Escolar Documentos

Profissional Documentos

Cultura Documentos

IACS UR Guide for Hull, Machinery and Safety Panels

Enviado por

Vu Tung LinhTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

IACS UR Guide for Hull, Machinery and Safety Panels

Enviado por

Vu Tung LinhDireitos autorais:

Formatos disponíveis

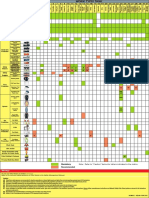

IACS URs and Panel Responsible

Page 1 of 13

UR Ax (Mooring and Anchoring)

UR Title Panel Responsible

A1 Equipment Hull

A2 Shipboard fittings and supporting hull structures

associated with towing and mooring on

conventional vessels

Hull

UR Cx (Container)

UR Title Panel Responsible

None to date

UR Dx (Mobile Offshore Drilling Units)

UR Title Panel Responsible

D1 Requirement concerning offshore drilling units and

other similar units

Hull (lead); Safety and

Survey may be

requested to assist the

lead Panel

D2 Definitions Hull (lead); Survey,

Machinery and Safety

Panels may be

requested to assist the

lead Panel

D3 General design parameters Hull (lead) Safety

Panel may be

requested to assist the

lead Panel

D4 Self-elevating drilling units Hull (lead) Safety

Panel may be

requested to assist the

lead Panel

D5 Column stabilized drilling units Hull (lead) Safety

Panel may be

requested to assist the

lead Panel

D6 Surface type drilling units Hull (lead) Safety

Panel may be

requested to assist the

lead Panel

D7 Watertight Integrity Safety

D8 Hazardous Areas Machinery

D9 Machinery Machinery

D10 Electrical installations Machinery

D11 Safety Features Safety

D12 Deleted

IACS URs and Panel Responsible

Page 2 of 13

UR Ex (Electrical Installations)

UR Title Panel Responsible

E1 Revised see M3.2

E2 Deleted

E3 Deleted

E4 Deleted

E5 Voltage and frequency variations Machinery

E6 Deleted

E7 Cables Machinery

E8 Deleted

E9 Earthing and bonding of cargo tanks/process

plant/piping systems for the control of static

electricity

Machinery

E10 Test specification for Type Approval Machinery

E11 Unified Requirements for Systems with voltages

above 1kV up to 15kV

Machinery

E12 Electrical equipment allowed in paint stores and in

the enclosed spaces leading to paint stores

Machinery

E13 Test requirements for rotating machines Machinery

E14 Not adopted, re-categorised as Rec.52

E15 Electrical services required to be operable under

fire conditions and fire resistant cables

Machinery

E16 Cable trays/protective casings made of plastic

materials

Machinery

E17 Generator and Generator systems, having the

ships propulsion machinery as their prime mover,

not forming part of the ships main source of

electrical power

Machinery

E18 Recording of the Type, Location and Maintenance

Cycle of Batteries

Machinery

E19 Ambient Temperature for Electrical Equipment

installed in environmentally controlled spaces

Machinery

E20 Installation of electrical and electronic equipment in

engine rooms protected by fixed water-based local

application fire-fighting systems (FWBLAFFS)

Machinery

E21 Requirements for uninterruptible power system

(UPS) units as alternative and/or transitional power

Machinery

E22 On Board Use And Application Of Programmable

Electronic Systems

Machinery

E23 Deleted Mar 2011

IACS URs and Panel Responsible

Page 3 of 13

UR Fx (Fire Protection)

