Escolar Documentos

Profissional Documentos

Cultura Documentos

Approved: Pöyry Energy

Enviado por

tvpham1230 notas0% acharam este documento útil (0 voto)

119 visualizações5 páginasThe document provides comments from Pöyry Energy on the outline drawing for a low pressure feedwater heater (LP-3) for the Two(2) x 500MW Mong Duong 1 Thermal Power Plant project. Pöyry provides several general comments regarding references to other drawings and documents, operating conditions, and design details. They also provide specific comments on issues with nozzle sizes and typographical errors in the outline drawing. The contractor addresses each comment and details the changes or references made in response. Pöyry closes most comments on further revisions, requesting any changes be cloud marked for easy identification.

Descrição original:

feed water heater submission

Título original

MD1-0-V-114-01-00001-C

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoThe document provides comments from Pöyry Energy on the outline drawing for a low pressure feedwater heater (LP-3) for the Two(2) x 500MW Mong Duong 1 Thermal Power Plant project. Pöyry provides several general comments regarding references to other drawings and documents, operating conditions, and design details. They also provide specific comments on issues with nozzle sizes and typographical errors in the outline drawing. The contractor addresses each comment and details the changes or references made in response. Pöyry closes most comments on further revisions, requesting any changes be cloud marked for easy identification.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

119 visualizações5 páginasApproved: Pöyry Energy

Enviado por

tvpham123The document provides comments from Pöyry Energy on the outline drawing for a low pressure feedwater heater (LP-3) for the Two(2) x 500MW Mong Duong 1 Thermal Power Plant project. Pöyry provides several general comments regarding references to other drawings and documents, operating conditions, and design details. They also provide specific comments on issues with nozzle sizes and typographical errors in the outline drawing. The contractor addresses each comment and details the changes or references made in response. Pöyry closes most comments on further revisions, requesting any changes be cloud marked for easy identification.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 5

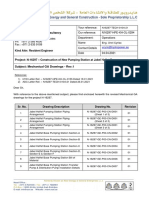

APPROVED A

Approved without exception

APPROVED WITH COMMENTS AC

Approved Subject to Incorporation of comments

RETURNED FOR CORRECTION RT

Insufficient Information/ Detail

Resubmit for Approval

REJECTED RJ

Complete redesign required

RECEIVED FOR INFORMATION I

Returned without comments

RECEIVED FOR INFORMATION IC

Returned with comments

any obligations covered under contract

Engineer:

Discipline:

Date:

Note: Approval or comments does not relieve the Contractor of

Pyry Energy

TWO(2) X 500MW

MONG DUONG 1 THERMAL POWER PLANT

David Langhorne

Senior Mec Engineer

5-Mar-13

Pyry Comment

Two(2) x 500MW Mong Duong 1 Thermal Power Plant Project

Dwg. / Doc. Title

Outline Drawing for LP-3

Low Pressure FWH

Dwg. / Doc. No. MD1-0-V-114-01-00001

HDEC DT No. MD1-HDH-EVN-X-1036 Submitted Date 2012.11.02 Rev. B

Pyry TR No. 9A000323-002559 Received Date 2012.11.28

New HDEC DT No. MD1-HDH-EVN-X-2233 Re-Submitted Date 2013.02.05 Rev. C

Status Received for Information Returned with Comments

Page1 / 4

No. Pyrys Comments Contractors Reply / Action

G General comments

G1 <Pyrys Comments on Rev.A>

HDEC is requested to check carefully all relative

latest P&I drawings, piping arrangement drawing

to make sure that nozzle number, nozzle size

and nozzle orientation on the outline drawing are

matched.

<Contractors Reply / Action on Rev.A>

Noted.

<Contractors Reply / Action on Rev.B>

Closed.

G2 <Pyrys Comments on Rev.A>

Please confirm the heaters shall be provided

with the ASME U stamp.

<Pyrys Comments on Rev.B>

Closed.

<Contractors Reply / Action on Rev.A>

Refer to Contract GTR 4.13 All pressure

vessels and heat exchangers shall be

manufactured by an approved ASME U-stamp

holder.

SEC is an ASME U-stamp holder. Heaters are

manufactured by an ASME U-stamp holder, but

are not provided with U-stamp.

G3 <Pyrys Comments on Rev.A>

Condensate water levels (low alarm, normal

level control, high alarm, emergency control) in

the shell side shall be shown.

.

<Pyrys Comments on Rev.B>

Closed.

