Escolar Documentos

Profissional Documentos

Cultura Documentos

Hydraulic Drives For Bridges Considering The New DIN Standard 19704

Enviado por

Nguyen Cong Cuong100%(1)100% acharam este documento útil (1 voto)

156 visualizações13 páginasdfa

Título original

Hydraulic Drives for Bridges Considering the New DIN Standard 19704

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentodfa

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

100%(1)100% acharam este documento útil (1 voto)

156 visualizações13 páginasHydraulic Drives For Bridges Considering The New DIN Standard 19704

Enviado por

Nguyen Cong Cuongdfa

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 13

Heavy Movable Structures, Inc.

SEVENTH BIENNIAL SYMPOSIUM

November 4 - 6,1998

Grosvenor Resort

Walt Disney World Village

Lake Buena Vista, Florida

"Hydraulic Drives for Bridges

Considering the New DIN

Standard 19704"

by

Erich Wirzberger, The Rexroth Corporation

m engineering

mannesmann

Y

Rexro th

Hydraulic Drives for Bridges Considering

the New DIN Standard 19704

Deffine Bridge

Rexro th Hydra ul i o

Herausgeber Mannesmann Rexroth AG

D-97813 Lohr a. Main

JahnstraBe 3-5 D-97816 Lohr a. Main

Telefon 0 93 52/18-10 12

Telefax 0 93 52/18-10 00

Telex 689418r r d

Nachdruck und ~bersetzung, auch auszugsweise,

nur mit Genehmigung des Herausgebers.

Anderungen vorbehalten

In July 1991 the working commltee NAW A4 114 "Hydraulic steel

structures" was set up within the Water resources srandard commitee. Its

objective was the first revision of the standard DIN 19704 and 19705 that

was first issued in 1976. The chalrman was Professor Dr.-Eng. Gerhard

SchmauBer. Under his competent chairmanship the worklng commitee was

able to pass the present revision of DIN 19704 in Spring 1997 after only

10 working sessions. Five working groups, into which the working

commitee had been subdivided, contributed to this success.

The DIN 19704 and 19705 has been completely revised according to the

latest developments and now consists of three parts:

Part 1: Hydraulic steel structures.

criteria for design and calculation

Part 2: Hydraulic steel structures,

design and manufacturing

Part 3: Hydraulic steel structures.

electrical equipment

DIN 19704 is valid for hydraulic

- hydro power plants

steel structures in:

- irrigation systems i

systems

ind high water storage

- constructions for rlver control and

installations for ~nl and navigation

- movable bridges

partial safety factors y, and combination values ly for ultimate limit

stare analys~s (except for farigue strength proof) of steel structures

- -

Basic combinattorts I Exceptional 1

I con~btnations '

I

I

Hydrodynam~c ad~ons

I

Water road

- 1 3 5

The most substantial changes as against previous issues of the standard

are:

a) The calculation of the steel structure and -as far as possible - also of the

machinery construction is based on the concept of limit state design

using partial safety factors and combination factors.

b) Steel structures and machinery constructions are generally not regarded

as being constructions under static load. Therefore, fatigue strength

proofs are required.

C) The (computat~onal) service life of steel struaures, machinery elements

and electrical equipment is given.

Considering their function, hydraulic steel structures must be designed

simple, robust and operationally safe. For steel structures a service life of 70

years has to be assumed, for machine elements, including their electrical

equipment for 35 years.This does not refer to wear parts.

Apart from some fundamental determinations, the standards DIN 19704

and 19705, issue 1976, contained only a few regulations regarding the

design of oil hydraulic drives.