UR Title Panel Responsible

F1 Cathodic protection on oil tanker Hull; EG/M&W to have

technical involvement

F2 Aluminium coating on board oil tankers and

chemical tankers

Hull; EG/M&W to have

technical involvement

F3 Tank cleaning openings Machinery

F4 Deleted

F5 Pump room alarms Safety

F6 Standardization of Flash Points Safety

F7 Portable instruments for measuring oxygen and

flammable vapour concentrations

Safety

F8 Pressurisation of cargo tanks Machinery

F9 Lighting and sighting ports in pump room/engine

room bulkheads - Deleted Dec 2013

Safety

F10 Deleted

F11 Deleted

F12 Deleted

F13 Gland seals in pump room bulkheads Machinery

F14 Deleted

F15 Piping passing through dangerous zones Machinery

F16 Bow and stern loading and unloading

arrangements on oil tankers

Machinery

F17 Deleted

F18 Deleted

F19 Deleted

F20 Inert gas system Machinery

F21 Pump room ventilation Safety

F22 Direct loading pipes to oil tanker cargo tanks Machinery

F23 Deleted

F24 Temperature of Steam and Heating Media within

the Cargo Area

Machinery

F25 Deleted

F26 Safety aspects of double bottoms and duct keels

under cargo oil tanks

Safety

F27 Cargo openings in the bottoms of topside tanks of

ships carrying alternatively oil and grain

Safety (lead); Hull may

be requested to assist

the lead Panel

F28 Deleted

F29 Non-sparking fans Machinery

F30 Deleted

F31 Deleted

F32 Fire detecting system for unattended machinery

spaces

Safety

F33 Prohibition of carriage in fore peak tanks of oil or

other liquid substances which are flammable

Safety

F34 Deleted J uly 2010

F35 Fire protection of machinery spaces Safety

F36 Deleted

F37 Re-categorised to Rec 53.1

F38 Re-categorised to Rec 53.2

F39 Deleted

F40 Deleted

IACS URs and Panel Responsible

Page 4 of 13

UR Title Panel Responsible

F41 Sea intakes for fire pumps on ships with ICE class Safety

F42 Fire testing of flexible pipes Safety

F43 Installation Requirements for analysing units for

continuous monitoring of flammable vapours

Machinery

F44 Fore peak ballast system on oil tankers Safety

IACS URs and Panel Responsible

Page 5 of 13

UR Gx (Gas Tankers)

UR Title Panel Responsible

G1 Cargo containment of gas tankers Hull (lead) Survey

and Machinery Panels

may be requested to

assist the lead Panel;

EG/M&W to have

technical involvement

G2 Liquified gas cargo tanks and process pressure

vessels

Machinery (lead)

Survey Panel may be

requested to assist the

lead Panel; EG/M&W

to have technical

involvement

G3 Liquefied gas cargo and process piping Machinery (lead)

Survey Panel may be

requested to assist the

lead Panel; EG/M&W

to have technical

involvement

G4 Re-categorised as Z16

UR Ix (Polar Class)

UR Title Panel Responsible

I1 Polar Class Descriptions and Application Hull; EG/M&W to have

technical involvement

I2 Structural Requirements for Polar Class Ships Hull; EG/M&W to have

technical involvement

I3 Machinery Requirements for Polar Class Ships Machinery; EG/M&W to

have technical

involvement

UR Kx (Propellers)

UR Title Panel Responsible

K1 Deleted

K2 Deleted

K3 Keyless Fitting of Propellers without Ice

Strengthening

Machinery

UR Lx (Load Line)

UR Title Panel Responsible

L1 Deleted

L2 Intact stability Matter of class Safety

L3 Deleted, re-categorised as Rec.60

L4 Closure of Chain Lockers Safety

L5 Onboard Computers for Stability Calculations Safety

IACS URs and Panel Responsible

Page 6 of 13

UR Mx (Machinery Installations)

UR Title Panel Responsible

M1 Deleted

M2 Alarm devices of internal combustion engines Machinery

M3 Speed governor and overspeed protective device Machinery

M4 Deleted

M5 Mass production of internal combustion engines,

procedure for inspection

Machinery

M6 Test pressures for parts of internal combustion

engines

Machinery

M7 Re-categorised as Rec.26

M8 Re-categorised as Rec.27

M9 Crankcase explosion relief valves for crankcases

of internal combustion engines

Machinery

M10 Protection of internal combustion engines against

crankcase explosions

Machinery

M11 Protective devices for starting air mains Machinery

M12 Fire extinguishing systems for scavenge manifolds Machinery

M13 Re-categorised as Rec.28

M14 Mass production of internal combustion engines:

definition of mass production

Machinery

M15 Re-categorised as Rec.29

M16 Devices for emergency operation of propulsion

steam turbines

Machinery

M17 Deleted

M18 Parts of internal combustion engines for which

material tests are required

Machinery; EG/M&W to

have technical

involvement

M19 Parts of internal combustion engines for which

nondestructive tests are required

Machinery; EG/M&W to

have technical

involvement

M20 Deleted

M21 Mass production of internal combustion engines:

