Escolar Documentos

Profissional Documentos

Cultura Documentos

A New Empirical Model

Enviado por

Md Zillur RahmanDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

A New Empirical Model

Enviado por

Md Zillur RahmanDireitos autorais:

Formatos disponíveis

A new empirical model for the acoustic

properties of loose granular media

N.N. Voronina

a

, K.V. Horoshenkov

b,

*

a

Institute of Building Physics, 21 Lokomotivnyi Pr., Moscow 127238, Russia

b

School of Engineering, Design and Technology, University of Bradford, Bradford BD7 1DP, UK

Received 3 December 2001; received in revised form 24 September 2002; accepted 2 October 2002

Abstract

This paper examines physical parameters of loose granular mixes and their empirical rela-

tions to the acoustic performance of these mixes. In this work a new classication of granular

media has been proposed which is related to the characteristic particle dimension and the

specic density of the grain base. It has been shown that this classication is a useful char-

acteristic for rapid evaluation of the acoustic performance of loose granular mixes. The

characteristic impedance and propagation constant have been measured for a representative

selection of grain mixes and used to develop a new empirical model. This model relates the

above acoustic characteristics to the characteristic particle dimension, porosity, tortuosity and

specic density of the grain base, which are routinely measurable parameters. A very good

agreement with the experimental data is illustrated in the frequency range of 2504000 Hz for

materials with the grain base of 0.43.5 mm and specic densities between 200 and 1200 kg/m

3

.

Unlike many theoretical models for the prediction of the acoustic properties of porous media,

the proposed expressions do not involve any special functions of complex argument, empirical

shape factors or sophisticated characteristics of porous structure. These are practical enough to

be of interest to acoustic and noise control engineers and material manufacturers.

# 2002 Elsevier Science Ltd. All rights reserved.

Keywords: Sound propagation; Loose granulates; Porous media; Acoustic absorption

1. Introduction

In recent years the use of acoustic porous materials for indoor and outdoor appli-

cations has been stimulated by legislation in the area of environmental noise and

public health. Absorbers are now routinely used to improve the acoustic performance

Applied Acoustics 64 (2003) 415432

www.elsevier.com/locate/apacoust

0003-682X/03/$ - see front matter # 2002 Elsevier Science Ltd. All rights reserved.

PI I : S0003- 682X( 02) 00105- 6

* Corresponding author. Tel.: +44-1274-233-877; fax: +44-1274-233-888.

E-mail address: k.horoshenkov@bradford.ac.uk (K.V. Horoshenkov).

of noise barriers, factory spaces, sports halls and auditoria. A large selection of

acoustic materials is currently oered for these uses, the majority of which are

brous layers and reticulated foams.

Recent work suggests that granular porous materials can be regarded as an alter-

native to many existing brous and foam absorbers in many indoor and outdoor

applications [1]. In granular materials good absorption can be combined with good

mechanical strength and very low manufacturing costs which is important in many

acoustic applications. There are many theoretical and empirical models which are

used to model sound propagation in granular porous media. However, recent results

for rubber granulates [2] suggest that some existing models for sound propagation in

porous media can fail due to the complexity of the porous structure of these mate-

rials. In this previous work four models [36] have been tested to predict the surface

impedance of loose and consolidated mixes of recycled rubber granulates. It has

been shown that in order to provide a tolerable t to the experimental data the

values of the ow resistivity and porosity in these models need adjusting by up to

70%. These results are of considerable concern, and suggest the need for developing

an improved model for the acoustic properties of granular media.

On the other hand, there is a general lack of experimental data on the character-

istic impedance and propagation constant in practical granular mixes. It appears

that many researchers report on routinely measurable acoustic surface impedance

and normal incidence absorption coecient, which, are in many cases, not particu-

larly helpful to obtain a clear insight into the physical mechanisms of the acoustic

absorption in the porous media. In this respect, the availability of independently

measured data on the acoustic characteristic impedance and propagation constant is

of great importance for developers of new models, which provide the basis for

benchmarks and validation of their work.

The purpose of this paper is to investigate experimentally the fundamental

acoustic properties of granular media and to use the experimental results to develop

a practical acoustic model, which is robust in a broad range of acoustic frequencies

and particle sizes. The following materials were investigated in this work: vermiculite

(phyllosilicate mica), granulated rubber from automotive tyres, perlite (expanded

silicone glass) and granulated nitrile foam.

The paper is organised in the following manner. Section 2 discusses the physical

parameters, which are required for modelling the acoustic properties of granular

media. Section 3 provides the methodology for the experimental investigation, which

was conducted on a representative selection of loose granular mixes. Section 4 pre-

sents the new empirical expression for the structural characteristic, which then is

used in Section 5 to predict the acoustic characteristic impedance and propagation

constant. Section 6 presents the conclusions.

