Escolar Documentos

Profissional Documentos

Cultura Documentos

QOL - Volume 4 - Issue 3-4 - Milan Vukic - 0

Enviado por

MilanVukic0 notas0% acharam este documento útil (0 voto)

29 visualizações6 páginasBread

Título original

QOL - Volume 4_Issue 3-4 - Milan Vukic_0

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoBread

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

29 visualizações6 páginasQOL - Volume 4 - Issue 3-4 - Milan Vukic - 0

Enviado por

MilanVukicBread

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 6

49

M. VUKI, ET AL.: ALVEOGRAPH AND BREAD MAKING QUALITY

OF WHEAT DOUGH AS AFFECTED BY ADDED GLUCOSE OXIDASE QUALITY OF LIFE (2013) 4(3-4):49-54

DOI: 10.7251/QOL1303049V UDC: 664.641.12.016.3/.8

Original scientic paper

ALVEOGRAPH AND BREAD MAKING QUALITY OF WHEAT DOUGH AS

AFFECTED BY ADDED GLUCOSE OXIDASE

MILAN VUKI

1

, MIROSLAV HADNAEV

2

, J ELENA TOMI

2

, J ASNA MASTILOVI

2

,

ALEKSANDRA TORBICA

2

,

RADOLSAV GRUJ I

1

1

Faculty of Technology University of East Sarajevo fakultet, Karakaj bb. 75400 Zvornik, B&H, vukic88@gmail.com

2

Institute for Food Technology Bulevar cara Lazara br.1 21000 Novi Sad, Serbia

Abstract: Although there is considerable interest in glucose oxidase, little is known about its activity on rheological

characteristics of wheat dough and with bread making quality. Inuence that the glucose oxidase exerts on rheological

properties of the wheat dough is investigated on the basic of rheological determinations obtained with alveograph. Inu-

ence of glucose oxidase on bread making properties is determined on the basic of result obtained from the laboratory scale

baking tests. In order to clearly establish relations between added dose of glucose oxidase (0.002; 0.004; 0.006 %) and

rheological properties of wheat dough, as well as with bread making quality, analysis of dough with and without glucose

oxidase (control sample) is performed and results are discussed with comparison with L-ascorbic acid as the most com-

monly used oxidative improver. Results show that glucose oxidase cause greatest increase of dough tenacity and causal

reduction of extensibility. This leads to a negative effect on specic volume. Glucose oxidase cause increase of crumb

hardness in smaller extent than L-ascorbic acid.

Keywords: bread-making, glucose oxidase, improver, alveograph, rheology

Introduction

Today, it is common practice to use oxidizing improvers in the preparation of bakery products in

order to optimize the quality of wheat our. Reduction of free sulfhydryl groups (SH grups) effects of

various oxidizing improvers on the process of protein networking is experimentally proved demonstrated

(Sokol, Mecham and Pence, 1960; Hird and Yates, 1961; Bloksma, 1963; Tsen and Hlynka, 1963). Selo-

mylio and Zhou, (2007) point that oxidizing improvers cause a signicant increase in bread volume and

optimization of all bread sensory quality characteristics that a customer takes into account in order to select

an product. L-ascorbic acid is most used oxidative improver in practice. It is concluded that by traditional

way of preparing the wheat dough, depending on wheat our quality, the usual dose of L- ascorbic acid is

10-50 ppm but it can be as high as 100 ppm.

Glucose oxidase is an enzyme with oxidizing effect due to the release of hydrogen peroxide in cata-

lyzed reactions. In the presence of oxygen, glucose oxidase catalyzes the oxidation of -D-glucose to the

-D-glukonlaktona and hydrogen peroxide (Steffolani, Ribotta, Prez and Len, 2010). Due to these facts

and release of hydrogen peroxide, glucose oxidase can be use in baking as oxidative improver, alone or in

synergy with L-ascorbic acid.

The aim of this research, presented in this paper, is to investigate the effects of addition of glucose

oxidase on the rheological properties and bread quality in comparison with the effects of L-ascorbic acid as

the commonly used oxidation improver.