type test conditions

Machinery

M22 No record

M23 Mass production of engines: mass produced

exhaust driven turboblowers

Machinery; EG/M&W to

have technical

involvement

M24 Requirements concerning use of crude oil or slops

as fuel for tanker boilers

Machinery

M25 Astern power for main propulsion Machinery

M26 Safety devices of steam turbines Machinery

M27 Bilge level alarms for unattended machinery

spaces

Machinery

M28 Ambient reference conditions Machinery

M29 Alarm systems for vessels with periodically

unattended machinery spaces

Machinery

M30 Safety Systems for vessels with periodically

unattended machinery spaces

Machinery

M31 Continuity of electrical power supply for vessels

with periodically unattended machinery spaces

Machinery

M32 Definition of diesel engine type Machinery

M33 Deleted

IACS URs and Panel Responsible

Page 7 of 13

UR Title Panel Responsible

M34 Scantlings of coupling flanges Machinery

M35 Alarms, remote indications and safeguards for

main reciprocating internal combustion engines

installed in unattended machinery spaces

Machinery

M36 Alarms and safeguards for auxiliary reciprocating

internal combustion engines driving generators in

unattended machinery spaces

Machinery

M37 Deleted

M38 Deleted

M39 Deleted

M40 Ambient conditions Temperatures Machinery

M41 Superseded by UR E10

M42 Steering gear Machinery

M43 Bridge control of propulsion machinery for

unattended machinery spaces

Machinery

M44 Documents for the approval of diesel engines Machinery

M45 Ventilation of Machinery Spaces Machinery

M46 Ambient conditions Inclinations Machinery

M47 Bridge control of propulsion machinery for

attended machinery spaces

Machinery

M48 Replaced by UR M68

M49 Merged with UR E8 to form UR M61

M50 Programme for type testing of nonmass produced

I.C. engines

Machinery

M51 Programme for trials of i.c. engines to assess

operational capability

Machinery

M52 Length of aft stern bush bearing Machinery

M53 Calculation of crankshafts for I.C. engines Machinery

M54 Deleted

M55 Deleted

M56 Marine gears Load capacity of involute parallel

axis spur and helical gears

Machinery

M57 Use of Ammonia as a Refrigerant Machinery

M58 Charge Air Coolers Machinery

M59 Control & Safety System for dual fuel diesel

engines

Machinery

M60 Control and Safety of Gas Turbines for Marine

Propulsion Use

Machinery

M61 Starting Arrangements of Internal Combustion

Engines

Machinery

M62 Rooms for emergency fire pumps in cargo ships Machinery

M63 Alarms and safeguards for emergency diesel

engines

Machinery

M64 Design of integrated cargo and ballast systems on

tankers

Machinery

M65 Draining and Pumping Forward Spaces in Bulk

Carriers

Machinery

M66 Type Testing Procedure for Crankcase Explosion

Relief Valves

Machinery

M67 Type Testing Procedure For Crankcase Oil Mist

Detection and Alarm Equipment

Machinery

IACS URs and Panel Responsible

Page 8 of 13

UR Title Panel Responsible

M68 Dimensions of propulsion shafts and their

permissible torsional vibration stresses

Machinery

M69 Qualitative Failure Analysis for Propulsion and

Steering on Passenger Ships

Machinery

IACS URs and Panel Responsible

Page 9 of 13

UR Nx (Navigation)

UR Title Panel Responsible

N1 One man bridge operated (OMBO) ships Safety

UR Px (Pipes and Pressure Vessels)

UR Title Panel Responsible

P1 Rules for pipes Machinery; EG/M&W to

have technical

involvement

P2 Rules for piping design, construction and testing Machinery; EG/M&W to

have technical

involvement

P3 Air pipe closing devices Machinery; EG/M&W to

have technical

involvement

P4 Production and Application of Plastic Pipes on

Ships

Machinery

P5 Deleted Apr 2011 Machinery

P6 Shell Type Exhaust Gas Heated Economizer That

May Be Isolated From The Steam Plant System

Machinery

IACS URs and Panel Responsible

Page 10 of 13

UR Sx (Strength of Ships)

UR Title Panel Responsible

S1 Requirements for Loading Conditions, Loading

Manuals and Loading Instruments

Hull

S1A Additional Requirements for Loading Conditions,

Loading Manuals and Loading Instruments for Bulk

Carriers, Ore Carriers and Combination Carriers

Hull

S2 Definition of ship's length L and of block coefficient

C

b

Hull

S3 Strength of end bulkheads of superstructures and

deckhouses

Hull

S4 Criteria for the use of high tensile steel with

minimum yield stress of 315 N/mm

2

, 355 N/mm

2

and 390 N/mm

2

Hull; EG/M&W to have

technical involvement

S5 Calculation of midship section moduli for

conventional ship for ship's scantlings

Hull

S6 Use of steel grades for various hull members-ships

of 90m in length and above

Hull; EG/M&W to have

technical involvement

S7 Minimum longitudinal strength standards Hull

S8 Bow doors and inner doors Hull

S9 Side shell doors and stern doors Hull

S10 Rudders, sole pieces and rudder horns Hull; EG/M&W to have

technical involvement

S11 Longitudinal strength standard Hull

S12 Side Structures in Single Side Skin Bulk Carriers Hull

S13 Strength of bottom forward in oil tankers Hull

S14 Testing Procedures of Watertight Compartments Hull

S15 Side shell doors and stern doors - Retrospective

application of UR-S9 to existing ro-ro passenger

ships

Hull

S16 Bow Doors and Inner Doors - Retrospective

Application of UR-S8, as amended to 1995, to

existing Ro-Ro Passenger Ships

Hull

S17 Longitudinal Strength of Hull Girder in flooded

condition for Bulk Carriers (Rev.7)

