Escolar Documentos

Profissional Documentos

Cultura Documentos

IS10

Enviado por

FranzKafkaDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

IS10

Enviado por

FranzKafkaDireitos autorais:

Formatos disponíveis

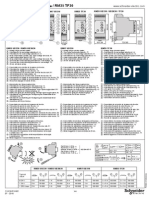

Pressure switch

with spacer

Pressure switch

with piping adapter

Pressure switch

Lubricator

Regulator Air filter

Series IS10

Pressure Switch/Reed Switch Type

0.1

to

0.4

5

Can be connected

to Modular type

F.R.L. units.

Specifications

Model IS10-01

Air/Inert gas

1.0 MPa

0.7 MPa

5 to 60C (No freezing)

1a

0.05 MPa or less

Fixed 0.08 MPa or less

0.05 MPa or less

Equivalent to IP40

1/8

62 g

Fluid

Proof pressure

Max. operating pressure

Set pressure range

Ambient and fluid temperature

Contacts

Error of scale

Hysteresis

Repeatability

Wiring specifications

Enclosure

Port size

Weight

Switch Characteristics

AC 2 A, DC 2 W

24 V or less

50 mA

48 V

40 mA

100 V

20 mA

Max. contact capacity

Voltage AC/DC

Max. operating current and range

Electrical Circuit

JIS Symbol

Up to 100 V AC/DC

R

e

e

d

s

w

i

t

c

h

Set Pressure Range

ON pressure OFF pressure

1

5

m

m

2

3

m

m

5

2

m

m

11% smaller

Overall height: 52mm

Previous type 58.5 mm

Compared with IS1000

(Made by SMC)

16% lighter

Weight: 62g

Previous type 74 g

Compared with IS1000

(Made by SMC)

0.1 to 0.4 MPa

Option: 0.1 to 0.6 MPa

Grommet, Lead wire length: 0.5 m

Option: 3 m, 5 m

0.1 0.2 0.3 0.4

0

0.5

Set pressure scale (MPa)

O

p

e

r

a

t

i

n

g

p

r

e

s

s

u

r

e

(

M

P

a

)

0.4

0.3

0.2

0.1

H

y

s

t

e

r

e

s

i

s

How to Order

IS10 01

q e w

+

+

+

+

Description Symbol

Nil

N

Nil

S

Thread type

Seal

Nil

6

Note1)

Set pressure

range

Nil

L

Z

Nil

P

Note2)

Lead wire

length

Scale plate

pressure unit

Rc

NPT

None

With seal

0.1 to 0.4 MPa

0.1 to 0.6 MPa

0.5 m

3 m

5 m

MPa

Both MPa and psi

a

b

c

q

w

q

w

qe

Semi-standard: Select one

option each in a through c.

Place them in alphanumerical

order.

Example) IS10-N01-6PZ

S

e

m

i

-

s

t

a

n

d

a

r

d

Note 1)

Note 2)

New

New

RoHS

CAT.ES60-19A

100 V AC/DC

specifications

Set pressure range

0.1

to

0.4

MPa

Service life:

5

million cycles

1

5

m

m

2

3

m

m

5

2

m

m

Set pressure range of

6P(L, Z) is 0.2 to 0.6

MPa (30 to 90 psi).

This product is for

overseas use only

according to the new

Measurement Law. (The

SI unit type is provided

for use in Japan.)

Part no.

CD-P11

CD-P12

Voltage

100 V AC

24 V DC

Lead wire length

Switch side: 0.5 m

Load side: 0.5 m

Brown lead wire

Blue lead wire

Choke coil

Surge

absorber

CD-P11

(+) Brown lead wire

() Blue lead wire

Choke coil

Capacitor

Resistor

CD-P12

1/8

0.2

0.4

0.1

0.3

MPa

(

5

0

0

0

)

(

3

0

0

0

)

(

5

0

0

)

15 23

5

2

4

4

(

2

3

)

(

1

3

)

r

e

q

w

t

!0

o

!2

i

u

!1

y

Dimensions/Construction

Component Parts

Body

Switch assembly

Shield plate

Cover

Adjusting screw

Hexagon nut

Indicator

Spring

Magnet

Piston

Seal piston

Scale plate

No. Description Material

1

2

3

4

5

6

7

8

9

10

11

12

ZDC

Steel sheet

Steel sheet

Brass

Brass

PBT

Stainless steel

POM

NBR

PC

Wiring

Warning

Connect load before connecting with power

source.

