Escolar Documentos

Profissional Documentos

Cultura Documentos

Module 05 Lecture 32: HEN Optimization: Key Words: HEN, Loop Breaking, PDM, Utility Path

Enviado por

api-256504985Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Module 05 Lecture 32: HEN Optimization: Key Words: HEN, Loop Breaking, PDM, Utility Path

Enviado por

api-256504985Direitos autorais:

Formatos disponíveis

HENoptimization Module05 Lecture32

Module05

Lecture32:HENOptimization

Keywords:HEN,Loopbreaking,PDM,utilitypath,

Inlectures29,30and31itwasshownhowtodesignMaximumEnergyRecovery(MER)HENs.

InMERHENscoldandhotutilitiesasexactlysameastargeted.However,MERHENsarenot

thebestHENsasfarastotalannualcost(TAC)isconcerned.Nowthequestioniswhether,the

MERHENsdesignedinLecture2931canbeimprovedfurther?Theanswertothisquestionis

yes.

Using the PDM a HEN structure can be created based on the assumption that no heat

exchanger should have a temperature difference less than T

min

. However, the structure thus

createdcantbetermedoptimumandsomeprocedureforoptimizationcanbeadopted.Letus

onebyoneseethedrawbacksoftheHENcreatedbyPDM.

In an MER design, the pinch divides the problem into two thermodynamically independent

regionsasshowninFig.5.48(a).HENdesignsareperformedindependentlyforthesetwoparts

andoncedonearejoinedtogethertogetacompleteHENfortheproblem.Duetothisprocess

someweaknessescreepintothedesign.

Now,supposethedesignisconvertedintoanonMERdesignbyallowingamountofheatto

pass through pinch division, then the hot and cold utility amount will rise to Q

Hmin

+ and

Q

Cmin

+ respectively as shown in Fig.5.48(b). Now the earlier regions( Hot end & cold end)

defined in MER design is no longer thermodynamically independent. Thus, if the number of

unitstargetisappliedtothewholeproblem,ignoringpinchdivision,thenonewillobservethat:

U

min(

NonMER)U

min

(MER)

The above result is an expected one and can be explained as follows: When one applies unit

targettoaMERdesign,streamsthatcrosspinchdivisionarecountedtwiceandthusinaMER

design the total number of units are always more than a nonMER design. This clearly shows

thatbyallowingheattotransferthroughpinchdivision,thoughtheamountofutilityincreases,

the number of units is decreased and thus offers an opportunity to decrease the fixed cost of

theHEN.Thusthereisatradeoffbetweenenergyrecoveryandnumberofunitsemployed.

TradingoffunitsandEnergy

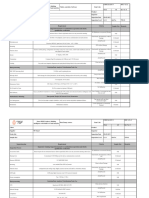

TheabovefactsareexplainedthroughtheexamplegiveninTable5.10.

HENoptimization Module05 Lecture32

Table5.10Afourstreamproblemtodemonstrateenergyvs.no.ofunitstradeoff(T

min

=10

0

C)

StreamName SupplyTemperature TargetTemperature CP

H1 160 60 2.5

H2 140 30 1.5

C1 20 125 2

C2 80 130 3.5

The hot pinch temperature for the above problem is 900 C whereas, the cold pinch

temperature 80

0

C. The hot utility requirement is 15 kW whereas that of cold utility

requirementis45kW. ThestreamdiagramisshowninFig.5.49.Thehotendaswellcoldend

designoftheHENwascarriedoutfortheproblem.AfterjoiningthehotandcoldendHENsthe

overall MER HEN is shown in Fig.5.50. It can be seen that the overall number of units in this

designis6includingheaterandcoolerswhereasanonMERdesignshouldproduce5(=4+21)

units. This clearly shows that there is a scope of decreasing one unit in a nonMER design

Q

HMIN

Q

CMIN

COLD END

HOTEND

Pinch

U

min

(MER)=U

min

(HotEnd) +U

min

(ColdEnd)

MaximumEnergyRecovery(MER)Design

NonMERDesign (noconceptof pinch division)

Q

CMIN+

Q

HMIN+

U

min

(nonMER)=N1

U

min

(nonMER)U

min

(MER)

(a)

(b)

