Escolar Documentos

Profissional Documentos

Cultura Documentos

Concrete Mix Design

Enviado por

vempadareddyDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Concrete Mix Design

Enviado por

vempadareddyDireitos autorais:

Formatos disponíveis

CONCRETE MIX DESIGN ( M50 GRADE )

(a ) design stipulations :

1

2

3

4

5

Characteristic compressive strength required in the field at 28

days

a!imum si"e of aggregate

#egree of $or%a&ility

#egree of quality control

'ype of e!posure

5(pa

2(mm (angular)

()*( (compaction factor )

+ood

severe

( &) test data for materials:

1

2

3

4

5

,

-

Cement used. ordinary portland cement satisfying the

requirements of /0 122,* 11***

0pecific gravity of cement (53 grade)

/ 0pecific gravity of coarse aggregate

/i specific gravity of fine aggregate

2ater a&sorption

/ coarse aggregate

/i fine aggregate

3ree surface moisture

3ine aggregate

Coarse aggregate

0ieve analysis

3ine aggregate

3ine ness modulus ( 3)

53 +rade

3)2(

2)85

2)-8

()8(4

1),84

()8(4

()4(4

Confirming to grading

"one ii of ta&le 4 of /0

38311**-

2),2

( c ) target mean strength of concrete

3t 5 fc%6 %s

3t55(61),5!55 58)25 78mm2

2here ft 5 target mean compressive strength at 28 days)

3c%55(. characteristic compressive strength at 28 days

05 5. standard deviations ( from ta&le 8 of /0 45,12((()

9 5 1),5 ( 'olerance factor)

(c) selection of $ater cement ratio :

from figure 4- of sp: 23 11*82. the $ater cement ratio required for the target mean strength of

58)25 78mm2 is o)33) this is lo$er than ma!imum value of ()45 prescri&ed for severe e!posure

( from ta&le 23 of sp231 1*82 )

(e ) selection of $ater and sand content:

3rom ta&le 43. for 2(mm nominal ma!imum si"e of aggregate and sand confirming to grading

"one ii . $ater content 8m3 of concrete is equal to 18( %g and sand content as a percentage of

total aggregate &y a&solute volume is equal to 254 ) for change in values in $ater cement ratio .

compacting factor . the follo$ing ad:ustment is required)

;d:ustment required in

Change in condition (from ta&le 44 of sp:

23)

2ater content4 4 sand in total

aggregate

3or decrease in $ater cement ratio &y

( o)451 ()33 )

3or increase in compacting factor (()*(1

()8(). that is .()(1

(

63)(

13)5

'otal 6 3)( 1 3)5

'here fore required sand content as 4 of total aggregate &y a&solute volume 5 2513)5 521)5 4

<equired $ater content518(618(!3)581(( 518,)3( %g8m3

(f ) determination of cement content:

2ater cement ratio 5 ()33

2ater5 18,)3%g

Cement 518,)38()33 55,4)54%g

=imit545( %g

2ater 5 45(!()335148)5%g

(g) determination of coarse and fine aggregate content

3rom ta&le 41. for the specified ma!imum si"e of aggregate of 2(mm. the amount of entrapped

air in the $et concrete is 2 4 ) ta%ing this into account and applying equation .

> 5 ( $ 6c80c 618p !fa8sfa) !181(((

> 5 ( $ 6 c80c 6 18(11p) ! ca 80ca) ! 181(((

> 5 a&solute volume of fresh concrete

5 gross volume (1m3) minus the volume of entrapped air .

0c 5 specific gravity of cement

2 mass of $ater (%g) per m3 of concrete .

C 5 mass of cement ( %g) per m3 of concrete

? 5 ratio of fine aggregate to total aggregate &y a&solute volume

3a. Ca 5total masses of fine aggregate and coarse aggregate %g per m3 of concrete

respectively.

0fa. 0ca5 specific gravity of saturated surface dry fine and coarse aggregate. respectively)

()*8m35 ( 148)56 45(83)2618()215 !fa82)-8)!181(((

3a 5 412)*45413 %g

*8(5 (148)5 6 45(83)2 618()-85!182)85)

1545),,5154, %g8m3

'he mi! proportions then &ecomes:

2ater(%g) Cement(%g) 3ine aggregate(9g) Coarse

aggregate(%g)

;dmi!ture

(%g)

148)5

()33

45(

1

413

()*1--

154,

3)43,

* or 13)5

( h ) actual quantities required for the mi! per &ag of cement :

'he mi! is o)33:1:()*1--:3)43, (&y mass )

