Escolar Documentos

Profissional Documentos

Cultura Documentos

Examen Ordinario - Ingeniería Térmica - 3ITI - 3ME - 3AUT - 1213 - SOLUCIÓN

Enviado por

Kais Garchi CasalTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Examen Ordinario - Ingeniería Térmica - 3ITI - 3ME - 3AUT - 1213 - SOLUCIÓN

Enviado por

Kais Garchi CasalDireitos autorais:

Formatos disponíveis

1

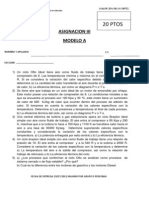

ALUMNO : ___________________________________________________________________________

Asignatura: IME - Ingeniera Trmica.

Cuatrimestre: 1 Examen: Final Convocatoria: Ordinaria

Grupo: 3 ITI 3 ME Curso:2.012/2.013 Fecha: 16 de enero de 2.013

CUESTIONES (0.8 puntos cada una):

C1.-Agua fra (c

p

= 4.18 kJ/kgC) entra en un intercambiador de calor a 18C con un flujo de 0.7 kg/s

donde es calentada mediante aire caliente (c

p

= 1.0 kJ/kgC) que entra en el intercambiador a 50C con

un caudal msico de 1.6 kg/s y abandona el intercambiador a 25C. La mxima temperatura posible del

agua fra es:

(a) 25.0C (b) 32.0C (c) 35.5C (d) 39.7C (e) 50.0C

11-154 Cold water enters a counter-flow heat exchanger at 18C at a rate of 0.7 kg/s where it is heated by hot air that

enters the heat exchanger at 50C at a rate of 1.6 kg/s and leaves at 25C. The maximum possible outlet temperature of

the cold water is

(a) 25.0C (b) 32.0C (c) 35.5C (d) 39.7C (e) 50.0C

Answer (c) 35.5C

Solution Solved by EES Software. Solutions can be verified by copying-and-pasting the following lines on a blank EES

screen.

T_c_in=18 [C]

m_dot_c=0.7 [kg/s]

c_p_c=4.18 [kJ/kg-C]

T_h_in=50 [C]

T_h_out=25 [C]

m_dot_h=1.6 [kg/s]

c_p_h=1.0 [kJ/kg-C]

C_c=m_dot_c*c_p_c

C_h=m_dot_h*c_p_h

C_min=min(C_c, C_h)

Q_dot_max=C_min*(T_h_in-T_c_in)

Q_dot_max=C_c*(T_c_out_max-T_c_in)

"Some Wrong Solutions with Common Mistakes"

W1_C_min=C_c "Using the greater heat capacity in the equation"

W1_Q_dot_max=W1_C_min*(T_h_in-T_c_in)

W1_Q_dot_max=C_c*(W1_T_c_out_max-T_c_in)

W2_T_c_out_max=T_h_in "Using T_h_in as the answer"

W3_T_c_out_max=T_h_out "Using T_h_in as the answer"

C2.- Un intercambiador de calor en contracorriente se usa para enfriar aceite desde 110C a 85C con

un caudal de 0.75 kg/s. Para ello se utiliza agua fra que entra en el intercambiador de calor a 20C con

un caudal de 0.6 kg/s. Si el coeficiente global de transferencia de calor del intercambiador de calor es

de 800 W/m

2

.C, el rea de transferencia de calor del intercambiador es:

DI I N

2

(a) 0.745 m

2

(b) 0.760 m

2

(c) 0.775 m

2

(d) 0.790 m

2

(e) 0.805 m

2

11-158 A counter-flow heat exchanger is used to cool oil (c

p

= 2.20 kJ/kgC) from 110C to 85C at a rate of 0.75 kg/s

by cold water (c

p

= 4.18 kJ/kgC) that enters the heat exchanger at 20C at a rate of 0.6 kg/s. If the overall heat transfer

coefficient is 800 W/m

2

C, the heat transfer area of the heat exchanger is

(a) 0.745 m

2

(b) 0.760 m

2

(c) 0.775 m

2

(d) 0.790 m

2

(e) 0.805 m

2

Answer (a) 0.745 m

2

Solution Solved by EES Software. Solutions can be verified by copying-and-pasting the following lines on a blank EES

screen.