2. Physical parameters of porous materials

Granular materials are often modelled as a rigid frame porous medium formed by

the rigid, interconnected particles and voids in which a slow compressional wave can

416 N.N. Voronina, K.V. Horoshenkov / Applied Acoustics 64 (2003) 415432

propagate. The sound speed and the attenuation of the compressional wave in the

porous medium are, therefore, functions of the size of pores and the proportion of

the open pores. These properties are largely related to the size, shape and the degree

of compaction of the particles, which constitute the rigid frame. The degree of

compaction is determined by the density of the granular mix and aects its porosity

and permeability (e.g. [7,8]). It is common to expect a considerable variation in the

acoustic properties of granular mixes, which are composed of dierently compacted

grains although the grains are identical in size [1]. The shape of particles largely

inuences the degree of compaction and, therefore, the porosity of the granular mix

[7]. As an example, particles of granulated rubber tend to take the form of irregular

parallelepipeds, particles of perlite are close to ellipses and particles of vermiculite

appear in the form of plates. In this respect, the denition of the characteristic

dimension can be confusing. A more general way to characterise granular mixes

with particles of dierent shape is to assume that the characteristic particle dimen-

sion is the diameter of a sphere which volume is equivalent to the mean volume of

the particles in a given mix. The way in which the characteristic dimension is dened

is of importance, because it is convenient to relate the acoustic properties of a loose

granular mix the to the characteristic dimension of its particles, D, and to the por-

osity, H 1 ,

m

,,

g

, both of which are routinely measurable characteristics. Here

,

m

is the density of the granular mix and ,

g

is the specic density of the grain

material. In many cases, the value of the latter parameter is signicantly inuenced

by the presence of the cracks and micro-pores, which also aect the acoustic per-

formance of the loose particle mix. The characteristic dimension of the particles can

be found provided that the number of the particles in a unit volume, V

g

, of the

granular mix is known, in which case D

V

g

,0.5233

p

. This method yields a 25%

accuracy for large grain mixes. For small grain mixes the accuracy of this method

deteriorates to around 20%, which is still an acceptable value for many applications

of engineering acoustics. The specic density of the granular mix is easily determined

from the principle of Archimedes.

When an acoustic wave is incident on a porous layer, the thermo-viscous eects in

the uid lling the voids between the particles are responsible for the energy loss in

the oscillating acoustic ow [913]. It has been shown that the thermal dissipation

eects in commercial porous materials are typically small (e.g. [14]). The viscous eects

are important only inside the viscous boundary layer and the viscous energy loss in the

acoustic model can be accounted for by introducing a dimensionless parameter

D,

0

c

j

10

4

1

where j is the dynamic viscosity of air, ,

0

is the equilibrium density of air and c is the

sound speed in air. The parameter can be used to classify granular mixes according

to the particle characteristic dimension, i.e. one can refer to large grain mixes for

52, medium grain mixes for 1 - - 2 and to small grain mixes for 41.

Recent results for porous materials with high porosity [15] suggest that the

acoustic properties of granular materials can be aected by the value ,

g

,,

0

. The

acoustic attenuation tends to increase with the reduced value of the grain density.

N.N. Voronina, K.V. Horoshenkov / Applied Acoustics 64 (2003) 415432 417

This can be related to two separate phenomena: mechanical friction between the

elements of the non-rigid frame in porous materials with low specic density and to

the absorption in the frame micro-pores. The friction phenomenon can be of

importance in the low frequency range, where the inertial eects are small and vis-

cous drag is relatively large. In this regime the shape of the particles is of relatively

small importance and the eect can be modelled using the expressions for the oscil-

lating ow drag experienced by a stack of identical spherical beads (e.g. [16]). The

inuence of the particle micro-porosity is likely to be pronounced in the higher fre-

quency range [17], where additional dissipation can take place due to the thermal

non-equilibrium in micro-pores. These two eects can be accounted for phenomen-

ologically by introducing a dimensionless parameter

M

,

g

10

3

,

0

. 2

where the factor of 10

3

is a dimensionless normalisation factor. The measured values

of the density, porosity, characteristic particle dimension and the dimensionless

parameters and M are provided in Table 1 for the eight granular mixes.