The new revision of DIN 19704-1, -2 and -3, issue 1997, which replace the

old standards 19704 and 19705, therefore took into account the new

developments in the field of oil hydraulics, so that this standard now reflects

state of the an.

d) For the first time, manufacturing tolerances are given for the steel In the previously valid standards DIN 19704, issue 1976, the following load

structures of firmly installed pans and hydrogates. The objective of this cases were relevant for the calculation and rating of the drives:

is to ensure that the calculation assumptions, e.g. bearing conditions,

comply with the design to a sufficient degree. In addition, the aspects of Normal operational case "NB"

se~iceability have been taken into account for the manufacturing Specific operational case "BB"

tolerances. Exceptional load case "AL"

e) In view of their importance hydraulic drives are dealt with in detail. The Investigations have shown that for approximately 80 % of all supplied

technical progress In the field of hydraulic drives has been significantly systems, the specific operational case "88" are relevant for the calculation

promoted by Mannesmann REXROTH. It was therefore possible to and design of the drives. For this reason the new standard norm DIN 19704.

consider the basic principles for design and matters of operational 1 provides only the operational case "moving" for the drives.

safety, reliability and fatigue strength in a comprehensive form in the

new regulations.

If "Exceptional actions" have to be additionally taken into account (e. g. If the operating pressures are considerably lower than 250 bar,

double-sided drive of a closing-off structure - failure of drive), the drive components with lower continuous operating pressures/nominal pressures

must be automatically shut down when these actions occur. At that can also be selected. This is also permitted wi th~n a hydraul~c system, e. g.

moment, only a single traversing to one of the two end positions for auxiliary drives.

"closing-off st ruct ure open" or "closing-off structure closed" w~l l

be permitted or, i f required, moving into a repair position. For this purpose B e actions of drives such as the stalling torque of the motor, rhe braking

the client must make unmistakable determinations which comprise both torque or the setting values of pressure reJief valves (which have t o be

operational measures. secured by sealing) in oil hydraulic systemsQre cons~dered as controlled,

variable actions. Their values have to be included in the calculation as

In the previously valid standard DIN 19704 the following maximum characteristic values of the highest possible transmiss~on of forces. The

operating pressures were determined: reactive effects of the highest possible transmission of forces have to be

traced in all essential machine pans, for which an ultimate state analysis

Normal operational case "NB" = 220 bar (except for the fatigue strewngth proof) is required, up to the connection

Specific operational case "BB" = 250 bar to the steel structure of the gate or, if required, up to their bearlng points.

Exceptional load case "AL" = 300 bar

These reactiv effects creates some problems which using mechanical hoists

It must be noted that these determinations have proven useful over the were an acurate overload protection is difficult to achive. With hydraulic

last 20 years since the DIN 19704 - issue 1976 was published. For this hoists this problem can be solved easily by installing maximum pressure

reason, in the new DIN the orders of the maximum operating pressures relief valves directly on the cylinder. Specially when the power pack is far

were in principle maintained. away from the cyl~nder the maximum pressure relief valve on the pump

has to be set to a higher pressure to obtain the pressure drop in the pipes.

The new standard DIN 19704 - 1 now provides only one operational case In case the gate is blocked this higher pressure can not occur in the

"moving", with the permissible maximum operating pressure being 250 cylinder by adjusting the cylinder to exactly the pressure required for the

bar. If "exceptional actions" have to be taken into account, during the maximum load.

presence of which operating movements do not occur, the permissible

static pressure in the cylinder or hydraulic motor must not exceed 300 bar.

(The pressures mentioned here are the set values of the pressure relief

valves, see chapter "Determination of computational operating

pressures").

In view of the rating of drives, this results in a

striking difference between the "old" and the

"new" DIN.

In the exceptional load case i t was acceptable

(at least not explicirly excluded in the "old"

DIN), to run an emergency mode at a maximum

pressure of 300 bar over a longer period of time

when these conditions occured. According to the

new DIN 19704 this is no longer permitted.

As already mentioned, the permissible maximum

pressure during "moving" amounts to 280 bar

which is justified as follows:

All the components of renowned manufacturers

are approved for an operating pressure of 280

to 31 5 bar. The actuators such as solenoids,

return springs, etc. are rated for these pressures.

Thus, sufficient safety is provided at maximum

operating pressure in order to ensure

operational safety also under unfavourable

conditions, e. g. low temperatures.