T_h_in=110 [C]

T_h_out=85 [C]

m_dot_h=0.75 [kg/s]

c_p_h=2.20 [kJ/kg-C]

T_c_in=20 [C]

m_dot_c=0.6 [kg/s]

c_p_c=4.18 [kJ/kg-C]

U=0.800 [kW/m^2-C]

Q_dot=m_dot_h*c_p_h*(T_h_in-T_h_out)

Q_dot=m_dot_c*c_p_c*(T_c_out-T_c_in)

DELTAT_1=T_h_in-T_c_out

DELTAT_2=T_h_out-T_c_in

DELTAT_lm=(DELTAT_1-DELTAT_2)/ln(DELTAT_1/DELTAT_2)

Q_dot=U*A_s*DELTAT_lm

C3.- Un ciclo de Carnot opera entre los lmites de temperatura de 300 K y 2000 K, y produce 600 kW

de potencia neta. La velocidad del cambio de entropa (kW/K) del fluido de trabajo durante el proceso

de adicin de calor es:

(a) 0 (b) 0.300 kW/K (c) 0.353 kW/K (d) 0.261 kW/K (e) 2.0 kW/K

9-198 A Carnot cycle operates between the temperatures limits of 300 K and 2000 K, and produces 600 kW of net

power. The rate of entropy change of the working fluid during the heat addition process is

(a) 0 (b) 0.300 kW/K (c) 0.353 kW/K (d) 0.261 kW/K (e) 2.0 kW/K

Answer (c) 0.353 kW/K

Solution Solved by EES Software. Solutions can be verified by copying-and-pasting the following lines on a blank EES

screen. (Similar problems and their solutions can be obtained easily by modifying numerical values).

TL=300 "K"

TH=2000 "K"

Wnet=600 "kJ/s"

Wnet= (TH-TL)*DS

"Some Wrong Solutions with Common Mistakes:"

W1_DS = Wnet/TH "Using TH instead of TH-TL"

W2_DS = Wnet/TL "Using TL instead of TH-TL"

W3_DS = Wnet/(TH+TL) "Using TH+TL instead of TH-TL"

C4.- En un ciclo Otto ideal el aire se comprime desde 1.20 kg/m

3

y 2,2 litros hasta 0,26 litros, y el

trabajo neto de salida del ciclo es de 440 kJ/kg. La presin media efectiva para este ciclo es:

(a) 612 kPa (b) 599 kPa (c) 528 kPa (d) 416 kPa (e) 367 kPa

3

9-201 In an ideal Otto cycle, air is compressed from 1.20 kg/m

3

and 2.2 L to 0.26 L, and the net work output of the cycle

is 440 kJ/kg. The mean effective pressure (MEP) for this cycle is

Answer (b) 599 kPa

Solution Solved by EES Software. Solutions can be verified by copying-and-pasting the following lines on a blank EES

screen. (Similar problems and their solutions can be obtained easily by modifying numerical values).

rho1=1.20 "kg/m^3"

k=1.4

V1=2.2

V2=0.26

m=rho1*V1/1000 "kg"

w_net=440 "kJ/kg"

Wtotal=m*w_net

MEP=Wtotal/((V1-V2)/1000)

"Some Wrong Solutions with Common Mistakes:"

W1_MEP = w_net/((V1-V2)/1000) "Disregarding mass"

W2_MEP = Wtotal/(V1/1000) "Using V1 instead of V1-V2"

W3_MEP = (rho1*V2/1000)*w_net/((V1-V2)/1000); "Finding mass using V2 instead of V1"

W4_MEP = Wtotal/((V1+V2)/1000) "Adding V1 and V2 instead of subtracting"

C5.- Considere un ciclo Brayton ideal que se ejecuta entre los lmites de presin de 1200 kPa y 100 kPa y los

lmites de temperatura de 20C y 100C con argn como fluido de trabajo. El trabajo neto de salida del ciclo es:

(a) 68 kJ/kg (b) 93 kJ/kg (c) 158 kJ/kg (d) 186 kJ/kg (e) 310 kJ/kg

9-203 Consider an ideal Brayton cycle executed between the pressure limits of 1200 kPa and 100 kPa and temperature

limits of 20C and 1000C with argon as the working fluid. The net work output of the cycle is

Answer (c) 158 kJ/kg

Solution Solved by EES Software. Solutions can be verified by copying-and-pasting the following lines on a blank EES

screen. (Similar problems and their solutions can be obtained easily by modifying numerical values).