The switch will break instantly if no load is

connected.

Make the wiring length as short as

possible. When the load which is

operated by the pressure switch is an

inductive load, or the lead wire is 5 m or

longer, use the contact protection box

shown in the table below.

Otherwise, damage to the switch can result.

1.

2.

When handling the product, hold the body and do

not apply tensile stress to the power supply cable.

Otherwise, damage may occur to the product.

Avoid repeatedly bending or stretching the lead wire.

Wiring which applies repeated bending and tensile

stress to the lead wire can break the circuit. If the

lead wire is damaged, causing operation failure,

replace the product with a new one.

Do not drop or bump the product when

handling the product.

Apply a wrench to the bottom of the

product when screwing.

Turning it by applying a wrench on the top of the

main body may cause damage to the product.

Recommended tightening torque: 7 to 9 Nm

Internal circuit of contact protection box

How to connect contact protection box

Connect the lead wires from the body and the

contact protective box side indicated

SWITCH. Make the lead wire as short as

possible, within 1 m.

Dimensions of lead wire

Enclosure: 3.4

Insulator: 1.1

Conductor: 0.64

3.

Mounting

Warning

Operating fluids are either air or inert gas

exclusively.

Never use other fluids. Never use in an

environment where flammable fluid or gas

is used. Since this is not an explosion-

proof construction, it may lead to an

explosive disaster.

Not applicable to corrosive gas and liquid.

Otherwise, damage to the body or liquid

leakage can result.

Avoid use in vacuum applications.

Switch may be imploded.

This product (Series IS10) uses a reed

switch. If the chattering of the output

signal is a problem, choose a solid state

type pressure switch or adjust by PLC.

Set within the display pressure range of

the scale plate.

The pressure can be adjusted by rotating the

adjustment screw. The red indicator goes up

and down according to the adjustment.

Rotate the screw clockwise for high pressure.

Use a screwdriver of a size suitable for

the groove of the adjustment screw.

Scale of switching set display is the set

value at the pressure drop.

The ON signal is output through the pressure set

on the scale plate, to which the hysteresis is

added for detecting the ON-pressure signal.

The pressure displayed on the scale plate

is a guideline only.

Measure the accurate pressure with the pressure gauge.

Warning

Pressure Source

Operating Environment

Warning

Pressure Setting

Warning

Caution

For details, refer to the operation manual.

Avoid using a switch in a magnetic environment.

It may cause a malfunction.

Do not use in such an environment, where water

or oil is splashed.

Since it is the open type construction, if

water or oil make an ingress into the internal

parts, the electric circuit will be corroded and

may result in a malfunction or damage.

Avoid vibration.

Vibration may cause a malfunction or may

cause setting to be incorrect.

1

Series IS10

Mounting direction is available in either

horizontal or perpendicular.

1.

2.

3.

4.

5.

1.

2.

3.

1.

2.

3.

4.

1.

1.

2.

3.

4.

5.

IS10M-20

IS10M-30

IS10M-40

IS10M-50

IS10M-60

Model

AC20

AC25, AC30

AC40

AC40-06

AC50, AC55, AC60

Applicable model A

11

13

15

17

22

B

74

85

93

97

91

C

61

67

72

75

64

D

28

30

36

44

53

Note) Prepare a spacer separately for modular connection.