3or 5( %g of cement the quantity of materials are $or%ed out as under

(i) cement5 5( %g

(ii) sand 5 45)885 %g

(iii) coarse aggregate 5 1-1)8 %g admi!ture5@ 24 . or 34 &y $eight of cement)

CONCRETE MIX DESIGN M50 ( Mix proportions with micro silic or silic !"m# )

/0 45, A 2((( recommends silica fume as replacement of cement in the proportion of 5 to 1(

percent of the cementitious materials )

Considering a cementing efficiency factor of silica fumes as 3)(

0ilica fume content @ 8 4 5 8! 45(81((53, %g

<eduction in cement content 5 3 ! 3, 5 1(8 %g

Buantity of cement 5 45(1 1(8 5 342 %g

3rom yield point of vie$ . sand content

C11 3428(3)2( ! 1((() A 3,8 (2)2! 1((( )1 154,8 (2)85! 1((() 118,)381((( A 381(()D

5 ()15*m3

5()2(m3 (say )

2eight of sand 5 ()2( ! 1((( ! 2)-85 55, %g

Eigh range $ater reducing admi!ture @ 3 4 53! (34263,)81(( 5 11)34 %g

7et $eight of $ater e!cluding that in high range $ater reducing admi!ture

18,)3 A 11)34 1-4)*, %g

?ercentage of silica fume5 3, ! 1(( 8(34263, ) 5 *)52 4 . $hich is $ith in the optimum range of

5 to 1( percent )

'he mi! proportions using silica fume are

/ngredients $eight 8m3 of concrete . %g

Cement 342 %g

0and 55, %g

Coarse aggregate 154, %g

2ater 1-4)*, %g

0uper plastici"er 11)34 %g

CONCRETE MIX DESIGN (M$0 GRADE)

() %#si&n stip"ltions '

1 Characteristic compressive strength required in the field at 28 days ,(78mm2

2

3

4

5

a!imum si"e of aggregate

#egree of $or%a&ility

#egree of quality control

'ype of e!posure

2(mmor 12)5mm

()*((compaction

factor)

+ood

severe

(() t#st %t !or mt#rils

1

2

3i

ii

4

i

ii

5

,

-

Cement used ordinary port land cement(opc) satisfying the

requirements of / 0 122,*11***

0pecific gravity of cement

0pecific gravity of coarse aggregate

0pecific gravity of fine aggregate

2ater a&sorption

Coarse aggregate

3ine aggregate

3ree surface moisture

/ coarse aggregate

/i fine aggregate

0ieve analysis (fine aggregate)

3ine ness modulus

53 grade

3)15

2),(

2)4,

()5

1),5

()2

()5

Confirming to grading "one ii of

ta&le 4 of /0 38311**-

2),-

( C ) 'arget mean compressive strength at 28 days)

3c% 5 fc% 6 %)s

5 ,( 6 1),5! -

-1)55 78mm2

2here ft 5 target mean compressive strength at 28 days

3c% 5 ,(. characteristic compressive strength at 28 days.

05 - . standard deviations ( from ta&le 1 /0 1(2,2 1*82)

95 tolerance factor

( d ) selection of $ater cement ratio from figure 4- of 0? 23 1*82. the $ater cement ratio required

for the target mean strength of -1)55 78mm2 is ()31 5()31

'his is lo$er than the ma!imum value of (),5 prescri&ed for F severe Fe!posure ( from ta&le 23 of

0? 2311*82))

( e ) selection of $ater and sand content)

3rom ta&le 43 of 0? 231 1*82 . for 2(mm nominal ma!imum si"e aggregate and sand confirming

to grading "one ii . $ater content8m3 of concrete is equal to 18( %g and sand content as

percentage of total aggregate &y a&solute volume is equal to 25 percent) 3or change in values in

the $ater content ratio .compacting factor . the follo$ing ad:ustment is required)

Change in condition ( from ta&le 44 of 0? 23)) ;d:ustment required in

2ater content 4 4 sand in total

aggregate

3or decrease in $ater cement ratio &y ((),51

()31)5 ()34

3or increase in compacting factor (()*(1 ()8( )

that is .()1

'otal 5

(

6 3)(

6 3)(

1 3)5

13)5

'here fore required sand content s as 4 of total aggregates &y a&solute volume 5 251 3)5 5 21)5

4

<equired $ater content 6 18(6 ( 18( !3)581(()

518,)3( %g )

( f ) determination of cement content :

2ater cement ratio 5 ()31

2ater 5 18,)3( %g

Cement 5 18,)3(8()31 5 ,(()*,1 %g

=imit 545( %g actual $ater 5 45(! ()31 13*)5 %g

Cement 5 13*)58()31 5 45( %g8m3

( g ) determination of coarse and fine aggregate content :

3rom ta&le 41 . for the ma!imum si"e of aggregate of 2(mm . the amount of entrapped air in the

$et concrete is 24 ) ta%ing this into account and applying equation .