In addition to the above parameters, it is also common to include in an acoustic

model the measured values of ow resistivity, r, and tortuosity, q, which are closely

related to the macrostructure of the porous mix [9]. In this work the ow resistivity

have been measured at Bradford University using the standard method detailed in

[18]. The results for six material samples are provided in Table 2. In the special case

of an oscillatory ow past a stack of spherical beads, the tortuosity can be predicted

from the approximate expression [16]

q

2

1 1 H2H

1

3

However, for realistic mixes with irregular particle shapes expression (3) is rather

idealised. In this particular work the tortuosity was experimentally deduced using

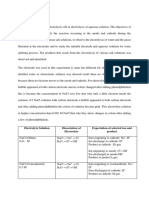

Table 1

Basic physical parameters used in the empirical model for granular media

Material Density, ,

m

(kg/m

3

)

Porosity, H Characteristic particle

size, D (mm)

Parameter

Vermiculite, ,

g

1200 kg/m

3

, M 0.975

1 385 0.68 1.4 3.1

2 370 0.69 0.5 1.1

3 420 0.65 0.4 0.89

Rubber crumb, ,

g

1050 kg/m

3

, M 0.925

4 590 0.44 3.5 7.1

5 520 0.54 1.6 3.6

Perlite, ,

g

200kg/m

3

, M 0.163

6 80 0.60 2.2 4.9

7 44 0.78 0.5 1.1

Nitrile foam granulate, ,

g

165 kg/m

3

, M 0.358

8 15 0.91 1.2 2.29

418 N.N. Voronina, K.V. Horoshenkov / Applied Acoustics 64 (2003) 415432

two independent methods: from the upper-frequency data on the real part of the

refraction index [19] and the ultrasonic time of ight method [20]. The results, which

are provided in Table 2 suggest that the experimentally determined values of the

tortuosity can dier considerably from those predicted by expression (3). In the case

of vermiculite, the predicted values are consistently lower that the experimental

results (see Table 2), which can be attributed to the deviation of the shape of ver-

miculite particles from the assumed spherical shape.

The values of the tortuosity can also be deduced from the behaviour of the real

part of the characteristic impedance. At frequencies above some critical frequency,

f

cr

, the real part of characteristic impedance approaches asymptotically to its higher-

frequency limit [9]

W

cr

a

q,H. 4

and is relatively independent of the frequency. The larger the size of the grain base,

the lower the value of the critical frequency. It can be shown experimentally that for

large grain mixes ( 52) f

cr

- 500 Hz, so that the tortuosity can be deduced from

expression (4) in which W

cr

a

is a routinely measurable constant. Table 2 provides the

deduced values of the tortuosity for large grain mixes 1, 4, 5 and 6 and for med-

ium grain mix 2. Generally, there is a good agreement between the values of the

turtuosity, which were measured with the three experimental methods (see

Table 2). For small grain mixes ( 41) the proposed experimental method for

measuring tortuosity is likely to fail, because of the relatively high value of the

critical frequency (f

cr

> 4000 Hz), above which the reliable impedance data are

usually unavailable.

Table 2

Values of non-acoustic parameters used for modelling of the acoustic properties of porous media. The

experimental values of the tortuosity were deduced using the method [19] and are compared with the

bracketed values from the method [20]

Material Flow resistivity (Pa s m

2

) r Tortuosity, q

Exp. (14) Experiment Exp. (3) Exp. (4) Experiment

Vermiculite

1 7610 7580 1.11 1.72 1.58 (1.51)

2 56800 61000 1.11 1.78 1.63 (1.76)

3 107000 135000 1.13 1.48 (1.45)

Rubber crumb

4 3190 2800 1.27 1.11 1.13 (1.19)

5 9800 13600 1.21 1.29 1.26 (1.23)

Perlite

6 4280 1.50 1.48

7 32800 1.08

Nitrile foam granulate

8 1163 2800 1.03 1.32 1.31 ()

N.N. Voronina, K.V. Horoshenkov / Applied Acoustics 64 (2003) 415432 419

3. Methodology

An experimental investigation of the acoustic properties has been carried out

using the impedance tube method in the frequency range of 2504000 Hz using the

standard procedure detailed in ISO 10534-1:1996 and ISO 10534-2:1998. Samples of

granular materials have been tested in two independent laboratories to ensure the

reproducibility of the experimental data. The impedance tube in the University of

Bradford (BK 4206) is installed in the vertical position to allow the acoustic prop-

erties of non-consolidated mixes to be easily measured. The impedance tube in the

Institute of Building Physics in Moscow (BK 4002) is installed in the horizontal

position. In the case of the horizontally installed tube the investigated materials were

packed in a special attachment container and the front surface of the samples was

covered with a nylon mesh to hold loose granules together and to ensure that the

surface was at. Loose samples were compacted suciently to ensure good friction

between individual particles and the walls of the impedance tube. A separate set of

measurements has been carried out to conrm that the mesh has a negligible eect

on the acoustic properties of the investigated samples. The density of the granular

mixes was measured and kept constant in all the experiments to ensure the same

degree of compaction between dierent experimental set-ups.