Fig.5.48Targetingfornumberofunitsin(a)MERaswellasin(b)nonMERdesigns

HENoptimization Module05 Lecture32

however, at the cost of increased hot and cold utility which is to be investigated to strike a

tradeoff.ThereasonforoneextranumberofunitisduetothepresenceofaloopintheMER

design(pleaseseeLecture14).Thusiftheloop(inFig.5.50)isbrokenthenoneunitcanbe

reduced in the design. However, this will convert the MER design to a nonMER design and

someamountofheatwillpassthroughpinchdivision.Nowthequestioniswhatshouldbethe

properwaytodoitsothatwegetthebenefitofreducednumberofunitsintheHENandatthe

sametimetheamountofheatpassedthroughthepinchisalsonotmuch.

Fig.5.51showsanattempttobreaktheloopbyremovingtheheatexchanger(45kW)placedat

onesideoftheloopandaddingthisloadwiththeheatexchanger(75kW)ontheothersideof

theloopmakingitsloadas120kW.Fromcommonsenseitappearsthatthisarrangementwill

work. However, it violates the T

min

criterion and thus the design is not acceptable. Fig.5.52

showsanalternatearrangementwheretheamountofhotaswellascoldutilitiesareincreased

by 45kW( load of the removed heater). Theoretically, this design works and does not violates

theT

min

criterionandthusacceptable.However,theutilityloadsareincreasedsignificantly.

Nowthequestioniscantherebeathirdalternativetothedesignwhichwilldecreasetheutility

loadsbutwillprovideafeasibledesign?Theanswerisyes,itcanbedonebyutilizingtheutility

pathasdiscussedbelow:

Fig.5.49StreamdiagramfortheproblemshowninTable5.10.

HENoptimization Module05 Lecture32

Fig.5.51GriddiagramoftheHEN(MERDesign)

175kW

75kW+45kW

15kW

75kW

45kW

60C

57.5C

T

min

violation

117.5C

Fig.5.50GriddiagramoftheHEN(MERDesign)

U

min

(MER)=6

175kW

75kW

15kW

75kW 45kW

45kW

HENoptimization Module05 Lecture32

42.5

Fig.5.53Identificationofloop(reddottedline)intheMERHENdesign

Loop1

A

B

C

D

Heater

Cooler

90

60

42.5

117.5

80

T

min

=10C

175kW

75kW

15kW

75kW 45kW

45kW

Fig.5.52GriddiagramoftheHEN(NonMERDesign)

175kW

75kW

15kW+45kW

75kW

45kW+45kW

90C

57.5C

95C

HENoptimization Module05 Lecture32

GiventheHENasinFig.5.53itispossibletoidentifyloopsandutilitypaths.IntheFig.5.53a

loopwhichisshownbyreddottedlinesconnectsexchangersBandD.Itispossibletotracea

closepathinthenetworkforaloop.Thoughtheexistenceofaloopintroducessomeelement

offlexibilitybytransferringloadfromoneunittootherintheloop,itaddsonemoreunitper

loop.Forexample,theloadofexchangerBcanbetransferredtoDwhichispresentinthe

sameloop.Further,bymakingtheloadofanexchangerzerotheexchangercanberemoved

fromtheloopandtheloopcanbebroken.ForexampleiftheloadofexchangerDismade

zeroandtocompensatetheloadtheloadofexchangerBisincreasedto120(=75+45)kW,

thentheloop1canbebroken.However,thiswilldisturbtheheatflowinthenetworkand

violationofT

min

(Fig.5.54)willtakeplacewhichhastoberestoredtokeeptheutilitiesnear

targetedvalue.

TherestorationoftheT

min

canbedonethroughautilitypath.Utilitypathsarethosepaths

whichconnectstwodifferentutilities.Thispathcouldbepathjoininghotutility,steamtocold

utilitycoldwaterorapathfromhighpressuresteamtolowpressuresteam.

ForthepresentcaseinFig.5.55autilitypathfromheaterthroughexchangerBtocooler(

purpledottedline)canbetracedtofindaT

min

compensationplanfortheproblem.