Material and Methods

Wheat our used in the experiment is obtained by laboratory milling of wheat variety Pobeda. Flour

had the following chemical parameters: protein: 12.6% (d.m.); moisture: 13.2%, ash: 0.518% (d.m.); water

50 www.qol-au.com

M. VUKI, ET AL.: ALVEOGRAPH AND BREAD MAKING QUALITY

OF WHEAT DOUGH AS AFFECTED BY ADDED GLUCOSE OXIDASE QUALITY OF LIFE (2013) 4(3-4):49-54

absorption: 64.95%, wet gluten: 32.81%. FOSS Infratec

TM

1241 Grain Analyzer is used for our composi-

tion analysis. Accuracy and precision of determination are validated by interlaboratory tests.

Oxidation improvers added in the experiment are:

L-ascorbic acid (Weifang Ensign Industry Co.., Ltd., China), given that it is in the form of

white crystalline powder, after dilution in water it is dosed. Three dosages are used (0.005%;

0.008%; 0.011% based on our);

Glucose oxidase (BakezymeGO 1500 BG - Royal DSM , Netherlands), given that it is in the

form of brown crystalline powder, after dilution in water it is dosed. Three dosages are used

(0.002%; 0.004%; 0.006% based on our);

Other ingredients used in this work were: Salt (Salt product, Serbia), yeast (Kvas Ltd., Croatia), all

were purchased at the local supermarket. For preparation of dough, drinking water of city of Novi Sad is

used.

Biaxial extension: Parameters of wheat dough quality are dened according to modied method

Chopin AlveographICC Standard No 121 (ICC Standards, 1996).

Modication is reected in the reduction of the amount of water added in salt solution for the

amount of water added through the solution of water and oxidation improvers. The amount of salt is calcu-

lated according to the total water.

According to Seyhun, Sumnu and Sahin (2005) change in the hardness of bread crumb is a good

indicator of bread aging process because there is a increase of hardness during storage. Increasing in the

hardness of bread crumb is due to the reduction of moisture as well as due to the phenomenon of retrograda-

tion (Biliarderis, Izydorczyk and Rattan, 1995).

Texture analysis: Hardness of bread crumb is measured on TA.XT2 Texture Analyzer (Stable Micro

Systems, UK), using TPA (Texture Prole Analysis). Flat disk with compression diameter of 75 mm is used

(accessory P/75).

Working conditions includes the following adjustments:

Speed probe before the test 1.0 mm / second;

Speed probe during the test 5.0 mm / second;

Speed probe after the test 5.0 mm / second;

Deformation of 75%.

The rst three slices, from both ends of the loaf are not used, for determination of bread crumb

hardness middle slice is used. Measurement is performed in three replicates with slice thickness of 35 mm.

Preperation of bread

Baking test is performed using basic formula (expressed in % of the our): wheat our (100%),

yeast (2%), salt (2%), pork fat (0.7%). Oxidative improvers are added in the form of solutions, each oxida-

tive improver is added in three concentrations, the amount of added water is reduced by the amount of water

added in solution of oxidative improver, so that the total amount of added water, provide dough consistency

of 500 farinograph units, that is consistency of wheat dough for which it is known by empirical rheology

experience that it gives the best possible quality of wheat bread. Baking test is conducted with the use of a

mixer Diosna (Dierks & Shne Maschinenfabrik, Osnabrck, Nemaka).

Dough fermented in the mass for 60 minutes, kneading is done by hand and then the dough is left

to ferment for another 60 minutes, after which kneading is performed again. Dough ferment for another 30

minutes, then it is divided into pieces weighing 150 g, shaped into loaves and placed in bread molds with

51

M. VUKI, ET AL.: ALVEOGRAPH AND BREAD MAKING QUALITY

OF WHEAT DOUGH AS AFFECTED BY ADDED GLUCOSE OXIDASE QUALITY OF LIFE (2013) 4(3-4):49-54

following dimensions (24.5 x 9 x 6.5). Final fermentation is carried out at 30C and 80% relative humidity

for a period of 75 minutes, baking is performed for 15 minutes at 220C with the addition of steam for 3

seconds in bakery oven (Thermodynamics, Croatia). After baking, bread is cooled up to room temperature

for 2h and then for the next 22h stored in a climate chamber at 22

o

C with a relative humidity of 65%.