30

Pressure Switch with Spacer

IS10E 30 03

Pressure Switch with Piping Adapter

Pressure switch with piping adapter

Left Right

IS10M

0.2

0.4

0.1

0.3

MPa

A D

C

B

15 23

(

5

0

0

0

)

(

3

0

0

0

)

(

5

0

0

)

(

2

3

)

(

1

3

)

Port size

0.2

0.4

0.1

0.3

MPa

C

B

A D

(

1

3

)

(

2

3

)

(

5

0

0

0

)

(

3

0

0

0

)

(

5

0

0

)

E 23

Note 1)

Note 2)

Note 3)

Model

IS10E-2001

IS10E-2002

IS10E-2003

IS10E-3002

IS10E-3003

IS10E-3004

IS10E-4002

IS10E-4003

IS10E-4004

IS10E-4006

Port size

1/8

1/4

3/8

1/4

3/8

1/2

1/4

3/8

1/2

3/4

Applicable model

Note 2)

AC40

AR40, AW40

AWM40, AWD40

A

30

32

32

B

66

73

79

C

52

56

58

D

28

30

37

E

16

13

13

AC20

AR20, AW20

AWM20, AWD20

AC25, AC30

AR25, AR30, AW30

AWM30, AWD30

Pressure switch

Lubricator

Regulator

Filter regulator

Air filter

Pressure Switch for Connecting to Modular/F.R.L. Units

For details, refer to Modular/F.R.L. Units, Series AC in Best Pneumatics No.5.

q w

Semi-standard: Select one option each in a through c.

Place them in alphanumerical order.

Example) IS10M-6LP

q w e r

Semi-standard: Select one option each in a through d.

Place them in alphanumerical order.

Example) IS10E-30N03-6PRZ

Note 1) For thread type: NPT only.

This product is for overseas use only according to the new

Measurement Law. (The SI unit type is provided for use in Japan.)

Note 2) Set pressure range of 6P(L, Z) is 0.2 to 0.6 MPa (30 to 90 psi).

Note 1)

Note 2)

JIS Symbol

JIS Symbol

a

c

b

S

e

m

i

-

s

t

a

n

d

a

r

d

+

+

Description

0.1 to 0.4 MPa

0.1 to 0.6 MPa

MPa

Both MPa and psi

Symbol

Nil

6

Note 1)

Nil

P

Note 2)

Nil

L

Z

Set pressure

range

Scale plate

pressure unit

Lead wire

length

0.5 m

3 m

5 m

30 40 20

50 60

Body size

a

c

d

b

S

e

m

i

-

s

t

a

n

d

a

r

d

+

+

+

+

+

Description

0.1 to 0.4 MPa

0.1 to 0.6 MPa

1/8

1/4

3/8

1/2

3/4

Rc

NPT

G

MPa

Both MPa and psi

Right

Left

Symbol

Nil

6

Note 2)

01

02

03

04

06

Nil

N

F

Nil

P

Note 1)

Nil

R

Nil

L

Z

Set pressure

range

Port size

Thread type

Scale plate

pressure unit

Mounting

position

Lead wire

length

0.5 m

3 m

5 m

30 40 20

Body size

2

Pressure Switch

Reed Switch Type

w

e

r

q

w

q

Series IS10

in the model numbers indicates a thread type. No indication is necessary for Rc;

however, indicate N for NPT, and F for G.

Cannot be mounted to the AC40-06 and AW40-06.

Prepare a spacer separately for modular connection.

The pressure switch can be mounted on the AC40-06 and above and the AW40-06 by screwing the IS10-01

into the piping adapter E500-06-X051 or E600-06-X501 to E600-10-X501 (Rc1/8 threaded on top surface).

Products with a premounted switch are available as a special order. Please contact SMC beforehand.

Set pressure range of 6P(L, Z) is 0.2 to 0.6 MPa (30 to 90 psi).

This product is for overseas use only according to the new

Measurement Law. (The SI unit type is provided for use in Japan.)

Safety Instructions Be sure to read Handling Precautions for SMC Products (M-E03-3) and operation manual before using.

Akihabara UDX 15F,

4-14-1, Sotokanda, Chiyoda-ku, Tokyo 101-0021, JAPAN

Phone: 03-5207-8249 Fax: 03-5298-5362

URL http://www.smcworld.com

2010 SMC Corporation All Rights Reserved

Specifications are subject to change without prior notice

and any obligation on the part of the manufacturer.

1st printing OT printing OT 7150SZ Printed in Japan. D-KS

1. The compatibility of the product is the responsibility of the

person who designs the equipment or decides its

specifications.

