Escolar Documentos

Profissional Documentos

Cultura Documentos

NPSH Calculations

Enviado por

seenu189Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

NPSH Calculations

Enviado por

seenu189Direitos autorais:

Formatos disponíveis

Low pressure at the suction side of a pump can encounter the fluid to start boiling with

reduced efficiency

cavitation

damage

of the pump as a result. Boiling starts when the pressure in the liquid is reduced to the vapor

pressure of the fluid at the actual temperature.

To characterize the potential for boiling and cavitation, the difference between the total head

on the suction side of the pump - close to the impeller, and the liquid vapor pressure at the

actual temperature, can be used.

Suction Head

Based on the Energy Equation - the suction head in the fluid close to the impeller can be

expressed as the sum of the static and the velocity head:

hs =ps / + vs

2

/ 2 g (1)

where

hs =suction head close to the impeller

ps =static pressure in the fluid close to the impeller

= specific weight of the fluid

vs =velocity of fluid

g =acceleration of gravity

Liqui ds Vapor Head

The liquids vapor head at the actual temperature can be expressed as:

hv = pv / (2)

where

hv =vapor head

pv =vapor pressure

Note! The vapor pressure in fluids depends on temperature. Water, our most common fluid,

starts boiling at 20 oC if the absolute pressure in the fluid is 2.3 kN/m2. For an absolute

pressure of 47.5 kN/m

2

, the water starts boiling at 80

o

C. At an absolute pressure of 101.3

kN/m

2

(normal atmosphere), the boiling starts at 100

o

C.

Net Positive Sucti on Head - NPSH

The Net Positive Suction Head - NPSH - can be expressed as the difference between the

Suction Head and the Liquids Vapor Head and expressed like

NPSH = h

s

- h

v

(3)

or, by combining (1) and (2)

NPSH = p

s

/ + v

s

2

/ 2 g - p

v

/ (3b)

Avail able NPSH - NPSH

a

or NPSHA

The Net Positive Suction Head made available the suction system for the pump is often

named NPSHa. The NPSHa can be determined during design and construction, or determined

experimentally from the actual physical system.

The available NPSHa can be calculated with the Energy Equation. For a common application -

where the pump lifts a fluid from an open tank at one level to an other, the energy or head at

the surface of the tank is the same as the energy or head before the pump impeller and can

be expressed as:

h0 =hs +hl (4)

where

h0 =head at surface

hs =head before the impeller

hl = head loss from the surface to impeller - major and minor loss in the suction pipe

In an open tank the head at surface can be expressed as:

h0 =p0 / = patm / (4b)

For a closed pressurized tank the absolute static pressure inside the tank must be used.

The head before the impeller can be expressed as:

hs =ps / + vs

2

/ 2 g +he (4c)

where

he = elevation from surface to pump - positive if pump is above the tank, negative if the pump

is below the tank

Transforming (4) with (4b) and (4c):

patm / = ps / + vs

2

/ 2 g +he +hl (4d)

The head available before the impeller can be expressed as:

ps / + vs

2

/ 2 g =patm / - he - hl (4e)

or as the available NPSHa:

NPSHa =patm / - he - hl - pv / (4f)

Available NPSH

a

- the Pump is above the Tank

If the pump is positioned above the tank, the elevation - he - is positive and the NPSHa

decreases when the elevation of the pump increases.

At some level the NPSHa will be reduced to zero and the fluid starts to evaporate.

Available NPSH

a

- the Pump is below the Tank

If the pump is positioned below the tank, the elevation - he - is negative and the NPSHa

increases when the elevation of the pump decreases (lowering the pump).

It's always possible to increase the NPSHa by lowering the pump (as long as the major and

minor head loss due to a longer pipe don't increase it more). This is important and it is

common to lower the pump when pumping fluids close to evaporation temperature.

Required NPSH - NPSH

r

or NPSHR

The NPSHr, called as the Net Suction Head as required by the pump in order to prevent

cavitation for safe and reliable operation of the pump.

The required NPSHr for a particular pump is in general determined experimentally by the

pump manufacturer and a part of the documentation of the pump.

The available NPSHa of the system should always exceeded the required NPSHr of the pump

to avoid vaporization and cavitation of the impellers eye. The available NPSHa should in

general be significant higher than the required NPSHr to avoid that head loss in the suction

pipe and in the pump casing, local velocity accelerations and pressure decreases, start boiling

the fluid on the impeller surface.

Note that the required NPSHr increases with the square capacity.

