.

Dimensions Performance Characteristics

Pressure drop curves for wire mesh G 100

2

Oil viscosity 30,200 mm /sec

3

specific gravity < 0,9 kg/dm

Maintenance Indicator

Maintenance Indicator

Filter Type

Filter Type

SE = Suction Filter

with housing

S = Suction Filter

Connection

Connection

00 =

pipe thread

S0 =

SAE flange

F0 =

square flange

00 = standard

Material

Material

Filter Element 6. 90 G 25 S 00 0 0

Filtration Grade

Filtration Grade

Differential

Pressure

Differential

Pressure

S = standard

S = standard

56

90

140

225

360

460

560

8, 16, 28,

45, 75, 115,

175, 280, 455

Nominal Size

Nominal Size

Filter Element

Type:

6.

Filter Element Design

Filter Element Design

Bypass Valve

Bypass Valve

Seal

Seal

Add. Info

Add. Info

Filter Assembly

Filter Assembly

Seal Kit H10SL

SE

S

D SE

90

45

90

G 25

G 130

S

S

00

00

0

0

1

0

A

0

0O

0O

P

0

0

0

0

0

A 0O P 0

Magnet

Magnet

0 = without

0 = without

Avisual Bvisual/electrical

normally closed 42 V

Cvisual/electrical

normally open 42 V

Ordering information

A = M 070

Ordering information

B 0,2 = l 0,2 HS 32 00P*

Ordering information

C 0.2 = l 0,2 HA 32 00P*

Switching symbol

Switching symbol

Ordering

Information

Selection of filter size:

using the computer program

"EPE - FILTERSELECT

or performance characteristics

in this brochure.

Special designs available on request.

0 = without

A = vacuum gauge

B 0,2 = vacuum switch

normally closed 42 V

C 0,2 = vacuum switch

normally open 42 V

0 = without

0 = standard

0 = standard

Nominal filtration grade in m

G = stainless steel wire mesh, cleanable

G10 G25 G40 G60 G80 G100

VS = nonwoven media, not cleanable

VS 25 VS 40 VS 80

P = paper, not cleanable

P5 P10 P25

Absolute filtration grade

(ISO4572)in m

H...SL = micro glass-fibre, not cleanable

H1SL H3SL H6SL H10SL

H20SL

AS = micro glass-fibre, water

absorbing, not cleanable

AS1 AS3 AS6 AS10 AS20

Nominal filtration grade in m

G = stainless steel wire mesh, cleanable

G25 G40 G 130

G 200 G 250 G 300

G 350 G 450 G 550

G 600 G 800 G 1000

G 1500 G 2000

0... = standard adhesive

T = 100C

...0 = standard material

0... = standard adhesive

T = 100C

1 = 0,3 bar

for

Filter Element

always 0

0 = without

1 = 0,3 bar

0 =

without

P =

Buna N

V =

Viton

for Filter

Element

always 0

0 =

without

0= without

5= silicon free

Y= with add.

strainer only

for SE 360 to

SE 560

on request

Z= inspection

certificate

5= silicon free

Z= inspection

certificate

0= without

V= non return

valve 0,02 bar

Z= inspection

certificate

Maintenance Indicator Filter Switching Symbol

*P = Buna N, V = Viton also possible

SE 56-560 S 8-455

Size Volume

in ltrs.

Weight

1)

in kg

A1 A2

2)

A3 A4 B1 B2 B3 B4 B5 B6 B7 B8 C1 C2

Tank-Bore Connection

S 8 0,05 45 12 24 40 G

3

/8

S 16

0,2

60

13 35 36 57

G

1

/2

S 28 90 G

3

/4

S 45 0,4 95

17 60 55 77

G 1

S 75 0,5 130 G 1

1

/4

S 115 0,6 135

21 54 75 108

G 1

1

/2

S 175 0,7 180 G 2

S 280

1,7

170

28 85 105 150

G 2

1

/2

S 455 250 G 3

SE 560 0,5 1,0 125

96 220 32 115 70 65 137 74 G 1

SE 900 0,8 1,2 180

SE 140 1,9 3,0 266 119 310 42 142 85 78 95,5 G 1

1

/2

SE 225

3,7 7,5 281 155

G 2

1

/2

SE 360

280

58 85

77

166

130

DN 80

SE 460 4,0 8,7 301

188 80 120

104

170

146

77,8 154 130,2

SAE4

SE560 4,8 9,1 361 3000 psi

1)

= weight including standard filter element

2)

= servicing height for filter element replacement

C3 C4 C5 C6 D1

11

11,5

11

M 12

120

22

M 16 100

S 8, S 16, S 28, S 45, S 75, S 115

S 175, S 280, S 455

SE 56, SE 90, SE 140 SE 225, SE 360, SE 460,

SE 560

51 89

112

Suction Filters

S8 - 455

SE56 -560

Nominal flow rate:

15 - 1000 l/min

Operating temperature:

-10C up to +100C

Connection up to SAE 4

Application

Filtration of liquids and lubricants.