P1=100 "kPa"

P2=1200 "kPa"

T1=20+273 "K"

T3=1000+273 "K"

rp=P2/P1

k=1.667

Cp=0.5203 "kJ/kg.K"

Cv=0.3122 "kJ/kg.K"

T2=T1*rp^((k-1)/k)

q_in=Cp*(T3-T2)

Eta_Brayton=1-1/rp^((k-1)/k)

w_net=Eta_Brayton*q_in

"Some Wrong Solutions with Common Mistakes:"

W1_wnet = (1-1/rp^((k-1)/k))*qin1; qin1=Cv*(T3-T2) "Using Cv instead of Cp"

W2_wnet = (1-1/rp^((k-1)/k))*qin2; qin2=1.005*(T3-T2) "Using Cp of air instead of argon"

W3_wnet = (1-1/rp^((k1-1)/k1))*Cp*(T3-T22); T22=T1*rp^((k1-1)/k1); k1=1.4 "Using k of air instead of argon"

W4_wnet = (1-1/rp^((k-1)/k))*Cp*(T3-T222); T222=(T1-273)*rp^((k-1)/k) "Using C for T1 instead of K"

4

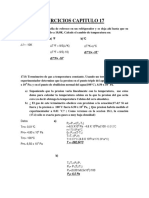

PROBLEMAS (Debe realizar 3 de los 4 problemas planteados. Puntuacin indicada en cada uno

de ellos):

P1.- (2 puntos) Se usa un intercambiador de calor de dos pasos por la carcasa y cuatro pasos por

los tubos para calentar un flujo de un hidrocarburo (c

P

= 2 kJ/kg.C) de manera continua,

desde 20C hasta 50C. Un flujo de agua (c

P

= 4.18 kJ/kg.C) entra por el lado de la carcasa a

80C y sale a 40C. Se tienen 160 tubos de pared delgada, cada uno con un dimetro de 2 cm y

una longitud de 1.5 m. Los coeficientes de transferencia de calor del lado del tubo y del lado

de la carcasa son 1.6 kW/m

2

.C y 2.5 kW/m

2

.C, respectivamente. Se pide calcular:

1. El ratio de transferencia de calor en el intercambiador.

2. Gastos msicos de agua y de hidrocarburo.

3. Con el tiempo se advierte que la temperatura de salida del hidrocarburo desciende en 5C

debido al depsito de slidos sobre la superficie del tubo. Estime la magnitud del factor de

incrustacin.

11-136 A hydrocarbon stream is heated by a water stream in a 2-shell passes and 4-tube passes heat exchanger. The rate

of heat transfer and the mass flow rates of both fluid streams and the fouling factor after usage are to be

determined.

Assumptions 1 Steady operating conditions exist. 2 The heat exchanger is well-insulated so that heat loss to the

surroundings is negligible and thus heat transfer from the hot fluid is equal to the heat transfer to the cold fluid. 3

Changes in the kinetic and potential energies of fluid streams are negligible. 4 Fluid properties are constant.

Properties The specific heat of HC is given to be 2 kJ/kg.C. The specific heat of water is taken to be 4.18 kJ/kg.C.

Analysis (a) The logarithmic mean temperature difference for counter-flow arrangement and the correction factor F are

C 20 = C 20 C 40

C 30 = C 50 C 80

, , 2

, , 1

= = A

= = A

in c out h

out c in h

T T T

T T T

C 66 . 24

) 20 / 30 ln(

20 30

) / ln(

2 1

2 1

,

=

=

A A

A A

= A

T T

T T

T

CF lm

90 . 0

33 . 1

20 50

40 80

5 . 0

20 80

20 50

1 2

2 1

1 1

1 2

=

=

=

=

F

t t

T T

R

t T

t t

P

(Fig. 11-18)

The overall heat transfer coefficient of the heat exchanger is

C W/m 6 . 975

2500

1

1600

1

1

1 1

1

2

=

+

=

+

=

o i

h h

U

The rate of heat transfer in this heat exchanger is

| | kW 326.5 = = = A = W 10 265 . 3 C) 66 . 24 ( (0.90) m) m)(1.5 (0.02 160 C) . W/m 6 . 975 (

5 2

,

t

CF lm s

T F UA Q

The mass flow rates of fluid streams are

kg/s 1.95

kg/s 5.44

=

=

=

=

=

=

C) 40 C C)(80 kJ/kg. (4.18

kW 5 . 326

) (

C) 20 C C)(50 kJ/kg. (2.0

kW 5 . 326

) (

out in p

h

in out p

c

T T c

Q

m

T T c

Q

m

Water

80C

HC

20C

50C

2 shell passes

4 tube passes 40C

5

(b) The rate of heat transfer in this case is

kW 272 = C) 20 C C)(45 kJ/kg. kg/s)(2.0 44 . 5 ( )] ( [

c

= =

in out p

T T c m Q

This corresponds to a 17% decrease in heat transfer. The outlet temperature of the hot fluid is

