Escolar Documentos

Profissional Documentos

Cultura Documentos

8 2006 Williams Katalogus 2012

Enviado por

Charles H SiahaanTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

8 2006 Williams Katalogus 2012

Enviado por

Charles H SiahaanDireitos autorais:

Formatos disponíveis

Chemical Injection Pumps and Products

API 675 PERFORMANCE

V Dual Seal

Plunger

X Dual Seal

Plunger

WILROY

Hydraulically

Actuated

Diaphragm

Pumps

WILROY

A

WILROY

B

MK XIIA Oscillamatic

Controller

W High Pressure

High Flow Plunger

LD Low Pressure

Diaphragm

MK VII APU-XP

Automatic Processing Unit

WPC 9001

Electronic Pump

Controller

V, X and W plunger

pumps available with

ceramic plungers

MAX

MODEL MAX VOLUME STROKE STROKES DISCHARGE

@ AIR/GAS VOLUME PER LENGTH PER MINUTE PRESSURE

SUPPLY PRESSURE STROKE (INCHES) (RANGE)

GPH / LPH CC PSIG / BARG

CP125V125

@ 100 PSI/6.9 BAR .07 / .27 .1 .5 1-45 8,650 / 596.4

CP250V225

@ 100 PSI/6.9 BAR .57 / 2.16 .8 1 1-45 7,200 / 496.4

CP250V300

@ 100 PSI/6.9 BAR .57 / 2.16 .8 1 1-45 13,100 / 903.2

CP500V225

@ 100 PSI/6.9 BAR 2.30 / 8.71 3.2 1 1-45 1,750 / 120.7

CP500V300

@ 100 PSI/6.9 BAR 2.30 / 8.71 3.2 1 1-45 3,250 / 224.1

CRP500V400

@ 100 PSI/6.9 BAR 2.30 / 8.71 3.2 1 1-45 6,300 / 434.4

@ 150 PSI/10.3 BAR 2.30 / 8.71 3.2 1 1-45 9,200 / 634.3

CRP750V400

@ 100 PSI/6.9 BAR 5.00 / 18.9 7.0 1 1-45 2,600 / 178.3

@ 150 PSI/10.3 BAR 5.00 / 18.9 7.0 1 1-45 4,000 / 275.8

CRP1000V400

@ 100 PSI/6.9 BAR 9.08 / 34.37 12.7 1 1-45 1,520 / 104.8

@ 150 PSI/10.3 BAR 9.08 / 34.37 12.7 1 1-45 2,300 / 158.6

CRP1000V600

@ 100 PSI/6.9 BAR 9.04 / 34.22 12.6 1 1-45 3,400 / 234.4

@ 150 PSI/10.3 BAR 7.00 / 26.50 9.8 1 1-35 4,700 / 324.0

CRP1000V800

@ 100 PSI/6.9 BAR 8.81 / 33.35 12.3 1 1-45 6,300 / 434.4

@ 150 PSI/10.3 BAR 6.82 / 25.81 9.5 1 1-35 9,100 / 627.4

* This data should only be used to provide you with your initial size selection.

You must refer to the actual performance graphs. Discharge pressures with use of MKXIIA controller.

MAX

MODEL MAX VOLUME STROKE STROKES DISCHARGE

@ AIR/GAS VOLUME PER LENGTH PER MINUTE PRESSURE

SUPPLY PRESSURE STROKE (INCHES) (RANGE)

GPH / LPH CC PSIG / BARG

CP125X125

@ 65 PSI / 4.5 BAR .07 / .27 .1 .5 1-45 5,000 / 344.8

CP250X225

@ 65 PSI / 4.5 BAR .57 / 2.16 .8 1 1-45 4,100 / 282.7

CP250X300

@ 65 PSI / 4.5 BAR .57 / 2.16 .8 1 1-45 6,500 / 448.2

CP500X225

@ 90 PSI / 6.2 BAR 2.30 / 8.71 3.2 1 1-45 1,300 / 89.6

CP500X300

@ 90 PSI / 6.2 BAR 2.30 / 8.71 3.2 1 1-45 2,200 / 151.7

CRP500X400

@ 50 PSI / 3.5 BAR 2.30 / 8.71 3.2 1 1-45 2,900 / 203.9

@ 90 PSI / 6.2 BAR 2.30 / 8.71 3.2 1 1-45 9,200 / 634.3

CRP750X400

@ 50 PSI / 3.5 BAR 5.00 / 18.9 7.0 1 1-45 1,150 / 80.9

@ 90 PSI / 6.2 BAR 5.00 / 18.9 7.0 1 1-45 2,300 / 161.7

* This data should only be used to provide you with your initial size selection.