> 5 ( 2 6 C80c 6 18? ! fa80fa ) 181(((

2here . >5 a&solute volume of fresh concrete

5 gross volume ( 1 m3) minus the volume of entrapped air)

0c 5 specific gravity of cement

2 5 mass of $ater (%g) per m3 of concrete

? 5 ratio of fine aggregate to total aggregate &y a&solute volume)

fa . Ca 5 total masses of fine and and coarse aggregate. * 9+ ( 8m3 of concrete respectively

and .

0fa. 0ca 5 specific gravities of saturated surface dry fine aggregate and coarse aggregate

respectively)

()*8 5 ( 13*)5 6 45(83)15 6 18()215 ! fa82)4,) ! 181(((

3a 5 3,* %g8 m3

()*8 5 ( 13*)5 6 45(83)15 618()-85 ! ca82),( ) !181(((

Ca 5 1423)88 %g

;dmi!ture @ 24 to 34 &y $eight of cement

2!45(81(( 5 * %g8m3 . or . 3! 45( 81(( 5 13)5 %g 8m3

'he mi! proportions &ecomes :

2ater

13*)5( %g

()31

Cement

45( %g

1

3ine aggregate

3,* %g

()82

Coarse aggregate

1424 %g

3)1,4

;dmi!ture (%g)

* or 13)5

( h) actual quantities required for the mi! per &ag of cement :

'he mi! is .

()31:1:()82:3)1,4 ( &y mass)

3or 5( %g of cement the quantity of materials are $or%ed out as follo$s.

( 1 ) cement 5 5( %g

( 2 ) sand 5 41 %g

(3) coarse aggregate 5 158)21 %g

(4 ) $ater for $ater cement ratio ()31 . $ater 5 15)5 liters)

G!tra $ater to &e a&sor&ed in case of coarse aggregate at (()81 ()3 ) 5 ()25 liters)

G!tra $ater to &e added for a&sorption in sand at ( 1),5 A ()5) &y mass 5 ()5-5 liters

;ctual $ater to &e added 5 15)5 6 ()25 6 ()5-5

5 1,)325 liters)

(5 ) actual quantity of sand required after allo$ing for mass of pre moisture

411 ()5-5 5 4()425 liters

5 4()425 %g

( , ) actual quantity of coarse aggregate required 5 158)2 A ()25 5 15-)*5 %g

5 15-)*5 %g

'here fore . the actual quantities of different constituents required for the mi! are

2ater 5 1,)325 lit8%g

0and 5 4()425 %g

Cement 5 5( %g

Coarse aggregate 5 15- )25 %g

CONCRETE MIX DESIGN M$0 GRADE (MIX )RO)ORTIONS *IT+ MICRO SI,ICA OR

SI,ICA -.ME )

/0 45, A 2((( recommends silica fume as replacement of cement in the proportion of

replacement of cement in the proportion of 5 to 1( percent of cementitious materials )

;ssuming 8 4 addition of silica fume in the concrete 5 45( ! 881((

5 3, %g

<eduction in the cement content 5 3, ! 3 5 1(8 %g

Cement 5 45(11(8 5 342 %g

3rom the yield point of vie$ C 1 A 3428(3)15! 1((() 13,8(2)2! 1((() 114248(2), !1((()1 18,)381(((

A 381(( D

5 11 ()8- 5 ()13 m3

()2(m3

2eight of sand 5 )2! 2), 1((( 5 52( %g

Eigh range $ater reducing admi!ture @ 3 4 5 3(34263,) 5 11)34 %g

7et $eight of $ater e!cluding that in the high range $ater reducing admi!ture

18,)3(1 11)34 5 1-4)*,%g

?ercentage of silica fume 5 3,! 1(( 8 (34263,) 5 *)523. $hich is $ith in the optimum range of

54 to 1( 4

'he mi! proportions using silica fume are :

/ngredients $eight 8m3 of concrete (%g)

Cement 342

icro silica (silica fume ) 3, %g

0and 52( %g

Coarse aggregate 1424 %g

2ater 1-4)*, %g

Eigh range $ater reducing admi!ture 11)34 %g

CONCRETE MIX DESIGN M/0 GRADE

( ) D#si&n stip"ltion '