Specic volume: Two hours after baking bread, mass and volume are measured, volume measure-

ment is conducted by displacement procedure of millet seeds (Kaluerski and Filipovi, 1998). Specic

bread volume (cm

3

/g) is calculated as ratio of the mean value of volume and mass of four bread

Statistical analysis: Analysis of variance was performed using the software Statistica 9.0 (Statsoft,

Tulsa, USA). Mean values were considered signicantly different at P values 0.05.

Results and Discussion

The rheological characterisation of dough has been performed on the basis of the determinations

carried out by the Chopin alveogrph. The phases of the Alveograph method tries to simulate phases of

dough processing (sheeting, rounding and molding) during baking process.

Generally, alveograph parameter (P) is considered as an indicator of the doughs tenacity. It is maxi-

mum pressure inside the dough bubble that cause rupture of bubble. Aldovrandi and Vitali (1995) indicate

that values of parameter P for standard wheat dough quality range 60-80 mm H

2

O, very good wheat dough

quality 80-100 mm H

2

O, whilst extra strong wheats dough are characterized by (P) value higher than 100

mm H

2

O. Lowest value of parameter P and therefore doughs tenacity is found for the control sample. Due

to activity of L-ascorbic acid, dough samples containing mention oxidizing improver, demonstrate greatest

maximum pressure that dough bubble can retain, that means that L-ascorbic acid exhibit improving effect

on strength of the gluten network.

Parameter of extensibility (L) of 100 mm is generally considered as good for bakery production. All

investigated samples with L-ascorbic acid have (L) values similar to the (L) value of control sample. Param-

eter (L) of control sample is not in optimal range for bakery production. From results it can be concluded

that samples with added glucose oxidase poses lower extensibility than samples with added L-ascorbic acid

or control sample and that both oxidising improvers degraded desirable property of extensibility. Swelling

index (G) represents measure of dough extensibility. As well as parameter L, swelling index is lower in all

samples with added oxidising improvers.

The ratio P/L of 0.50 indicates either resistant and very extensible wheat dough or moderately extensible

and less resistant wheat dough. Value of 1.50 indicates very strong and moderately extensible wheat dough, whilst

wheat dough with P/L value in the range 0.40-0.80 is suitable for bakery production. Ratio of P/L increased with

the increase of added ascorbic acid dose. P/L ratio of samples with glucose oxidase shows same tendency as with

addition of L-ascorbic acid. Compared to the control sample all samples with added oxidising improvers posses

biger P/L ratio, addition of glucose oxidase in dose of 0,006% show greatest increase of P/L ratio.

Standard quality wheat dough is characterized by (W) value in range 160-200, whilst good quality

wheat dough is characterized by (W) value in the range 220-300 and higher than 300, respectively (Bordes,

Branlard, Oury, Charmet and Balfourier, 2008). Parametar of energy (W) is higher in all samples treated

with oxidising improvers compared with control sample, samples with added glucose oxidase exhibit the

greatest enlargement. L-ascorbic acid increase elasticity index (Ie) which is indicator of dough elasticity, all

samples with glucose oxidase show increased rigidity of dough.

Remarkable fact is that glucose oxidase creates some effects as L-ascorbic acid, but their magnitude

is greater. All samples with doses of glucose oxidase have higher maximum pressure (P), P/L ratio and

52 www.qol-au.com

M. VUKI, ET AL.: ALVEOGRAPH AND BREAD MAKING QUALITY

OF WHEAT DOUGH AS AFFECTED BY ADDED GLUCOSE OXIDASE QUALITY OF LIFE (2013) 4(3-4):49-54

lower (L) and (G) values. While some parameters and these are dough energy (E) and elasticity index (Ie )

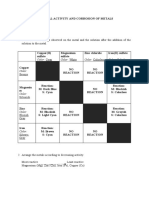

have lower values. Results are shown in table 1.

Table 1. The parameters obtained by the alveograph for the control dough and dough with different doses of L-ascorbic acid

and glucose oxidase

Sample Dose (%) P L G W P/L Ie

Control 92 77 19.5 236 1.19 52.2

L-ascorbic acid

0.005% 98 75 19.3 252 1.31 53.3

0.008% 99 78 19.7 267 1.27 54.7

0.011% 99 73 19.0 257 1.36 55.5

Glucose oxidase

0.002% 105 69 18.5 253 1.52 53.1

0.004% 109 66 18.1 249 1.65 50.3

0.006% 174 34 13.0 245 5.12 0.0

P-maximum pressure(mm H

2

O), L-extensibility (mm), G-swelling index (mm), W-energy (J 10

-4

).