Filtration of liquids and gases.

Filtration of industrial liquids.

Direct installation in suction lines or tank

mounting installation.

Design

S8-455 with pleated filter element an pipe thread

connection.

SE56 - 560: filter head with screwable cover,

bypass valve and outlet.

Filter housing with filter element locator , filter

inlet and return flow blockage for element service.

Material: as per spare parts list in this brochure.

Filter Element

Pleated design with optimised pleat density and

various filter media.

The filter element is the most important

component of the filter in view of prolonged life

and wear protection of the system.

Oil cleanliness, the initial pressure drop and the

dirt holding capacity are the most important

criteria for selection.

For further detailed information please refer our

"Filter Elements" brochure.

A proper filter selection is enabled by our

"EPE - FILTERSELECT" software.

Accessories

Maintenance Indicators

For monitoring the filter element's contamination

status, visual and visual/electrical indicators, with

one or two switching points are available.

Bypass Valve

S8-455: bypass valve available

SE56-560: standard bypass valve with opening

pressure of 0,3 bar included.

To protect the pump against cavitation during

start up and over pressurisation due to clogging.

Industrial Filters Accumulators Industrial Filters Accumulators

Quality assured!

K. & H. Eppensteiner GmbH & Co. KG

Hardtwaldstrae 43 D-68775 Ketsch/Rh.

Postfach 1120 D-68768 Ketsch/Rh.

Telefon: 06202 / 603-0

Telefax: 06202 / 603-199

E-Mail: Eppensteiner@compuserve.com

Internet: www.Eppensteiner.de Technical modifications reserved! 20A/01/10.99/6000

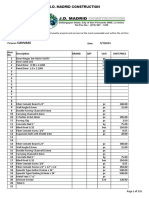

Spare Parts

Filter head

Filter cover

Filter element

Profile seal

Profile seal

O-ring

Plug

Maintenance Indicator

Seal

Reduction for

M 070

Duplex fitting

for I...

Pressing with

valve

Part No. 785 Part No. 770

Part No. 1372

Part No. 1371

Buna N/Viton

Buna N/Viton

5.8

Various

Fibre

Steel

Steel

Various

plastic

Aluminium cast

Various

Various

Quality and Standardisation

The development, manufacturing and assembly of EPE Industrial filters and filter elements is performed within the guidelines

of a certified quality management system according to DIN EN ISO 9001. The calculation of strength and the filter tests are

done in compliance to actual pressure vessel regulations and national & international standards.

A filter inspection by accredited certification bodies ( e.g. TV, GL, LRS, LRIS, ABS, BV, DNV, DRIRE, UDT etc. ) is possible

on request.

please indicate ordering information "Filter Assembly"

please indicate ordering information "Filter Assembly"

please indicate ordering information "Filter Assembly"

please indicate ordering information "Filter Element"

please indicate ordering information "Seal Kit"

please indicate ordering information "Seal Kit"

please indicate ordering information "Seal Kit"

please indicate ordering information "Seal Kit"

Size 56 90 140 225 360 460 560

Part Qty. Designation Material

1 1

2 1

3 1

4 1

5 1

6 1

7 1

8 1 refer section "Maintenance Indicator"

9 1

10 1

11 1

12 1

Installation, Starting and Maintenance

Filter Installation

Screw suction filter type S8-455 direct on pump suction line.

Type SE 56- 560: remove dust protection plug from filter inlet.

Mount filter assembly at tank using mounting device on the head

(Part 2) considering and servicing length required for cleaning /

replacing elements (Part 3 ).

Connection of Electrical Maintenance Indicator

Type: SE 56- 560:

Connect indicator using the two wired cable.

Please verify electrical ratings on the indicators name plate.

Starting

Switch on system pump.

Pay attention to pump noise, dismount filter assembly if necessary and

check filtration grade and seals.

Maintenance

The filter element is clogged and needs to be replaced or cleaned if the

vacuum gauge indicator moves into red alert range or the electrical

switch is activated.

Filter Element Service

S8-455: switch off system , drain tank , disconnect suction filter from

suction line.

SE 56-560: switch off system pump. Unscrew filter cover (Part 1), return

flow blockage closes automatically, remove filter element from filter

housing. Check filter housing inside and clean if necessary.

Replace filter element H..-SL , P ... and VS... .

