Escolar Documentos

Profissional Documentos

Cultura Documentos

Owc Cementing

Enviado por

raghunagar44Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Owc Cementing

Enviado por

raghunagar44Direitos autorais:

Formatos disponíveis

1

1

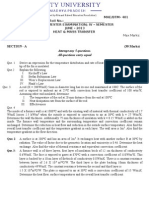

SPE Distinguished Lecturer Program

The SPE Distinguished Lecturer Program is funded principally through a

grant from the SPE Foundation.

The society gratefully acknowledges the companies that support this

program by allowing their professionals to participate as lecturers.

Special thanks to the American Institute of Mining, Metallurgical, and

Petroleum Engineers (AIME) for its contribution to the program.

Society of Petroleum Engineers

Distinguished Lecturer Program

www.spe.org/dl

Cement and Cementing:

An Old Technique With a Future?

Bernard Piot

Schlumberger

Society of Petroleum Engineers

Distinguished Lecturer Program

www.spe.org/dl

2

3

Outline

Cement

Cementing: a necessary evil?

Alternative isolation techniques

Todays well challenges

Cement versatility

Well architecture tool for the future

4

Cement

Material and Regulations

3

5

0:00 0:30 1:00 1:30 2:00

Time (HH:MM)

0

20

40

60

80

100

V

is

c

o

s

it

e

(B

c

)

Thickening time test (neat class G)

0:00 0:30 1:00 1:30 2:00

0

20

40

60

80

100

C

o

n

s

is

t

e

n

c

y

,

B

c

Time, h

Portland Cement

Hydraulic binder

Suspension (paste or

slurry) for placement

Controllable setting

Solid

Strong

Impermeable

Inexpensive

Available everywhere

0 15 30 45 60 75

Time (HH)

0

500

1000

1500

2000

2500

3000

3500

4000

C

o

m

p

re

s

s

iv

e

S

tre

n

g

th

T

y

p

e

B

(p

s

i)

Strength development test (neat class G)

Time, h

0 15 30 45 60 75

C

o

m

p

r

e

s

s

iv

e

s

t

r

e

n

g

t

h

,

p

s

i

1,000

500

1,500

2,000

2,500

3,000

3,500

4,000

0

6

History of Oilfield Cement

Before our era

Clay, lime

Ca(OH)2 + CO2 CaCO3

Roman times

Pozzolanic cements

1824: Portland cement

Selected raw materials

1903: Portland cement in oil wells

1917: Oilfield cements

API created 20 Mar 1919

1940: ASTM Types 1 to 5

1948: API Code 32 released

Became API RP10B in 52

1952: 6 classes of cement

1953: API Std 10A

API Spec 10A in 72

ISO 10426 since 2000

4

7

Cement Types

Construction cements

Common cement

API classes A, B, C

Retarded cements

Deeper wells

Classes D, E, F

Pressurized consistometer

Cementing companies

Abandoned early 80s

Plain Portland cement

Classes G, H

Quality control, reproducibility

More universal

Class J cement

Replaced by G/H + Silica

Slag cement

~80s Brine resistance

~90s Mud compatibility

Others

8

Use of Cement

USA

~ 80% class H and G

~ 10% class A, ~ 10% Class C

Rest of the world (international service companies)

>95% class G (often imported)

Class A or C; or local common cement: preferentially

Type V (ASTM), or CEM-I 42.5 or 52.5 (EN 197-1)

Logistics allowing

If good and even quality

If adequate quality control

5

9

From API to ISO (since 1998)

API Committee 10

ISO TC 67 /SC 3/WG 2

ISO 10426 well cements

ISO 10426-1 (ANSI/API 10A) - specification

ISO 10426-2 (ANSI/API RP 10B-2) - testing

ISO 10426-3 (ANSI/API RP 10B-3) deepwater wells

ISO 10426-4 (ANSI/API RP 10B-4) - foam cement

ISO 10426-5 (ANSI/API RP 10B-5) shrinkage/expansion

ISO 10426-6 (ANSI/API RP 10B-6) static gel strength

Other work groups:

Evaluation (logs), High Temperature, Deepwater

10

Cementing: A Necessary Evil?

Evolution of Equipment and Technology,

and an Outline of Their Shortcomings

6

11

Technology Older Than a Century

First well cementing ~ 1903

Perkins Oil Well Cementing Co., Calif.