P/L- ratio,Ie- elasticy index (%)

Strengthening effects of glucose oxidase is associated with gluten protein crosslinking via disulde

bonds (Primo Martin, De Beukelear, Hamer and Van Vliet, 2003). But unlike L-ascorbic acid effects are

associated and with oxidative gelation of soluble pentazans (Vemulapalli, Miller and Hoseney, 1998).

Evaluation of L-ascorbic acid and glucose oxidase as oxidative improvers is complemented with

baking tests. The variations of bread quality parameters is shown in tables 2 and 3. It is obvious that the

specic volume depends on both, dose and used oxidative improver.

Lowest and highest dose of L-ascorbic acid, increased specic volume of bread compared to con-

trol sample. Statistically this two samples are most similar to one another and different from medium and

highest dose of glucose oxidase. Medium dose of L-ascorbic acid shows negative effect on specic volume

of bread. This means that increase of L-ascorbic acid dose will not necessary result in increased specic

volume of bread.

Table 2. Effect of adition of glucose oxidase and L-ascorbic acid on the specic volume of bread

Sample Specic volume (cm

3

/g) Standard dev.

Control 3.530

ab

0.060

L-ascorbic acid

0.005% 3.603

b

0.064

0.008% 3.432

ab

0.190

0.011% 3.605

b

0.105

Glukose oxidase

0.002% 3.442

ab

0.167

0.004% 3.404

a

0.044

0.006% 3.385

a

0.107

Results are the mean values of four replicates, values labeled with identical uppercase letter in col-

umn are not signicantly different (P 0.05)

53

M. VUKI, ET AL.: ALVEOGRAPH AND BREAD MAKING QUALITY

OF WHEAT DOUGH AS AFFECTED BY ADDED GLUCOSE OXIDASE QUALITY OF LIFE (2013) 4(3-4):49-54

Addition of glucose oxidase exhibit negative effect on specic volume in all doses. Lowest dose of

glucose oxidase is statistically similar to the control sample and medium dose of L-ascorbic acid. Negative

effect on specic volume of bread compared to the control sample are due to to too strong gluten network

with insufcient extensibility which produce rigid dough and bread with lower specic volume which is

unfavorable characteristics by consumer.

Different authors claim different effects of glucose oxidase on bread specic volume. Martnez-

Anaya and J imnez (1998) claim that addition of glucose oxidase produce positive effect on specic vol-

ume while some authors claim that effect of glucose oxidase on specic volume is negative or not noticable

(Risiah, Suttom, Low, Lin and Gerrard, 2005; Vemulapalli et al., 1998).

On the basis of data presented in table 3 it can be observed that with the addition of both oxidation

improvers, bread crumb hardness is statistically signicantly modied, compared with the control sample.

Addition of glucose oxidase in doses over 0.004% and L-ascorbic acid in doses over 0.008% increase hard-

ness of breads signicantly compared to the control sample.

Table 3. Effect of adition of glucose oxidase and L-ascorbic acid on the bread crumb hardness

Sample Hardness (g) Standard dev.

Control 5332

a

905.722

L-ascorbic acid

0.005% 7717

abcd

822.009

0.008% 10095

de

344.411

0.011% 11168

e

2922.411

Glucose oxidase

0.002% 6749

ab

1135.613

0.004% 11454

e

1090.786

0.006% 8087

bcd

921.457

Results are the mean values of three replicates, values labeled with identical uppercase letter in

column are not signicantly different (P 0.05)

According to the results, glucose oxidase added in all concentrations has led to increase of hardness, com-

pared with the control sample. This nding is not in accordance with research of Bonet, Rosell, Caballero, Gomez,

Perez-Manuera and Liuch, (2006), they are of opinion that glucose oxidase added in doses less than 0.005% creates

softer bread crumb compared to the control sample. Sample with glucose oxidase added in a minimum concentra-

tion of 0.002% provided a minimum hardness of sample bread crumb, with added oxidising improver.