Fig.5.54Identificationofloop(reddottedline)

Loop1

A

B

C

D

Heater

Cooler

60

117.5

57.5

T

min

=10C

45kW45kW=0 75kW+45kW

T

min

violation

175kW

75kW

15kW

75kW 45kW

45kW

HENoptimization Module05 Lecture32

IfweaddheatloadofXtotheheater,itloadbecomes15+XkW,thenforenthalpybalance

theloadofexchangerBshouldbedecreasedbyXamountandtheloadoncoolerbe

increasedbyXamount.Letthetemperatureofstream2beT

1

aftertheexchangerB.Now

torestoretheT

min

,T157.5shouldbeequalto10C.

Theaboveispossiblewhenfollowingequationissatisfied.

140(120X)/1.5=T

1

=57.5+10=67.5C

Or30+(45+X)/1.5=T

1

==57.5+10=67.5C

TosatisfytheaboveequationthevalueofXshouldbe11.25kW.

TheabovesolutionisclearlybetterthanthesolutionofferedinFig.5.52

PDM creates network structures based on the assumption that none of the exchanger in the

network should have a temperature difference less than T

min

. Once a HEN structure is

designed based on PDM, it can be subjected to optimization to improve its cost effectiveness.

Theconstraintimposedonitcanberemovedonebyonetogetimprovedsolutionintermsof

fixedcostofHEN,numberofunitsorshellsinHENorfinallyTACofHEN.

175kW

75kW

75kW

90kW

90kW 120kW

175kW 175kW

75kW

15kW

75kW 45kW

45kW

Fig.5.55Identificationofloop(reddottedline)intheMERHENdesign

A

B

C

15+XkW

Cooler T

1

57.5

T

min

=10C

120XkW

45+XkW

HENoptimization Module05 Lecture32

1. Theconstraintthatnoneoftheexchangershouldhavetemperaturedifferencelessthan

T

min

canberelaxed

2. Theexchangerdutiescouldberedistributedorevensettozerotoremoveoneofit.

3. RemovalofextranumberofunitsintheHENbybreakingloops.

4. ProperselectionofutilitypathsintheHENafterloopbreakingtorestoreT

min

.Utility

pathsandloopsprovidedegreeoffreedomforoptimizationandshouldbeutilizedto

improvecosteffectivenessofHEHs.

5. Streamsplittingalsooffersanadditionaldegreeoffreedomintheprocessof

optimizationandshouldbemanipulatedfortheimprovementofHENs.

References

1. AngelMartn*,FidelA.Mato,Hint:Aneducationalsoftwareforheatexchanger

networkdesignwiththepinchmethod,educationforchemicalengineers3(2008)e6

e14

2. Linnhoff,B.andFlower,J.R.,1978,Synthesisofheatexchangernetworks,AIChEJ,24(4):

633.

3. Linnhoff,B.andHindmarsh,E.,1983,Thepinchdesignmethodforheatexchanger

networks,ChemEngSci,38(5):745.

4. Linnhoff,B.,Townsend,D.W.,Boland,D.,Hewitt,G.F.,Thomas,B.E.A.,Guy,A.R.and

Marsland,R.H.,1994,AUserGuideonProcessIntegrationfortheEfficientUseof

Energy.(TheInstitutionofChemicalEngineers,Rugby,Warks,UK).

5. Smith,R.2005,ChemicalProcess:DesignandIntegration(seconded.),(J.Wiley,JWiley.

HENoptimization Module05 Lecture32

Você também pode gostar

- Module 05: Pinch Design Method For HEN Synthesis Lecture 29: MER Design For Threshold Problem Key WordsDocumento7 páginasModule 05: Pinch Design Method For HEN Synthesis Lecture 29: MER Design For Threshold Problem Key Wordsapi-256504985Ainda não há avaliações

- Energy and Thermal Management, Air-Conditioning, and Waste Heat Utilization: 2nd ETA Conference, November 22-23, 2018, Berlin, GermanyNo EverandEnergy and Thermal Management, Air-Conditioning, and Waste Heat Utilization: 2nd ETA Conference, November 22-23, 2018, Berlin, GermanyChristine JuniorAinda não há avaliações

- Module 05: Pinch Design Method For HEN Synthesis Lecture 28: Application of PDM For MER HEN Synthesis Key WordsDocumento9 páginasModule 05: Pinch Design Method For HEN Synthesis Lecture 28: Application of PDM For MER HEN Synthesis Key Wordsapi-256504985Ainda não há avaliações