Since the product specified here is used under various operating

conditions, its compatibility with specific equipment must be decided by

the person who designs the equipment or decides its specifications

based on necessary analysis and test results. The expected performance

and safety assurance of the equipment will be the responsibility of the

person who has determined its compatibility with the product. This person

should also continuously review all specifications of the product referring

to its latest catalog information, with a view to giving due consideration to

any possibility of equipment failure when configuring the equipment.

2. Only personnel with appropriate training should operate

machinery and equipment.

The product specified here may become unsafe if handled incorrectly.

The assembly, operation and maintenance of machines or equipment

including our products must be performed by an operator who is

appropriately trained and experienced.

3. Do not service or attempt to remove product and

machinery/equipment until safety is confirmed.

1. The inspection and maintenance of machinery/equipment should only

be performed after measures to prevent falling or runaway of the

driven objects have been confirmed.

2. When the product is to be removed, confirm that the safety measures

as mentioned above are implemented and the power from any

appropriate source is cut, and read and understand the specific

product precautions of all relevant products carefully.

3. Before machinery/equipment is restarted, take measures to prevent

unexpected operation and malfunction.

4. Contact SMC beforehand and take special consideration of

safety measures if the product is to be used in any of the

following conditions.

1. Conditions and environments outside of the given specifications, or use

outdoors or in a place exposed to direct sunlight.

2. Installation on equipment in conjunction with atomic energy, railways,

air navigation, space, shipping, vehicles, military, medical treatment,

combustion and recreation, or equipment in contact with food and

beverages, emergency stop circuits, clutch and brake circuits in press

applications, safety equipment or other applications unsuitable for the

standard specifications described in the product catalog.

3. An application which could have negative effects on people, property,

or animals requiring special safety analysis.

4. Use in an interlock circuit, which requires the provision of double

interlock for possible failure by using a mechanical protective function,

and periodical checks to confirm proper operation.

Warning

Limited warranty and Disclaimer/

Compliance Requirements

The product used is subject to the following Limited warranty and

Disclaimer and Compliance Requirements.

Read and accept them before using the product.

1. The product is provided for use in manufacturing industries.

The product herein described is basically provided for peaceful use in

manufacturing industries.

If considering using the product in other industries, consult SMC

beforehand and exchange specifications or a contract if necessary.

If anything is unclear, contact your nearest sales branch.

Caution

Limited warranty and Disclaimer

1. The warranty period of the product is 1 year in service or 1.5

years after the product is delivered.

2)

Also, the product may have specified durability, running distance or

replacement parts. Please consult your nearest sales branch.

2. For any failure or damage reported within the warranty period which is

clearly our responsibility, a replacement product or necessary parts will

be provided.

This limited warranty applies only to our product independently, and not

to any other damage incurred due to the failure of the product.

3. Prior to using SMC products, please read and understand the warranty

terms and disclaimers noted in the specified catalog for the particular

products.

2) Vacuum pads are excluded from this 1 year warranty.

A vacuum pad is a consumable part, so it is warranted for a year after it is

delivered.

Also, even within the warranty period, the wear of a product due to the use of

the vacuum pad or failure due to the deterioration of rubber material are not

covered by the limited warranty.

Compliance Requirements

1. The use of SMC products with production equipment for the manufac-

ture of weapons of mass destruction (WMD) or any other weapon is

strictly prohibited.

2. The exports of SMC products or technology from one country to

another are governed by the relevant security laws and regulations of

the countries involved in the transaction. Prior to the shipment of a

SMC product to another country, assure that all local rules governing

that export are known and followed.

These safety instructions are intended to prevent hazardous situations and/or

equipment damage. These instructions indicate the level of potential hazard with

the labels of Caution,Warningor Danger. They are all important notes for

safety and must be followed in addition to International Standards (ISO/IEC)

1)

,

and other safety regulations.

1) ISO 4414: Pneumatic fluid power General rules relating to systems.

ISO 4413: Hydraulic fluid power General rules relating to systems.

IEC 60204-1: Safety of machinery Electrical equipment of machines.

(Part 1: General requirements)

ISO 10218-1: Manipulating industrial robots - Safety.

etc.

Caution indicates a hazard with a low level of risk

which, if not avoided, could result in minor or

moderate injury.