C 46.6 =

) C C)(80 kJ/kg. kg/s)(4.18 95 . 1 ( kW 272

)] ( [

,

,

h

=

=

out h

out h

out in p

T

T

T T c m Q

The logarithmic temperature difference is

C 26.6 = C 20 C 6 . 46

C 35 = C 45 C 80

, , 2

, , 1

= = A

= = A

in c out h

out c in h

T T T

T T T

C 61 . 30

) 6 . 26 / 35 ln(

6 . 26 35

) / ln(

2 1

2 1

,

=

=

A A

A A

= A

T T

T T

T

CF lm

97 . 0

34 . 1

20 45

6 . 46 80

42 . 0

20 80

20 45

1 2

2 1

1 1

1 2

=

=

=

=

F

t t

T T

R

t T

t t

P

(Fig. 11-18)

The overall heat transfer coefficient is

| |

C . W/m 5 . 607

C) 61 . 30 ( (0.97) m) m)(1.5 (0.02 160 W 000 , 272

2

,

=

=

A =

U

U

T F UA Q

CF lm s

t

The fouling factor is determined from

C/W m 10 6.21

2 4

= = =

6 . 975

1

5 . 607

1 1 1

clean dirty

f

U U

R

PE2.- (2 puntos) Un recipiente rgido cerrado contiene inicialmente una mezcla gaseosa de 1 kmol

de pentano (C5H12) y 150% de aire terico a 25C y 1 atm. Si la mezcla se quema

completamente, determine la transferencia de calor desde la cmara de combustin, en kJ.

6

P3.- (2 puntos) Un ciclo de turbina de gas con regeneracin opera con dos etapas de compresin y

dos etapas de expansin. La relacin de presiones a travs de cada etapa de compresor y de

turbina es de 3,5. El aire entra a cada etapa del compresor a 300 K, y a cada etapa de la turbina

a 1200 K. Las eficiencias de compresor y turbina son del 78% y del 86% respectivamente, y la

7

eficiencia del regenerador es del 72%. Suponiendo calores especficos constantes para el aire

(como fluido de trabajo) a temperatura ambiente, se pide calcular:

1. Propiedades de los puntos del ciclo y dibujo del mismo en un diagrama T-s.

2. La relacin de trabajo de retroceso o retrotrabajo.

3. Eficiencia trmica del ciclo.

9-179 A gas-turbine plant operates on the regenerative Brayton cycle with reheating and intercooling. The back work

ratio, the net work output, the thermal efficiency, the second-law efficiency, and the exergies at the exits of the

combustion chamber and the regenerator are to be determined.

Assumptions 1 The air-standard assumptions are applicable. 2 Kinetic and potential energy changes are negligible. 3 Air

is an ideal gas with variable specific heats.

Properties The gas constant of air is R = 0.287 kJ/kg K.

Analysis (a) For this problem, we use the properties from EES software. Remember that for an ideal gas, enthalpy is a

function of temperature only whereas entropy is functions of both temperature and pressure.

Optimum intercooling and reheating pressure is

kPa 4 . 346 ) 1200 )( 100 (

4 1 2

= = = P P P

Process 1-2, 3-4: Compression

K kJ/kg 7054 . 5

kPa 100

K 300

kJ/kg 43 . 300 K 300

1

1

1

1 1

=

)

`

=

=

= =

s

P

T

h T

kJ/kg 79 . 428

kJ/kg.K 7054 . 5

kPa 4 . 346

2

1 2

2

=

)

`

= =

=

s

h

s s

P

kJ/kg 88 . 460

43 . 300

43 . 300 79 . 428

80 . 0

2

2 1 2

1 2

C

=

= h

h h h

h h

s

q

K kJ/kg 5040 . 5

kPa 4 . 346

K 350

kJ/kg 78 . 350 K 350

3

3

3

3 3

=

)

`

=

=

= =

s

P

T

h T

kJ/kg 42 . 500

kJ/kg.K 5040 . 5

kPa 1200

4

3 4

4

=

)

`

= =

=

s

h

s s

P

kJ/kg 83 . 537

78 . 350

78 . 350 42 . 500

80 . 0

4

4 3 4

3 4

C

=

= h

h h h

h h

s

q

Process 6-7, 8-9: Expansion

K kJ/kg 6514 . 6

kPa 1200

K 1400

kJ/kg 9 . 1514 K 1400

6

6

6

6 6

=

)