- Module 05: Pinch Design Method For HEN Synthesis Lecture 26: Rules of Pinch Design Method (PDM) 1 Key WordsDocumento9 páginasModule 05: Pinch Design Method For HEN Synthesis Lecture 26: Rules of Pinch Design Method (PDM) 1 Key Wordsapi-256504985Ainda não há avaliações

- Part (Unequal Film Heat Transfer Coefficient) Key Words:: Module 04: Targeting Lecture 17: AREA TARGETING 1Documento13 páginasPart (Unequal Film Heat Transfer Coefficient) Key Words:: Module 04: Targeting Lecture 17: AREA TARGETING 1api-256504985Ainda não há avaliações

- Electrical Compression Cooling Versus Absorption Cooling - A ComparisonDocumento3 páginasElectrical Compression Cooling Versus Absorption Cooling - A Comparisonquynhanh2603Ainda não há avaliações

- Module 04: Targeting Lecture‐22: Cost targeting for optimal ΔT (Supertargeting) Key wordsDocumento8 páginasModule 04: Targeting Lecture‐22: Cost targeting for optimal ΔT (Supertargeting) Key wordsapi-256504985Ainda não há avaliações

- Assignment 3Documento4 páginasAssignment 3kietAinda não há avaliações

- EES Code For Transient SystemDocumento2 páginasEES Code For Transient SystemDhrupad Parikh0% (1)

- Resumen Analítico 4Documento2 páginasResumen Analítico 4Isaac SolorioAinda não há avaliações

- Review Paper - KhushbooDocumento10 páginasReview Paper - Khushboosarin.gaganAinda não há avaliações

- How To Calculate Cost Optimal Nzeb Energy PerformanceDocumento6 páginasHow To Calculate Cost Optimal Nzeb Energy PerformancebedogyulaAinda não há avaliações

- Designing and Simulating Heat Exchanger NetworksDocumento6 páginasDesigning and Simulating Heat Exchanger NetworksJhonatan33xAinda não há avaliações

- Design of Heat Exchanger Network For VCM Distillation Unit Using Pinch Technology PDFDocumento7 páginasDesign of Heat Exchanger Network For VCM Distillation Unit Using Pinch Technology PDFJose Luis EscobarAinda não há avaliações

- Total Site Exergy Analysis Using A New CDocumento14 páginasTotal Site Exergy Analysis Using A New Ca7510378Ainda não há avaliações

- HT andPI2009-2010Documento6 páginasHT andPI2009-2010sajni123Ainda não há avaliações

- Introduction To CourseDocumento33 páginasIntroduction To Courseabdul rehmanAinda não há avaliações

- Development of Finite Difference Solver For Heat Transfer Analysis in FinsDocumento24 páginasDevelopment of Finite Difference Solver For Heat Transfer Analysis in FinsAashutosh MistryAinda não há avaliações

- Discoverability ScoreDocumento8 páginasDiscoverability ScoreimoomexAinda não há avaliações

- Energy Optimization Using Pinch Analysis: Practical ConsiderationsDocumento10 páginasEnergy Optimization Using Pinch Analysis: Practical ConsiderationsconfyAinda não há avaliações

- Heat Exchanger Network Retrofit by Pinch Technology On Reformer Area of Aromatics PlantDocumento10 páginasHeat Exchanger Network Retrofit by Pinch Technology On Reformer Area of Aromatics PlantАнтон КоробейниковAinda não há avaliações

- A Simple Case Study On Application in Synthesising A Feasible Heat Exchanger NetworkDocumento6 páginasA Simple Case Study On Application in Synthesising A Feasible Heat Exchanger NetworkAndi SyahputraAinda não há avaliações

- Using LS-DYNA For Hot FormingDocumento6 páginasUsing LS-DYNA For Hot FormingPeter ZubarikAinda não há avaliações

- Cooling System Optimization in Polymer Injection MouldingDocumento1 páginaCooling System Optimization in Polymer Injection MouldingSemana da Escola de Engenharia da Universidade do MinhoAinda não há avaliações

- PINCHDocumento115 páginasPINCHSyed Muhammad Saqib BariAinda não há avaliações

- Use of PinchDocumento24 páginasUse of PinchAnonymous jlLBRMAr3OAinda não há avaliações

- Accepted Manuscript: Applied Thermal EngineeringDocumento30 páginasAccepted Manuscript: Applied Thermal Engineeringsebaa haddiAinda não há avaliações