Hull

S18 Evaluation of Scantlings of Corrugated Transverse

Watertight Bulkheads in Bulk Carriers considering

hold flooding

Hull

S19 Evaluation of Scantlings of the transverse

watertight corrugated bulkhead between cargo

holds Nos. 1 and 2, with cargo hold No. 1 flooded,

for existing bulk carriers

Hull (lead), Survey

Panel may be

requested to assist the

lead Panel

S20 Evaluation of Allowable Hold Loading for Bulk

Carriers Considering Hold Flooding

Hull

S21 Evaluation of Scantlings of Hatch Covers and

Hatch Coamings of Cargo Holds of Bulk Carriers,

Ore Carriers and Combination Carriers (Rev.4)

Hull

S21A Evaluation of Scantlings of Hatch Covers and

Hatch Coamings and Closing Arrangements of

Cargo Holds of Ships

Hull

S22 Evaluation of Allowable Hold Loading of Cargo

Hold No.1 with Cargo Hold No.1 Flooded, for

existing bulk carriers

Hull (lead), Survey

Panel may be

requested to assist the

lead Panel

IACS URs and Panel Responsible

Page 11 of 13

UR Title Panel Responsible

S23 Implementation of IACS Unified Requirements S19

and S22 for Existing Single Side Skin Bulk Carriers

Hull (lead), Survey

Panel may be

requested to assist the

lead Panel

S24 Deleted

S25 Deleted May 2010

S26 Strength and securing of Small Hatches on the

Exposed Fore Deck

Hull (lead), Survey

Panel may be

requested to assist the

lead Panel

S27 Strength Requirements for Fore Deck Fittings and

Equipment

Hull (lead), Survey

Panel may be

requested to assist the

lead Panel

S28 Requirements for the Fitting of a Forecastle for

Bulk Carriers, Ore Carriers and Combination

Carriers

Hull

S29 No record

S30 Cargo Hatch Cover Securing Arrangements for

Bulk Carriers not Built in Accordance with UR

S21(Rev.3)

Hull (lead), Survey

Panel may be

requested to assist the

lead Panel

S31 Renewal Criteria for Side Shell Frames and

Brackets in Single Side Skin Bulk Carriers and

Single Side Skin OBO Carriers not Built in

accordance with UR S12 Rev.1 or subsequent

revisions

Hull (lead), Survey

Panel may be

requested to assist the

lead Panel

S32 Deleted May 2010

S33 Requirements for use of Extremely Thick Steel

Plates

Hull

IACS URs and Panel Responsible

Page 12 of 13

UR Wx (Materials and Welding)

UR Title Panel Responsible

W1 Materials and welding for gas tankers EG/M&W

W2 Test specimens and mechanical testing

procedures for materials

EG/M&W

W3 Deleted

W4 Deleted

W5 Deleted

W6 Deleted

W7 Hull and machinery steel forgings EG/M&W

W8 Hull and machinery steel castings EG/M&W

W9 Grey iron castings EG/M&W

W10 Spheroidal or nodular graphite iron castings EG/M&W

W11 Normal and higher strength hull structural steels EG/M&W; Hull to have

technical involvement

W12 Deleted

W13 Thickness tolerances of steel plates and wide flats EG/M&W; Hull to have

technical involvement

W14 Steel plates and wide flats with specified minimum

through thickness properties (Z quality)

EG/M&W; Hull to have

technical involvement

W15 Deleted

W16 High strength quenched and tempered steels for

welded structures

EG/M&W; Hull to have

technical involvement

W17 Approval of consumables for welding normal and

higher strength hull structural steels

EG/M&W

W18 Anchor Chain Cables and Accessories including

chafing chain for emergency towing arrangement

EG/M&W

W19 Deleted, superseded by UR W11

W20 Deleted, superseded by UR W11

W21 Deleted, superseded by UR W11

W22 Offshore Mooring Chain EG/M&W

W23 Approval of welding consumables for high strength

quenched and tempered steels for welded

structures

EG/M&W

W24 Cast Copper Alloy Propellers EG/M&W

W25 Aluminium Alloys for Hull Construction and Marine

Structure

EG/M&W; Hull to have

technical involvement

W26 Requirements for Welding Consumables for

Aluminium Alloys

EG/M&W

W27 Cast Steel Propeller EG/M&W

W28 Welding procedure qualification tests of steels for

hull construction and marine structures

EG/M&W; Hull to have

technical involvement

W29 Requirements for manufacture of anchors EG/M&W

W30 Normal and higher strength corrosion resistant

steels for cargo oil tanks

Hull

W31 Application of YP47 Steel Plates Hull

IACS URs and Panel Responsible

Page 13 of 13

UR Zx (Survey and Certification)

UR Title Panel Responsible

Z1 Annual and intermediate classification survey

coverage of IMO Resolution A.997(25) as

amended by IMO Resolution A.1020(26)