`

=

=

= =

s

P

T

h T

kJ/kg 9 . 1083

kJ/kg.K 6514 . 6

kPa 4 . 346

7

6 7

7

=

)

`

= =

=

s

h

s s

P

s

T

3

4

1

5

q

in

8 6

7

10

9

2

8s 6s

4s 2s

8

kJ/kg 1 . 1170

9 . 1083 9 . 1514

9 . 1514

80 . 0

7

7

7 6

7 6

T

=

= h

h

h h

h h

s

q

K kJ/kg 9196 . 6

kPa 4 . 346

K 1300

kJ/kg 6 . 1395 K 1300

8

8

8

8 8

=

)

`

=

=

= =

s

P

T

h T

kJ/kg 00 . 996

kJ/kg.K 9196 . 6

kPa 100

9

8 9

9

=

)

`

= =

=

s

h

s s

P

kJ/kg 9 . 1075

00 . 996 6 . 1395

6 . 1395

80 . 0

9

9

9 8

9 8

T

=

= h

h

h h

h h

s

q

Cycle analysis:

kJ/kg 50 . 347 78 . 350 83 . 537 43 . 300 88 . 460

3 4 1 2 in C,

= + = + = h h h h w

kJ/kg 50 . 664 9 . 1075 6 . 1395 1 . 1170 9 . 1514

9 8 7 6 out T,

= + = + = h h h h w

0.523 = = =

50 . 664

50 . 347

out T,

in C,

bw

w

w

r

kJ/kg 317.0 = = = 50 . 347 50 . 664

in C, out T, net

w w w

Regenerator analysis:

kJ/kg 36 . 672

83 . 537 9 . 1075

9 . 1075

75 . 0

10

10

4 9

10 9

regen

=

= h

h

h h

h h

c

K kJ/kg 5157 . 6

kPa 100

K 36 . 672

10

10

10

=

)

`

=

=

s

P

h

kJ/kg 40 . 941 83 . 537 36 . 672 9 . 1075

5 5 4 5 10 9 regen

= = = = h h h h h h q

(b) kJ/kg 54 . 573 40 . 941 9 . 1514

5 6 in

= = = h h q

0.553 = = =

54 . 573

0 . 317

in

net

th

q

w

q

PE3.- (2 puntos) Un ciclo de aire estndar Otto tiene una relacin de compresin de 9. A inicio del

proceso de compresin la presin es de 100 kPa y la temperatura es de 300K. La adicin de

calor por unidad de masa de aire es de 1350 kJ/kg. Se pide

determinar:

(a) Trabajo neto en kJ por kg de aire.

(b) Eficiencia trmica del ciclo.

(c) Presin media efectiva, en kPa.

(d) Mxima temperatura del ciclo, en K.

(e) Razonar cmo le afecta a la eficiencia trmica el valor de la

relacin de compresin (dibujar curva aproximada).

9

Você também pode gostar

- Inter Cam Bi Adores de Calor. Ejercicios H Cap 10Documento13 páginasInter Cam Bi Adores de Calor. Ejercicios H Cap 10Juan BarbechoAinda não há avaliações

- Ingeniería química. Soluciones a los problemas del tomo INo EverandIngeniería química. Soluciones a los problemas del tomo IAinda não há avaliações

- Repaso ParcialDocumento3 páginasRepaso ParcialJHOAN ROY RAMIREZ SOLISAinda não há avaliações

- Orlando-Cerda - Semana3 TermodinamicaDocumento5 páginasOrlando-Cerda - Semana3 Termodinamicaorlando cerda100% (1)

- Problemas resueltos de Hidráulica de CanalesNo EverandProblemas resueltos de Hidráulica de CanalesNota: 4.5 de 5 estrelas4.5/5 (7)

- Examenes Termo PDFDocumento188 páginasExamenes Termo PDFdavid_gmhAinda não há avaliações

- Eficiencia energética en las instalaciones de calefacción y acs en los edificios. ENAC0108No EverandEficiencia energética en las instalaciones de calefacción y acs en los edificios. ENAC0108Ainda não há avaliações

- Practica - Intercambiadores de Calor FaltaDocumento8 páginasPractica - Intercambiadores de Calor FaltaYordy AlvarezAinda não há avaliações

- Experiencias sobre circuitos eléctricos en serie operados por corriente directaNo EverandExperiencias sobre circuitos eléctricos en serie operados por corriente directaAinda não há avaliações

- Ejercicios EntropíaDocumento5 páginasEjercicios EntropíafenderjosephAinda não há avaliações