1

2

3

4

5

Characteristic compressive strength required in the field at 28 days

a!imum si"e of aggregate

#egree of $or%a&ility

#egree of quality control

'ype of e!posure

-( 78mm2

2(mm or 12)5mm

(angular)

()* (C) 3))

+ood

0evere

( ( ) t#st %t !or mt#rils

1

2

3

4

5

,

-

Cement used A ordinary portland cement satisfying the

requirements of /0 122,*

0pecific gravity of cement ( 53 grade )

/ 0pecific gravity of coarse aggregate

/i specific gravity of fine aggregate

2ater a&sorption. / coarse aggregate

/i fine aggregate

3ree surface moisture. / coarse aggregate

/i fine aggregate

0ieve analysis

3ine aggregate . confirming to grading "one ii of ta&le 4 of /0 383

1**-

3ine ness modulus

53 pa

3)1,

2)-5

2),(

()84

1),84

()44

()84

2)51

( c ) target mean strength of concrete

3t 5 fc% 6 %s

3t 5 -( 61),5! - ( 05- . as per /0 1(2,2)

5 81)5578mm2

2here ft 5 target mean compressive strength at 28 days)

05 - . standard deviation

95 1),5 tolerance factor)

(d ) selection of $ater cement ratio from figure 4- of 0? 231 1*82 . the $ater cement ratio

required for the target mean strength of 81)55 78mm2 is ()3() this is lo$er than the ma!imum

value of (),5 prescri&ed for severe e!posure ( from ta&le 23 of sp 231 1*82))

(e) selection of $ater and sand content:

3rom ta&le 43. for 2(mm or 125 mm . nominal ma!imum si"e aggregate and confirming to

grading "one // . $ater content 8m3 of concrete is equal to 18( %g and sand content as

percentage of total aggregate &y a&solute volume is equal to 25 percent ) for change in values of

$ater cement ratio . compacting factor. the follo$ing ad:ustment is required )

Change in condition ( from ta&le ta&le

44 of 0? 23)

;d:ustment required

2ater content 4

in

4 sand in total aggregate)

3or decrease in $ater cement ratio &y (

(),(1()3() 5()3(

3or increase in compacting factor

(()*(1()8() that is ()(1

'otal 5

(

6 3)(

6 3)(

13)(

(

13)(

'here required sand content as 4 of total aggregate &y a&solute volume.

>olume 5 251 3)( 522 4

<equired $ater content 5 18(6 18(!381((

18(6 5)4 5 185)4 %g)

(f ) determination of cement content

2ater1 cement ratio 5 ()3(

2ater 185)4%g

Cement 5 185)48()3( ,18%g

=imit5 53( %g 8m3

2ater 5 53(! ()3( 5 15* %g

(g ) determination of coarse and fine aggregate content:

3or the specified ma!imum si"e of aggregate of 2(mm. the amount of entrapped air in the $et

concrete is 24 ) ta%ing this into account and applying equation

>5( $ 6 c80c 6 18p ! fa80fa)!181(((

>5 ($6 c80c 6 18(11p) ! Ca80ca) !181(((

2here. v 5a&solute volume of fresh concrete

5gross volume (1m3) minus the volume of entrapped air.

0c 5 specific gravity of cement

2 5 mass of $ater ( %g) per m3 of concrete

C 5 mass of cement ( %g) per m3 of concrete)

? 5 ratio of fine aggregate to total aggregate &y a&solute volume)

3a . Ca . 5 total masses of fine aggregate and coarse aggregate ( %g) per cu&ic meter of concrete

respectively.

()*8m3 5 n(15*653(83)1, 6 18()22 !fa82),() 181(((

3a 5 3-3),-%g8m3

()*8 5 ( 15*6 53(83)1, 6 18()-8 !Ca82)-5) ! 181(((

Ca 5 14(1)3 %g8m3

;dmi!ture 5 @ 24 to 34 &y $eight of cement

2! 53(81((.51(), %g. or

3! 53(81(( 5 15)* %g8m3

'he mi! proportions then &ecomes :

2ater(%g) Cement (%g) 3ine aggregate(%g) Coarse aggr (%g) ;dmi!ture(%g)

15*

()3(

53(

1

3-4

()-(,

14(1)3

2),44

1(), or 15)*

(h) actual quantities required for the mi! per &ag of cement :

'he mi! is. ()3(:1:()-(,:2),44 )

3or 5( %g of cement the quantities of materials are $or%ed out as &elo$)

1 cement 5 5( %g

2 sand 535)3 %g

3 coarse aggregate 5 132)2 %g

(4) $ater . for $ater cement ratio ()3(.