<Contractors Reply / Action on Rev.A>

Reflected.

G4 <Pyrys Comments on Rev.A>

Shell side and tube side operating condition

(inlet/outlet temperature and pressure of steam

and water) at VWO condition to be included in

the design data table.

<Pyrys Comments on Rev.B>

Noted, please include a cross reference to this

document on each Heater Outline Drawing.

<Pyrys Comments on Rev.C>

Reference document should include the

technical data sheet in additional to the

mentioned drawings.

It is noted that the list of reference drawings is

on hold at present so please add the technical

data sheet to the reference list.

<Contractors Reply / Action on Rev.A>

For VWO operating condition, please refer to the

Technical Data Sheet. MD1-0-V-114-09-00002

<Contractors Reply / Action on Rev.B>

Reflected.

Page2 / 4

No. Pyrys Comments Contractors Reply / Action

G5 <Pyrys Comments on Rev.A>

Water velocity in the tube side shall be indicated

in the design data table.

<Pyrys Comments on Rev.B>

Noted, see G4 above.

<Pyrys Comments on Rev.C>

Reference document should include the

technical data sheet in additional to the

mentioned drawings.

<Contractors Reply / Action on Rev.A>

For water velocity in the tube side, please refer

to the Technical Data Sheet. MD1-0-V-114-09-

00002

<Contractors Reply / Action on Rev.B>

Reflected.

G6 <Pyrys Comments on Rev.A>

Include the Heater KKS identifier in the

document title.

<Pyrys Comments on Rev.B>

Closed.

<Contractors Reply / Action on Rev.A>

Reflected.

G7 <Pyrys Comments on Rev.A>

Confirm how the tubes are expanded into the

tube sheet. Indicate whether there is a seal

weld.

<Pyrys Comments on Rev.B>

The question is how are the tubes expanded?

The fact that they are expanded was already

noted on the Rev A document.

<Pyrys Comments on Rev.C>

Closed.

<Contractors Reply / Action on Rev.A>

Refer to the design table on outline drawings.

LP Heater : Expand only

HP Heater : Expand +Seal weld

<Contractors Reply / Action on Rev.B>

Please refer to the ATT#1

(Tube Expanding Procedure Sample)

Drawing/documents to also be provided for

all Heaters.

D1 <Pyrys Comments on Rev.A>

Design Calculation Sheets for heat transfer

calculations and to support the data provided in

the tables on the outline drawing.

The calculation document should also identify

the number or percentage of surplus tubes.

<Pyrys Comments on Rev.B>

Noted. The margin of spare tubes over the

calculated tube requirements should be 3%.

Closed as a comment on these documents

however the percentage of spare tubes shall be

identified in the calculations.

<Contractors Reply / Action on Rev.A>

SEC will submit Design Calculation Sheets for

heat transfer calculations later. SEC has

considered margin for heat transfer surface. And

also, SEC has shop margins for tube plugging of

four(4) to five(5) ea.

<Contractors Reply / Action on Rev.B>

Closed.

D2 <Pyrys Comments on Rev.A>

Design Detail Drawings which indicate:

- arrangement of instrument equipments

and tube bundle.

- Name plate, stamping plate location shall

be indicated

<Contractors Reply / Action on Rev.A>

Noted.

SEC will submit drawings the following;

1. Outline drawing

2. Embedded detail drawing

3. Name plate drawing

Page3 / 4

No. Pyrys Comments Contractors Reply / Action

- Heater shell diameter and thickness

- Earth lugs

- Access to the heater waterbox and tube

sheet

- Inspection manholes to allow visual

inspection of the internal condition of the

heat exchanger tubes.

- Measures implemented to prevent

erosion and corrosion on other details

requested in Clause 6.4.3 of the ERQ.

<Pyrys Comments on Rev.B>

Noted.

And also, you can refer to the outline drawing

you want information such as heater shell

diameter, thickness, Earth lug, Access to the

channel barrel and tube sheet.

In case of prevent erosion and corrosion, you

can refer to the impingement plate from

stainless steel for tube erosion and corrosion.

<Contractors Reply / Action on Rev.B>

Closed.

Detail comments on MD1-0-V-114-01-00001

1 <Pyrys Comments on Rev.A>

There are two (2) steam inlet line having pipe

size of DN650mm (refer to P&ID No. MD1-0-M-

110-21-00033 Rev. C). Therefore, there should

be two (2) nozzles DN650 instead of one nozzle

DN550 as shown in the nozzle data table.