This effect could be associated with the ability of pentazans to absorb large amounts of water in the

process of gelation under the inuence of glucose oxidase, our quality as well as with laboratory baking

test procedure and it should be investigated futher.

Conclusions

In general, three major parameters of wheat our for bakery production are characterized by me-

dium tenacity (P), medium or high energy (W) and medium (L) values.

Investigation of the activity of glucose oxidase show greatest increase of dough tenacity and re-

duction of extensibility for all samples of wheat dough, compared with control sample and samples with

54 www.qol-au.com

M. VUKI, ET AL.: ALVEOGRAPH AND BREAD MAKING QUALITY

OF WHEAT DOUGH AS AFFECTED BY ADDED GLUCOSE OXIDASE QUALITY OF LIFE (2013) 4(3-4):49-54

L-ascorbic acid. Relationship of this two parameters is not within the desired limits, i.e., strong and short

wheat is obtained.

The use of glucose oxidase in higher doses leads to a large networking of gluten, with consequent

increased rigidity of dough.

Largest improvement of bread quality, in terms of increase of specic volume is observed in sample

with highest dose of L-ascorbic acid, statistically there is no difference between highest and lowest dose.

Addition of glucose oxidase in all doses exhibit negative effects on the specic volume. This observation is

in accordance with claims of some authors.

Addition of both oxidative improvers resulted in the increase of bread crumb hardness with signi-

cant changes compared to the control sample. Crumb hardness of sample with lowest dose of glucose oxi-

dase exhibit statistically greatest similarity with control sample. All samples with glucose oxidase exhibit

lower parameter of hardness compared to the corresponding dose of L-ascorbic acid.

On the basis of the results obtained, glucose oxidase should be used with L-ascorbic acid and could

provide the improvement of alveograph parametars, as well as crumb hardness.

References

Aldovrandi, L.. & Vitali, F. (1995). Criteri di valutazione del frumento tenero da parte dellindustria molitoria. Molini dItalia, Vol. 46, No. 3,

pp. 16-19.

Biliarderis, C.G., Izydorczyk, M.S., Rattan, O. (1995). Effects of arabinoxylans on breadmaking quality of wheat ours. Food Chemistry, 53,

165-171.

Bloksma, A.H. 1963. Oxsidation by molecular oxygen of thiol groups in unleavened doughs from normal and defatted wheat ours. J ournal of

Science Food Agr., 14, 529.

Bonet, A., Rosell, C.M., Caballero, P.A., et al. (2006). Glucose oxidase effect on dough rheology and bread quality: a study from macroscopic

to molecular level. Food Chemistry, 99, 408-415.

Bordes, J . Branlard, G., Oury, F. X., Charmet, G. & Balfourier, F. (2008). Agronomic Characteristics, Grain Quality and Flour Rheology of

372 Bread Wheats in a Worldwide Core Collection. J ournal of Cereal Science, Vol. 48, No. 3, (November 2008), pp. (569-579), ISSN

0733-5210.

Hird, F.J .R.,Yates, J .R. (1961). The oxidation of protein thiol groups by iodate, bromate and persulphate. Biochemistry J urnal, 80. 612

ICC Standard Method No. 121 Method for Using the Chopin Alveograph. 1996.

Kaluerski, G., Filipovi, N. (1998). Metode ispitivanja kvaliteta ita, brana i gotovih proizvoda. Tehnoloki fakultet, Zavod za tehnologiju

ita i brana, Novi Sad.

Martnez-Anaya, M.A., J imnez, T. (1998). Physical properties of enzyme supple mented doughs and relationship to bread quality parameters.

Zeitschrift fur Lebensmittel-Untersuchung und-Forschung A, 206, 134-142.

Primo Martin, C., De Beukelear, H., Hamer R.J ., Van Vliet, T. (2008). Effect of ingredient modication. J ournal of Cereal Science, 48, 604-612.

Risiah, I.A., Suttom, K.H., Low, F.L., Lin, H.M., Gerrard, J .A. (2005). Crosslinking of wheat dough protein by glucose oxidase and resulting

effects on bread and croissants. Food Chemistry, 89, 325-332.