- Heat and Power Optimization in Ammonia PlantDocumento23 páginasHeat and Power Optimization in Ammonia PlantDaniel Puello RodeloAinda não há avaliações

- Design and Optimization of District Energy SystemsDocumento6 páginasDesign and Optimization of District Energy Systemsduplicado2012Ainda não há avaliações

- Heat IntegrationDocumento47 páginasHeat IntegrationAnkitSinghAinda não há avaliações

- Matlab Model For The Design of Heat Exchanger Networks in Chemical ProcessesDocumento10 páginasMatlab Model For The Design of Heat Exchanger Networks in Chemical ProcessesKay LimAinda não há avaliações

- Application For Pinch Design of Heat Exc PDFDocumento9 páginasApplication For Pinch Design of Heat Exc PDFStefanie Guzman AznaranAinda não há avaliações

- Sabp A 009Documento208 páginasSabp A 009sethu1091100% (2)

- Heat ChemCADDocumento25 páginasHeat ChemCADthawdarAinda não há avaliações

- Off-Line Energy Optimization ModelDocumento6 páginasOff-Line Energy Optimization ModelSata AjjamAinda não há avaliações

- Finishing School Programme - 2020 Process Integration & Automation in Chemical Industries TutorialDocumento2 páginasFinishing School Programme - 2020 Process Integration & Automation in Chemical Industries TutorialGulli GullaAinda não há avaliações

- CHP 2023Documento16 páginasCHP 2023Thomas MeylaersAinda não há avaliações

- Key Words:: Module 04: Targeting Lecture 14: No. of Units TargetDocumento8 páginasKey Words:: Module 04: Targeting Lecture 14: No. of Units TargetimoomexAinda não há avaliações

- Steady-State 2D Axisymmetric Heat Transfer WithconductionDocumento8 páginasSteady-State 2D Axisymmetric Heat Transfer WithconductionAhmed Badr MabroukAinda não há avaliações

- Injection MouldingDocumento10 páginasInjection MouldinggoldencometAinda não há avaliações

- Usman PDO 20 Feb 2023 OptimizationDocumento47 páginasUsman PDO 20 Feb 2023 Optimizationcrazzyboy292Ainda não há avaliações

- Compact Thermal ModelingDocumento6 páginasCompact Thermal ModelingteomondoAinda não há avaliações

- (Ebook Eng) - Closed Cycle Gas Turbine ProjectDocumento2 páginas(Ebook Eng) - Closed Cycle Gas Turbine Projectbeny31100% (2)

- Project 2Documento3 páginasProject 2Charlie DowlingAinda não há avaliações

- State of The Art: 1. Thermal FieldsDocumento46 páginasState of The Art: 1. Thermal Fieldsgalio28Ainda não há avaliações

- Anantharaman (2006)Documento6 páginasAnantharaman (2006)Roody908Ainda não há avaliações

- 837 1Documento7 páginas837 1azlanAinda não há avaliações

- 2002 - ECM - Soylemez - On The Thermoeconomical Optimization of Heat Pipe Heat Exchanger HPHE For Waste Heat RecoveryDocumento9 páginas2002 - ECM - Soylemez - On The Thermoeconomical Optimization of Heat Pipe Heat Exchanger HPHE For Waste Heat RecoveryJoshep SeoAinda não há avaliações

- Analysis of PV Panels Thermal Control Under Different PCM PropertiesDocumento11 páginasAnalysis of PV Panels Thermal Control Under Different PCM Propertieshesham metwallyAinda não há avaliações

- HEN Task and OptimizationDocumento24 páginasHEN Task and OptimizationMuataman KhAinda não há avaliações

- Application of CFD in Thermal Power PlantsDocumento1 páginaApplication of CFD in Thermal Power Plantssandeep singhAinda não há avaliações

- PP 2Documento311 páginasPP 2Dinesh MechAinda não há avaliações

- Heat Recuperator Efficiency CalculationDocumento5 páginasHeat Recuperator Efficiency CalculationRAJESH S KAinda não há avaliações

- Influence of Power Modules On The Thermal Design o PDFDocumento13 páginasInfluence of Power Modules On The Thermal Design o PDFSunny ElAinda não há avaliações