The filter element with G... media is cleanable. The efficiency of the

cleaning process depends on the characteristics of contamination and

the final pressure drop prior to servicing / cleaning the element.

Install cleaned or replaced filter element.

Check O-ring (Part 6 ) on filter head , replace in case of damage or wear.

Screw filter cover (Part 1) and tighten it at hexagon bolt using a suitable

tool.

Operate filter as described above.

Suction Filters

S8 - 455

SE56- 560

Nominal flow rate: 15 - 1000 l/min

Connection up to SAE 4

Filters for installation in

suction pipes

Suctions filters with housing for

tank mounting

Suction filters with housing

including automatic shut off valve.

Low pressure drop

Various filter media available

Industrial Filters Accumulators Industrial Filters Accumulators

Quality assured!

K. & H. Eppensteiner GmbH & Co. KG

Hardtwaldstrae 43 D-68775 Ketsch/Rh.

Postfach 1120 D-68768 Ketsch/Rh.

Telefon: 06202 / 603-0

Telefax: 06202 / 603-199

E-Mail: Eppensteiner@compuserve.com

Internet: www.Eppensteiner.de Technical modifications reserved! 20A/01/10.99/6000

Spare Parts

Filter head

Filter cover

Filter element

Profile seal

Profile seal

O-ring

Plug

Maintenance Indicator

Seal

Reduction for

M 070

Duplex fitting

for I...

Pressing with

valve

Part No. 785 Part No. 770

Part No. 1372

Part No. 1371

Buna N/Viton

Buna N/Viton

5.8

Various

Fibre

Steel

Steel

Various

plastic

Aluminium cast

Various

Various

Quality and Standardisation

The development, manufacturing and assembly of EPE Industrial filters and filter elements is performed within the guidelines

of a certified quality management system according to DIN EN ISO 9001. The calculation of strength and the filter tests are

done in compliance to actual pressure vessel regulations and national & international standards.

A filter inspection by accredited certification bodies ( e.g. TV, GL, LRS, LRIS, ABS, BV, DNV, DRIRE, UDT etc. ) is possible

on request.

please indicate ordering information "Filter Assembly"

please indicate ordering information "Filter Assembly"

please indicate ordering information "Filter Assembly"

please indicate ordering information "Filter Element"

please indicate ordering information "Seal Kit"

please indicate ordering information "Seal Kit"

please indicate ordering information "Seal Kit"

please indicate ordering information "Seal Kit"

Size 56 90 140 225 360 460 560

Part Qty. Designation Material

1 1

2 1

3 1

4 1

5 1

6 1

7 1

8 1 refer section "Maintenance Indicator"

9 1

10 1

11 1

12 1

Installation, Starting and Maintenance

Filter Installation

Screw suction filter type S8-455 direct on pump suction line.

Type SE 56- 560: remove dust protection plug from filter inlet.

Mount filter assembly at tank using mounting device on the head

(Part 2) considering and servicing length required for cleaning /

replacing elements (Part 3 ).

Connection of Electrical Maintenance Indicator

Type: SE 56- 560:

Connect indicator using the two wired cable.

Please verify electrical ratings on the indicators name plate.

Starting

Switch on system pump.

Pay attention to pump noise, dismount filter assembly if necessary and

check filtration grade and seals.

Maintenance

The filter element is clogged and needs to be replaced or cleaned if the

vacuum gauge indicator moves into red alert range or the electrical

switch is activated.

Filter Element Service

S8-455: switch off system , drain tank , disconnect suction filter from

suction line.

SE 56-560: switch off system pump. Unscrew filter cover (Part 1), return

flow blockage closes automatically, remove filter element from filter

housing. Check filter housing inside and clean if necessary.

Replace filter element H..-SL , P ... and VS... .

The filter element with G... media is cleanable. The efficiency of the

cleaning process depends on the characteristics of contamination and

the final pressure drop prior to servicing / cleaning the element.

Install cleaned or replaced filter element.

Check O-ring (Part 6 ) on filter head , replace in case of damage or wear.

Screw filter cover (Part 1) and tighten it at hexagon bolt using a suitable

tool.

Operate filter as described above.

Suction Filters

S8 - 455

SE56- 560

Nominal flow rate: 15 - 1000 l/min

Connection up to SAE 4

Filters for installation in

suction pipes

Suctions filters with housing for

tank mounting

Suction filters with housing

including automatic shut off valve.