Survey

Z2 Deleted, Superseded by UR Z10.1

Z3 Periodical survey of the outside of the ship's

bottom and related items

Survey

Z4 Surveys of hatch covers and coamings,

Deleted May 2013

Survey

Z5 Deleted, Re-categorised as Rec.59

Z6 Continuous system for hull special survey Survey

Z7 Hull Classification Surveys Survey

Z7.1 Hull Surveys for General Dry Cargo Ships Survey

Z7.2 Hull Surveys for Liquefied Gas Carriers Survey

Z8 Corrosion protection coating for salt water ballast

spaces

Survey

Z9 Corrosion protection coatings for cargo hold

spaces on bulk carriers

Survey

Z10.1 Hull surveys of oil tankers Survey

Z10.2 Hull surveys of bulk carriers Survey

Z10.3 Hull surveys of chemical tankers Survey

Z10.4 Hull surveys of double hull oil tankers Survey

Z10.5 Hull Surveys of Double Skin Bulk Carriers Survey

Z10.6 Re-categorised as UR Z7.1

Z11 Mandatory ship type and Enhanced Survey

Programme (ESP) notations

Survey

Z12 Deleted

Z13 Voyage repairs and maintenance Survey; EG/M&W to

have technical

involvement

Z14 No record

Z15 Hull, Structure, Equipment and Machinery Surveys

of Mobile Offshore Drilling Units

Survey

Z16 Periodical Surveys of Cargo Installations on ships

carrying liquefied gases in bulk

Survey

Z17 Procedural requirements for service suppliers Survey

Z18 Periodical Survey of Machinery Survey

Z19 Calibration of Measuring Equipment Survey

Z20 Planned Maintenance Scheme (PMS) for

Machinery

Survey

Z21 Surveys of Propeller Shafts and Tube Shafts Survey

Z22 Survey Requirements for Automatic Air Pipe

Heads

Survey

Z23 Hull Survey for New Construction Survey; EG/M&W to

have technical

involvement

Z24 Survey Requirements for Shell and Inner Doors

of Ro-Ro Ships

Survey

Você também pode gostar

- PPE MatrixDocumento1 páginaPPE MatrixIvan Barkagan100% (3)

- RTCA/DO-160 Testing PMA PartsDocumento15 páginasRTCA/DO-160 Testing PMA Partsfrdgsdfgsdfg100% (1)

- Witherby Seamanship2014 PDFDocumento92 páginasWitherby Seamanship2014 PDFDinesh Dangri100% (1)

- ABS - Special SurveyDocumento16 páginasABS - Special SurveyprasetyoAinda não há avaliações

- Ship Building MaterialsDocumento31 páginasShip Building MaterialsgirishAinda não há avaliações

- Procedure For Internal AuditDocumento3 páginasProcedure For Internal AuditVu Tung Linh100% (1)

- Procedure For Internal AuditDocumento3 páginasProcedure For Internal AuditVu Tung Linh100% (1)

- LPG Co-MinglingDocumento17 páginasLPG Co-MinglingderhgawenrahulAinda não há avaliações

- OCIMF Ship - Shore Safety Check List GuidelinesDocumento19 páginasOCIMF Ship - Shore Safety Check List Guidelinesgpabelenda100% (1)

- PSPC Ballast Tank IACS Procedural Requirments PDFDocumento4 páginasPSPC Ballast Tank IACS Procedural Requirments PDFGhoozyAinda não há avaliações

- IACS requirements for materials and welding for gas tankersDocumento247 páginasIACS requirements for materials and welding for gas tankersDenny AgusAinda não há avaliações

- Hull Coating BreakdownDocumento18 páginasHull Coating Breakdownswapneel_kulkarniAinda não há avaliações

- TB Rule Reference Original 1st January 2014 Issue Pdf2304Documento385 páginasTB Rule Reference Original 1st January 2014 Issue Pdf2304Carmen IchimAinda não há avaliações

- REGULATIONS FOR SHIPSDocumento62 páginasREGULATIONS FOR SHIPSBasong SanAinda não há avaliações

- 561 NR - 2022 11Documento72 páginas561 NR - 2022 11ENG PTBBSAinda não há avaliações

- Imo-Pspc - Abg (54K Bulk Carrier) - 2Documento112 páginasImo-Pspc - Abg (54K Bulk Carrier) - 2Tanmay Gor100% (1)

- Hull Survey MethodsDocumento21 páginasHull Survey MethodsSanta Clara100% (2)

- Good Maintenance On Board ShipsDocumento94 páginasGood Maintenance On Board ShipsTaner AkciğerAinda não há avaliações

- ABS Inspection Grading CriteriaDocumento64 páginasABS Inspection Grading Criteriapescarra100% (1)

- Deck Maintenance - 1Documento18 páginasDeck Maintenance - 1SIDDHARTH MOHANTYAinda não há avaliações

- 4 Preparation For InspectionDocumento16 páginas4 Preparation For InspectionG.O.D 7Ainda não há avaliações

- SURVEY REQUIREMENTS FOR CLASSIFICATION SOCIETIESDocumento573 páginasSURVEY REQUIREMENTS FOR CLASSIFICATION SOCIETIESkoib789Ainda não há avaliações