Selomylio, V.O., Zhou, W. (2007). Frozen bread dough: Effect of freezing storage and dough improvers. J ournal of Cereal Science, 45, 1-17.

Seyhun, N., Sumnu, G., Sahin, S. (2005). Effects of diferent starch types on retardation of staling of microwave-baked cakes. Food and Bio-

products Processing, 83, 1-5.

Sokol, H.A., Mecham, D.K., Pence, J .W. (1960). Sulfhydryl losses during mixing of dough: Comparasion of ours having varius mixing char-

acteristics. Cereal chemestry 39, 739.

Steffolani, E., Ribotta, P., Prez, G., Len, A. (2010). Effect of glucose oxidase, transglutaminase, and pentosanase on wheat proteins: Relation-

ship with dough properties and bread-making quality. J ournal of Cereal Science, 51, 366-373.

Tsen, C.C., Hlynka, I. (1963). Flour lipids and oxidation of sulfhydryl groups in dough. Cereal Chemestry, 40, 145.

Vemulapalli, V., Miller, K.A., Hoseney, R.C. (1998). Glucose oxidase in breadmaking systems. Cereal Chemistry, 75, 439-442.

Recived: 26.10.2013.

Accepted: 29.11.2013.

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- C - A - J - Appelo and D - Postma-Geochemistry Groundwater and Pollution Second Edition-Taylor Francis (2005)Documento647 páginasC - A - J - Appelo and D - Postma-Geochemistry Groundwater and Pollution Second Edition-Taylor Francis (2005)Omar Rodriguez100% (1)

- IGCSE Chemistry NotesDocumento40 páginasIGCSE Chemistry Notestasha100% (5)

- Report Sheet: Color: Cyan Color: White Color: Colorless Color: ColorlessDocumento6 páginasReport Sheet: Color: Cyan Color: White Color: Colorless Color: ColorlessMigs MlaAinda não há avaliações

- A History of Membrane Transport and Bioenergetics PDFDocumento383 páginasA History of Membrane Transport and Bioenergetics PDFEdmilson RodriguesAinda não há avaliações

- Cloud Point Extraction As A Method For Preconcentration of Metal IonsDocumento6 páginasCloud Point Extraction As A Method For Preconcentration of Metal IonsMilanVukicAinda não há avaliações

- 3D Model of A Monolithic Honeycomb Adsorber For Electric Swing Adsorption For Carbon Dioxide CaptureDocumento14 páginas3D Model of A Monolithic Honeycomb Adsorber For Electric Swing Adsorption For Carbon Dioxide CaptureMilanVukicAinda não há avaliações

- Simulation of A Single-Stage Evaporator System Integrated With A Mechanical Vapor Compressor For Concentrating The Electrolytic System KNO - H ODocumento7 páginasSimulation of A Single-Stage Evaporator System Integrated With A Mechanical Vapor Compressor For Concentrating The Electrolytic System KNO - H OMilanVukicAinda não há avaliações

- Quality Testing of Industrially Produced Essential Oil of White Pine (Pinus Sylvestris L.) From The Republic of SrpskaDocumento8 páginasQuality Testing of Industrially Produced Essential Oil of White Pine (Pinus Sylvestris L.) From The Republic of SrpskaMilanVukicAinda não há avaliações

- Packaging Materials and Articles For Food: Legislation and Codes of Good Manufacturing PracticeDocumento10 páginasPackaging Materials and Articles For Food: Legislation and Codes of Good Manufacturing PracticeMilanVukicAinda não há avaliações

- Sitosterol and Gentisic Acid Loaded 1,2 Dipalmitoyl SN Glycero 3 Phosphocholine Liposomal ParticlesDocumento8 páginasSitosterol and Gentisic Acid Loaded 1,2 Dipalmitoyl SN Glycero 3 Phosphocholine Liposomal ParticlesMilanVukicAinda não há avaliações

- Bošković & Bugarski 2018Documento13 páginasBošković & Bugarski 2018MilanVukicAinda não há avaliações

- Behr Labor Technik Extraction En-1Documento28 páginasBehr Labor Technik Extraction En-1MilanVukic100% (1)

- Vemag 500 Bakery BrochureDocumento4 páginasVemag 500 Bakery BrochureMilanVukicAinda não há avaliações