- Guía de cálculo y diseño de conductos para ventilación y climatizaciónNo EverandGuía de cálculo y diseño de conductos para ventilación y climatizaciónNota: 5 de 5 estrelas5/5 (1)

- Diseño de intercambiadores de calorDocumento11 páginasDiseño de intercambiadores de calor601195Ainda não há avaliações

- Trabajo TermoDocumento16 páginasTrabajo TermoCRISTIAN PIERSK SALAZAR NEIRA100% (1)

- Mantenimiento de motores térmicos de dos y cuatro tiempos. TMVG0409No EverandMantenimiento de motores térmicos de dos y cuatro tiempos. TMVG0409Nota: 4 de 5 estrelas4/5 (1)

- Problemas de Análisis ExergéticoDocumento2 páginasProblemas de Análisis ExergéticoDer Gute Kerl RealAinda não há avaliações

- Unidad Demostracion de RefrigeracionDocumento10 páginasUnidad Demostracion de RefrigeraciondricardocanAinda não há avaliações

- UF0565 - Eficiencia energética en las instalaciones de calefacción y ACS en los edificiosNo EverandUF0565 - Eficiencia energética en las instalaciones de calefacción y ACS en los edificiosAinda não há avaliações

- Boletín I-1-IETC-19 - 20 PDFDocumento18 páginasBoletín I-1-IETC-19 - 20 PDFFrancisco José Ager VázquezAinda não há avaliações

- Problemas IDC-2 NFRT Marzo 6Documento14 páginasProblemas IDC-2 NFRT Marzo 6Nestor ReyesAinda não há avaliações

- #7 - Ejercicio 10.122Documento8 páginas#7 - Ejercicio 10.122Rodrigo Sifuentes0% (1)

- Prob TermodinamicaDocumento11 páginasProb TermodinamicaDiego100% (1)

- Taller Modelos de OptimizaciónDocumento5 páginasTaller Modelos de OptimizaciónLIBARDOAinda não há avaliações

- Ex. Parcial MN 121 SolucionarioDocumento11 páginasEx. Parcial MN 121 SolucionarioSteven OsorioAinda não há avaliações

- Ciclo Rankine Ejercicios ResueltosDocumento7 páginasCiclo Rankine Ejercicios ResueltosIsa CardonaAinda não há avaliações

- Balance de EnergiaDocumento12 páginasBalance de EnergiaAle OsbertoAinda não há avaliações

- Seminario 7 Intercambiadores-2021Documento4 páginasSeminario 7 Intercambiadores-2021Gastón AristizabalAinda não há avaliações

- GUIA 1 - Resuelta - Energia Trabajo Calor y Primera Ley de La TermodinamicaDocumento7 páginasGUIA 1 - Resuelta - Energia Trabajo Calor y Primera Ley de La TermodinamicaCristian Soto PintoAinda não há avaliações

- CICLOS TERMODINÁMICOS Y SUS APLICACIONESDocumento3 páginasCICLOS TERMODINÁMICOS Y SUS APLICACIONESFedericoAinda não há avaliações

- Solucionario Problemas Balance de MateriaDocumento22 páginasSolucionario Problemas Balance de MateriaSamuel LepeAinda não há avaliações

- Solucion Examen Feb 13Documento7 páginasSolucion Examen Feb 13jose80% (5)

- Solucionario de Termodinamica - 2Documento20 páginasSolucionario de Termodinamica - 2Jorge M. Q.Ainda não há avaliações

- Termonidamica de Gases y VaporesDocumento54 páginasTermonidamica de Gases y VaporesGenaro Jauregui67% (12)

- 1 PBDocumento14 páginas1 PBAngela GarciaAinda não há avaliações

- Capitulo 17 y 18 ResueltosDocumento28 páginasCapitulo 17 y 18 ResueltosCesar Alexander0% (3)

- Ejercicios de Sistemas de Cogeneración Unidad 2Documento55 páginasEjercicios de Sistemas de Cogeneración Unidad 2Alejandro Lopez100% (2)

- Analisis de IrreversivilidadesDocumento4 páginasAnalisis de IrreversivilidadesMemo NatreAinda não há avaliações

- PDF Rebeca Lascano DLDocumento29 páginasPDF Rebeca Lascano DLTatiana CastañedaAinda não há avaliações

- MarcoVidalJ Tarea ProyectoFinalDocumento17 páginasMarcoVidalJ Tarea ProyectoFinalAlexander Vidal JerezAinda não há avaliações