Warning indicates a hazard with a medium level of

risk which, if not avoided, could result in death or

serious injury.

Caution:

Warning:

Danger :

Danger indicates a hazard with a high level of risk

which, if not avoided, will result in death or serious

injury.

Safety Instructions

Você também pode gostar

- FLIR - Food Monitoring PDFDocumento4 páginasFLIR - Food Monitoring PDFDavis CahuaAinda não há avaliações

- Dgpne96 Ep01 PDFDocumento48 páginasDgpne96 Ep01 PDFoki121Ainda não há avaliações

- 266 XSH Ueberdruck Absolutdruck Differenzdruck MessumformerDocumento20 páginas266 XSH Ueberdruck Absolutdruck Differenzdruck MessumformerFranzKafkaAinda não há avaliações

- Vacuum Filters for Medical Non-Sanitary Areas Under 40 CharactersDocumento1 páginaVacuum Filters for Medical Non-Sanitary Areas Under 40 CharactersFranzKafkaAinda não há avaliações

- PLC ProgrammingDocumento116 páginasPLC ProgrammingVali Ene100% (4)

- SF4101 IpDocumento2 páginasSF4101 IpFranzKafkaAinda não há avaliações

- Grease Nipples From UMETA Catalogue GK84-E 04-2012-2Documento46 páginasGrease Nipples From UMETA Catalogue GK84-E 04-2012-2FranzKafkaAinda não há avaliações

- Dgpne96 Ei06 PDFDocumento68 páginasDgpne96 Ei06 PDFoki121100% (1)

- Vciom 02377 enDocumento8 páginasVciom 02377 enFranzKafkaAinda não há avaliações

- Lambao LE17 LE18 AC2 InductiveDocumento1 páginaLambao LE17 LE18 AC2 InductiveFranzKafkaAinda não há avaliações

- Schneider Electric RM35TF30 DatasheetDocumento5 páginasSchneider Electric RM35TF30 DatasheetJ raymond FAinda não há avaliações

- RM35Documento4 páginasRM35zarun1Ainda não há avaliações

- PLP GageDocumento3 páginasPLP GageFranzKafkaAinda não há avaliações

- Ethernet IP Texas InstrumentsDocumento6 páginasEthernet IP Texas InstrumentsFranzKafkaAinda não há avaliações

- VXD Old SMC 0900766b8094a5b0Documento32 páginasVXD Old SMC 0900766b8094a5b0FranzKafkaAinda não há avaliações

- Ethernet IP Texas InstrumentsDocumento6 páginasEthernet IP Texas InstrumentsFranzKafkaAinda não há avaliações

- Imm Ex510-Gen1-X73 TFP46GBDocumento1 páginaImm Ex510-Gen1-X73 TFP46GBFranzKafkaAinda não há avaliações

- Low Pressure Transducer and Pressure Transmitter SpecificationsDocumento1 páginaLow Pressure Transducer and Pressure Transmitter SpecificationsFranzKafkaAinda não há avaliações

- Ma Optimass Mfc400 Haz - Areas - enDocumento28 páginasMa Optimass Mfc400 Haz - Areas - enFranzKafkaAinda não há avaliações

- Pneumatics Symbols Din ISO 1219 PDFDocumento4 páginasPneumatics Symbols Din ISO 1219 PDFN.Palaniappan100% (1)

- PH-180 E3FN Series ObsDocumento5 páginasPH-180 E3FN Series ObsFranzKafkaAinda não há avaliações

- E2K C Datasheet en 201008Documento8 páginasE2K C Datasheet en 201008FranzKafkaAinda não há avaliações

- G5a 0609-297732Documento9 páginasG5a 0609-297732FranzKafkaAinda não há avaliações

- A B PDF 872c Ca508 - en PDocumento3 páginasA B PDF 872c Ca508 - en PFranzKafkaAinda não há avaliações

- E2K C Datasheet en 201008Documento8 páginasE2K C Datasheet en 201008FranzKafkaAinda não há avaliações

- Datasheet 101107771 BPS33 1932014-18255Documento2 páginasDatasheet 101107771 BPS33 1932014-18255FranzKafkaAinda não há avaliações