$ater 5 15)( %g

e!tra $ater to &e added for a&sorption in case of coarse aggregate at (()81()4)&y mass5()54

liters)

G!tra $ater to &e added for a&sorption in sand at (1),84 1 ()84)5()4* liters)

;ctual $ater to &e added 5 15)(6()54 6()4* 51,)3 litres)

(5)actual quantity of sand required after allo$ing for mass of pre moisture 35)31()4*534)81%g

(,) actual quantity of coarse aggregate required5132)21()545 131),,%g

'herefore. the actual quantities of different constituents required for the mi! are:

2ater5 1,)(3%g

Cement55(%g

0and 534)81%g

Coarse aggregate 5 131),, %g

CONCRETE MIX DESIGN M/0 GRADE ( MIX )RO)ORTIONS *ITR+ MICRO SI,ICA OR

SI,ICA -.ME ) '

/0 : 45, A 2((( recommends silica fume as replacement of cement in the proportion of 5 to 1(

percent of the cementitious materials ) cementing efficiency factor of silica fume as 3)( )

0ilica fume content @ -)5 5 5 53( ! -)5 81(( 53*)-5%g 5 4( %g

<eduction in cement content 5 4(! 3 5 12( %g

Cement content 5 53(1 12( 541( %g

3rom the yield point of vie$

C 11 41(8(3)1, ! 1((( ) A 4(8(2)2!1((() A 14(18(2)-5!1((()115*81((( 1381(( D

5 ()154m3 5 ()2((m3

2eight of sand ()2(! 1((( ! 2),

552( %g

Eigh range $ater reducing admi!ture @ 3 4 5()(3! (41(64()

13)5%g5 13)5litres

2ater 5 15*113)5 5 145)5 %g

?ercentage of micro silica 5 4( 1((8 (41(64() 5 8)88.

2hich is $ith in the optimum range of 5 to 1( percent )

'he mi! proportions using the silica fume are

/ngredients $eight 8m3 of concrete . %g

Cement 41( %g

icro silica 4( %g

0and 52( %g

Coarse aggregate 14(1 %g

2ater 145)5 %g

Eigh range $ater reducing admi!ture 13)5 %g

CONCRETE MIX DESIGN (M 00 GRADE)

( ) D#si&n stip"ltions

1

2

3

4

5

Characteristic compressive strength required in the field at 28 days

a!imum si"e of aggregate

#egree of $or%a&ility

#egree of quality control

'ype of e!posure

8(78mm2

2(mm or

12)5mm (angular)

()*((compaction factor)

good

severe

(()t#st %t !or mt#rils

1

2

3

4

5

,

-

Cement used .ordinary portland cement confirming to /0 122,*

11***)

0pecific gravity of cement (53 grade )

/ specific gravity of coarse aggregate

/i specific gravity of fine aggregate

2ater a&sorption

/ coarse aggregate

/i fine aggregate

3ree surface moisture

/ coarse aggregate

/i fine aggregate

0ieve analysis

/ fine aggregate

3ine ness modulus

53 grade

3)2(

2)8-

2)-3

()84

2)(4

()44

()84

Confirming to grading

"one ii of ta&le 4 of /0 :

38311**-

2)52

(c) Tr&#t m#n str#n&th o! concr#t#

ft 5 fc% 6 %)s

5 8(6 1),5!8 (s 8 as per is 1(2,2)

5 *3)2 78mm2

2here ft 5 target mean compressive strength at 28 days

3c% 5 8(78mm2. characteristic compressive strength at 28 days

0 58 ( standard deviation from /0 1(2,2 .assumed )

9 5 tolerance factor

( % ) s#l#ction o! wt#r c#m#nt rtio'

3rom figure 4- of 0? 231 1*82. the $ater cement ratio required for the target mean strength of

*3)2 78mm2 is ()28 ) this is lo$er than the ma!imum value of ()45 prescri&ed for severe

e!posure( from ta&le 23 of 0? 23 A 1*82)

( # ) s#l#ction o! wt#r n% sn% cont#nt :

3rom ta&le 43. for 2(mm nominal ma!imum si"e aggregate and sand confirming to grading "one

ii . $ater content 8m3 of concrete is equal to 18( %g and sand content as percentage of total

aggregate &y a&solute volume is equal to 25 percent ) for change in values in $ater cement ratio .

ad:ustment is required )

;d:ustment required in

Change in condition (from ta&le 44 of sp: 23) 2ater content 4 4 sand in total

aggregate

3or decrease in $ater cement ratio ((),1

()41)5()25

3or increase in compacting factor (()*1 ()8 )

that is ()(1

(

6 3)(

13)(

(

total 63)( 13)(

'here fore required sand contents as 4 of total aggregate &y a&solute volume5 251 3)( 5224