- Major Project: Pinch Analysis & Process IntegrationDocumento8 páginasMajor Project: Pinch Analysis & Process IntegrationShreyJainAinda não há avaliações

- Models - Heat.chip CoolingDocumento26 páginasModels - Heat.chip CoolingJose Andres GarroAinda não há avaliações

- Intel - Thermal Design For Embedded AppsDocumento28 páginasIntel - Thermal Design For Embedded Appsbrownbag80Ainda não há avaliações

- Ansys Fluent Simulations ChapterDocumento10 páginasAnsys Fluent Simulations ChapterMuhammad NabeelAinda não há avaliações

- Of of The Heat: Optimization A Construction Compact Exchanger Themal StressesDocumento4 páginasOf of The Heat: Optimization A Construction Compact Exchanger Themal Stressesdragomir0marianAinda não há avaliações

- UntitledDocumento27 páginasUntitledapi-256504985Ainda não há avaliações

- Lecture 4.4: Transfer Molding and Compression Molding Transfer MoldingDocumento5 páginasLecture 4.4: Transfer Molding and Compression Molding Transfer Moldingapi-256504985Ainda não há avaliações

- Advanced Transport Phenomena Module 1 Lecture 2: Overview & "Hot Corrosion" ExampleDocumento32 páginasAdvanced Transport Phenomena Module 1 Lecture 2: Overview & "Hot Corrosion" Exampleapi-256504985Ainda não há avaliações

- Lecture 4.7: Rotational Molding and Blow MoldingDocumento8 páginasLecture 4.7: Rotational Molding and Blow Moldingapi-256504985Ainda não há avaliações

- UntitledDocumento6 páginasUntitledapi-256504985Ainda não há avaliações

- Lecture 4.2: Processing of PlasticsDocumento3 páginasLecture 4.2: Processing of Plasticsapi-256504985Ainda não há avaliações

- UntitledDocumento3 páginasUntitledapi-256504985Ainda não há avaliações

- Lecture 4.6: ThermoformingDocumento4 páginasLecture 4.6: Thermoformingapi-256504985Ainda não há avaliações

- 5 Abrasive Processes (Grinding)Documento15 páginas5 Abrasive Processes (Grinding)animi100% (1)

- LM 28Documento13 páginasLM 28Deepak Kumar Kant KesriAinda não há avaliações

- Abrasive Processes (Grinding) : Version 2 ME, IIT KharagpurDocumento13 páginasAbrasive Processes (Grinding) : Version 2 ME, IIT KharagpurRAVINDER KUMARAinda não há avaliações

- Lecture 4.1: Thermoplastics and ThermosetsDocumento8 páginasLecture 4.1: Thermoplastics and Thermosetsapi-256504985Ainda não há avaliações

- Heat Exchanger PDFDocumento9 páginasHeat Exchanger PDFsunita45Ainda não há avaliações

- Gopinath@acer Iitm Ernet inDocumento3 páginasGopinath@acer Iitm Ernet inapi-256504985Ainda não há avaliações

- Advanced Transport Phenomena Module 1 Lecture 2: Overview & "Hot Corrosion" ExampleDocumento32 páginasAdvanced Transport Phenomena Module 1 Lecture 2: Overview & "Hot Corrosion" Exampleapi-256504985Ainda não há avaliações

- Advanced Transport Phenomena Module 1 Lecture 2: Overview & "Hot Corrosion" ExampleDocumento32 páginasAdvanced Transport Phenomena Module 1 Lecture 2: Overview & "Hot Corrosion" Exampleapi-256504985Ainda não há avaliações

- UntitledDocumento13 páginasUntitledapi-256504985Ainda não há avaliações

- Only Questions HTDocumento2 páginasOnly Questions HTrkiran05Ainda não há avaliações

- What Are Heat Exchangers For?Documento33 páginasWhat Are Heat Exchangers For?captainhassAinda não há avaliações

- Module 7: Learning ObjectivesDocumento1 páginaModule 7: Learning Objectivesapi-256504985Ainda não há avaliações

- Uncontrolled IntersectionDocumento16 páginasUncontrolled Intersectionapi-256504985Ainda não há avaliações

- UntitledDocumento12 páginasUntitledapi-256504985Ainda não há avaliações

- Traffic RotariesDocumento9 páginasTraffic RotariesJinal MistryAinda não há avaliações