Low pressure drop

Various filter media available

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (120)

- Technical CatalogueDocumento53 páginasTechnical CatalogueDaniel MilosevskiAinda não há avaliações

- Drilling Engineering Course ObjectivesDocumento118 páginasDrilling Engineering Course ObjectivesNelson Frendika Yudha100% (4)

- I Rod How To Order SheetDocumento1 páginaI Rod How To Order SheetPaulAinda não há avaliações

- Amendment No. 6 June 2021 To Is 1239 (Part 1) : 2004 Steel Tubes, Tubulars and Other Wrought Steel Fittings - SpecificationDocumento3 páginasAmendment No. 6 June 2021 To Is 1239 (Part 1) : 2004 Steel Tubes, Tubulars and Other Wrought Steel Fittings - Specificationbeshnu garanaikAinda não há avaliações

- 396 001230 PumpRight For Field IQ Rev 02.20.201411Documento71 páginas396 001230 PumpRight For Field IQ Rev 02.20.201411Denis OhmakAinda não há avaliações

- Wall Thickness Calculation Followed B31.8 PDFDocumento3 páginasWall Thickness Calculation Followed B31.8 PDFBPCL HCULOBS100% (1)

- s10-2 Water Pump Sandvik WBP (Rev. A - 05.2018) SPDocumento116 páginass10-2 Water Pump Sandvik WBP (Rev. A - 05.2018) SPEduardo Gamboa MarinAinda não há avaliações

- Materials List 1Documento231 páginasMaterials List 1KaJong JaclaAinda não há avaliações

- Iso 4633-2002Documento6 páginasIso 4633-2002Parimal PatelAinda não há avaliações

- How Do I Calculate The Surface Area of An Elbow - QuoraDocumento3 páginasHow Do I Calculate The Surface Area of An Elbow - QuoraAVINASHRAJAinda não há avaliações

- Circuit Breaker Technical SpecificationsDocumento24 páginasCircuit Breaker Technical SpecificationssanjayAinda não há avaliações

- Lesson 14 WelderQuals - New2Documento80 páginasLesson 14 WelderQuals - New2Mohd Syafiq100% (1)

- Red Book GlossaryDocumento6 páginasRed Book GlossaryAlejandro ViscarraAinda não há avaliações

- Welded, Unannealed Austenitic Stainless Steel Tubular ProductsDocumento4 páginasWelded, Unannealed Austenitic Stainless Steel Tubular ProductsGhulam DastaggirAinda não há avaliações

- Formula Sae Series Cost Module OperationsDocumento35 páginasFormula Sae Series Cost Module OperationsMateus FlausinoAinda não há avaliações

- API Non Upset EndDocumento1 páginaAPI Non Upset EndChoerunnisa Firli FitriahAinda não há avaliações

- Complete Guide To Pressure and Vacuum Sealing AssembliesDocumento22 páginasComplete Guide To Pressure and Vacuum Sealing Assembliesrahulkraj123Ainda não há avaliações

- Manuale Solitax SC enDocumento30 páginasManuale Solitax SC ensakarisoAinda não há avaliações

- Prince Item Code BookletDocumento69 páginasPrince Item Code BookletDharmesh MehtaAinda não há avaliações

- Design Criteria MechanicalDocumento35 páginasDesign Criteria MechanicalNoushad P HamsaAinda não há avaliações

- Hose Reel Catalogue 2018Documento12 páginasHose Reel Catalogue 2018FrancisAinda não há avaliações

- ISO standards oil & gasDocumento1 páginaISO standards oil & gasguerrero65Ainda não há avaliações

- Bem-650-Shale - Shaker PDFDocumento8 páginasBem-650-Shale - Shaker PDFWilliamAinda não há avaliações

- WTP 150m3 PDFDocumento9 páginasWTP 150m3 PDFEtcl FactoryAinda não há avaliações

- Guidelines For Acoustic Induced Vibration (AIV), Flow Induced Vibration (FIV) AnalysisDocumento8 páginasGuidelines For Acoustic Induced Vibration (AIV), Flow Induced Vibration (FIV) AnalysisVijaybalaji VijayakumarAinda não há avaliações

- Lab Manual - Refrigeration & Air CONDITIONING (2161908) : January 2018Documento47 páginasLab Manual - Refrigeration & Air CONDITIONING (2161908) : January 2018Getachew TikueAinda não há avaliações

- Pipe Supports PDFDocumento10 páginasPipe Supports PDFleotvrdeAinda não há avaliações

- Addendum 5. December 2019 Changed Pages OnlyDocumento210 páginasAddendum 5. December 2019 Changed Pages OnlyMelele MuAinda não há avaliações

- Foam Chamber Model - FCDocumento6 páginasFoam Chamber Model - FCtez tezAinda não há avaliações

- Process Engineering Deliverables OverviewDocumento7 páginasProcess Engineering Deliverables Overviewsohambandyopadhyay1677Ainda não há avaliações