You must refer to the actual performance graphs. Discharge pressures with use of MKII or MKVII controllers.

MODEL MAX VOLUME STROKE STROKES DISCHARGE

VOLUME PER LENGTH PER MINUTE PRESSURE

STROKE (INCHES) (RANGE)

GPH / LPH CC PSIG / BARG

CRP1500W400 22.90 / 86.40 36.0 1 1/4 1-40 950 / 66

CRP1500W600 22.90 / 86.40 36.0 1 1/4 1-40 1,800 / 124

CRP1500W800 22.90 / 86.40 36.0 1 1/4 1-40 3,200 / 221

CRP2250W600L 90.00 / 336.00 160.0 2 1/2 1-35 1,000 / 69

CRP2250W800L 90.00 / 336.00 160.0 2 1/2 1-35 1,650 / 114

NOTE:

(1)

The minimum volume recommended for any pump should be calculated on the

basis of 1/4 inch minimum stroke length and 5 strokes per minute minimum with a

controller, or 1 stroke minimum with a solenoid.

DUAL SEAL PLUNGER

V

HIGH FLOW, HIGH PRESSURE PLUNGER

W

S E R I E S O F M E T E R I N G P U M P S

Featuring our Oscillamatic

Controller, Pneumatic Relay & All 316 SS Construction

S E R I E S O F M E T E R I N G P U M P S

Featuring our Oscillamatic

Controller & Corrosion-resistant 316 SS Construction

DUAL SEAL PLUNGER

X

S E R I E S O F M E T E R I N G P U M P S

Featuring our Oscillamatic

Controller & Anodized Aluminum for Non-corrosive Applications

ATEX Approved

ATEX Approved

ATEX Approved

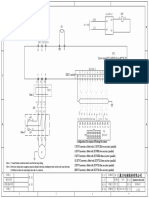

35 to 100 psig

24 VDC

0.5A

WPC 9001

Exhaust

Signal

4-20 mA

Power

Supply

115 VAC

230 VAC

PROCESS FLUID

6 0 0 STROKES PER MINUTE

RESET NO FLOW SELECT

PUMP 1

PUMP

RATE

AUTO

MANUAL

CONTROL LOSS OF I/P MANUAL ADJUST

0 100 %

PUMP 2

TOTAL

WPC9001

12345678

3-WAY

SOLENOID

VALVE

AIR/GAS

SUPPLY

CHEMICAL

SUPPLY

PRESSURE

REGULATOR

PUMP

FLOW

OR PH

METER

WPC9001

APU-XP AUTOMATIC PROCESSING UNIT

WPC-9001-XP (Nema 7)

For Hazardous Locations

MK II & MK VII

WPC-9001-GP (Nema 4x)

For General Purpose Locations

Operation

Auto Mode - The output is 0 to 45

strokes per minute in proportion to

the 4-20 mA input. The rate is field

adjustable.

Manual Mode - Field adjustable from

0 to 45 strokes per minute.

Pump Switching Mode - With a two

pump system using the optional flow

switch the unit selects the standby

pump when no flow signal is trans-

mitted.

Auto/Manual Switching Mode - With

the loss of signal (signal drops below

3.5 mA for more than one minute)

the unit automatically switches to

manual mode.

The APU Series AUTOMATIC PROCESSING UNIT is designed to automate pneumatic metering

pumps. The APU accepts a linear 4-20 mA signal from a process flow meter and operates a

pneumatic metering pump to operate proportional to the input signal for more efficient

chemical usage.

This is accomplished by the use of a normally closed, 3-way solenoid valve

connected to air or gas supply.

Accepts 12 VDC, 24 VDC, 120 VAC, or 220 VAC power supply.