The surface impedance W

s

of each sample has been measured for the doubled

thickness of the porous layer W

2s

, so that the characteristic impedance,

W W

a

iW

i

, and propagation constant, , o i[, in the porous samples can be

determined from the expressions W

s

Wcoth ,d and W

2s

Wcoth ,2d . Here

W

a

, W

i

, are real and imaginary parts of the characteristic impedance, and o and [

are real and imaginary parts of the propagation constant, respectively, and d is the

layer thickness. The experimental data for the above characteristics were applied to

develop and propose new empirical expressions for the acoustic properties of porous

granulates. The reproducibility of the experimental data between the two labora-

tories was within 10%.

4. Structural characteristic for granular materials

Experimental results for the characteristic impedance and propagation constant

have been used to determine the eects of the porosity and grain size on the struc-

tural characteristic Q. The structural characteristics Q has been introduced in pre-

vious work [5,15] and is included in the expression for the real part of the

characteristic impedance,

W

a

1 Q. f - f

cr

5

Fig. 1 shows the experimentally determined frequency dependence of the structural

characteristic Q for three granular mixes. The results conrm that the functional

behaviour of this characteristic is similar to that derived previously for rigid frame

porous media [5,15], where Q / 1 H , HD

k

p

, k 2f,c being the wave number

in air, f is the frequency and c is the sound speed in air. From the comparison of the

420 N.N. Voronina, K.V. Horoshenkov / Applied Acoustics 64 (2003) 415432

data for granular materials with dierent values of the parameter M (see Table 1) an

empirical expression for the structural characteristic has been deduced and is pro-

posed in the following form

Q

0.2 1 H 1 H

2

H

kD

p . 6

The above expression has been used to calculate the predicted values of Q, which

are shown in Fig. 1 and compared with the experimental data.

Since Q W

a

1, the above expression can be used to determine the transition

frequency f

cr

, which is calculated from

f

cr

200j 1 H

2

1 H

4

,

0

D

2

q H

2

7

using the values of the parameters provided in Tables 1 and 2 and the relation

Q

cr

q

H

1. The critical value Q

cr

corresponds to the frequency at which the beha-

viour of the real part of the characteristic impedance W becomes frequency-inde-

pendent.

For frequencies f 5f

cr

the real part of the characteristic impedance can be pre-

dicted by expression (4). For frequencies f - f

cr

, expressions (5) and (6) are su-

ciently accurate for a majority of practical applications.

Fig. 1. The experimentally measured and empirically predicted values of the structural characteristic as a

function of frequency.

N.N. Voronina, K.V. Horoshenkov / Applied Acoustics 64 (2003) 415432 421

5. Empirical expressions for the acoustic properties

Expression (6) for the structural characteristic can also be used to predict the

imaginary part of the characteristic impedance and real and imaginary parts of the

propagation constant. The expressions for these properties have been originally

proposed in [5] for materials with low porosity. These expressions have been mod-

ied to t the experimental data for granular materials and are provided below

o

kQH

1 A

8

[ k 1 QH 1 B 9

W

i

QH

1 C

. 10

Here A, B and C are coecients which depend upon the porosity, structural

characteristic and dimensionless parameters M and .

Fig. 2(a)(c) shows the experimentally determined values of the coecients A, B

and C as functions of the structural characteristic Q for materials 1, 4 and 6. The

results suggest that the coecient A is proportional to 1,1 Q and that the coef-

cient B is proportional to 1,

Q

p

[see Fig. 2(a) and (b)]. The results also suggest that

for a given value of Q the coecient A increases and coecient B decreases with the

increasing value of M. The results for the investigated granular mixes show that for

a xed value of Q the coecients A and C are proportional to 1 H and the

coecient B is proportional to 1,1 H.

These dependencies provide the basis to derive the interpolated expressions for the

three coecients, which are provided below

A

1 H M

1 Q

11

B

1

Q

p

1 H 1 Q

2

M

12

and

C

1 H

Q

p . 13

The solid lines in Fig. 2(a)(c) show the calculated values of the coecients A, B

and C for materials 1, 4 and 6 as functions of the structural characteristic Q.

Expressions (11)(13) provide a close t to the experimental results throughout the

considered range of values of the structural characteristic, porosity and dimension-

less parameter M.

Empirical expressions (6)(11) can also be used to predict the ow resistivity of

granular mixes, which is determined from the low frequency limit r

,

0

clim

f !0

W

a

o W

i

[ as

422 N.N. Voronina, K.V. Horoshenkov / Applied Acoustics 64 (2003) 415432

Fig. 2. Experimental and empirically predicted values of the coecients A, B and C.