- Termonamica Balance de EnergiaDocumento12 páginasTermonamica Balance de EnergiaNathaly AlexandraAinda não há avaliações

- Máquina térmica reversible entre vapor y hielo calcula rendimiento máximo y trabajo producidoDocumento4 páginasMáquina térmica reversible entre vapor y hielo calcula rendimiento máximo y trabajo producidoFrancisco De León-Sotelo EstebanAinda não há avaliações

- Termodinamica Ejercicios ResueltosDocumento14 páginasTermodinamica Ejercicios ResueltosRonald Mirano TitoAinda não há avaliações

- Actividad TermodinamicaDocumento27 páginasActividad TermodinamicaDiego SuarezAinda não há avaliações

- Fisica Cap17 18Documento28 páginasFisica Cap17 18Paula GomezAinda não há avaliações

- Calculo de U en RAMDocumento17 páginasCalculo de U en RAMEric Jasso CelayaAinda não há avaliações

- Ejercicios Control 2Documento12 páginasEjercicios Control 2Anzo NuazAinda não há avaliações

- Termoquimica y Primera Ley de La Termo G1 1.21Documento4 páginasTermoquimica y Primera Ley de La Termo G1 1.21Gabriela RevillaAinda não há avaliações

- Fisica Cap17,18Documento28 páginasFisica Cap17,18Byron Gustavo57% (7)

- Guía de Ejercicios 1Documento6 páginasGuía de Ejercicios 1blaskyyAinda não há avaliações

- Ejercicios 1º ParcialDocumento13 páginasEjercicios 1º ParcialMaría Joaquina Fernández chiacchioAinda não há avaliações

- Termodinámica Unidad 2 ProblemasDocumento31 páginasTermodinámica Unidad 2 ProblemasManuel63% (8)

- Termodinamica Ejercicios ResueltosDocumento15 páginasTermodinamica Ejercicios ResueltosRonald Mirano TitoAinda não há avaliações

- Info9 IntercambiadoresDocumento19 páginasInfo9 IntercambiadoresTakeshi Tanohuye TanohuyeAinda não há avaliações

- Ejercicios Resueltos 2 2013BDocumento9 páginasEjercicios Resueltos 2 2013Bdemer22Ainda não há avaliações

- Discusion 3 TermodinámicaDocumento12 páginasDiscusion 3 TermodinámicaCesar HernandezAinda não há avaliações

- Problemas de Turbinas de VaporDocumento38 páginasProblemas de Turbinas de VaporDaniel GarciaAinda não há avaliações

- 1problemas Turbinas de VaporDocumento54 páginas1problemas Turbinas de VaporPippo Huaman CornelioAinda não há avaliações

- Examen Parcial - Ingeniería Térmica - 3ME - 3AUT - 1213 - SOLUCIÓNDocumento4 páginasExamen Parcial - Ingeniería Térmica - 3ME - 3AUT - 1213 - SOLUCIÓNKais Garchi CasalAinda não há avaliações

- Examen Parcial - Ingeniería Térmica - 3ITI - 1213 - SOLUCIÓNDocumento5 páginasExamen Parcial - Ingeniería Térmica - 3ITI - 1213 - SOLUCIÓNKais Garchi CasalAinda não há avaliações

- Practica 2 Kais GarchiDocumento6 páginasPractica 2 Kais GarchiKais Garchi CasalAinda não há avaliações

- Practica 1 Kais GarchiDocumento3 páginasPractica 1 Kais GarchiKais Garchi CasalAinda não há avaliações

- Examen Extraordinario - Ingeniería Térmica - 3ITI - 3ME - 3AUT - 1213 - SOLUCIÓNDocumento7 páginasExamen Extraordinario - Ingeniería Térmica - 3ITI - 3ME - 3AUT - 1213 - SOLUCIÓNKais Garchi CasalAinda não há avaliações

- Formulario - Ingeniería TérmicaDocumento0 páginaFormulario - Ingeniería TérmicaKais Garchi CasalAinda não há avaliações

- Proceso SDocumento7 páginasProceso SKais Garchi CasalAinda não há avaliações

- Tema 6. Ingeniería TérmicaDocumento0 páginaTema 6. Ingeniería TérmicaKais Garchi CasalAinda não há avaliações

- Asignacion 3 Tema III Sec 12 I 2012Documento2 páginasAsignacion 3 Tema III Sec 12 I 2012Kais Garchi CasalAinda não há avaliações

- Ciclos TermodinamicosDocumento17 páginasCiclos TermodinamicosRomeritho JC Vsqz VgAinda não há avaliações