Featuring our latest addition to the Williams line the MK XIIA controller which combines the corrosion resistance of

316 SS with the diaphragm-style spool design for ease of maintenance. The Williams Oscillamatic controllers are

unique and precise pneumatic instruments. These units are designed to operate any pneumatic metering pumps or

instrument requiring pilot pulses. The controllers accept a constant supply of air or gas pressure which produces

pneumatic output pulses. The output signal is manually adjusted by a control rate valve. The controller, installed on

the metering pump, provides the most accurate and reliable pneumatic control available today.

SQUARE

WAVE

PULSE

OUTPUT

POWER SUPPLY

220VAC

120VAC

24VDC

12VDC

APU-XP

PRESSURE

REGULATOR

3-WAY

SOLENOID

VALVES AIR/GAS

SUPPLY

CHEMICAL

SUPPLY

PROCESS FLUID

INPUT SIGNAL

4-20mA

Oscillamatic

PNEUMATIC CONTROLLERS

MK XIIA

MODELS SUPPLY RANGE BODY STROKE ELASTOMERS SPOOL STYLE

PSI BAR MATERIAL SPM AVAILABLE

MK II 25-65 1.7-4.5 ANODIZED 1-45 NEOPRENE DIAPHRAGM

ALUMINUM VITON

MK VII 50-90 3.4-6.2 ANODIZED 1-45 NEOPRENE DIAPHRAGM

ALUMINUM VITON

MK XIIA 30-100 2.0-6.9 316 SS 1-45 NEOPRENE DIAPHRAGM

ELECTRONIC PUMP CONTROLLER

* With 100 PSI air supply

S E R I E S O F M E T E R I N G P U M P S

Featuring our Oscillamatic

Controller

LOW-PRESSURE DIAPHRAGM

CLD

LD100-316-TFE 0.75 / 2.8 80 5.52 100:80 1-45 1.0

LD200-316-TFE 10.0 / 37.8 98 6.76 100:96 1-45 14.0

LD400-316-TFE 45.0 / 170.3 93 6.41 100:93 1-45 63.0

LD100-TFE-TFE 0.75 / 2.8 75 5.17 100:75 1-45 1.0

LD200-TFE-TFE 10.0 / 37.8 93 6.41 100:93 1-45 14.0

LD400-TFE-TFE 45.0 / 170.3 90 6.20 100:90 1-45 63.0

Maximum Maximum Air to Strokes Volume

Volume Discharge Fluid Per Per

Pressure* Pressure Minute Stroke

Model GPH / LPH PSI Bar (SPM) (cc)

The LD Pump Features All-PTFE diaphragms, improved stroke

adjustment, higher flow range, and 316 SS or TFE construction.

WILROY

HY DR AUL I C AL LY AC T UAT E D DI AP HR AGM P UMP

316 SS exposure

Integral relief valve

Maintenance-free hydraulic system

Two sizes in one housing Field reconfigurable

Compact size for ease of installation

Centralized design for ease of maintenance & operation

Gylon

diaphragm for diverse compatibility

Optimum chemical containment

Williams and Milton Roy have combined technologies to design a pump blending the proven mRoy

hydraulic by-pass

diaphragm design with the Williams V Series pump. The result is the low volume, high turndown characteristics of a

pneumatic drive coupled with the chemical containment and high pressure capabilities of a hydraulically actuated

diaphragm.

The WILROY

is a hydraulically actuated diaphragm pump which delivers

chemical containment, low maintenance, overpressurization protection

with unsurpassed accuracy and repeatability. We invite you to look at how

we can meet your chemical injection needs with proven solutions from

Williams Milton Roy.

ATEX Approved

ATEX Approved

Maximum Volume Per Stroke Strokes Max Max Air Consumption

Volume Stroke CC Length Per Minute Discharge @100 PSIG @6.9 BAR

Model

INCH (Range) Pressure

SCF SCM

PSIG / BARG Per Day Per Day

WRA 2M .57 / 2.16 .8 1 1-45 3000 / 207 2100 5

WRA 5M 2.26 / 8.55 3.2 1 1-45 3000 / 207 2100 32

WRB 754 5.0 / 18.9 7.00 1 1-45 3000 / 207 3584 101

WRB 104 9.08 / 33.37 12.7 1 1-45 3000 / 207 2100 101

WRB 106 9.08 / 33.37 12.7 1 1-45 3000 / 207 7190 203

2006 Williams Milton Roy. All Rights Reserved. Doc# 39495 Revised 8-06

Distributed by:

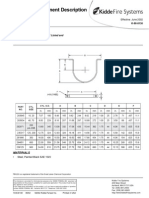

MICRO FLOW SWITCH

WFS6704

Explosion Proof

Class I, Division 1&2,

Groups A, B, C, D

Class II, Division 1&2,

Groups E, F, G

Fully Field Adjustable

Operates in Any Orientation

Miniature Compact Size

Operating Temperature

-40 F to +300 F (-40 C to +150 C)

Operating Pressure 3000 PSIG (207 bar)

Corrosion Resistant 316 Stainless Steel

Shock & Vibration Resistant

1/4 NPT Connections

TYPICAL INSTALLATION

PUMP ACCESSORIES

FlowTracking Controller Configuration Standard Pneumatic Controller Configuration

AIR OR GAS DRYER-FILTERS

Complete with Manual Drain Valve

FLOW

MODELS RATES MAX. PRESSURE

J-150 40SCFM 150 PSI

J-500 40SCFM 500 PSI

PCV125 AL

Pressure Regulator

FLOW

SENSITIVITY RATES MAX. PRESSURE

0.1 PSI 20SCFM 250 PSI

0.689kPa .566m3/min 1724 kPa

AUTOMATIC DUMP VALVES

Used with the Air or Gas Dryer-Filters

MODELS BOWL MAX. PRESSURE

ADV-150-A Plastic 150 PSI

ADV-250-A Steel 250 PSI

LIQUID CHEMICAL FILTERS

316 Stainless Steel

CONNECTION OPTIONAL

MODELS FILTER ELEMENT FILTER ELEMENT

LCF-10-25

1/4 NPT

25 micron, Std

LCF-15-25

1/2 NPT

25 micron, Std

1, 2, 8

microns or

100 mesh

stainless

steel screen

DRUM GAUGES

Liquid Level/Injection Rate Gauge

MODELS MATERIALS

C779WS Carbon Steel

C779WS-V Carbon Steel - Vented

C779WS-SS Stainless Steel

C779WS-SS-V Stainless Steel - Vented

30216-CS-V-GPD-S Carbon Steel

30216-S6-V-GPD-S Stainless Steel

For Detecting Increases & Decreases in Flow Rates

201 Ivyland Road Ivyland, PA 18974 USA

(800) 235-3421 (215) 293-0415 Fax: (215) 293-0498

E-mail: info@williamspumps.com

www.williamspumps.com

www.miltonroy-americas.com

Você também pode gostar

- Soportes AbrazaderaDocumento1 páginaSoportes AbrazaderaCharles H SiahaanAinda não há avaliações

- PM Series MotorDocumento2 páginasPM Series MotorCharles H SiahaanAinda não há avaliações

- EYS116 EYS116 1/2 Cond Seal: AppletonDocumento2 páginasEYS116 EYS116 1/2 Cond Seal: AppletonCharles H SiahaanAinda não há avaliações

- 10 208Documento1 página10 208Charles H SiahaanAinda não há avaliações

- Getting Started Quick Access Menu Basic OperationDocumento1 páginaGetting Started Quick Access Menu Basic OperationCharles H SiahaanAinda não há avaliações

- Factorysealedspliceboxes/Sealingmethods: Fxbseries - ControlsDocumento1 páginaFactorysealedspliceboxes/Sealingmethods: Fxbseries - ControlsCharles H SiahaanAinda não há avaliações

- Replacement Parts: Starters and Contactors - AC CoilsDocumento1 páginaReplacement Parts: Starters and Contactors - AC CoilsCharles H SiahaanAinda não há avaliações

- Welker CatalogDocumento98 páginasWelker CatalogCharles H Siahaan100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- 645295-P56790A-0154 - 01 Acoustic Insulation PDFDocumento18 páginas645295-P56790A-0154 - 01 Acoustic Insulation PDFAnsar AliAinda não há avaliações

- Isuzu FX Fy GX Series 2011 2013my Engine 6uz1 Euro5 Workshop ManualDocumento22 páginasIsuzu FX Fy GX Series 2011 2013my Engine 6uz1 Euro5 Workshop Manualreneehayes080299ifg100% (57)

