Escolar Documentos

Profissional Documentos

Cultura Documentos

SM 64080

Enviado por

HENKO7659Descrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

SM 64080

Enviado por

HENKO7659Direitos autorais:

Formatos disponíveis

SM64080

September 2008

Applicable addition manuals:

None

Maintenance & Repair Manual

Line Mounted Pressure Control Valves - 3 & 4

Model 64080

Model 64124

Aerospace Group

Conveyance Systems Division

Carter

Brand

Ground Fueling Equipment

carter ground fueling

A Division of J.C. Carter Co. Inc.

UNDERWI NG NOZZLES

FBO OPERATIONS

MODELS 64049

Carter now offers an underwing nozzle designed for small

airfield, FBO, use with a new easy to use quick disconnect

for strainer checking, with or without an effective dry

break. The underwing nozzle, a derivation of the 64348,

utilizes the Carter Unisex Coupling as the disconnect.

Along with this underwing nozzle, Carter also offers an

interchange fitting to effect easy underwing to overwing or

Closed Circuit Refueling (CCR) Nozzle interchange with a

minimumof fuel spillage.

64049B2KEJ

Underwing Nozzle with 60-mesh Strainer,

Unisex Coupling Inlet with Dry-break

and Dust Caps for both Unisex Couplings

FEATURES:

Unisex Coupling used for quick disconnect or dry

break disconnect.

Designed for small airport applications on 1 or 2

hoses.

Overwing or CCR Nozzle to Underwing Nozzle

interchange fitting available.

Integral swivel, independent of quick disconnect,

makes connection to aircraft easy.

Connects to 3-lug international standard aircraft

adapter.

Self-adjusting pressure loaded nose seal. No

mechanical adjustments or springs used. Leak free

under extreme side loads, worn adapters and extreme

temperatures.

Long-life stainless steel lead-in ramps interface aircraft

adapter for longer life.

Positive interlock - nozzle cant be removed from

aircraft in open position.

Flow control handle, of high strength zinc aluminum

alloy, fully protected fromdamage.

Replaceable bicycle-type handles and grips standard for

ease of operation, circular grip also available.

Two threaded ports in nozzle body for simultaneous

vacuumbreaker and product sampling fitting

installation are standard.

Lightweight and rugged.

Modular construction.

1 & 2 female NPT & BSPP threaded quick

disconnect inlets optional.

1 & 2 female NPT & BSPP threaded quick

disconnect dry break inlets optional.

Optional 40-, 60- & 100-mesh screens retained with

snap ring for ease of removal.

Bonding cable, vacuumbreaker - optional.

Bulletin 64049 9/99

671 W. 17th St., Costa Mesa, CA 92627 (949) 548-3421 FAX (949) 631-2673 E-mail cgf_sales@jccarter.com

See our web page at http://www.jccarter.com

BACK

SM64080 September 2008

2

TABLE OF CONTENTS

Page

1.0 Introduction.........................................................................................................3

2.0 Equipment Description........................................................................................3

3.0 Table of Options..................................................................................................3

4.0 Disassembly........................................................................................................3

5.0 Inspection............................................................................................................5

6.0 Reassembly........................................................................................................6

7.0 Test.....................................................................................................................8

8.0 Illustrated Parts Catalog......................................................................................9

Figure 1..........................................................................................................................11

Figure 2..........................................................................................................................13

Figure 3A .......................................................................................................................14

Figure 3B .......................................................................................................................14

Figure 4..........................................................................................................................15

Figure 5..........................................................................................................................15

SM64080 September 2008

3

Maintenance, Overhaul & Test Instructions

Carter

Models 64080 & 64124

Line Mounted Pressure Control Valves

1.0 INTRODUCTION

This manual furnishes detailed instructions

covering the maintenance and overhaul of Eatons

Carter brand Models 64080 and 64124 line

mounted pressure control valves.

2.0 EQUIPMENT DESCRIPTION

Carter brand Model 64080 (3") and Model 64124

(4") line mounted pressure control valves are

designed to provide a nominal constant pressure at

a remote sense port as a function of the air

reference pressure provided.

Refer to the Table of Options in paragraph 3.0 for

available options. The unit is a normally closed

spring-loaded piston valve. With the application of

an air reference pressure to the appropriate port,

the valve will open to allow flow downstream. The

reference pressure should be approximately 20-35

psi greater than the desired fuel control pressure.

For example, if the desired downstream-regulated

pressure is 50 psi, the air reference pressure

supplied should be nominal 70 to 85 psi. As the flow

of fuel increases and the pressure at the sense

point begins to increase, it will be sensed at the fuel

sense port on the unit. This fuel pressure reacting

against the smaller piston diameter, combined with

the spring force, balances the air reference

pressure reacting against the larger diameter of the

piston. The piston, thereby regulating the flow

through the unit, achieves a relatively constant

pressure. Opening time of the valve is fixed and

controlled by the orifice in the fuel sense port. The

check valve located within the fuel sense port allows

restricted flow out of the piston chamber and

relatively unrestricted flow into the chamber. Hence

upon sensing a rapid build up of downstream

pressure in excess of approximately 1.5 psi will

cause the check valve to open, flooding the piston

chamber, causing the valve to close quickly in

response.