Please check and correct.

<Pyrys Comments on Rev.B>

Closed.

<Contractors Reply / Action on Rev.A>

There are two(2) steam inlet nozzle (C1, C2) in

the nozzle data table. And nozzle size was

calculated as per HEI code and standard.

Two(2) DN550 steam inlet were reflected to

P&ID.

2 <Pyrys Comments on Rev.A>

Complete the nozzle bevel detail table.

<Pyrys Comments on Rev.B>

Closed.

<Contractors Reply / Action on Rev.A>

Noted.

3 <Pyrys Comments on Rev.A>

Emergency drain outlet (F) and Drain outlet (E)

having nozzle size of DN250mm while it is

DN200 in P&ID No. MD1-0-M-110-21-00042.

Please clarify.

<Pyrys Comments on Rev.B>

Closed.

<Contractors Reply / Action on Rev.A>

The nozzle sizes are calculated as per HEI

standard. HDEC will use 250 x 200 reducer for

drain outlet.

4 <Pyrys Comments on Rev.A>

Correct nozzle size for channel relief valve from

DN80(3/4) to DN80(3).

<Pyrys Comments on Rev.B>

Closed.

<Contractors Reply / Action on Rev.A>

Correct nozzle size for channel relief valve from

DN80(3/4) to DN80(3).

5 <Pyrys Comments on Rev.A>

Correct typing error word in the nozzle data

table from Sehll level to Shell level.

<Pyrys Comments on Rev.B>

Closed.

Reflected.

Page4 / 4

No. Pyrys Comments Contractors Reply / Action

6 <Pyrys Comments on Rev.B>

Any change from the previous version shall be

cloud marked.

<Pyrys Comments on Rev.C>

Closed.

<Contractors Reply / Action on Rev.B>

Reflected.

Você também pode gostar

- Approved: Pöyry EnergyDocumento3 páginasApproved: Pöyry Energytvpham123Ainda não há avaliações

- MD1 0 V 111 01 00003 BDocumento5 páginasMD1 0 V 111 01 00003 Btvpham1230% (1)

- Approved: Pöyry EnergyDocumento2 páginasApproved: Pöyry Energytvpham123Ainda não há avaliações

- Approved: Pöyry EnergyDocumento3 páginasApproved: Pöyry Energytvpham123Ainda não há avaliações

- Approved: Pöyry EnergyDocumento2 páginasApproved: Pöyry Energytvpham123Ainda não há avaliações

- MD1 0 V 113 01 00001 ADocumento2 páginasMD1 0 V 113 01 00001 Atvpham123Ainda não há avaliações

- Bill of Quantities For Plant Room FloorDocumento3 páginasBill of Quantities For Plant Room FloorAwais JalaliAinda não há avaliações

- Mechanical GA Drawings - Rev.1Documento14 páginasMechanical GA Drawings - Rev.1unnicyriacAinda não há avaliações

- Approved: Pöyry EnergyDocumento2 páginasApproved: Pöyry Energytvpham123Ainda não há avaliações

- Approved: Pöyry EnergyDocumento2 páginasApproved: Pöyry Energytvpham123Ainda não há avaliações

- 1.00.00 GENERAL Information: (For Vendor Registration Purpose)Documento7 páginas1.00.00 GENERAL Information: (For Vendor Registration Purpose)Rajendran SrnAinda não há avaliações

- TB#15 PDFDocumento8 páginasTB#15 PDFAnonymous 2wNNl0ULEAinda não há avaliações

- 10P87-D0003-046-R0-WHRU by TEPLDocumento23 páginas10P87-D0003-046-R0-WHRU by TEPLjigarAinda não há avaliações

- For Information: ApprovedDocumento2 páginasFor Information: Approvedtvpham123Ainda não há avaliações

- Bharat Heavy Electricals Limited Bhopal: Transformer Engineering DepartmentDocumento3 páginasBharat Heavy Electricals Limited Bhopal: Transformer Engineering Departmentsuleman247Ainda não há avaliações

- Transformer Comment Sheet - 20.11.2020Documento3 páginasTransformer Comment Sheet - 20.11.2020Mani SAinda não há avaliações

- TB#14 PDFDocumento8 páginasTB#14 PDFAnonymous 2wNNl0ULEAinda não há avaliações

- 200-1013-06-003 RFQ Full Package and High Pressure Coil Design CalculationDocumento15 páginas200-1013-06-003 RFQ Full Package and High Pressure Coil Design CalculationBilel MahjoubAinda não há avaliações