- 3 Faze ConverterDocumento22 páginas3 Faze ConverterCristi Chihaia100% (1)

- Chromatography ReviewerDocumento4 páginasChromatography ReviewerAnthony Val RolunaAinda não há avaliações

- Is 7001 1989Documento14 páginasIs 7001 1989Kevin100% (1)

- En71 SGSDocumento46 páginasEn71 SGSMax Arias100% (1)

- FMDS 03 10 - Installation & Maintenance of Fire Service MainsDocumento59 páginasFMDS 03 10 - Installation & Maintenance of Fire Service MainsNazri Nawi100% (1)

- Gas Metal Arc WeldingDocumento26 páginasGas Metal Arc WeldingnansusanAinda não há avaliações

- ME 375 - Refrigeration & Building Mechanical Systems - BME0319 Manchar - Lecture 01Documento12 páginasME 375 - Refrigeration & Building Mechanical Systems - BME0319 Manchar - Lecture 01Ahmed Zawad ShovonAinda não há avaliações

- D10D632 Electrical Schematic diagram-ENDocumento31 páginasD10D632 Electrical Schematic diagram-ENPrakashAinda não há avaliações

- Rawlplug en R Kex II Pure Epoxy Resin Threaded RodsDocumento9 páginasRawlplug en R Kex II Pure Epoxy Resin Threaded RodsgumuskapiAinda não há avaliações

- TLCDocumento6 páginasTLCDoni DermawanAinda não há avaliações

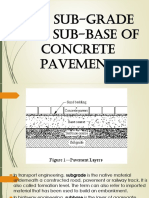

- The Sub-Grade and Sub-Base of Concrete PavementDocumento16 páginasThe Sub-Grade and Sub-Base of Concrete PavementPatrick TaylorAinda não há avaliações

- Ringfeder Fricton Spring Manual (2019)Documento3 páginasRingfeder Fricton Spring Manual (2019)Guang ChenzAinda não há avaliações

- Sae As1650b-2010Documento23 páginasSae As1650b-2010EchoZhangAinda não há avaliações

- Accuris ASPIRE V0020 Instruction ManualDocumento8 páginasAccuris ASPIRE V0020 Instruction ManualTrung Hiếu CamAinda não há avaliações

- CONTRINEX Safety Screen CatalogDocumento23 páginasCONTRINEX Safety Screen CatalogMemik TylnAinda não há avaliações

- RX 6-8 PDFDocumento30 páginasRX 6-8 PDFCyrusAinda não há avaliações

- Structural Steel Design BowlesDocumento276 páginasStructural Steel Design BowlesIonut Narcis Iuga88% (8)

- 1.vision and Mission of Tata Nano: 1. Economic FactorsDocumento5 páginas1.vision and Mission of Tata Nano: 1. Economic FactorsSaprem KulkarniAinda não há avaliações

- KS Series Master Format CSI SpecificationDocumento14 páginasKS Series Master Format CSI SpecificationMohammad Maher AlSafariniAinda não há avaliações

- She 29Documento124 páginasShe 29fitashah2634Ainda não há avaliações

- Forced Convection by Rahul MondalDocumento25 páginasForced Convection by Rahul MondalRahul Mondal100% (1)

- Berta BlastingDocumento13 páginasBerta Blastingkandrian76100% (1)

- Hojas de Sierra Wood-Mizer.Documento8 páginasHojas de Sierra Wood-Mizer.Enrique HernandezAinda não há avaliações

- Bomba Vacio C Lateral FPZ TDDocumento52 páginasBomba Vacio C Lateral FPZ TDchristian_ignacioAinda não há avaliações

- Oxygen Concentrator PDFDocumento25 páginasOxygen Concentrator PDFPavithran SKAinda não há avaliações

- IncinerationDocumento50 páginasIncinerationinder4180100% (1)

- Machining Processes SyllabusDocumento2 páginasMachining Processes SyllabusshailkhanAinda não há avaliações

- LRFD Pedestrian Bridge Example RevDocumento12 páginasLRFD Pedestrian Bridge Example Rev魏学军Ainda não há avaliações