- doughLAB 20110901Documento2 páginasdoughLAB 20110901MilanVukicAinda não há avaliações

- Redox ReaxDocumento2 páginasRedox ReaxKristine Celaya AlbinoAinda não há avaliações

- Chemical BondingDocumento51 páginasChemical BondingDaniel MaglalangAinda não há avaliações

- Coenzymes and CofactorsDocumento11 páginasCoenzymes and CofactorsGovindaraju ShruthiAinda não há avaliações

- MIC in Heat Exchanger TubingDocumento6 páginasMIC in Heat Exchanger TubingdutuconstantinAinda não há avaliações

- Experiment 8 Sem2Documento12 páginasExperiment 8 Sem2Fatin NurhudaAinda não há avaliações

- Cambridge Ordinary Level: Cambridge Assessment International EducationDocumento16 páginasCambridge Ordinary Level: Cambridge Assessment International EducationMaameama FrempongAinda não há avaliações

- Chemistry Study Notes Igcse EdexcelDocumento34 páginasChemistry Study Notes Igcse EdexcelAhmed KhalilAinda não há avaliações

- Electrochemical Activation of Graphite Electrode For Nitrate ReductionDocumento9 páginasElectrochemical Activation of Graphite Electrode For Nitrate Reductionwonkyoung789Ainda não há avaliações

- Redox Chemistry Unit 2Documento51 páginasRedox Chemistry Unit 2Nicola NguyenAinda não há avaliações

- Copper Oxidation LabDocumento3 páginasCopper Oxidation Labapi-348321624Ainda não há avaliações

- Not CR or CR (II) .: A2-Level Chemistry Unit 5.3 (Transition Metal Chemistry) Mark Scheme For Sample QuestionsDocumento5 páginasNot CR or CR (II) .: A2-Level Chemistry Unit 5.3 (Transition Metal Chemistry) Mark Scheme For Sample QuestionsJake RobinsonAinda não há avaliações

- Arihant NEET 34 Years Chapterwise Solutions Chemistry 2022Documento253 páginasArihant NEET 34 Years Chapterwise Solutions Chemistry 2022Prathamesh Patwa100% (1)

- Class X Chemistry Asm Term IiDocumento10 páginasClass X Chemistry Asm Term IiAarush GuptaAinda não há avaliações

- Ppo WhiteDocumento9 páginasPpo WhiteJohnnyAinda não há avaliações

- Unit 1 Chemical EquilibriumDocumento14 páginasUnit 1 Chemical EquilibriumNgo Anh HuyenAinda não há avaliações

- Espito, Ralph Project DescriptionDocumento6 páginasEspito, Ralph Project Descriptionceeresk12Ainda não há avaliações

- Preg-Robbing Phenomena in The Cyanidation of Sulphide Gold OresDocumento20 páginasPreg-Robbing Phenomena in The Cyanidation of Sulphide Gold Orescuberbill1980Ainda não há avaliações

- Ftre 2013 Class Viii Paper 2Documento13 páginasFtre 2013 Class Viii Paper 2cutebene83% (23)

- Taler Chemical Reactios. General Chemistry Teacher: William Alejandro Andrade BarreiroDocumento8 páginasTaler Chemical Reactios. General Chemistry Teacher: William Alejandro Andrade BarreiroENITH HERRERA MONTALVOAinda não há avaliações

- Strategies and Tactics in Organic Synthesis Lucidi - PapagniDocumento472 páginasStrategies and Tactics in Organic Synthesis Lucidi - PapagnimcgilicuttyAinda não há avaliações

- CatalysisDocumento329 páginasCatalysisRakesh ReddyAinda não há avaliações

- Redox ReactionsDocumento29 páginasRedox ReactionsSoniaAlexAinda não há avaliações

- GATE Chemistry Study Material Book 1 Inorganic Chemistry 1Documento21 páginasGATE Chemistry Study Material Book 1 Inorganic Chemistry 1Sudhanshu PandeyAinda não há avaliações

- Electro Chemistry FinalDocumento51 páginasElectro Chemistry FinalManoj50% (2)

- Expt 8 Act 3 and 5 & ApplicationsDocumento5 páginasExpt 8 Act 3 and 5 & ApplicationsWAinda não há avaliações