- Approved: Pöyry EnergyDocumento3 páginasApproved: Pöyry Energytvpham123Ainda não há avaliações

- TQ - Air Fin Cooler (CS) - ModificationDocumento6 páginasTQ - Air Fin Cooler (CS) - ModificationAvinash ShuklaAinda não há avaliações

- Tell Tale HoleDocumento45 páginasTell Tale HoleSingarao Katta33% (3)

- 000-GC-P-009 R.3 Piping Installation PDFDocumento35 páginas000-GC-P-009 R.3 Piping Installation PDFJessica Torres100% (1)

- Approved: Pöyry EnergyDocumento2 páginasApproved: Pöyry Energytvpham123Ainda não há avaliações

- 2 11 KV Panel - Shop Drawings & Data Sheet Shop Drawings 3 2.7 A NDocumento1 página2 11 KV Panel - Shop Drawings & Data Sheet Shop Drawings 3 2.7 A NFaizan KhanAinda não há avaliações

- ZAU 256 MS 2105 00003 0001 A01 Datasheet For Produced Water Storage Vessel (V 8421)Documento6 páginasZAU 256 MS 2105 00003 0001 A01 Datasheet For Produced Water Storage Vessel (V 8421)Vijayaraj KumarAinda não há avaliações

- Sop Panel Coil Tubes Standard Repair ProcedureDocumento3 páginasSop Panel Coil Tubes Standard Repair ProcedureMoustafa FaresAinda não há avaliações

- Checklist For Separator Cum Storage TankDocumento5 páginasChecklist For Separator Cum Storage TankRamalingam PrabhakaranAinda não há avaliações

- SOP - Standard Repair Procedure For PipingDocumento3 páginasSOP - Standard Repair Procedure For PipingBrahim BahriAinda não há avaliações

- Essar Steel PlantDocumento62 páginasEssar Steel PlantKrishnadev C.SAinda não há avaliações

- KBR Piping Stress SpecificationDocumento23 páginasKBR Piping Stress Specificationsamprof4vw83% (6)

- Kta Tb-Pac03-032 1 DatasheetDocumento3 páginasKta Tb-Pac03-032 1 DatasheetLê Đức ThiệnAinda não há avaliações

- Consultant Queries - Chilled Water PumpDocumento6 páginasConsultant Queries - Chilled Water PumpMohammad Abdul KhadeerAinda não há avaliações

- Technical Queries PoweQ-02 IRAN TRANSFODocumento3 páginasTechnical Queries PoweQ-02 IRAN TRANSFO54045114Ainda não há avaliações

- Approved: David Langhorne Senior Mec Engineer 03-Apr-13Documento2 páginasApproved: David Langhorne Senior Mec Engineer 03-Apr-13tvpham123Ainda não há avaliações

- Sample UDS DocumentDocumento14 páginasSample UDS Documentnilesh_raykarAinda não há avaliações

- Guidelines For Piping Design & ErectionDocumento55 páginasGuidelines For Piping Design & ErectionKartik Varma Namburi100% (2)

- Ab-083fa Guide For Completing Form Ab-83fDocumento5 páginasAb-083fa Guide For Completing Form Ab-83fDrewAinda não há avaliações

- Project Standard Specification: Heat Exchangers 15710 - Page 1/3Documento3 páginasProject Standard Specification: Heat Exchangers 15710 - Page 1/3adel rihanaAinda não há avaliações

- Piping SpecDocumento355 páginasPiping Speclcaron44100% (1)

- YSD-P02-0508-HV-BKG-MS-00024 (01) - Air Handling Units-B PDFDocumento1.168 páginasYSD-P02-0508-HV-BKG-MS-00024 (01) - Air Handling Units-B PDFZac Riego100% (2)

- Checklist For Storage Tank (F-33) : Rprabhakaran 10/12/2020Documento3 páginasChecklist For Storage Tank (F-33) : Rprabhakaran 10/12/2020Ramalingam PrabhakaranAinda não há avaliações

- Addendum No. 1: Gate Apron Rehabilitation and Drainage Improvements (GARDI) Concourse B SoutheastDocumento208 páginasAddendum No. 1: Gate Apron Rehabilitation and Drainage Improvements (GARDI) Concourse B SoutheastgobiAinda não há avaliações

- A 02Documento30 páginasA 02senioor2004Ainda não há avaliações

- Proc LTSC HRRL Sow R2Documento12 páginasProc LTSC HRRL Sow R2Subrata DasAinda não há avaliações