Pumps with double-suction impellers has lower NPSHr than pumps with single-suction

impellers. A pump with a double-suction impeller is considered hydraulically balanced but is

susceptible to an uneven flow on both sides with improper pipe-work.

Example - Pumpi ng Water from an Open Tank

When increasing the the elevation for a pump located above a tank, the fluid will start to

evaporate at a maximum level for the actual temperature.

At the maximum elevation NPSH

a

is zero. The maximum elevation can therefore be

expressed by (4f):

NPSHa =patm / - he - hl - pv / = 0

For optimal theoretical conditions we neglect the major and minor head loss. The elevation

head can then be expressed as:

he =patm / - pv / (5)

The maximum elevation or suction head for an open tank depends on the atmospheric

pressure - which in general can be regarded as constant, and the vapor pressure of the fluid -

which in general vary with temperature, especially for water.

The absolute vapor pressure of water at temperature 20 oC is 2.3 kN/m2. The maximum

theoretical elevation height is therefore:

he =(101.33 kN/m2) / (9.80 kN/m3) - (2.3 kN/m2) / (9.80 kN/m3)

=10.1 m

Due to the head loss in the suction pipe and the local conditions inside the pump - the

theoretical maximum elevation is significantly decreased.

The maximum theoretical elevation of a pump above an open water tank at different

temperatures can be found from the table below.

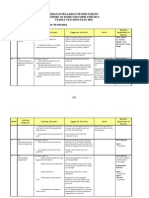

Suction Head as Affected by Temperature

Temperature

Vapor

Pressure

Max. elevation

(

o

C) (

o

F) (kN/m

2

) (m) (ft)

0 32 0.6 10.3 33.8

5 41 0.9 10.2 33.5

10 50 1.2 10.2 33.5

15 59 1.7 10.2 33.5

20 68 2.3 10.1 33.1

25 77 3.2 10.0 32.8

30 86 4.3 9.9 32.5

Temperature

Vapor

Pressure

Max. elevation

(

o

C) (

o

F) (kN/m

2

) (m) (ft)

35 95 5.6 9.8 32.2

40 104 7.7 9.5 31.2

45 113 9.6 9.4 30.8

50 122 12.5 9.1 29.9

55 131 15.7 8.7 28.5

60 140 20 8.3 27.2

65 149 25 7.8 25.6

70 158 32.1 7.1 23.3

75 167 38.6 6.4 21

80 176 47.5 5.5 18

85 185 57.8 4.4 14.4

90 194 70 3.2 10.5

95 203 84.5 1.7 5.6

100 212 101.33 0.0 0

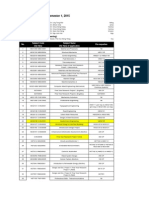

Pumping Hydrocarbons

Be aware that the NPSH specification provided by the manufacturer in general is for use with

cold water. For hydrocarbons these values must be lowered to account for the vapor release

properties of complex organic liquids.

Fluid

Temperature

(

o

C)

Vapor

Pressure

(kPa abs)

Ethanol

20 5.9

65 58.2

Methyl

Acetate

20 22.8

55 93.9

Note that the head developed by a pump is independent of the liquid, and that the

performance curves for water from the manufacturer can be used for Newtonian liquids like

gasoline, diesel or similar. Be aware that required power depends on liquid density and must

be adjusted.

NPSH and Liquids with Dissolved Gas

Be aware that NPSH calculations might have to be modified if there are significant amounts of

dissolved gas in the liquid. The gas saturation pressure is often much higher than the liquid's

vapor pressure.

Solubility of Gases in Water

Você também pode gostar

- NPSH - Net Positive Suction HeadDocumento9 páginasNPSH - Net Positive Suction Headlokeshjaddu6Ainda não há avaliações

- Pump NPSH (Net Positive Suction Head)Documento8 páginasPump NPSH (Net Positive Suction Head)farhan_katpar1838Ainda não há avaliações

- NPSH - Net Positive Suction HeadDocumento5 páginasNPSH - Net Positive Suction HeadSutrisno KlsAinda não há avaliações

- Net Positive Suction HeadDocumento7 páginasNet Positive Suction HeadNenad MutavdzicAinda não há avaliações

- Net Positive Suction HeadDocumento4 páginasNet Positive Suction Headjorge alarconAinda não há avaliações

- NPSH - Net Positive Suction HeadDocumento7 páginasNPSH - Net Positive Suction Headpryor.lamarioAinda não há avaliações