N.N. Voronina, K.V. Horoshenkov / Applied Acoustics 64 (2003) 415432 423

r

4001 H

2

1 H

5

j

HD

2

14

The values of the ow resistivity which are predicted from the above expression

are shown in Table 2, where they are compared to the measured data. Good agree-

ment between the measured and predicted data is observed for materials 1, 2, 4 and

8. Expression (12) is less accurate in the case of materials 3 and 5, which can be

attributed to the high sensitivity of the ow resistivity to the material compaction.

Figs. 38 showthe experimental and predicted values of the characteristic impedance

and propagation constant for the eight materials used in the experiments. The agree-

ment between the experimental results and the proposed empirical model for all the

eight granular mixes is good throughout the considered frequency range. The model

does not involve any special functions of complex argument and is easy to implement.

The classication according to the value of the parameter is very useful to pre-

dict the behaviour of the real part of the characteristic impedance of a granular mix.

The results show that for large grain mixes with 52 (materials 1, 4, 5, 6 and 8 in

Table 1) the transition frequency f

cr

is low. In these cases the real part of its char-

acteristic impedance is relatively independent of frequency and can be predicted

accurately from expression (4). For these mixes the imaginary part of the char-

acteristic impedance is relatively small, W

i

- 1, throughout the considered fre-

quency range. The attenuation constant for these materials is limited and the phase

velocity is relatively high.

Fig. 2. (continued)

424 N.N. Voronina, K.V. Horoshenkov / Applied Acoustics 64 (2003) 415432

Fig. 3. The real (a) and imaginary (b) parts of the normalised characteristic impedance of vermiculite.

N.N. Voronina, K.V. Horoshenkov / Applied Acoustics 64 (2003) 415432 425

Fig. 4. The real (a) and imaginary (b) parts of the normalised characteristic impedance of loose rubber crumb.

426 N.N. Voronina, K.V. Horoshenkov / Applied Acoustics 64 (2003) 415432

Fig. 5. The real (a) and imaginary (b) parts of the normalised characteristic impedance of perlite and

nitrile granulate.

N.N. Voronina, K.V. Horoshenkov / Applied Acoustics 64 (2003) 415432 427

Fig. 6. The real (a) and imaginary (b) parts of the propagation constant for vermiculite.

428 N.N. Voronina, K.V. Horoshenkov / Applied Acoustics 64 (2003) 415432

Fig. 7. The real (a) and imaginary (b) parts of the propagation constant for loose rubber crumb.

N.N. Voronina, K.V. Horoshenkov / Applied Acoustics 64 (2003) 415432 429

Fig. 8. The real (a) and imaginary (b) parts of the propagation constant for perlite and nitrile granulate.

430 N.N. Voronina, K.V. Horoshenkov / Applied Acoustics 64 (2003) 415432

The transition frequency of small (materials 3 and 7) and medium grain materials

(material 2) is relatively high and is outside the considered frequency range (see

Figs. 3 and 5). The behaviour of the real part of the characteristic impedance for

these materials is frequency dependent and can be predicted closely by expression

(5). The attenuation coecient for materials 2, 3 and 7 is relatively large and the

phase velocity is relatively small (see Figs. 6 and 8). These properties are desirable in

the design of ecient acoustic absorbers. In this respect, the classication according

to the value of the parameter makes easier the correct choice of the optimal grain

mix.

6. Conclusions

An experimental investigation has been carried out to determine the characteristic

impedance and propagation constant in a representative selection of loose granular

materials. A new classication of granular media has been proposed which is related

to the characteristic particle dimension and the specic density of the grain base. It

has been shown that the proposed classication is a useful characteristic for pre-

liminary estimation of the acoustic performance of loose granular mixes.

The experimental results have been used to develop a new empirical model, which

can predict reliably the acoustic performance of loose granular mixes. The model

requires knowledge of the characteristic particle dimension, porosity, tortuosity and

the specic density of the grain base, most of which are routinely measurable para-

meters. The introduction of the specic density of the grain base is important and

can empirically account for the eects of friction between the elements of the non-

rigid frame in porous materials with low density and for the absorption in the par-

ticles micro-pores.

It has been shown that the tortuosity can be predicted or deduced from experi-

mental data. Unlike many other models, the proposed model does not require the

knowledge of the ow resistivity which values can be very sensitive to the compac-

tion state of a loose granular mix. The characteristics which the model predicts are

the real and imaginary parts of the normalised characteristic impedance and propa-

gation constant. These characteristics are required to predict the eciency of

acoustic porous absorbers and sound propagation over porous soils.