From this consideration results the requirement

in DIN 19704 - 1 that for all hydraulic

components, the continous operaring pressure/

nominal pressure must be 25 % higher than the

computational operating pressure.

Example of an arrangement o f the pressure control valves in conjunction with a wngle acting,

single rod cylinder

Acceleration and deceleration

The followrng is strpulated here: "The closing-off structure must be

accelerated and decelerated within a reasonable time in dependence upon

the design type, weight, travel time and for bridges also the own

frequency of the bridge leafs". With oil hydraulic drives, acceleration and

deceleration are achieved by changing the flow. When accelerating the

cylinder or hydraulic motor, the flow continuously increases from 0 or a

minimum value up to the required maximum value, when deceleration

time must be infinitely variable. It depends on the closing-off structure and

its application conditions and usually ranges between 3 and 15 seconds.

Proportional valve

The following preferred systems are used:

- Flow control by means of proportional valve

- Flow control by means of variable displacement pumps

The f~gure beolow shows a circuit version,using proporrional valve

technology. The proportional valve is a combination of a directional valve

for the control of direction and a flow control valve for controlling the flow

volume.

1 Proportional valves

2 Pressure compensator for ensuring a

constant Ap across the control spool

3 Pressure relief valve

4 Axial piston pump

5 Electric motor

The figure below shows a system with variable displacement pump.

The pump supplies a variable displacement from 0 to maximum and thus

allows the required acceleration or deceleration of the drive. The direction

is controlled by means of a directional valve.

1 Axial piston pump wi t h infinitely variable

displacement

2 Pump for pi l ot oi l supply

3 Pressure filter

4 Control valve for pump adjustment

5 Electric motor

6 Directional valve for the control of

direction

7 Pressure relief valve

I

Var~able displacement pump

Hydraulic fl ui ds or

b) unalloyed steel with ox~de ceramic coating.

If in the case of leakage (e. g. in the case of an accident) the hydraulic

medium can get into the water, bio-degradable hydraulic fluids have to be The arithmet~c average roughness value for both constructions should be

used preferably instead of media on the basis of mineral oil. R,< 0.3 p.

If synthetic esters or polyglycols are used, special precautions must be

taken for planning and for maintenance and operation (e. g. material The oxide ceramic coating must be designed to rule out corrosion of the

selection, monitoring). base material. *!, .

Triglycerides (vegetable, animal oils) are not suitable for use in hydraulic

steel structures due to their ageing behaviour. It should be homogeneous, scratch-resistant, crack-free and non-

The type of hydraulic fluid to be used must be specified by the client. conductive and have a coating thickness of at least 150 m and a surface

However, the use of fast bio-degradable fluids does not represent a relief hardness of 800 to 1000 HV

from the obligation to prevent the possible leakage of these fluids.

Subsequent sealing of pores is not permined

In general, hydraulic fluids must be suitable for a temperature range of -

25C to +60C. The corrosion resistance of the oxide ceramic coating must meet the

requirements of the test according to DIN 50021-ESS over a testing period

Filling of the system and subsequent topping up may only be carried out of 1000 hours.

through filter~ng units with a filter rating according to the filtration

requirements to 10.1.4.3. Piston rods may only be manufactured of several parts in justified,

exceptional cases.

Hydraulic cylinder - Design and manufacture

In general, the piston rods with piston rod heads, which are f~tted with

Cylinder barrels shall be manufactured from seamless steel tubes, plain bearings, have to be connected to the gate or the supporting

whenever possible without joints, and must be designed for flanges for structure.

head and ccap.

The connection of piston rodlpiston rod head should preferably be

The cylinder bore must be manufactured w~t h an arithmetic roughness designed with male threads on the piston rod.

value R,< 0.4 p.

Piston rods of hydraulic cylinders must be manufactured from The threads of the piston rod heads must be sealed against the ingress of

water. Bores for safety equipment must not be drilled into the thread and

a) stainless steel with a weight proportion of chromium of at least 15.5 % must be sealed.

and a multi-layer hard chromium plating with an overall thickness of 2

50 p.