- 3M 951 - 952 - 953Documento3 páginas3M 951 - 952 - 953FranzKafkaAinda não há avaliações

- A B PDF 872c Ca508 - en PDocumento3 páginasA B PDF 872c Ca508 - en PFranzKafkaAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- HP HP3-X11 Exam: A Composite Solution With Just One ClickDocumento17 páginasHP HP3-X11 Exam: A Composite Solution With Just One ClicksunnyAinda não há avaliações

- Revit 2010 ESPAÑOLDocumento380 páginasRevit 2010 ESPAÑOLEmilio Castañon50% (2)

- Physioex 9.0 Exercise 1 Act 1Documento5 páginasPhysioex 9.0 Exercise 1 Act 1Adela LhuzAinda não há avaliações

- Condition Based Monitoring System Using IoTDocumento5 páginasCondition Based Monitoring System Using IoTKaranMuvvalaRaoAinda não há avaliações

- Analyze and Design Sewer and Stormwater Systems with SewerGEMSDocumento18 páginasAnalyze and Design Sewer and Stormwater Systems with SewerGEMSBoni ClydeAinda não há avaliações

- 4 Factor DoeDocumento5 páginas4 Factor Doeapi-516384896Ainda não há avaliações

- Weone ProfileDocumento10 páginasWeone ProfileOmair FarooqAinda não há avaliações

- Ielts Practice Tests: ListeningDocumento19 páginasIelts Practice Tests: ListeningKadek Santiari DewiAinda não há avaliações

- Felizardo C. Lipana National High SchoolDocumento3 páginasFelizardo C. Lipana National High SchoolMelody LanuzaAinda não há avaliações

- Production of Sodium Chlorite PDFDocumento13 páginasProduction of Sodium Chlorite PDFangelofgloryAinda não há avaliações

- Ecc Part 2Documento25 páginasEcc Part 2Shivansh PundirAinda não há avaliações

- Test Bank For Fundamental Financial Accounting Concepts 10th by EdmondsDocumento18 páginasTest Bank For Fundamental Financial Accounting Concepts 10th by Edmondsooezoapunitory.xkgyo4100% (47)

- Cableado de TermocuplasDocumento3 páginasCableado de TermocuplasRUBEN DARIO BUCHELLYAinda não há avaliações

- Endangered EcosystemDocumento11 páginasEndangered EcosystemNur SyahirahAinda não há avaliações

- An Introduction To Ecology and The BiosphereDocumento54 páginasAn Introduction To Ecology and The BiosphereAndrei VerdeanuAinda não há avaliações

- Evil Days of Luckless JohnDocumento5 páginasEvil Days of Luckless JohnadikressAinda não há avaliações

- Chromate Free CoatingsDocumento16 páginasChromate Free CoatingsbaanaadiAinda não há avaliações

- Form Active Structure TypesDocumento5 páginasForm Active Structure TypesShivanshu singh100% (1)

- ERIKS Dynamic SealsDocumento28 páginasERIKS Dynamic Sealsdd82ddAinda não há avaliações

- CBSE Class 6 Whole Numbers WorksheetDocumento2 páginasCBSE Class 6 Whole Numbers WorksheetPriyaprasad PandaAinda não há avaliações

- C4 ISRchapterDocumento16 páginasC4 ISRchapterSerkan KalaycıAinda não há avaliações

- Breaking NewsDocumento149 páginasBreaking NewstigerlightAinda não há avaliações

- Iphoneos 31Documento159 páginasIphoneos 31Ivan VeBoAinda não há avaliações

- Lecture NotesDocumento6 páginasLecture NotesRawlinsonAinda não há avaliações

- Lewis Corporation Case 6-2 - Group 5Documento8 páginasLewis Corporation Case 6-2 - Group 5Om Prakash100% (1)

- Chapter 19 - 20 Continuous Change - Transorganizational ChangeDocumento12 páginasChapter 19 - 20 Continuous Change - Transorganizational ChangeGreen AvatarAinda não há avaliações

- 3d Control Sphere Edge and Face StudyDocumento4 páginas3d Control Sphere Edge and Face Studydjbroussard100% (2)