Shovel/cement mixer

First use of an eductor

Jet mixer invented 1921

High pressure mixing

In use till the 1970s

Still used by some

Gravity cement feed

12

Primary Cementing Objectives

Casing anchor (axial

support)

Protection against corrosion

and erosion

Support of borehole walls

Zonal isolation

Hole

Casing

Cement

Gas zone

Oil zone

7

13

Unsuccessful Zonal Isolation

Risk to

HSE

ACP/SCP Remedial

work

Early

water

prod

n

Loss of

prod

n

Interzonal

fluid flow

NPV

Loss of Loss of

well well

14

Cementing Process at Surface

Additives

Water

Slurry

Homogenizing/

Control

Pumping Well

Dosing and

Mixing

Dry Additives

Cement Bulk

Blend

8

15

Handling Dry Cement

From cutting sacks to

pneumatic handling

Storage

Transport

Blending

Typical problems

Contamination

Humidity (air)

Deliverability

Homogeneity

Fully automated blender

16

Control of Mixing

SG - 1.0

+

SLURRY SG ~ 1.9

CEMENT

SG - 3.2

=

Density Control

9

17

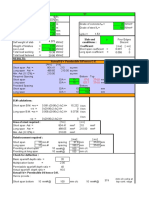

Cement Quality = Slurry Performance

0

0.2

0.4

0.6

0.8

1

Density

Viscosity

Gelation

Free Fluid

Stability

Dehydration

Pump Time

Early Strength

W/C ratio; extender;

weighting agent

Fluid loss agent

Anti-settling agent

Dispersant / viscosifier

Retarder/accelerator

Viscosity

Gelation

Pump time

Free fluid

Dehydration

Stability

Early strength

Density

18

Cementing Additives Key Milestones

Lignosulphonates and cellulosics

Sugars and superplasticizing agents (~ 1960s)

Polyamine/imine ( ~1970s)

SB Latex ( ~ 1980s)

Co/ter-polymers AMPS (~ 1980s)

Temperature stability

Biopolymers (~ 1990s)

Not based on Xanthan gum

Environmentally friendly additives (end 1990s)

OSPAR (OSlo-PARis) convention 1998

10

19

Cementing Process Downhole

Failures identified 30-40s

Field practices

Turbulent displacement

High Reynolds ~50s

10 min contact ~60s

SloFlo / Plug Flow ~70s

Fluid with yield stress

Displacement studies

Yield stress fluids ~end 60s

Mobility ratio/differential

velocity ~70s

Pump as fast as you can

All semi-empirical

Very mixed results

Even in vertical wells

DIRECTION OF FLOW

V = 0

V = 0

V max

20

Mud Removal Modeling

More complex wells

Deviated, horizontal

& extended reach

More critical wells

Deepwater, high-pressure

high-temperature

Importance for Zonal Isolation

Very difficult modeling

Computational Fluid Dynamics

(CFD) tools not applicable

Eccentricity effects

Modeling ~ end 80s

Turbulent/Effective Laminar Flow

Rheology/Density contrast

Erodability / PDGM concept

Polymer muds

Numerical 2D Modeling (2002)

Lubrication analytical model (2003)

11

21

Cement Evaluation Logs

Sonic logs

CBL ~60s

Compensated CBL ~80s

Segmented Compensated

Ultrasonic logs

8 sensors ~80s

1 rotating sensor ~90s

Limitation of cement logs

Strength or Impedance ~80s

Microannulus/Isolation???

Microdebonding ~mid-90 s

Casing interface exclusively

Flexural Attenuation (2006)

1 + 3 sensors

Full cemented annulus width

3rd interface

Differentiate lightweight

cements from liquids

Confirm hydraulic isolation

Visualize casing in borehole

22

Alternative Isolation Techniques

Other Fluids and Mechanical Means

12

23

Organic Resins

Very limited applications

Cost

Shelf-life

Sensitivity

Health, safety, and environment

Compatibility (water, mud)

Placement

24

Mechanical Systems

Complementary to cement

Casing drilling, expandable casing (EC)

Swellable elastomer layer

Exclusive of cement

EC/Casing with (oil or water) swellable

packer

Another form of completion

May still require cement for most other

casings

13

25

Todays Well Challenges and

Versatility of Cement

26

New Reservoir Isolation Challenges

Aging and depleting fields

Completions at lower pressures

Steam injection, stimulation

Workovers and repairs

Plugging and abandonment

Exploration and new developments

Isolation under higher pressure and temperature

Very narrow pore/frac pressures margin

In deeper water and at colder temperatures

14

27

Need for Ultra-Low Density

Conventional Cement

Slurries

Directly linked to W/C ratio

Slurry

Very low rheology

Stability

Set cement

Very low strength, high

permeability, very long

setting times

High performance/high solid

cements

Adapted from concrete industry

Same water/solid ratio at all

densities

From 900 to 2800 kg/m3

Similar rheology

High strength, low permeability

28

Slurry Quality Control?