1 Plain bearing

2 Cover

3 Seal for the plain bearing

4 Protection against torsion

5 Threaded plug wi t h seal

6 Cover wi t h seal for sealing the thread

,

Self-aligning clevis

If the cylinder is mounted by means of clevises, these have to be made of The cylinder head must be flned with dirt wipers at the p~ston rod passage

a single part. Welded clevises subjected to tensile srress have to be and, in the case of a possible formation of ice, with additional ~ce scrapers

designed with but welds. of a serrated design.

In the case of trunnions or cardanic bearing of the cylinders, all bearings When using cylinders under water, additional seals, wh~ch are ~nsened in a

must be self-lubricating. The sliding bearings and bearing pins must be corrosion-resistant housing, shall be provided against the sucking-in of

made from stainless steel. water.

, .

In general, copper alloys shall be used for the guides of pistons and piston Hydraulic cylinders which are temporarily or permanently pressurized at

rods. Moreover, plastic guides are permitted. system pressure must be leakfree isolated in the direction of load by

directly flanged-on shut-off or control manifolds. The control manifolds

For sealing, only multi-lip seal systems shall be used. Trailing pressure must must be equipped with manual shut-off valves between the hydraul~c

not be built up. cylinder and the shut-off valve.

The seals used between components without counter-movements such as

cylinder barrellcylinder head must be O-ring seals. O-ring seals with

diameters > 125 mm must be fitted with additional back-up rings.

1 Tapered sleeve

2 Orifice ring

3 By-pass bore

4 Throttle for adjusting the seating velocity

of the closing-off structure

Hydraulic cylinder

Hydraulic cylinders which are submerged temporarily or over a longer

period of time, should be monitored for leakage by suitable means. These

must be specified by the client.

Both cylinder chambers must be permanenrly filled with oil. If the gate is

lowered without the pumps running, it must be ensured by suitable

measures that the pressureless cylinder chamber is filled with oil.

For proper bleeding of the hydraulic cylinder, pressure measurement

connections must be provided at suitable locations. If required, a suitable

procedure must be specified for the assembly and filling of the cylinder.

Hydraulic components

Pressure is generated by pumps which operate according to the

displacement principle with fixed or steplessly variable displacement.

For systems with heavily fluctuating flows, pumps with variable

displacement are recommended.

It must be possible to replace motors and pumps without having to

remove other components. Motors have to be mounted on anti-vibration

mounts.

All the devices required for the control of the hydraulic system such as

directional valves, flow control valves, pressure relief valves, etc. have to be

clearly arranged on common control plates wherever possible. The

actuator ports are d~rectly connected t o the manifolds.

For electrically operated valves, DC wet-pin solenoids should be used

whereever possible. These valves shall be fitted with an easily accessible

manual override with detent.

Pilot operated directional valves have to be indicated by LEDs, except for

proportional and servo-valves.

The electrical connnection for any electrical components such as valves.

pressure switches and float switches must be made via plug-in

connections.

Hydraulic oil filters

Hydraulic stations have to be fitted with ar least one return line filler with

a maximum filter rating of 20 m with non recycable insens. Paper filters

are not permitted.The filter system must be matched with the components

used.

The nominal flow rate of the filter should at least be four times the

maximum flow. All filters have to be provided with a visual clogging

indicator, with an electrical connection and a by-pass valve having an

opening pressure of 3 bar.

Hydraulic stations

The design can be compact, e.g. oil reservoir with mounted-on motor1

pump units and control, or individual assemblies, e.g. oil reservoir, pump

station, valve station and, if required, accumulator station.

Oil reservoirs have to be dimensioned sufficiently large to accommodate

four times the volume of the maximum flow supplied by the pump(s) in

one minute, plus the pendulum volume of all connected cylinders, plus the

contents of the piston rod chamber of the largest connected cylinder plus

the contents of the associated pipes.

Reservoirs have to be designed with an oilique bottom, dram valve,

cleaning openings, permanent oil level inditator and float switch. The

latter must be removable wirhout requiring the removal of other

components.