- General Spec - Feed HeaterDocumento9 páginasGeneral Spec - Feed HeaterDeepikaAinda não há avaliações

- HP Dosing - AgecDocumento12 páginasHP Dosing - AgecShameer MajeedAinda não há avaliações

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1No EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Nota: 3.5 de 5 estrelas3.5/5 (3)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsNo EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsNota: 4.5 de 5 estrelas4.5/5 (10)

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNo EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsAinda não há avaliações

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentAinda não há avaliações

- Industrial Process Plant Construction Estimating and Man-Hour AnalysisNo EverandIndustrial Process Plant Construction Estimating and Man-Hour AnalysisNota: 5 de 5 estrelas5/5 (1)

- How to prepare Welding Procedures for Oil & Gas PipelinesNo EverandHow to prepare Welding Procedures for Oil & Gas PipelinesNota: 5 de 5 estrelas5/5 (1)

- All-in-One Manual of Industrial Piping Practice and MaintenanceNo EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceNota: 5 de 5 estrelas5/5 (1)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsNo Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsNota: 4 de 5 estrelas4/5 (1)

- Fire Fighting Layout For Underground Piping (13/17) : Two (2) X 500Mw Mong Duong1 Thermal Power PlantDocumento1 páginaFire Fighting Layout For Underground Piping (13/17) : Two (2) X 500Mw Mong Duong1 Thermal Power Planttvpham123Ainda não há avaliações

- MD1 0 V 121 01 00001Documento2 páginasMD1 0 V 121 01 00001tvpham123100% (1)

- CONVEYOR CALCULATION SHEET DraftDocumento37 páginasCONVEYOR CALCULATION SHEET Drafttvpham12350% (6)

- 01-08-2013 Issue For InformationDocumento5 páginas01-08-2013 Issue For Informationtvpham123Ainda não há avaliações

- MD1 0 V 113 01 00001 ADocumento2 páginasMD1 0 V 113 01 00001 Atvpham123Ainda não há avaliações

- MD1-0-E-505!06!00001 Generator Transformer Sizing CalculationDocumento19 páginasMD1-0-E-505!06!00001 Generator Transformer Sizing Calculationtvpham12350% (2)

- MD1 0 e 505 06 00001 0Documento19 páginasMD1 0 e 505 06 00001 0tvpham123Ainda não há avaliações

- Approved: Soumen Mitra Senior Mec Engineer 30-May-12Documento2 páginasApproved: Soumen Mitra Senior Mec Engineer 30-May-12tvpham123Ainda não há avaliações

- MD1 0 e 182 06 00001 0Documento6 páginasMD1 0 e 182 06 00001 0tvpham123Ainda não há avaliações

- ADB MD1 0 C D 0001 A, Geotechnical Soil Investigation Plan DrawingDocumento2 páginasADB MD1 0 C D 0001 A, Geotechnical Soil Investigation Plan Drawingtvpham123Ainda não há avaliações

- Pressure Form Test PlanDocumento1 páginaPressure Form Test Plantvpham123Ainda não há avaliações

- As BuiltExamplesDocumento28 páginasAs BuiltExamplestvpham123Ainda não há avaliações

- Vmon 0030M Dji Irc 001Documento83 páginasVmon 0030M Dji Irc 001tvpham123Ainda não há avaliações

- MD1-0-V-191!11!10601-A, Detail Drawings For Compressed Air System HoistDocumento2 páginasMD1-0-V-191!11!10601-A, Detail Drawings For Compressed Air System Hoisttvpham123Ainda não há avaliações

- Commercial Invoice: 1. Shipper/Exporter 8. No. & Date of InvoiceDocumento1 páginaCommercial Invoice: 1. Shipper/Exporter 8. No. & Date of Invoicetvpham123Ainda não há avaliações

- Modeling & Simulation of Water Gas Shift ReactionDocumento5 páginasModeling & Simulation of Water Gas Shift Reactionagarwalashwin32Ainda não há avaliações

- Exp8.Synthesis of Acetylsalicylic AcidDocumento2 páginasExp8.Synthesis of Acetylsalicylic AcidjspontejosAinda não há avaliações

- Calculation of The Platinum's Active Surface PDFDocumento3 páginasCalculation of The Platinum's Active Surface PDFUriel Cedeño AntunezAinda não há avaliações

- Casio Chemical EquilibriumDocumento2 páginasCasio Chemical EquilibriumPraise OrogunAinda não há avaliações