<equired $ater content 5 18(6 3!18(81(( 5185)4 %g

( ! ) %#t#rmintion o! c#m#nt cont#nt

2ater cement ratio 5()28

2ater content 5 185)4 liters .or %g

Cement 5 185)48()28 5,,2)14 %g

=imit 5 53( %g 8m3

2ater content 553(!()28

5 148)4%g

'his cement content is adequate for severe e!posure conditions ta&le 23. page ,5. 0? 231.1*82 )

(G) D#t#rmintion o! cors# n% !in# &&r#&t# cont#nt'

3rom ta&le 41. for the specified ma!imum si"e of aggregate 2(mm. the amount of entrapped air

in the $et concrete is 2 4 ) ta%ing this into account and applying equation)

> 5 ( $6c80c 618p ! fa 8sfa )!181(((

> 5 ( $ 6 c80c 618(11p) !Ca80ca)!181(((

2here. v 5a&solute volume of fresh concrete

5 gross volume (1m3) minus the volume of entrapped air)

0c 5 specific gravity of cement

2 5mass of $ater (%g) per m3 of concrete

C 5 mass of cement (%g) 8m3 of concrete

? 5 ratio of fine aggregate to total aggregate &y a&solute volume)

fa. ca5 total masses of fine aggregate and coarse aggregate %g8m3 of concrete respectively. and

0fa and 0ca 5 specific gravity of saturated surface dry fine aggregate and coarse aggregate

respectively)

()*8m35 (148)4 6 53(83)2()618()22 ! fa82)-3)!181(((

fa53**)*8%g 5 4(( %g8m3

()*8m35( 148)4 6 53(83)2(6 18()-8 !ca82)8- ) !181(((

Ca5 14*()85 %g8m35 14*1%g8m3

;dmi!ture @ 24 &y $eight of cement

2!53(81(( 51(), %g. or

3!53(81(( 5 125)* %g

'he mi! proportions then &ecomes

2ater(%g) Cement(%g) 3ine aggregate(%g) Coarse

aggregate(%g)

;dmi!ture

(%g)

148)4

()28

53(

1

4((

()-54

14*1

2)813

1(),.or.15)*

(h) ct"l 1"ntiti#s r#1"ir#% !or th# mix p#r (& o! c#m#nt '

'he mi! is ()28:1:()-54:2)813 (&y mass ) . for 5( %g of cement the quantities of materials are

$or%ed out as &elo$:

1 Cement 5 5( %g

2 sand 53-)-%g

3 coarse aggregate

4 $ater

3or $ater cement ratio of ()28

2ater 5 ()28!5(

G!tra $ater to &e added for a&sorption in case of coarse aggregate at (()8 A ()4 )4 5&y mass 5

()55 %g

G!tra $ater to &e added for a&sorption in sand at(1),81 ()8 )4&y mass5 ()4* %g

;ctual $ater to &e added

5 146()556()4* 5 15)(4 %g

( 5 ) actual quantity of sand required after allo$ing for mass of pre moisture 5 3-)-1 ()4* 63-)21

%g)

(5) actual quantity of coarse aggregate required 5 14(),51()55 514()1 %g

there fore . the actual quantity of different materials required for the mi! are :

$ater5 15)(4 %g

cement 5 5( %g

sand 5 3-)21 %g

coarse aggregate 514()1 %g)

CONCRETE MIX DESIGN M00 GRADE CONCRETE (Mix proportions with silic !"m# or

micro silic )

/0: 45, A 2((( recommends silica fume as replacement of cement in the proportion of 5 4 to 1(

4 of the cementitious materials)

;ssuming efficiency factor of silica fume 5 3

0ilica fume content @ -)5 4

5 53( ! -)5 8 1(( 5 3*)-5%g 5 4( %g

<eduction in cement content 5 3 ! 4(5 12( %g

Cement5 53(112( 541( %g

0and content .