- NPSH - Net Positive Suction HeadDocumento5 páginasNPSH - Net Positive Suction HeadBilal ÇetinerAinda não há avaliações

- NPSH - Net Positive Suction HeadDocumento12 páginasNPSH - Net Positive Suction HeadhbithoAinda não há avaliações

- Net Positive Suction Head (NPSH) theory and cavitation preventionDocumento3 páginasNet Positive Suction Head (NPSH) theory and cavitation preventionOstwald GarciaAinda não há avaliações

- Condensate Pumping: High Temperatures and Danger of Impeller Cavitation Is The Major Challenge of Condensate PumpingDocumento2 páginasCondensate Pumping: High Temperatures and Danger of Impeller Cavitation Is The Major Challenge of Condensate PumpingcordobaluisfAinda não há avaliações

- GPM RevDocumento138 páginasGPM RevJuan Cortes TorizAinda não há avaliações

- Pumps DefinitionsDocumento31 páginasPumps DefinitionsFortuna JohnAinda não há avaliações

- NPSH Is An: Acronym Hydraulic Vapor PressureDocumento5 páginasNPSH Is An: Acronym Hydraulic Vapor PressureSantosh Yellappa SulebhavikarAinda não há avaliações

- Understanding NPSH and How it Impacts Pump PerformanceDocumento24 páginasUnderstanding NPSH and How it Impacts Pump Performanceneerajtrip123100% (1)

- Pump Suction CharacteristicsDocumento10 páginasPump Suction Characteristicsvermaakash22Ainda não há avaliações

- NPSHDocumento4 páginasNPSHrex tanongAinda não há avaliações

- Pump Equations and Formulas CalculatorDocumento11 páginasPump Equations and Formulas CalculatorOmar Elhady100% (2)

- How Pump Suction Limits FlowDocumento6 páginasHow Pump Suction Limits FlowNilesh GohelAinda não há avaliações

- Net Positive Suction HeadDocumento16 páginasNet Positive Suction HeadpandiangvAinda não há avaliações

- Is 5120Documento52 páginasIs 5120Otavio123Ainda não há avaliações

- Fluid Mahiney 5Documento15 páginasFluid Mahiney 5Jacob BenningsAinda não há avaliações

- Libro de BombasDocumento260 páginasLibro de BombasBoris SalazarAinda não há avaliações

- Calculate NPSH to Prevent CavitationDocumento22 páginasCalculate NPSH to Prevent CavitationShesadri ChakrabartyAinda não há avaliações

- Centrifugal Pump - HandbookDocumento26 páginasCentrifugal Pump - HandbookPrafull Dhakate100% (2)

- NPSHDocumento15 páginasNPSHnamlidjordieAinda não há avaliações

- Natalie Portmans Shaved Head Glossary of Firefighting Equipment#n Talk PageDocumento34 páginasNatalie Portmans Shaved Head Glossary of Firefighting Equipment#n Talk PageMikelaAinda não há avaliações

- NPSH For Pump UsersDocumento4 páginasNPSH For Pump Userssepideh_entezariAinda não há avaliações

- NPSH For Metering PumpsDocumento7 páginasNPSH For Metering PumpsRahul S. ChandrawarAinda não há avaliações

- Pumping TerminologyDocumento24 páginasPumping TerminologychandrasencciAinda não há avaliações

- Logics PumpsDocumento155 páginasLogics PumpsKashif ChaudhryAinda não há avaliações

- SPE 176284 MS With Cover Page v2Documento14 páginasSPE 176284 MS With Cover Page v2Adelia Dwi cahyaniAinda não há avaliações

- NPSHDocumento5 páginasNPSHmbakhshi2Ainda não há avaliações

- NPSH Note Piping Easy23764Documento6 páginasNPSH Note Piping Easy23764Samuel OlonadeAinda não há avaliações

- Calculate TDH and NPSH for pumpsDocumento2 páginasCalculate TDH and NPSH for pumpsRajat MinochaAinda não há avaliações

- Net Positive Suction Head or NPSHDocumento4 páginasNet Positive Suction Head or NPSHSathish LingamAinda não há avaliações

- NPSH - An Introduction For Pump Users: 1. General FormulationDocumento4 páginasNPSH - An Introduction For Pump Users: 1. General FormulationTravis SkinnerAinda não há avaliações

- NPSH Calculating ItDocumento6 páginasNPSH Calculating ItJerry MateoAinda não há avaliações

- Net Positive Suction Head NPSH PDFDocumento5 páginasNet Positive Suction Head NPSH PDFSanthosh ThekkethottiyilAinda não há avaliações