- 06 Surveys and DrydockDocumento5 páginas06 Surveys and DrydockLucky BoatAinda não há avaliações

- Ship Structures IDocumento279 páginasShip Structures IHermawan SainiAinda não há avaliações

- RINA Academy technical courses for naval ships personnelDocumento24 páginasRINA Academy technical courses for naval ships personnelmaria_bustelo_2Ainda não há avaliações

- Shipbuilding PipingDocumento36 páginasShipbuilding PipingSurajPowarAinda não há avaliações

- ABS Rules & USCG Requirements for Int'l Steel VesselsDocumento115 páginasABS Rules & USCG Requirements for Int'l Steel Vesselsluckystrike9008100% (1)

- Ships in Service Survey Report: DRB0/2012/J0251Documento31 páginasShips in Service Survey Report: DRB0/2012/J0251Efthymios LouridasAinda não há avaliações

- Effects of PSPC on Shipbuilding Industry CostsDocumento15 páginasEffects of PSPC on Shipbuilding Industry CostsdineshbankarAinda não há avaliações

- ABS Construction SurveyDocumento15 páginasABS Construction SurveyMilandro Lou AcuzarAinda não há avaliações

- Harmonized System of Survey and Certification (HSSC)Documento7 páginasHarmonized System of Survey and Certification (HSSC)Prem PrakashAinda não há avaliações

- LLoyd's Register Final Survey of MV ConfederationDocumento24 páginasLLoyd's Register Final Survey of MV ConfederationThe GuardianAinda não há avaliações

- NOx Questions and Answers July 02 PDFDocumento27 páginasNOx Questions and Answers July 02 PDFMannMannAinda não há avaliações

- Marine Energy ConversionDocumento64 páginasMarine Energy Conversionsachu chandranAinda não há avaliações

- Marine Engineering Bedplates and ChocksDocumento13 páginasMarine Engineering Bedplates and Chocksdeevan rajAinda não há avaliações

- USCG SFLCStdSpec8634-2014Documento67 páginasUSCG SFLCStdSpec8634-2014ssAinda não há avaliações

- Pipeline Welding SpecificationDocumento35 páginasPipeline Welding Specificationyehia100% (1)

- Weld failures in ships and the loss of lifeDocumento53 páginasWeld failures in ships and the loss of lifeswapneel_kulkarni100% (4)

- HSSC (Harmonized System of Survey & Certification) : Class:-Chief Mates Phase IDocumento40 páginasHSSC (Harmonized System of Survey & Certification) : Class:-Chief Mates Phase ISankaran PanchanathanAinda não há avaliações

- Ship Inspection Form F P - R: 1. G I / S DDocumento6 páginasShip Inspection Form F P - R: 1. G I / S DRonachai FuangfoongAinda não há avaliações

- Hull Survey for New Construction DocumentationDocumento43 páginasHull Survey for New Construction Documentationheinz billAinda não há avaliações

- Rules For Classification of Sea-Going Steel Ships Amendments 2020 20200612Documento275 páginasRules For Classification of Sea-Going Steel Ships Amendments 2020 20200612Muhammad Ikhwan KurniawanAinda não há avaliações

- Report On The Surveys Concerning International Oil Pollution Prevention CertificateDocumento3 páginasReport On The Surveys Concerning International Oil Pollution Prevention CertificateSUNILAinda não há avaliações

- Allowable Thickness Diminution For Hull StructuresDocumento13 páginasAllowable Thickness Diminution For Hull Structuresjstoute100% (1)

- Osv Class AbsDocumento40 páginasOsv Class AbsAhmad ImranAinda não há avaliações

- MT Mosunmola Stern Tube Seal Service Report FinalDocumento10 páginasMT Mosunmola Stern Tube Seal Service Report FinalNevzat AlkoçAinda não há avaliações

- NM 409 Marine Transmission and Propulsion Systems PDFDocumento3 páginasNM 409 Marine Transmission and Propulsion Systems PDFtoshugoAinda não há avaliações

- Fire Types: Image Description Europe (EN 2) United States Asia Suitable SuppressionDocumento1 páginaFire Types: Image Description Europe (EN 2) United States Asia Suitable SuppressionBatak LegendsAinda não há avaliações

- Marine Standards IACSDocumento8 páginasMarine Standards IACSAbhinav OjhaAinda não há avaliações

- Marine Survey Practice - Notes Relative To Shell and Deck Plate RepairsDocumento3 páginasMarine Survey Practice - Notes Relative To Shell and Deck Plate RepairsJym GensonAinda não há avaliações

- Introduction To Load Line Survey - Ass2014Documento77 páginasIntroduction To Load Line Survey - Ass2014septian aji dewangkaraAinda não há avaliações

- 390Documento129 páginas390Moe LattAinda não há avaliações

- Welding Handbook Maritime UnitorDocumento552 páginasWelding Handbook Maritime UnitorPeter BournelisAinda não há avaliações