- UntitledDocumento11 páginasUntitledapi-256504985Ainda não há avaliações

- UntitledDocumento3 páginasUntitledapi-256504985Ainda não há avaliações

- UntitledDocumento40 páginasUntitledapi-256504985Ainda não há avaliações

- Traffic SignsDocumento6 páginasTraffic Signsapi-256504985Ainda não há avaliações

- UntitledDocumento6 páginasUntitledapi-256504985Ainda não há avaliações

- Simulation Methods: DX X F PDocumento7 páginasSimulation Methods: DX X F Papi-256504985Ainda não há avaliações

- UntitledDocumento1 páginaUntitledapi-256504985Ainda não há avaliações

- 1.nursing As A ProfessionDocumento148 páginas1.nursing As A ProfessionveralynnpAinda não há avaliações

- Damage To Bottom Ash Handling SysDocumento6 páginasDamage To Bottom Ash Handling SyssanjeevchhabraAinda não há avaliações

- Northern Lights - 7 Best Places To See The Aurora Borealis in 2022Documento15 páginasNorthern Lights - 7 Best Places To See The Aurora Borealis in 2022labendetAinda não há avaliações

- Kpolovie and Obilor PDFDocumento26 páginasKpolovie and Obilor PDFMandalikaAinda não há avaliações

- A List of 142 Adjectives To Learn For Success in The TOEFLDocumento4 páginasA List of 142 Adjectives To Learn For Success in The TOEFLchintyaAinda não há avaliações

- Mastering American EnglishDocumento120 páginasMastering American Englishmarharnwe80% (10)

- HSG Vs SonohysterographyDocumento4 páginasHSG Vs Sonohysterography#15Ainda não há avaliações

- 1.12 Properties of The Ism - FlexibilityDocumento4 páginas1.12 Properties of The Ism - FlexibilityyomnahelmyAinda não há avaliações

- D2E133AM4701 Operating Instruction UsDocumento9 páginasD2E133AM4701 Operating Instruction UsMohamed AlkharashyAinda não há avaliações

- First Aid Transportation of The InjuredDocumento30 páginasFirst Aid Transportation of The InjuredMuhammad Naveed Akhtar100% (1)

- Nugent 2010 Chapter 3Documento13 páginasNugent 2010 Chapter 3Ingrid BobosAinda não há avaliações

- 3 HVDC Converter Control PDFDocumento78 páginas3 HVDC Converter Control PDFJanaki BonigalaAinda não há avaliações

- Jail Versus Substance Abuse TreatmentDocumento5 páginasJail Versus Substance Abuse Treatmentapi-240257564Ainda não há avaliações

- Dr. Babasaheb Ambedkar Technological UniversityDocumento3 páginasDr. Babasaheb Ambedkar Technological UniversityalfajAinda não há avaliações

- Integrated Management System 2016Documento16 páginasIntegrated Management System 2016Mohamed HamedAinda não há avaliações

- Corporate Members List Iei Mysore Local CentreDocumento296 páginasCorporate Members List Iei Mysore Local CentreNagarjun GowdaAinda não há avaliações

- N164.UCPE12B LANmark - OF - UC - 12x - Singlemode - 9 - 125 - OS2 - PE - BlackDocumento2 páginasN164.UCPE12B LANmark - OF - UC - 12x - Singlemode - 9 - 125 - OS2 - PE - BlackRaniaTortueAinda não há avaliações

- EIL 6-51-0051-Rev 06 - 1.1kv-Xlpe - Dimension Cat - B Armour-BbpDocumento2 páginasEIL 6-51-0051-Rev 06 - 1.1kv-Xlpe - Dimension Cat - B Armour-BbpShubham BaderiyaAinda não há avaliações

- Language EducationDocumento33 páginasLanguage EducationLaarni Airalyn CabreraAinda não há avaliações

- Thesis Statement On Corporate Social ResponsibilityDocumento5 páginasThesis Statement On Corporate Social Responsibilitypjrozhiig100% (2)

- Buku BaruDocumento51 páginasBuku BaruFirdaus HoAinda não há avaliações

- Quality Assurance Plan-75FDocumento3 páginasQuality Assurance Plan-75Fmohamad chaudhariAinda não há avaliações