References

[1] Swift, MJ. The physical properties of porous recycled materials. PhD thesis, University of Bradford,

December 2000.

[2] Horoshenkov K, Swift MJ. Acoustic properties of consolidated granular mixes. Appl Acoust 2001;

62(6):66590.

[3] Miki Y. Acoustic properties of porous materialsgeneralization of empirical models. J Acoust Soc

Jap (E) 1990;11:258.

[4] Wilson K. Simple, relaxational models for the acoustic properties of porous media. Appl Acoust

1997;50:17188.

N.N. Voronina, K.V. Horoshenkov / Applied Acoustics 64 (2003) 415432 431

[5] Voronina N. An empirical model for rigid-frame porous materials with low porosity. Appl Acoust

1999;58:295304.

[6] Horoshenkov KV, Attenborough K, Chandler-Wilde SN. Pade approximants for the acoustical

properties of rigid frame porous media with pore size distribution. J Acoust Soc Am 1998;104:1198

209.

[7] Zou RP, Yu AB. Evaluation of the packing characteristics of mono-sized non-spherical particles.

Powder Tech 1996;88:719.

[8] Bourbie T, Zinszner B. Hydraulic and acoustic properties as a function of porosity in fountainebleau

sandstone. J Geophys Res 1985;90(B13):1152432.

[9] Attenborough K. Acoustical characteristics of rigid brous absorbents and granular materials.

J Acoust Soc Am 1983;73(3):78599.

[10] Rayleigh S. Theory of sound. 2nd ed. 1976. Vol. 2.

[11] Zwikker C, Kosten CW. Sound absorbing materials. Amsterdam: Elsevier; 1949. Chapter 2.

[12] Biot MA. Theory of elastic wave propagation in a uid saturated porous solid. Parts I and II.

J Acoust Soc Am 1956;28:16891.

[13] Stinson MR. The propagation of plane sound waves in narrow and wide circular tubes, and gen-

eralisation to uniform tubes of arbitrary cross-sectional shape. J Acoust Soc Am 1991;89:5508.

[14] Brennan MJ, To MM. Acoustic properties of rigid-frame porous materialsan engineering per-

spective. Appl Acoust 2001;62(7):793811.

[15] Voronina N. An empirical model for rigid frame porous materials with high porosity. Appl Acoust

1997;51(2):18198.

[16] Umnova O, Attenborough K, Li KM. Cell model calculations of dynamic drag parameters in pack-

ings of spheres. J Acoust Soc Am 2000;107(6):31139.

[17] Boutin C, Royer P, Auriault JL. Acoustic absorption of porous surfacing with dual porosity. Int

J Solids Structures 1998;35(34-35):470937.

[18] Bies DA, Hansen CH. Flow resistance information for acoustical design. Appl Acoust 1980;13:357

91.

[19] Allard J-F, et al. Evaluation of tortuosity in acoustic porous materials saturated by air. Rev Sci

Instrum 1994;65:7545.

[20] Leclaire P, Kelders L, Lauriks W, Glorieux C, Thoen J. Determination of the viscous characteristic

length in air-lled porous materials by ultrasonic attenuation measurements. J Acoust Soc Am 1996;

99(4):19448.

432 N.N. Voronina, K.V. Horoshenkov / Applied Acoustics 64 (2003) 415432

Você também pode gostar

- Deriving Operating Rules For A Large Scale Hydro Photovo 2018 Journal of CleDocumento11 páginasDeriving Operating Rules For A Large Scale Hydro Photovo 2018 Journal of CleMd Zillur RahmanAinda não há avaliações

- Benefits of Transmission Switching and Energy Storage in Power 2018 AppliedDocumento16 páginasBenefits of Transmission Switching and Energy Storage in Power 2018 AppliedMd Zillur RahmanAinda não há avaliações

- Refrigeration and Air Conditioning Systems 3Documento1 páginaRefrigeration and Air Conditioning Systems 3Md Zillur RahmanAinda não há avaliações

- Leissa - Vibration of Plates Nasa ReportDocumento362 páginasLeissa - Vibration of Plates Nasa Report王轩100% (1)

- Mohanty Et Al-2006-Journal of Applied Polymer ScienceDocumento10 páginasMohanty Et Al-2006-Journal of Applied Polymer ScienceMd Zillur RahmanAinda não há avaliações

- Prospects For Pumped Hydro Storage in Germany 2012 Energy PolicyDocumento10 páginasProspects For Pumped Hydro Storage in Germany 2012 Energy PolicyMd Zillur RahmanAinda não há avaliações

- Advantage of Natural FiberDocumento1 páginaAdvantage of Natural FiberMd Zillur RahmanAinda não há avaliações