Fillet welds must be double-sided whenever possible

Venting of the reservoir must be realised via a humidity adsorber with

transparent container. Air escaping when the oil level Increases mut not be

directed through the adsorber. Openings in the reservoir must be plugged

air-tight.

In general, fittings and valves shall not be arranged within the oil reservoir,

If the drlve rooms cannot be deigned to 3.3, the o ~ l reservoir must be

erected in a steel sheet tray, wh~ch corresponds to the nominal capacity of

the reservoir.

Hydraulic variable displacement pumps should be installed in a

rnaintenance-friendly manner next to the reservoir. The suction lines have

to be equipped with manually operated shut-off valve with limit switch

monitor.

In general, the required total flow is subdivided to at least 2 motor/pump

units.

Pipework

When determining the routing of the pipes, good accessibility must be

taken into account. The distance of pipes must be so that fittings and

flanges can be mounted without difficulties. The pipes should not be laid

onto each other.

Moved parts, movable connections and expansion joints have to be fitted

with flexible hydraulic hoses. Only hoses to DIN 20066 in conjunction with

corrosion-protected fittings are permitted. The installation instructions to

DIN 20066-4 have to be observed. The use of rotary joints is permitted.

If the arrangement of pipe or hose lines in flowing water or in its direct

vicinity cannot be avoided, protective measures against flotsam have t o be

provided.

Pipes have to be fitted with manually operated shut-off valves for partial

shutdowns, at least at the porn of the hydraulic statlon and at the pons of

hydraulic cylinders and hydraulic motors. Equipment with additional shut-

off valves, e.g. on hoses, has to be specified by rhe client.

Depressurization must be possible - if required, also for sub-sections.

Proper bleeding of the pipe system must be ensured. Pressure

measurement connections are reccommended for this.

The hydraulic pipe system has to be equipped with monitoring devices,

which switch the drives off electrically in the case of a pipe break or hose

burst. The use of flow-related, switching pipe burst valves is not permitted

Possible pipe connecting fittings:

Status of IS0 standardization

Pipe fittings IS0 8434

Cutting ring Flared Flat face Weld-on Testing procedures

fitting fitting fitting fitting

24 degrees 37 degrees 90 degrees 24 degrees

DIN 2353 SAE 1514 SAE J1453 DIN 3865

Part 1 Pan 2 Pan 3 Pan 4 Part 5

Pipe fittings IS0 8434

New development

Pipe fining with soft seal

Flow speeds

Pressure lines

(supply and return)

The following guidel~ne values must be taken for the flow speeds in

hydraulic pipework:

Pilot oil return and < DN 40 1.0 mls

2 DN 40 1.5 mls leakage lines

Pump suction lines 0.6 mls

Você também pode gostar

- Manual Manutenção Guincho WarnDocumento35 páginasManual Manutenção Guincho WarnAnderson K LimaAinda não há avaliações

- Parker (PAVC33 PAVC38) Hydraulic Piston Pumps Service Literature Service PartsDocumento10 páginasParker (PAVC33 PAVC38) Hydraulic Piston Pumps Service Literature Service PartsAnonymous gKfTqXObkDAinda não há avaliações

- Re77502 2004-05Documento20 páginasRe77502 2004-05pamururamuAinda não há avaliações

- Re91401 A2foDocumento20 páginasRe91401 A2foTaz Juan GAinda não há avaliações

- Steering SystemsDocumento48 páginasSteering SystemsOscar Coaquira FelicianoAinda não há avaliações

- A17FODocumento16 páginasA17FOJose SalvadorAinda não há avaliações

- Aa2fm Model CodeDocumento27 páginasAa2fm Model CodeCristianAinda não há avaliações

- High Torque Geared Motors: T 238.000 NM Output Torque (175.500 LBF - FT)Documento26 páginasHigh Torque Geared Motors: T 238.000 NM Output Torque (175.500 LBF - FT)SAKDA MAPRADITKULAinda não há avaliações