Solid Fraction Monitoring

SG - 1.0

+

CEMENT

SG - 3.2

Slurry Density - 1.0 ??

=

What if density 1.0?

15

29

Well Architecture and Logistics

Lighter isolation-quality cements

Depleted reservoirs

Single-stage cementing

Production liner instead of casing

Light cements that set faster at

low temperatures

Deepwater conductors,

surface casings

30

Cement A

Cement B

Is Isolation Durable?

Cement is strong, but fragile

Understanding failures

P or T increases

Drilling, milling, repairs

P or T decreases

Modeling capability

Parameter sensitivity

rock

cement

casing

P,T

rock

cement

casing

rock

cement

casing

P,T

16

31

Isolation Made Durable

Controlled flexibility

and expansion

Isolation maintained

during P, T changes

From construction to

abandonment

32

A Tool in Well Architecture

Summary

17

33

Cement in the Past

A necessary evil?

Commodity?

34

Cementing Today

0

0.2

0.4

0.6

0.8

1

Early strength

Final strength

Permeability

Shrinkage

Bonding

Flexibility

Durability

Toughness

Solutions portfolio

Not only slurry

performance

Set material properties

Short/long-term well

requirements

Modeling tools

Fit-for-purpose,

cost-effective system

18

35

Cementing Tomorrow:

A Technology for the Future

Oilwell cementing has evolved considerably

Oilwell cementing will continue to quickly adapt

New cements from cement manufacturers

New tools from cementing service industry

Physically active, chemically re-active or inert materials

Process design/simulation means

A true well engineering technology

An interesting future

Evolving cement industry

Still considerable academic

research

CO2 emissions

Important engineering

development

Oilfield cementing industry

More tools in the toolbox

Materials, simulators

Adapt to tomorrows well

requirements

A true well engineering

technology

36

Thank you for your attention

Você também pode gostar

- Mesh To Micron ConverterDocumento1 páginaMesh To Micron ConverterAniket royAinda não há avaliações

- Specifications For Concrete SleepersDocumento28 páginasSpecifications For Concrete Sleepersgerfreecalls50% (2)

- RpnagarDocumento2 páginasRpnagarraghunagar44Ainda não há avaliações

- InTech-Design Efficiency of Esp PDFDocumento25 páginasInTech-Design Efficiency of Esp PDFPravivVivpraAinda não há avaliações

- 1 LaboratoryCementTestingDocumento29 páginas1 LaboratoryCementTestingejuchiacAinda não há avaliações

- Is 4082 1996Documento2 páginasIs 4082 1996raghunagar44Ainda não há avaliações

- Airtel Prepaid RechargeDocumento1 páginaAirtel Prepaid Rechargeraghunagar44Ainda não há avaliações

- Business Post CentresDocumento69 páginasBusiness Post Centresraghunagar44Ainda não há avaliações

- Business Post CentresDocumento69 páginasBusiness Post Centresraghunagar44Ainda não há avaliações

- Test Manager CV TemplateDocumento2 páginasTest Manager CV Templateraghunagar44Ainda não há avaliações

- Ravi Chauhan +918007679752Documento1 páginaRavi Chauhan +918007679752raghunagar44Ainda não há avaliações

- Glassware Sti For One MarksDocumento10 páginasGlassware Sti For One Marksraghunagar44Ainda não há avaliações

- Assesor Training-2Documento4 páginasAssesor Training-2Raghu Nagar100% (1)

- Calibration VolumetricWareDocumento10 páginasCalibration VolumetricWareraghunagar44Ainda não há avaliações

- Not For Sale: Amendment No. 2 March 2010 TO Is 4032: 1985 Method of Chemical Analysis of Hydraulic CementDocumento5 páginasNot For Sale: Amendment No. 2 March 2010 TO Is 4032: 1985 Method of Chemical Analysis of Hydraulic CementRaghu NagarAinda não há avaliações