- NPSHA For PumpDocumento11 páginasNPSHA For PumpHariharan KandasamyAinda não há avaliações

- Net Positive Suction Head (NPSH) and CavitationDocumento14 páginasNet Positive Suction Head (NPSH) and CavitationSri GaneshAinda não há avaliações

- NPSH, Cavitation and Priming in Pumps ExplainedDocumento11 páginasNPSH, Cavitation and Priming in Pumps ExplainedSahilAinda não há avaliações

- 10 Pump Cavitation TenDocumento27 páginas10 Pump Cavitation TenAbdallah MansourAinda não há avaliações

- Basic Hydraulics Prework - Wildfire - 2012Documento37 páginasBasic Hydraulics Prework - Wildfire - 2012Gaurav KumarAinda não há avaliações

- For Turbine: For Pump & Compressor:: Design Parameter - NPH - NQH Specific Speed of TurbineDocumento7 páginasFor Turbine: For Pump & Compressor:: Design Parameter - NPH - NQH Specific Speed of TurbineVirender SawaliyaAinda não há avaliações

- 162-White Paper On NPSHR by GrundfosDocumento6 páginas162-White Paper On NPSHR by GrundfosRavindra Pawar100% (1)

- Fluid Machinery Part 4Documento19 páginasFluid Machinery Part 4s75957xxktAinda não há avaliações

- Pump Head CalculationsDocumento4 páginasPump Head CalculationsPrabhjot Singh SahiAinda não há avaliações

- Centrifugal PumpDocumento23 páginasCentrifugal Pumpheri monawir zebuaAinda não há avaliações

- Help For Calculating The Impeller Tip Speed To Avoid Excessive Erosion Due To Suspended ParticlesDocumento22 páginasHelp For Calculating The Impeller Tip Speed To Avoid Excessive Erosion Due To Suspended Particlesmihai37Ainda não há avaliações

- Pumps & NPSH-Avoid ProblemsDocumento4 páginasPumps & NPSH-Avoid ProblemsChem.EnggAinda não há avaliações

- Reduced Efficiency Cavitation Damage: Suction HeadDocumento8 páginasReduced Efficiency Cavitation Damage: Suction Head1988nutanAinda não há avaliações

- NPSH CalculationDocumento12 páginasNPSH CalculationKiran YadavAinda não há avaliações

- Understanding NPSHDocumento34 páginasUnderstanding NPSHeliyanto budiartoAinda não há avaliações

- NPSHDocumento1 páginaNPSHmass34449079Ainda não há avaliações

- Centrifugal Pump TheoryDocumento5 páginasCentrifugal Pump TheoryFungsam LimAinda não há avaliações

- Pumping of LiquidsDocumento20 páginasPumping of Liquidsahmedyashar67% (3)

- Low Frequency EvaluationDocumento13 páginasLow Frequency EvaluationthrillerxAinda não há avaliações

- Sealing Piping Plan (API&ANSI)Documento54 páginasSealing Piping Plan (API&ANSI)Prashanttewari100% (1)

- 3 True Job Interview QuestionsDocumento4 páginas3 True Job Interview QuestionsharabnezhadAinda não há avaliações

- Entrepreneurship at A GlanceDocumento2 páginasEntrepreneurship at A GlancethrillerxAinda não há avaliações

- Electrical Machines and DrivesDocumento123 páginasElectrical Machines and Drivesanon-427532100% (14)

- 7 Climate Control Air Handling Unit 2020Documento2 páginas7 Climate Control Air Handling Unit 2020Fahri Husaini NstAinda não há avaliações

- Paulo Correa and Alexandra Correa - Experimental Aetherometry Volume IIA IntroductionDocumento9 páginasPaulo Correa and Alexandra Correa - Experimental Aetherometry Volume IIA IntroductionSonyRed100% (1)

- Thermotron CE Catalogue 2022 VOL10 - MidresDocumento54 páginasThermotron CE Catalogue 2022 VOL10 - MidresChristy LaheteAinda não há avaliações

- Physics Form 4 Yearly Lesson Plan 2010Documento26 páginasPhysics Form 4 Yearly Lesson Plan 2010Mohd Khairul AnuarAinda não há avaliações

- Closed-Book Practice-Ch 03 (2016!12!10)Documento8 páginasClosed-Book Practice-Ch 03 (2016!12!10)JuanAinda não há avaliações