- Damage Tolerance of Carbonflax Hybrid Composites Subjected To LowDocumento10 páginasDamage Tolerance of Carbonflax Hybrid Composites Subjected To LowMd Zillur RahmanAinda não há avaliações

- Composites OverviewDocumento15 páginasComposites OverviewSantosh OjhaAinda não há avaliações

- Basic of Mechanical EngeneeringDocumento144 páginasBasic of Mechanical Engeneeringjhny4444Ainda não há avaliações

- Recent Advances in The Sound Insulation Properties of Bio-Based MaterialsDocumento23 páginasRecent Advances in The Sound Insulation Properties of Bio-Based MaterialsMd Zillur RahmanAinda não há avaliações

- Investigation On Static and Dynamic Mechanical Properties ofDocumento10 páginasInvestigation On Static and Dynamic Mechanical Properties ofMd Zillur RahmanAinda não há avaliações

- MT Lectures 11-20Documento249 páginasMT Lectures 11-20Md Zillur RahmanAinda não há avaliações

- Module 10 VibrationsDocumento15 páginasModule 10 VibrationsYosheph YangAinda não há avaliações

- ANSYS TutorialDocumento16 páginasANSYS Tutorialpriyankar007Ainda não há avaliações

- Describing Spatial Images On The Task 1 Portion of Your IELTS ExamDocumento15 páginasDescribing Spatial Images On The Task 1 Portion of Your IELTS ExamMd Zillur RahmanAinda não há avaliações

- Free Vibration Analysis of Layered Beams With Delamination Damage-An Ansys Based Fem Investigation PDFDocumento107 páginasFree Vibration Analysis of Layered Beams With Delamination Damage-An Ansys Based Fem Investigation PDFMd Zillur Rahman100% (1)

- Finite Element Analysis of Double Cracked Beam and Its Experimental ValidationDocumento6 páginasFinite Element Analysis of Double Cracked Beam and Its Experimental ValidationMd Zillur RahmanAinda não há avaliações

- Even Though Developing Countries Receive Financial HelpDocumento13 páginasEven Though Developing Countries Receive Financial HelpMd Zillur RahmanAinda não há avaliações

- Analytical Model For Prediction of The Damping Factor of Composite MaterialsDocumento12 páginasAnalytical Model For Prediction of The Damping Factor of Composite MaterialsMd Zillur RahmanAinda não há avaliações

- FEW - Telling Stories With NumbersDocumento49 páginasFEW - Telling Stories With NumberspdistintoAinda não há avaliações

- Effect of Fibre Orientation and Laminate Geometry On The Dynamic PropertiesDocumento27 páginasEffect of Fibre Orientation and Laminate Geometry On The Dynamic PropertiesMd Zillur RahmanAinda não há avaliações

- A Dynamic Stiffness Analysis of Damped Tubes Filled With Granular MaterialsDocumento12 páginasA Dynamic Stiffness Analysis of Damped Tubes Filled With Granular MaterialsMd Zillur RahmanAinda não há avaliações

- Cohesion Linking Words and PhrasesDocumento2 páginasCohesion Linking Words and PhrasesMd Zillur RahmanAinda não há avaliações

- 4 1 TranscendentalDocumento10 páginas4 1 TranscendentalMd Zillur RahmanAinda não há avaliações

- Unusual activity discovered through FuroshikiDocumento53 páginasUnusual activity discovered through FuroshikiMd Zillur RahmanAinda não há avaliações

- Adwords QuizDocumento82 páginasAdwords QuizIoana CiudinAinda não há avaliações

- (Model Essay) Academic Exam As Seen in Vietnam, Australia and Malaysia in August 2011Documento4 páginas(Model Essay) Academic Exam As Seen in Vietnam, Australia and Malaysia in August 2011Md Zillur Rahman100% (1)

- The Topic Below Was Seen in The Academic IELTS Exam in The UKDocumento14 páginasThe Topic Below Was Seen in The Academic IELTS Exam in The UKMd Zillur RahmanAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Puppo, F. (2012) - Dalla Vaghezza Del Linguaggio Alla Retorica Forense. Saggio Di Logica GiuridicaDocumento3 páginasPuppo, F. (2012) - Dalla Vaghezza Del Linguaggio Alla Retorica Forense. Saggio Di Logica GiuridicaAldunIdhunAinda não há avaliações

- Deep Learning: Huawei AI Academy Training MaterialsDocumento47 páginasDeep Learning: Huawei AI Academy Training Materialsfadhil muhammad hanafiAinda não há avaliações

- Lab 8 - LP Modeling and Simplex MethodDocumento8 páginasLab 8 - LP Modeling and Simplex MethodHemil ShahAinda não há avaliações