- Catalog Vinciuri IMATRANSDocumento18 páginasCatalog Vinciuri IMATRANSVlad AndronacheAinda não há avaliações

- Bracket Hydraulic WinchDocumento4 páginasBracket Hydraulic WinchIrnaldi Yoza WijayaAinda não há avaliações

- Salami Catalog Group3 Zupcaste PumpeDocumento32 páginasSalami Catalog Group3 Zupcaste Pumpeado_22Ainda não há avaliações

- Table of ContentsDocumento27 páginasTable of ContentsEng-Mohammed SalemAinda não há avaliações

- Flupec Overview Hawe v30dDocumento4 páginasFlupec Overview Hawe v30dArdeleana TisaAinda não há avaliações

- Katalog Hagglunds Motor CBM TypeDocumento28 páginasKatalog Hagglunds Motor CBM TypeRudianto SakkaAinda não há avaliações

- Lantec LW Series Winches Catalog PDFDocumento16 páginasLantec LW Series Winches Catalog PDFFareedMohmed100% (1)

- M318S-Steering PumpDocumento88 páginasM318S-Steering Pumpzeck28Ainda não há avaliações

- Hydraulic Drive SystemDocumento23 páginasHydraulic Drive Systemsitiajaar100% (1)

- W1500 Series Hydraulic Pump: Concentric ABDocumento12 páginasW1500 Series Hydraulic Pump: Concentric ABvut73 a100% (1)

- HLRM90 5SDocumento2 páginasHLRM90 5SAna HafidzAinda não há avaliações

- DCVDocumento35 páginasDCVTanoj Patro100% (1)

- Amca Mev A e 06 07 PDFDocumento32 páginasAmca Mev A e 06 07 PDFthijssilderhuisAinda não há avaliações

- BH-RS Products Presentation SC22Documento8 páginasBH-RS Products Presentation SC22walk111Ainda não há avaliações

- Allison Transmission BrochureDocumento3 páginasAllison Transmission Brochurem mainAinda não há avaliações

- 5016 CraneDocumento96 páginas5016 CraneChristopher Bixenman100% (1)

- 2011 AC & DC Hydraulic Power Packs CompactDocumento97 páginas2011 AC & DC Hydraulic Power Packs CompactNicolae MogosAinda não há avaliações

- Hydraulic Pumps and MotorsDocumento1 páginaHydraulic Pumps and MotorsChumporn SaraphatmarkyingAinda não há avaliações

- 2015 Seven Ocean-CatalogDocumento142 páginas2015 Seven Ocean-CatalogCristobal0% (1)

- Centrifugal Pump Test Rig FinalDocumento7 páginasCentrifugal Pump Test Rig FinalanimeshkumarvermaAinda não há avaliações

- Block Making Machine - Types & FeaturesDocumento6 páginasBlock Making Machine - Types & FeaturesVikas MishraAinda não há avaliações

- HDM HDS - 100 P 000040 e 02Documento10 páginasHDM HDS - 100 P 000040 e 02Eng-Mohammed SalemAinda não há avaliações

- Hydraulic Brake Systems and Components For Off-Highway Vehicles and EquipmentDocumento10 páginasHydraulic Brake Systems and Components For Off-Highway Vehicles and EquipmentJenner Volnney Quispe ChataAinda não há avaliações

- 89-100 11069970 PDFDocumento44 páginas89-100 11069970 PDFeng13Ainda não há avaliações

- Sauerdanfoss Series s90 Pumps Catalogue en 520l0603Documento68 páginasSauerdanfoss Series s90 Pumps Catalogue en 520l0603Mohamed HarbAinda não há avaliações

- Hydroirma Catalog Gear PumpDocumento104 páginasHydroirma Catalog Gear PumpEng-Mohammed Salem100% (1)

- 1 Fluid Power Devices CircuitsDocumento20 páginas1 Fluid Power Devices CircuitshamidouAinda não há avaliações

- Eaton Walterscheid TrilogyDocumento12 páginasEaton Walterscheid TrilogyM MAinda não há avaliações