C 11 41(8 (3)2(! 1((() 14( 8 (2)2! 1((() A 14*18(2)8- ! 1((() A 148)4 81((( A

381(( D

5 ()1-1m3 5 ()2( m3 (say)

2eight of dry sand 5 ()2(! 2)-3! 1((( 5 54, %g

Eigh range $ater reducing admi!ture @ 3 4 5 3! (41(64( ) 81(( 5 13)5 %g

2eight of $ater 185)4(113)5 5 1-1)* %g

?ercentage of silica fume 5 (4( ! 1(( ( 8 (41( 64( ) 5 8)88 . $hich is $ith in the optimum range 5

to 1( percent )

'he mi! proportions using silica fume are :

/ngredients $eight 8m3 of concrete . %g

Cement 41( %g

0ilica fume 4( %g

0and 54, %g

Coarse aggregate 14*1%g

2ater 1-1)* %g

0uper plastici"er 13)5 %g

DESIGN O- MIX

ean strength 5 (5( 8 ()8() 5 ,3 ?a

<eference num&er (fig)1)5 25

2ater cement ratio (fig 5) 5 ()35

3or a 1(mm ma!imum si"e aggregate and very lo$ $or%a&ility. the aggregate1cement ratio for

the desired $or%a&ility (ta&le11) 53)2

'he aggregates are com&ined &y the graphical method as sho$n in figure ,. so that 3( percent of

the material passes through the 4)-5 mm /0 sieve)

<atio of fine to total aggregate 5 254

<equired proportions &y $eight of dry materials:

Cement A 1

3ine aggregates A C(2581(()!3)2D 5 ()8

Coarse aggregates A C(-581(()!3)2)D 5 2)4

2ater 5 ()35

/f C 5 $eight of cement required per cu&ic meter of concrete. then

Você também pode gostar

- Representative Student's NameDocumento2 páginasRepresentative Student's NamevempadareddyAinda não há avaliações

- SD PrintDocumento5 páginasSD PrintvempadareddyAinda não há avaliações

- Print SDDocumento4 páginasPrint SDvempadareddyAinda não há avaliações

- Tep - Set 1Documento1 páginaTep - Set 1vempadareddyAinda não há avaliações

- WAC and PorosityDocumento11 páginasWAC and PorosityvempadareddyAinda não há avaliações

- Springer Journal Paper On Bacterial ConcreteDocumento12 páginasSpringer Journal Paper On Bacterial Concretevempadareddy100% (1)

- List of Paper Publications Journals: InternationalDocumento7 páginasList of Paper Publications Journals: InternationalvempadareddyAinda não há avaliações

- Questions For The Revised BloomDocumento2 páginasQuestions For The Revised BloomvempadareddyAinda não há avaliações

- Principles of SafetyDocumento24 páginasPrinciples of SafetyvempadareddyAinda não há avaliações

- Self Healing Concrete - Sample DetailsDocumento1 páginaSelf Healing Concrete - Sample DetailsvempadareddyAinda não há avaliações

- How Is HRA Decided?: Basic SalaryDocumento1 páginaHow Is HRA Decided?: Basic SalaryvempadareddyAinda não há avaliações

- BTech Thesis GuidelinesDocumento17 páginasBTech Thesis Guidelinesvempadareddy100% (1)

- Notes For Print TEPDocumento21 páginasNotes For Print TEPvempadareddyAinda não há avaliações

- Acsge 2018 Extended Abstract TemplateDocumento2 páginasAcsge 2018 Extended Abstract TemplatevempadareddyAinda não há avaliações

- Railway FAQDocumento9 páginasRailway FAQvempadareddyAinda não há avaliações

- Setting Time of ConcreteDocumento2 páginasSetting Time of ConcretevempadareddyAinda não há avaliações

- PGS 506 DISASTER MANAGEMENT 1+0 (E-Course)Documento1 páginaPGS 506 DISASTER MANAGEMENT 1+0 (E-Course)vempadareddy0% (1)

- Linear and Non-Linear Dynamic AnalysisDocumento10 páginasLinear and Non-Linear Dynamic AnalysisvempadareddyAinda não há avaliações

- Arch ActionDocumento14 páginasArch ActionvempadareddyAinda não há avaliações

- Linear and Non-Linear Dynamic AnalysisDocumento9 páginasLinear and Non-Linear Dynamic AnalysisvempadareddyAinda não há avaliações

- CVR Jour No.11Documento112 páginasCVR Jour No.11vempadareddyAinda não há avaliações

- Mlrit Int ConfDocumento8 páginasMlrit Int ConfvempadareddyAinda não há avaliações

- I. Teaching: Performance in The Last Two Completed SemestersDocumento7 páginasI. Teaching: Performance in The Last Two Completed SemestersvempadareddyAinda não há avaliações

- Imrf Journals: Editorial Board Nomination FormDocumento3 páginasImrf Journals: Editorial Board Nomination FormvempadareddyAinda não há avaliações

- Nat Conf Mrec - DR VSRDocumento8 páginasNat Conf Mrec - DR VSRvempadareddyAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Section 7 BOQ - 0Documento83 páginasSection 7 BOQ - 0techsmith124Ainda não há avaliações