- -4618918اسئلة مدني فحص التخطيط مع الأجوبة من د. طارق الشامي & م. أحمد هنداويDocumento35 páginas-4618918اسئلة مدني فحص التخطيط مع الأجوبة من د. طارق الشامي & م. أحمد هنداويAboalmaail Alamin100% (1)

- Rules of Bursa Malaysia Securities Clearing 2019Documento11 páginasRules of Bursa Malaysia Securities Clearing 2019Evelyn SeethaAinda não há avaliações

- GSM Based Prepaid Electricity System With Theft Detection Using Arduino For The Domestic UserDocumento13 páginasGSM Based Prepaid Electricity System With Theft Detection Using Arduino For The Domestic UserSanatana RoutAinda não há avaliações

- Test 1801 New Holland TS100 DieselDocumento5 páginasTest 1801 New Holland TS100 DieselAPENTOMOTIKI WEST GREECEAinda não há avaliações

- 3114 Entrance-Door-Sensor 10 18 18Documento5 páginas3114 Entrance-Door-Sensor 10 18 18Hamilton Amilcar MirandaAinda não há avaliações

- Sample Paper Book StandardDocumento24 páginasSample Paper Book StandardArpana GuptaAinda não há avaliações

- Cryptocurrency Research PDFDocumento59 páginasCryptocurrency Research PDFAnupriyaAinda não há avaliações

- LCP-027 VectraLCPDesignGuideTG AM 0613Documento80 páginasLCP-027 VectraLCPDesignGuideTG AM 0613Evert100% (1)

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincNo EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincNota: 3.5 de 5 estrelas3.5/5 (137)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresNo EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresNota: 1 de 5 estrelas1/5 (2)

- To Engineer Is Human: The Role of Failure in Successful DesignNo EverandTo Engineer Is Human: The Role of Failure in Successful DesignNota: 4 de 5 estrelas4/5 (138)

- Formulating, Packaging, and Marketing of Natural Cosmetic ProductsNo EverandFormulating, Packaging, and Marketing of Natural Cosmetic ProductsAinda não há avaliações

- AP® Chemistry Crash Course, For the 2020 Exam, Book + Online: Get a Higher Score in Less TimeNo EverandAP® Chemistry Crash Course, For the 2020 Exam, Book + Online: Get a Higher Score in Less TimeNota: 5 de 5 estrelas5/5 (1)

- The Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactNo EverandThe Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactNota: 5 de 5 estrelas5/5 (5)

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeNo EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeNota: 5 de 5 estrelas5/5 (4)

- The Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsNo EverandThe Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsNota: 4 de 5 estrelas4/5 (146)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeNo EverandChemistry for Breakfast: The Amazing Science of Everyday LifeNota: 4.5 de 5 estrelas4.5/5 (90)

- Handbook of Formulating Dermal Applications: A Definitive Practical GuideNo EverandHandbook of Formulating Dermal Applications: A Definitive Practical GuideAinda não há avaliações

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolNo EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolAinda não há avaliações

- The Periodic Table: A Very Short IntroductionNo EverandThe Periodic Table: A Very Short IntroductionNota: 4.5 de 5 estrelas4.5/5 (3)

- Tribology: Friction and Wear of Engineering MaterialsNo EverandTribology: Friction and Wear of Engineering MaterialsNota: 5 de 5 estrelas5/5 (1)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeNo EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeNota: 4 de 5 estrelas4/5 (1)

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisNo EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisNota: 5 de 5 estrelas5/5 (1)

- AP Chemistry Flashcards, Fourth Edition: Up-to-Date Review and PracticeNo EverandAP Chemistry Flashcards, Fourth Edition: Up-to-Date Review and PracticeAinda não há avaliações

- Ingredients: A Visual Exploration of 75 Additives & 25 Food ProductsNo EverandIngredients: A Visual Exploration of 75 Additives & 25 Food ProductsNota: 4 de 5 estrelas4/5 (1)

- Taste: Surprising Stories and Science About Why Food Tastes GoodNo EverandTaste: Surprising Stories and Science About Why Food Tastes GoodNota: 3 de 5 estrelas3/5 (20)

- The Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableNo EverandThe Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableNota: 3.5 de 5 estrelas3.5/5 (22)

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsNo EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsNota: 5 de 5 estrelas5/5 (3)

- The Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactNo EverandThe Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactNota: 5 de 5 estrelas5/5 (1)