- Chapel Hydraulic ComponentsDocumento76 páginasChapel Hydraulic ComponentsSaeed OsheeAinda não há avaliações

- аксиальник 250Documento70 páginasаксиальник 250anon_757712831Ainda não há avaliações

- Technical Tips Regenerative Valves: ApplicationsDocumento8 páginasTechnical Tips Regenerative Valves: ApplicationsIkeoAinda não há avaliações

- EADocumento14 páginasEAanggieAinda não há avaliações

- TG Series Tractors TG210, TG230, TG255, AND TG285 Equipped With Megaflow RAC. 87025178 Nao Hydraulic SchematicDocumento2 páginasTG Series Tractors TG210, TG230, TG255, AND TG285 Equipped With Megaflow RAC. 87025178 Nao Hydraulic SchematicbrunosamaeianAinda não há avaliações

- Junttan PM16 DatasheetDocumento4 páginasJunttan PM16 DatasheetjovanangelssAinda não há avaliações

- Circuit RecommendationsDocumento37 páginasCircuit RecommendationsTatiana Mancera100% (1)

- J-Gear Pumps CatalogueDocumento21 páginasJ-Gear Pumps CatalogueturandotAinda não há avaliações

- Hidraulico CaterpillarDocumento4 páginasHidraulico CaterpillarJoseCorreaAinda não há avaliações

- Load Sensing: Series Pumps With ControlDocumento10 páginasLoad Sensing: Series Pumps With ControlMiguel Angel Del Carpio Zuñiga100% (1)

- Re 01200Documento24 páginasRe 01200Ahmed Abd ElhakeemAinda não há avaliações

- Hydraulic TechnologyDocumento76 páginasHydraulic TechnologyOgulcan CafAinda não há avaliações

- Unloading Pressure Hk66j102Documento12 páginasUnloading Pressure Hk66j102seaqu3stAinda não há avaliações

- Cat. Hy15-3502-R PDFDocumento659 páginasCat. Hy15-3502-R PDFRuddy Ral100% (1)

- Pressure Relief and Anti-Cavitation Valves (Cartridge Type) For Mobile ApplicationsDocumento12 páginasPressure Relief and Anti-Cavitation Valves (Cartridge Type) For Mobile ApplicationsOleg080Ainda não há avaliações

- Using The 8T-2700 Blowby/Air Flow Indicator (0774, 0781, 0785)Documento34 páginasUsing The 8T-2700 Blowby/Air Flow Indicator (0774, 0781, 0785)Jorge Luis Cervantes Carrillo100% (1)

- Gep22 4Documento4 páginasGep22 4RktBatam100% (1)

- P1 PD CompensatorsDocumento13 páginasP1 PD CompensatorsxxshAinda não há avaliações

- Gear PumpsDocumento7 páginasGear PumpsPrince ShanAinda não há avaliações

- Technical Proposal ECrane 1000 Series EH7359Documento16 páginasTechnical Proposal ECrane 1000 Series EH7359Satrio Agung WijonarkoAinda não há avaliações

- Pipeline System DesignDocumento75 páginasPipeline System Designjoreli50% (2)

- Pipe Stress Basics DTD 23oct2006Documento9 páginasPipe Stress Basics DTD 23oct2006Javier García100% (1)

- Code of Practice For Testing & Commissioning of Transformers and Related Switchgears IPSS:1-04-035-08Documento27 páginasCode of Practice For Testing & Commissioning of Transformers and Related Switchgears IPSS:1-04-035-08nishantpsbAinda não há avaliações

- Hose Surge ReportDocumento17 páginasHose Surge ReporttoyuedoxxAinda não há avaliações

- Catalogue Solid Core PDFDocumento16 páginasCatalogue Solid Core PDFdangodAinda não há avaliações

- Methods of Test For Rheometer - ODR: 1. ScopeDocumento1 páginaMethods of Test For Rheometer - ODR: 1. ScopeArun GuptaAinda não há avaliações