- Case Study For Tunnel in Concrete Lining On JKDocumento12 páginasCase Study For Tunnel in Concrete Lining On JKPremnath YadavAinda não há avaliações

- TDS ASP-coatSLDocumento2 páginasTDS ASP-coatSLtatenda mhuruAinda não há avaliações

- Lean To Shed Plans 4x8Documento13 páginasLean To Shed Plans 4x8clanleader16Ainda não há avaliações

- B S Brick SpecialsDocumento32 páginasB S Brick SpecialswdfearonAinda não há avaliações

- How To Clean Dining Room by Avery Alumaga Tle 9Documento15 páginasHow To Clean Dining Room by Avery Alumaga Tle 9leam.alumaga002Ainda não há avaliações

- T 1 2 1 LvsDocumento6 páginasT 1 2 1 Lvsaca111111Ainda não há avaliações

- R1116010-00000-CI-SPC-0006-0A-Civil WorksDocumento37 páginasR1116010-00000-CI-SPC-0006-0A-Civil WorksLAinda não há avaliações

- Pet 101 JavpssDocumento1 páginaPet 101 Javpsswww.everything4less.comAinda não há avaliações

- SEMINAR REPORT RCC RoadDocumento25 páginasSEMINAR REPORT RCC RoadAkshay GhorpadeAinda não há avaliações

- VocabulárioTécnico InglêsDocumento80 páginasVocabulárioTécnico InglêsEvandro Cesário da SilvaAinda não há avaliações

- RFQ For Building, Electricals and HardwareDocumento3 páginasRFQ For Building, Electricals and HardwareSimbarashe KamudyariwaAinda não há avaliações

- Dubai Municipality G 1 G 4 G 12 Exams MCQs 1690895684Documento20 páginasDubai Municipality G 1 G 4 G 12 Exams MCQs 1690895684osama78% (9)

- DMDave - Dungeons & Lairs 9 - Mummy Lord's PyramidDocumento21 páginasDMDave - Dungeons & Lairs 9 - Mummy Lord's PyramidFelipe Klann100% (1)

- Squah Court QuotationDocumento3 páginasSquah Court QuotationOmair Akhtar KhanAinda não há avaliações

- Steps BuildingDocumento4 páginasSteps BuildingIJGamingAinda não há avaliações

- Standardsand Specificationsfor KspanprojectsDocumento45 páginasStandardsand Specificationsfor KspanprojectsDonnabel CaleAinda não há avaliações

- Fabrication Jansen Profile system-VMDocumento98 páginasFabrication Jansen Profile system-VMSimon KennyAinda não há avaliações

- Ivy Apartment Brochure 2022Documento16 páginasIvy Apartment Brochure 2022Rory MurrayAinda não há avaliações

- Green Building Material Used in ConstructionDocumento8 páginasGreen Building Material Used in ConstructionIqRa JaVedAinda não há avaliações

- 45662597562obj CivilEngineering 2006paper IDocumento18 páginas45662597562obj CivilEngineering 2006paper I94738183Ainda não há avaliações

- AnstarDocumento49 páginasAnstarhanuman sharmaAinda não há avaliações

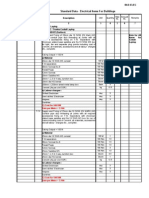

- Revised Standard Data For ElectrificationDocumento120 páginasRevised Standard Data For ElectrificationKishore Ainavilli100% (1)

- Non Pre-Load Bolt Assemblies BS EN 15048 Parts 1 & 2Documento2 páginasNon Pre-Load Bolt Assemblies BS EN 15048 Parts 1 & 2vomawew647Ainda não há avaliações

- High Temp ResinDocumento8 páginasHigh Temp ResinwaiplAinda não há avaliações

- 2018 Ibc Seaoc Structural Seismic Design Manual Volume 2 Examplespdf CompressDocumento385 páginas2018 Ibc Seaoc Structural Seismic Design Manual Volume 2 Examplespdf Compressvkch saipavan100% (3)

- Slab On GradeDocumento2 páginasSlab On GradeVistash Buhary100% (1)

- Brochures For Block MakingDocumento3 páginasBrochures For Block MakingJefftzAinda não há avaliações

- Building Construction I-Lecture 1C (Introduction)Documento22 páginasBuilding Construction I-Lecture 1C (Introduction)sujan shresthaAinda não há avaliações

- BS 3712-2 1973Documento13 páginasBS 3712-2 1973Mahmoud hassanAinda não há avaliações