- Southern Marine Engineering Desk Reference: Second Edition Volume INo EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IAinda não há avaliações

- E FuchsDocumento48 páginasE FuchsMartin SinagaAinda não há avaliações

- Checklist For Explosion-Proof GearmotorDocumento10 páginasChecklist For Explosion-Proof Gearmotormarius_brkt6284Ainda não há avaliações

- Introduction To A380 ARFFDocumento48 páginasIntroduction To A380 ARFFszilvascribdAinda não há avaliações

- Trex 50428Documento148 páginasTrex 50428OSDocs2012Ainda não há avaliações

- Explosion Proof Motor CatalogDocumento152 páginasExplosion Proof Motor CatalogBudy AndikaAinda não há avaliações

- Hal ReportDocumento14 páginasHal Reportamer_maassAinda não há avaliações

- 2009 MODU Code A.1023Documento148 páginas2009 MODU Code A.1023Praveen BalachandranAinda não há avaliações

- LS ManridersDocumento8 páginasLS ManridersAnonymous 48jYxR1CAinda não há avaliações

- Rec ListDocumento8 páginasRec ListmusebladeAinda não há avaliações

- WEG Three Phase Flameproof Motors w22x and Bfgc4 Series Technical European Market 125.71 Brochure EnglishDocumento202 páginasWEG Three Phase Flameproof Motors w22x and Bfgc4 Series Technical European Market 125.71 Brochure EnglishVishal NarkhedeAinda não há avaliações

- 7 Most Common Motor Enclosure Types Defined by NEMA StandardsDocumento8 páginas7 Most Common Motor Enclosure Types Defined by NEMA StandardsjcarloscuscAinda não há avaliações

- Master's SMS Review Report SummaryDocumento3 páginasMaster's SMS Review Report Summaryoto saviour100% (1)

- Photographs of Deficiencies identified during Port State ControlDocumento57 páginasPhotographs of Deficiencies identified during Port State ControlVu Tung Linh100% (1)

- Guidelines Low Load HFODocumento11 páginasGuidelines Low Load HFOVu Tung Linh100% (1)

- Ballast Water Exchange Procedure APPROVED by DNVDocumento93 páginasBallast Water Exchange Procedure APPROVED by DNVVu Tung LinhAinda não há avaliações

- DMLCIIDocumento2 páginasDMLCIIVu Tung LinhAinda não há avaliações

- Bridge Equipment Due - Jan 2017Documento8 páginasBridge Equipment Due - Jan 2017Vu Tung LinhAinda não há avaliações

- HT - 02 Procedure For Organisation, ResponsibilitiesDocumento17 páginasHT - 02 Procedure For Organisation, ResponsibilitiesVu Tung Linh100% (1)

- Maintaining Ship Safety and ComplianceDocumento94 páginasMaintaining Ship Safety and CompliancecriAinda não há avaliações

- Audit Status For CompanyDocumento2 páginasAudit Status For CompanyVu Tung LinhAinda não há avaliações

- AE 5L16-24 Fuel TimingDocumento1 páginaAE 5L16-24 Fuel TimingVu Tung LinhAinda não há avaliações

- Ballast Water Exchange ProcedureDocumento4 páginasBallast Water Exchange ProcedureVu Tung LinhAinda não há avaliações

- Panama Canal UMS and InstructionDocumento3 páginasPanama Canal UMS and InstructionVu Tung LinhAinda não há avaliações

- Ballast Water Exchange ProcedureDocumento4 páginasBallast Water Exchange ProcedureVu Tung LinhAinda não há avaliações

- Safety EquipmentDocumento10 páginasSafety EquipmentVu Tung LinhAinda não há avaliações

- PortDocumento5 páginasPortVu Tung LinhAinda não há avaliações

- Ballast Management Plan Approval by ABSDocumento3 páginasBallast Management Plan Approval by ABSVu Tung LinhAinda não há avaliações

- Fleet Broadband Users ManualDocumento250 páginasFleet Broadband Users ManualMarkAinda não há avaliações

- Ballast Water Exchange Procedure APPROVED by DNVDocumento93 páginasBallast Water Exchange Procedure APPROVED by DNVVu Tung LinhAinda não há avaliações

- MOT-No 168 PDFDocumento9 páginasMOT-No 168 PDFVu Tung LinhAinda não há avaliações

- Isle of Man Official Log Book and List of Crew Required Entries, Format and GuidanceDocumento28 páginasIsle of Man Official Log Book and List of Crew Required Entries, Format and GuidanceVu Tung LinhAinda não há avaliações

- PROCEDURE COMMUNICATIONDocumento2 páginasPROCEDURE COMMUNICATIONVu Tung Linh100% (1)