- Selection of Dryers I - IndiaDocumento38 páginasSelection of Dryers I - Indiasilvership2291100% (1)

- Discussion Exp 2 Chm674Documento4 páginasDiscussion Exp 2 Chm674Eva Lizwina MatinAinda não há avaliações

- The Chemistry of Gemstone Colours 2016Documento1 páginaThe Chemistry of Gemstone Colours 2016Lukau João PedroAinda não há avaliações

- Sambungan Chapter 2.2Documento57 páginasSambungan Chapter 2.2iffahAinda não há avaliações

- Qualcomm Snapdragon 660 Mobile Platform Product BriefDocumento2 páginasQualcomm Snapdragon 660 Mobile Platform Product BriefTuxInfoAinda não há avaliações

- Laing Electric Heater-CirculatorDocumento20 páginasLaing Electric Heater-Circulatorkamilawehbe100% (1)

- Profit Signals How Evidence Based Decisions Power Six Sigma BreakthroughsDocumento262 páginasProfit Signals How Evidence Based Decisions Power Six Sigma BreakthroughsM. Daniel SloanAinda não há avaliações

- Foundation DetailsDocumento29 páginasFoundation DetailsSUSOVAN BISWASAinda não há avaliações

- Section 3 - Vibration MeasurementDocumento24 páginasSection 3 - Vibration MeasurementAbbas AkbarAinda não há avaliações

- Frege: Sense and Reference One Hundred Years LaterDocumento215 páginasFrege: Sense and Reference One Hundred Years LaterfabioingenuoAinda não há avaliações

- Ab5 PDFDocumento93 páginasAb5 PDFbhavani nagavarapuAinda não há avaliações

- Hospital Management System: A Project Report OnDocumento24 páginasHospital Management System: A Project Report OnRama GayariAinda não há avaliações

- FOUNDATION REPAIR AND REGROUT FOR BODYMAKER AT CARNDAUD METALBOX SINGAPOREDocumento15 páginasFOUNDATION REPAIR AND REGROUT FOR BODYMAKER AT CARNDAUD METALBOX SINGAPORETrúc NguyễnAinda não há avaliações

- Uptime Awards: Recognizing The Best of The Best!Documento40 páginasUptime Awards: Recognizing The Best of The Best!Eric Sonny García AngelesAinda não há avaliações

- Matlab DrawingDocumento82 páginasMatlab Drawinghpeter195798Ainda não há avaliações

- A-019730-1647416754604-137865-W.M.Supun Anjana DSADocumento175 páginasA-019730-1647416754604-137865-W.M.Supun Anjana DSADishan SanjayaAinda não há avaliações

- Transportation Installation R2000iC210FDocumento25 páginasTransportation Installation R2000iC210FMeet PAtel100% (2)

- Experimentalstudies On The Effects of Reduction in Gear Tooth Stiffness Lubricant Film Thicknessina Spur Geared SystemDocumento13 páginasExperimentalstudies On The Effects of Reduction in Gear Tooth Stiffness Lubricant Film Thicknessina Spur Geared SystemBurak TuncerAinda não há avaliações

- Flex-Shaft Attachment Instructions Model 225: WarningDocumento1 páginaFlex-Shaft Attachment Instructions Model 225: WarningFernando Lopez Lago100% (1)

- Triad Over Root Chords Companion PDF 2.1Documento18 páginasTriad Over Root Chords Companion PDF 2.1Vlado PetkovskiAinda não há avaliações

- Mobile GIS Platforms and Applications with ArcGISDocumento28 páginasMobile GIS Platforms and Applications with ArcGISZachary Perkins100% (1)

- Pythagorean TheoremDocumento27 páginasPythagorean Theoremapi-241390860Ainda não há avaliações

- Measurement: Scaling, Reliability, ValidityDocumento34 páginasMeasurement: Scaling, Reliability, ValidityFajar Farhan Muhtasir100% (1)

- Barium Strontium TitanateDocumento15 páginasBarium Strontium Titanatekanita_jawwAinda não há avaliações

- Development and Validation of UV Spectrophotometric Method For The Estimation of Curcumin in Bulk Drug and Pharmaceutical Dosage FormsDocumento6 páginasDevelopment and Validation of UV Spectrophotometric Method For The Estimation of Curcumin in Bulk Drug and Pharmaceutical Dosage FormswiracanaAinda não há avaliações

- Template 8dDocumento165 páginasTemplate 8dLuis Alberto Quiroz GranadosAinda não há avaliações

- Dev - Mag - 09Documento26 páginasDev - Mag - 09georgpiorczynskiAinda não há avaliações