- Andi 4.7G Cobalt: Gyro Sensor, G - Sensor, Proximity Sensor, Light Sensor, Magnetic SensorDocumento2 páginasAndi 4.7G Cobalt: Gyro Sensor, G - Sensor, Proximity Sensor, Light Sensor, Magnetic SensorRaghu NagarAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Hardness Test Lab Report PDFDocumento9 páginasHardness Test Lab Report PDFKalKatu MaLam76% (42)

- Flare Piping PDFDocumento1 páginaFlare Piping PDFNilesh GohelAinda não há avaliações

- Cable Tray NEMA VE2 CodeDocumento50 páginasCable Tray NEMA VE2 CodeNavneet Singh100% (1)

- Refractories For The Lime Kiln IndustriesDocumento8 páginasRefractories For The Lime Kiln IndustriesFarshid Torabi100% (1)

- Pyrometric ConesDocumento1 páginaPyrometric Coneslhoffman3Ainda não há avaliações

- Technology Liquid Coating Resins Liquid Coating Resins Product Range Emea EnglishDocumento8 páginasTechnology Liquid Coating Resins Liquid Coating Resins Product Range Emea EnglishUsama AwadAinda não há avaliações

- BPSC AE Paper 5 (Civil) 2022 (English)Documento9 páginasBPSC AE Paper 5 (Civil) 2022 (English)धीरज कुमारAinda não há avaliações

- 3 Truss BridgeDocumento22 páginas3 Truss BridgeVishvanjayAinda não há avaliações

- No Flange Barometric Relief Damper: Application & DesignDocumento3 páginasNo Flange Barometric Relief Damper: Application & DesignEduhar Jesus Vasquez FernandezAinda não há avaliações

- Laminat Revelation 832 - Tehnički List PDFDocumento1 páginaLaminat Revelation 832 - Tehnički List PDFparecproAinda não há avaliações

- Corrosion Resistant Type CF8M (UNS J92900) and CF12MDocumento4 páginasCorrosion Resistant Type CF8M (UNS J92900) and CF12MAnonymous kU3uh2dZ5IAinda não há avaliações

- Rheology TannerDocumento11 páginasRheology TannerRajashree ParidaAinda não há avaliações

- Outershield 71E-H: Mild Steel Rutile Cored WireDocumento2 páginasOutershield 71E-H: Mild Steel Rutile Cored WireLuis DuarteAinda não há avaliações

- All Slab - LSDocumento15 páginasAll Slab - LSTechnical OriliteAinda não há avaliações

- Austentite Steel Thermal StabilizationDocumento17 páginasAustentite Steel Thermal StabilizationArangamar KumaranAinda não há avaliações

- Rockwool Vs GlasswoolDocumento8 páginasRockwool Vs Glasswooly2karein100% (1)

- ATC BrochureDocumento24 páginasATC BrochureCésar HermosoAinda não há avaliações

- 001 Lca Standard ComponentsDocumento4 páginas001 Lca Standard ComponentsYUCARIE HIGUCHIAinda não há avaliações

- Monel® Alloy 400: C MN S Si Ni Cu FeDocumento2 páginasMonel® Alloy 400: C MN S Si Ni Cu FeD_D_76Ainda não há avaliações

- Carter Sy: ApplicationsDocumento1 páginaCarter Sy: ApplicationsmhAinda não há avaliações

- Tower A DesignDocumento254 páginasTower A DesignAnderson Quispe VilcaAinda não há avaliações

- Stauff Surface Cable ClampsDocumento54 páginasStauff Surface Cable ClampsOliver HermosaAinda não há avaliações

- WM3535 1Documento4 páginasWM3535 1aguileraenrique0505Ainda não há avaliações

- A Seminar Report OnDocumento20 páginasA Seminar Report Onadarsh_m00675% (4)

- Engine Cooling System: SectionDocumento48 páginasEngine Cooling System: SectionLuis Alfonso Ortiz ESpinosaAinda não há avaliações

- Connections-I Bolted ConnectionsDocumento21 páginasConnections-I Bolted ConnectionsA.k.MandalAinda não há avaliações

- Report Failure STUB-rev-00Documento38 páginasReport Failure STUB-rev-00JORGE CAICEDOAinda não há avaliações

- Contact Stresses and DeformationsDocumento10 páginasContact Stresses and DeformationsSwamy BabuAinda não há avaliações

- TDS ASTM LM915 Eng 210923Documento2 páginasTDS ASTM LM915 Eng 210923PrashaAinda não há avaliações

- HMT Question PaperDocumento1 páginaHMT Question PaperSanjay GomastaAinda não há avaliações