- S08.s1 - CAF3-2021Documento46 páginasS08.s1 - CAF3-2021David MachacaAinda não há avaliações

- Guía de prácticas de laboratorio de transferencia de masa IIDocumento21 páginasGuía de prácticas de laboratorio de transferencia de masa IIIsrael CachumbaAinda não há avaliações

- Ventilador CentrifugoDocumento21 páginasVentilador CentrifugoStephanieZaghloul100% (1)

- Manual de alistamiento y control de destilación continuaDocumento51 páginasManual de alistamiento y control de destilación continuaMelissa Filizzola MerlanoAinda não há avaliações

- GM3N3 ExergíaDocumento3 páginasGM3N3 ExergíaSergio MendozaAinda não há avaliações

- Yermo DinamicaDocumento3 páginasYermo DinamicaRcristian DherreraAinda não há avaliações

- Eficiencia IsoentrópicaDocumento26 páginasEficiencia IsoentrópicaPaul Torres0% (1)

- Tema 5 Equilibrio Quimico Rev1Documento13 páginasTema 5 Equilibrio Quimico Rev1Rafael Rivas SantistebanAinda não há avaliações

- Energia TermicaDocumento18 páginasEnergia TermicaLuis Alberto González SalgadoAinda não há avaliações

- Cálculo de la eficiencia térmica y teórica de un ciclo termodinámicoDocumento2 páginasCálculo de la eficiencia térmica y teórica de un ciclo termodinámicoIntegradora MifisaAinda não há avaliações

- Refri CarneDocumento28 páginasRefri Carnejunior trujillo mattos100% (1)

- NEUMATICA (Flujo, Densidad y Humedad)Documento11 páginasNEUMATICA (Flujo, Densidad y Humedad)diego181802Ainda não há avaliações

- 2.1. Calculo en ExcelDocumento9 páginas2.1. Calculo en ExcelFernando Chirinos GarateAinda não há avaliações

- RadiaciónDocumento3 páginasRadiaciónEdith IbarraAinda não há avaliações

- Clima y Geografía de San MiguelDocumento13 páginasClima y Geografía de San MiguelR VillalobosAinda não há avaliações

- Secado PDFDocumento16 páginasSecado PDFAlvaro Izquierdo RamirezAinda não há avaliações

- Cálculos TRANSMITANCIA TÉRMICADocumento6 páginasCálculos TRANSMITANCIA TÉRMICAFiorentino CruzAinda não há avaliações

- Equilibrio TermicoDocumento6 páginasEquilibrio TermicoBrenda SorucoAinda não há avaliações

- Ciclo de Potencia de Gas CombinadoDocumento4 páginasCiclo de Potencia de Gas CombinadoGary Hamel RojasAinda não há avaliações

- Sistemas abiertos, cerrados y aislados: definiciones y ejemplosDocumento5 páginasSistemas abiertos, cerrados y aislados: definiciones y ejemplosAnnie ReyesAinda não há avaliações

- Relacion CP CVDocumento7 páginasRelacion CP CVNelson Ysmael Chirinos VielmaAinda não há avaliações

- Informe Reaccion Redox FDocumento18 páginasInforme Reaccion Redox FAlexisAinda não há avaliações

- Calculo Integral Fase 3Documento4 páginasCalculo Integral Fase 3miguel jaimesAinda não há avaliações

- Practica 2Documento15 páginasPractica 2Aylin SalinasAinda não há avaliações

- Ejercicios de Transferencia de CalorDocumento2 páginasEjercicios de Transferencia de CalorAlex Jimeno100% (1)

- Practica 5. DETERMINAR EL PESO MOLECULAR DE UN LIQUIDO VOLÁTILDocumento5 páginasPractica 5. DETERMINAR EL PESO MOLECULAR DE UN LIQUIDO VOLÁTILAna Karen CAinda não há avaliações

- Presión de VaporDocumento6 páginasPresión de VaporAxel Chachaqui MamaniAinda não há avaliações

- Solucionario Semana 2 Ordinario 2015-IDocumento93 páginasSolucionario Semana 2 Ordinario 2015-IJose Miguel N75% (4)

- Carpeta Teoria Refrigeracion para Re Par Adores 2011-05-21Documento45 páginasCarpeta Teoria Refrigeracion para Re Par Adores 2011-05-21gfc1Ainda não há avaliações

- Problemas Tema 9Documento2 páginasProblemas Tema 9Caterina PerezAinda não há avaliações