- Phytochemical Analysis of WeedsDocumento4 páginasPhytochemical Analysis of WeedsvishcrimeAinda não há avaliações

- Commissioning of BFPLDocumento11 páginasCommissioning of BFPLsaravananknpcAinda não há avaliações

- USP-NF 1092 The Dissolution Procedure - Development and ValidationDocumento26 páginasUSP-NF 1092 The Dissolution Procedure - Development and Validationmohamedzahafa2Ainda não há avaliações

- Osaka 2018 PDFDocumento148 páginasOsaka 2018 PDFcmc261185Ainda não há avaliações

- Pharmaceutical Oral PresentationDocumento3 páginasPharmaceutical Oral PresentationLRWthe3rdAinda não há avaliações

- Why Russians Ban Microwave Ovens: 479 Turnpike Street, Suite 3 South Easton, MA Tel.: 508-238-8521Documento2 páginasWhy Russians Ban Microwave Ovens: 479 Turnpike Street, Suite 3 South Easton, MA Tel.: 508-238-8521Tamara Alvarado CastilloAinda não há avaliações

- Topics of Water PollutionDocumento7 páginasTopics of Water PollutionsabaAinda não há avaliações

- Operation Management of Particle Board PlantDocumento18 páginasOperation Management of Particle Board PlantMainul AlamAinda não há avaliações

- EFMA Ammonia Pipeline Guidance 2008Documento50 páginasEFMA Ammonia Pipeline Guidance 2008Robert Smallwood100% (1)

- PROCEEDINGS of The 4th International Conference On Heap Leach SolutionsDocumento455 páginasPROCEEDINGS of The 4th International Conference On Heap Leach SolutionsjoelAinda não há avaliações

- Organic Chemistry 3 Assignment 1, B1748443Documento7 páginasOrganic Chemistry 3 Assignment 1, B1748443zacksAinda não há avaliações

- Rates of Reaction - Disappearing Cross LabDocumento3 páginasRates of Reaction - Disappearing Cross Lab4L Anisha SieudassAinda não há avaliações

- 2011 - Sage - Natural Fiber-Based Reinforcements in Epoxy Composites Processed by Filament WindingDocumento9 páginas2011 - Sage - Natural Fiber-Based Reinforcements in Epoxy Composites Processed by Filament WindingECE IV YearAinda não há avaliações

- Whitewares (Class-04)Documento40 páginasWhitewares (Class-04)Zahid HasanAinda não há avaliações

- Comparing The Degree of Unsaturation of Olive Oil and That of Margarine Jameela Comments by FM PDFDocumento2 páginasComparing The Degree of Unsaturation of Olive Oil and That of Margarine Jameela Comments by FM PDFFrank Massiah0% (1)

- Vectra GL Brochure PDFDocumento4 páginasVectra GL Brochure PDFpexyAinda não há avaliações

- Apa Structurata PDFDocumento101 páginasApa Structurata PDFromeocostiAinda não há avaliações

- CP 00143-15-1973 (2007) PDFDocumento34 páginasCP 00143-15-1973 (2007) PDFStanislav PerevezentsevAinda não há avaliações

- A5 32-A5 32mPVDocumento7 páginasA5 32-A5 32mPVAnonymous 1GK9Hxp5YKAinda não há avaliações

- Marine Engine Brochure 4.4TGMDocumento2 páginasMarine Engine Brochure 4.4TGMinfraAinda não há avaliações

- PE Film CatalogueDocumento2 páginasPE Film CatalogueMERVEAinda não há avaliações

- Bainite Transformation During Continuous Cooling: Analysis of Dilatation DataDocumento6 páginasBainite Transformation During Continuous Cooling: Analysis of Dilatation DataVanina DuttoAinda não há avaliações

- NMAT Chemistry Practice Questions Set 3Documento9 páginasNMAT Chemistry Practice Questions Set 3Nurshayma JalilAinda não há avaliações

- Fill Volume Weight and Other Checks For Parenteral Products During Filling-1Documento4 páginasFill Volume Weight and Other Checks For Parenteral Products During Filling-1SolomonAinda não há avaliações

- Allproductscatalog PDFDocumento578 páginasAllproductscatalog PDFrajpvikAinda não há avaliações

- Act. 6 - Correct Execution of Clearing TechniqueDocumento4 páginasAct. 6 - Correct Execution of Clearing Techniquechristian Jay HorseradaAinda não há avaliações