- CHH LVL Portal Frame Design Example - Sept 2008Documento92 páginasCHH LVL Portal Frame Design Example - Sept 2008podderickAinda não há avaliações

- 022 URTT en Rev 02 20.12.2019 20149Documento89 páginas022 URTT en Rev 02 20.12.2019 20149ramadan rashadAinda não há avaliações

- Matter - Its States, Classification, Changes, and TransitionsDocumento20 páginasMatter - Its States, Classification, Changes, and TransitionsShayne Nicole . AndradeAinda não há avaliações

- University of Tripoli Faculty of Engineering Petroleum EngineeringDocumento8 páginasUniversity of Tripoli Faculty of Engineering Petroleum EngineeringRoba SaidAinda não há avaliações

- Units Offered S1 2015 Engineering DegreeDocumento4 páginasUnits Offered S1 2015 Engineering DegreescytheVSAinda não há avaliações

- Quarterly Miller Welding Machine MaintenanceDocumento3 páginasQuarterly Miller Welding Machine MaintenanceMuhammad RosihanAinda não há avaliações

- Physics VIVA PPT Group 5Documento11 páginasPhysics VIVA PPT Group 5NIHARIKA JHAAinda não há avaliações

- Deep Beam-1Documento14 páginasDeep Beam-1mohammed04149778Ainda não há avaliações

- HYDRAULICS EXAMDocumento4 páginasHYDRAULICS EXAMPrince VinceAinda não há avaliações

- STULZ CyberOne EC DX Engineering ManualDocumento30 páginasSTULZ CyberOne EC DX Engineering ManualBùi LinhAinda não há avaliações

- Cement and Concrete Research: Xiao-Yong Wang, Han-Seung LeeDocumento13 páginasCement and Concrete Research: Xiao-Yong Wang, Han-Seung LeeMyname AtAinda não há avaliações

- Acoustic ReportDocumento17 páginasAcoustic Reportgia hân phamAinda não há avaliações

- D 4332 - 99 - RdqzmzitotkDocumento3 páginasD 4332 - 99 - RdqzmzitotkAnh MinhAinda não há avaliações

- SpectrOil 100 Series DatasheetDocumento2 páginasSpectrOil 100 Series DatasheetClydeA.SardoncilloAinda não há avaliações

- Analisis Gangguan Hubung Singkat Pada Jaringan Pemakaian Sendiri Pltu Bolok Pt. Smse (Ipp) Unit 3 Dan 4 MenggunakanDocumento10 páginasAnalisis Gangguan Hubung Singkat Pada Jaringan Pemakaian Sendiri Pltu Bolok Pt. Smse (Ipp) Unit 3 Dan 4 MenggunakanTeguh Dwi DdarmawanAinda não há avaliações

- ZeutechDocumento9 páginasZeutechthaniAinda não há avaliações

- Climate Changes Emission of Greenhouse Gases Human Nature ContributionDocumento5 páginasClimate Changes Emission of Greenhouse Gases Human Nature ContributionMuhammad Asim ShahzadAinda não há avaliações

- Biodegradable Polymers and Their Bone Applications: A ReviewDocumento19 páginasBiodegradable Polymers and Their Bone Applications: A ReviewNileshTipanAinda não há avaliações

- Flexibility Method TrussDocumento5 páginasFlexibility Method TrussMAGED MOHMMED AHMED QASEM100% (1)

- BS 1474-1987Documento31 páginasBS 1474-1987raftipdo0aAinda não há avaliações

- Solution of Problems: Bearing Capacity of Shallow FoundationDocumento19 páginasSolution of Problems: Bearing Capacity of Shallow FoundationKashif Marwat100% (1)

- 8P2A.3 & 4 Newton's Laws of Motion PPT 2017Documento52 páginas8P2A.3 & 4 Newton's Laws of Motion PPT 2017Jerome Nicolas Jr. MoraAinda não há avaliações

- The Guiding Star Free of Charge Special Coaching Class Pre-ExaminationDocumento4 páginasThe Guiding Star Free of Charge Special Coaching Class Pre-ExaminationSANLU HTUTAinda não há avaliações

- Franck-Hertz Experiment TheoryDocumento3 páginasFranck-Hertz Experiment TheoryAman GoyalAinda não há avaliações

- International Journal of Coal Geology: John Coggan, Fuqiang Gao, Doug Stead, Davide ElmoDocumento10 páginasInternational Journal of Coal Geology: John Coggan, Fuqiang Gao, Doug Stead, Davide Elmopradhith kattaAinda não há avaliações