- MSC.1-Circ.1235 - Guidelines On Security-Related Training and Familiarization For Shipboard Personnel (Secretariat)Documento8 páginasMSC.1-Circ.1235 - Guidelines On Security-Related Training and Familiarization For Shipboard Personnel (Secretariat)Vu Tung LinhAinda não há avaliações

- Shipboard Maintenance PolicyDocumento1 páginaShipboard Maintenance PolicyVu Tung LinhAinda não há avaliações

- MSC.1-Circ.1030 - Guidance For Port State Control Officers On Issues Related To Certificates of Competency (Secretariat)Documento1 páginaMSC.1-Circ.1030 - Guidance For Port State Control Officers On Issues Related To Certificates of Competency (Secretariat)Vu Tung LinhAinda não há avaliações

- Procedure For Crew ChangeDocumento5 páginasProcedure For Crew ChangeVu Tung Linh100% (1)

- ALLSEA DMCC Underkeel Clearance PolicyDocumento1 páginaALLSEA DMCC Underkeel Clearance PolicyVu Tung LinhAinda não há avaliações

- Cyber Security PolicyDocumento1 páginaCyber Security PolicyVu Tung LinhAinda não há avaliações

- Energy Management PolicyDocumento1 páginaEnergy Management PolicyVu Tung LinhAinda não há avaliações

- Manifold of A Gas TankerDocumento17 páginasManifold of A Gas Tankerana serna100% (1)

- Pdf1610 TMPDocumento12 páginasPdf1610 TMPTimmyJuriAinda não há avaliações

- MSC 1151-1175 PDFDocumento255 páginasMSC 1151-1175 PDFCostinRotaruAinda não há avaliações

- LNG AnswersDocumento4 páginasLNG AnswersSanjiv KumarAinda não há avaliações

- Seaborne EthaneDocumento27 páginasSeaborne EthaneAnonymous icnhaNsFAinda não há avaliações

- INSG Nandgi July22Documento10 páginasINSG Nandgi July22candymaluAinda não há avaliações

- Matrix PersyaratanDocumento28 páginasMatrix Persyaratanadrian pratamaAinda não há avaliações

- Sigtto Publications Catalogue July 2021Documento52 páginasSigtto Publications Catalogue July 2021Thanh Quynh PhamAinda não há avaliações

- LPG Tanker Practice Hyproc SCDocumento128 páginasLPG Tanker Practice Hyproc SCIlyes ArAinda não há avaliações

- ICS Class Updates Survey RequirementsDocumento4 páginasICS Class Updates Survey RequirementsArunkumar MuthukrishnanAinda não há avaliações

- 2nd Mate Past Question Papers Till Nov18 1Documento143 páginas2nd Mate Past Question Papers Till Nov18 1arbaazAinda não há avaliações

- Rules of Ships in OperationDocumento85 páginasRules of Ships in OperationJagmohan SinghAinda não há avaliações

- FGCE TTP GuideDocumento230 páginasFGCE TTP Guidemouloud miloudAinda não há avaliações

- Ammonia As A Marine Fuel Safety HandbookDocumento25 páginasAmmonia As A Marine Fuel Safety HandbookPhan Anh Duong100% (1)

- Newswave2015 02Documento10 páginasNewswave2015 02Juan Manuel JorqueraAinda não há avaliações

- 8 Major Types of Cargo Transported Through The Shipping IndustryDocumento10 páginas8 Major Types of Cargo Transported Through The Shipping IndustryGiorgi KandelakiAinda não há avaliações

- Carriage of Liquefied GasesDocumento7 páginasCarriage of Liquefied Gasesrajee7Ainda não há avaliações

- LNG Bunkering CaseStudyDocumento11 páginasLNG Bunkering CaseStudysaubu8xAinda não há avaliações

- 2016 So Las CompleteDocumento76 páginas2016 So Las CompleteJohn MondalaAinda não há avaliações

- CV Marine Surveyor 2020Documento9 páginasCV Marine Surveyor 2020Yazid MananAinda não há avaliações

- Marine Law and Management An Introduction (DF0LJ34)Documento145 páginasMarine Law and Management An Introduction (DF0LJ34)Merchant NavyAinda não há avaliações

- Ship TankerDesignDocumento103 páginasShip TankerDesignmariodalAinda não há avaliações

- NEW IGC CODE AND IGF CODE SAFETY ASPECTSDocumento33 páginasNEW IGC CODE AND IGF CODE SAFETY ASPECTSKaran Doshi100% (1)

- Guide For Vessels Intended To Carry Compressed Natural Gases in Bulk 2020Documento235 páginasGuide For Vessels Intended To Carry Compressed Natural Gases in Bulk 2020EIRINI KONDYLIAinda não há avaliações

- Btlgtco Questions & Answers - Clyde DmelloDocumento15 páginasBtlgtco Questions & Answers - Clyde DmelloKennen LasradoAinda não há avaliações

- Tanker Familiarization CourseDocumento149 páginasTanker Familiarization CourseANDREW1318100% (2)