- CG Mod 3Documento51 páginasCG Mod 3Misba nausheenAinda não há avaliações

- Soda Ash PDFDocumento45 páginasSoda Ash PDFM TAinda não há avaliações

- LISTA PRECIOS CORPORATIVOS - Garantia en Partes de Diez (10) MesesDocumento10 páginasLISTA PRECIOS CORPORATIVOS - Garantia en Partes de Diez (10) MesesJavier DavidAinda não há avaliações

- RS 385SHDocumento3 páginasRS 385SHshahpinkalAinda não há avaliações

- Subjects Revised Curriculum BS ELECTRICAL ENGINEERINGDocumento18 páginasSubjects Revised Curriculum BS ELECTRICAL ENGINEERINGData StatsAinda não há avaliações

- Planning SchedulingDocumento20 páginasPlanning Schedulingvague100% (1)

- Septic Tank - Components and Design of Septic Tank Based On PopulationDocumento7 páginasSeptic Tank - Components and Design of Septic Tank Based On Populationمنير أحمدAinda não há avaliações

- Ns 3 TutorialDocumento105 páginasNs 3 TutorialparabavireoAinda não há avaliações

- Normativ Panouri SandwichDocumento58 páginasNormativ Panouri SandwichAlex ChiraAinda não há avaliações

- Arthashastra: Citation NeededDocumento4 páginasArthashastra: Citation NeededtusharAinda não há avaliações

- T60 Transformer Management Relay: UR Series Instruction ManualDocumento404 páginasT60 Transformer Management Relay: UR Series Instruction Manualeng amadaAinda não há avaliações

- Exercises Conditional SentencesDocumento2 páginasExercises Conditional SentencesDivine GuancoAinda não há avaliações

- APCO Air Valve 613Documento4 páginasAPCO Air Valve 613jones0055Ainda não há avaliações

- Sample Questions Paper 2 - TNQT Digital-4July19Documento6 páginasSample Questions Paper 2 - TNQT Digital-4July19Gudimetla KowshikAinda não há avaliações

- National Programming Skills Report - Engineers 2017 - Report BriefDocumento20 páginasNational Programming Skills Report - Engineers 2017 - Report BriefNewsBharati100% (2)

- Game TheoryDocumento13 páginasGame TheoryPriyanka ChaurasiyaAinda não há avaliações

- Atomic Structure ActivityDocumento4 páginasAtomic Structure ActivityClarisse BonaobraAinda não há avaliações

- 2017 Alcon Catalogue NewDocumento131 páginas2017 Alcon Catalogue NewJai BhandariAinda não há avaliações

- Data Structure and AlgorithmDocumento12 páginasData Structure and Algorithmleah pileoAinda não há avaliações

- DC Lecture Slides 1 - Information TheoryDocumento22 páginasDC Lecture Slides 1 - Information TheoryG VenkateshAinda não há avaliações

- Virtual Memory & Demand PagingDocumento22 páginasVirtual Memory & Demand PagingAli AhmadAinda não há avaliações

- Pump Station System Curves Session 1Documento29 páginasPump Station System Curves Session 1Toan LeAinda não há avaliações

- Lab 9: Standard Plate Count: How Do We Know How Many Bacteria Are in A Liquid?Documento4 páginasLab 9: Standard Plate Count: How Do We Know How Many Bacteria Are in A Liquid?Penelope MeloAinda não há avaliações

- Jee Advanced PaperDocumento3 páginasJee Advanced PaperGaurav YadavAinda não há avaliações

- Mesh Based Multicast Routing ProtocolDocumento10 páginasMesh Based Multicast Routing ProtocolArul JothiAinda não há avaliações

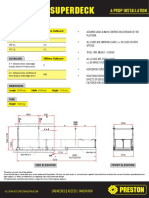

- SuperDeck All ModelsDocumento12 páginasSuperDeck All Modelsarthur chungAinda não há avaliações

- NPTEL CC Assignment4Documento4 páginasNPTEL CC Assignment4Paul Stark100% (1)