The adjustable orifice in the air reference port

controls closing time.

The air reference pressure is normally routed

through a three-way deadman valve which when

released vents the air pressure from the unit. The

line pressure reacting upon the differential areas of

the piston, aided by the spring, will cause the unit to

close.

The unit has a vent port located next to the air

reference port. This port provides the capability of

draining off any seal leakage, when it occurs, to

keep from getting fuel in the air system of the

refueling vehicle. In addition, the unit has a port

designed to allow bleeding of the fuel sense line of

air. This port is adjacent to the fuel sense port and

can be plumbed into a drain tank with a small

petcock or plugged. The unit should be installed

such that the bleed port is placed in an upward

direction to facilitate the bleeding operation. This will

also make sure the leakage vent port is then placed

in a downward direction. The vent port, if desired

can be plumbed to a low pressure area such as a

slop tank or pump inlet to keep any possible

leakage contained.

The 64124 differs from the previous 61024 only in

that the newer units incorporates a "cartridge" type

insert for installing the two smaller piston seals

within the body. This facilitates the assembly

procedure. All replacement parts are the same. In

addition, Victaulic inlet and outlet connections are

now available.

3.0 TABLE OF OPTIONS

Option

Letter Description

Option

Letter Description

B Adds trapped pressure relief valve E Adds flange outlet, victaulic inlet

C Adds spacer to make length same as Whittaker

F370 (4 valve only)

DE Adds victaulic inlet & outlet

D Adds flange inlet, victaulic outlet

4.0 DISASSEMBLY

NOTE:

Before proceeding, make sure safety glasses are

worn.

64080- 3 VALVE ASSEMBLY Refer to Figure 1

for this operation.

4.1 Remove Check Valve Housing (1-29) followed by

Check Valve (1-32), O-ring (1-31) and Gasket (1-

30) and Spring (1-33). Discard O-ring (1-31) and

Gasket (1-30).

4.2 Remove Screws (1-6A) from unit with flanged

outlet or (1-6B) from unit with the Victaulic outlet

and remove Housing (1-2A) or (1-2B) from

SM64080 September 2008

4

Housing (1A-1D). Remove and discard O-ring (1-

3) and O-ring (1-5) and Seal (1-4).

4.3 Rotate Outer Piston (1-11), if necessary to gain

access to the four Screws (1-7).

4.3.1 Screws (1-7) are a self locking type screw that

utilizes a nylon insert in the threads to affect the

resistance required to provide the locking. They are

designed to be reused a number of times before

losing their locking effectiveness. Using a torque

wrench, remove Screws (1-7) from the Housing (1A-

1D) measuring the torque during removal. If the

torque is less than 2 in lb. (0.023 m kg) discard the

screw and replace it during reassembly.

4.3.2 Discard O-rings (1-8).

4.3.3 Grasp Outer Piston (1-11) and remove the entire

piston/shaft assembly from the outlet of the unit.

4.3.4 Remove and discard O-rings (1-15) and (1-16)

from the shoulder and groove of the Piston

Retainer (1-12).

WARNING

Before proceeding further beware that the Outer

Piston and the attaching parts are heavily spring

loaded and a vise or similar should be used to

safely disassemble the piston assembly.

4.3.5 As indicated above, a vise or woodworkers clamp

is required to proceed further. Wood blocks should

be used to secure the piston.

Assemble such that an axial load is exerted yet

allows access to both Nuts (1-9).

CAUTION:

Be certain the piston assembly is securely held in

place and cannot slip, allowing the unit to forcibly

separate when the first nut (1-9) is removed.

Forcible separation may cause personal injury. Be

careful not to damage the sealing surface of the

inner or outer piston. Damage to these surfaces

will cause leakage and may cause regulator

malfunction.

NOTE:

Shaft (1-19) and nut (1-9) are both stainless steel.

Nut (1-9) also includes a locking element. Due to

this combination there is the possibility when these

items are disassembled that the threads may gall

or become damaged beyond repair. If it is

necessary to disassemble these items replace

both nuts (1-9) and consider replacing the shaft

(1-19).

4.3.6 With the assembly securely clamped in place,

carefully remove Nut (1-9) from the piston assembly,

use Lockease or similar as an aid in removing the

nut. Remove Washer (1-10) from piston assembly.

Slowly open the clamping device allowing the spring

force to cause the inner piston assembly to follow the

clamp until all spring force is relieved. Then carefully

remove the clamp and lift the Inner Piston (1-23)

from the Spring (1-18). Remove the two bronze

Washers (1-20) from the Inner Piston (1-23) then

remove Spring (1-18) and Teflon Washer (1-17B)

from the Guide (1-17). Remove O-ring (1-22) and

Washer (1-21) from the end of Shaft (1-19). Discard

O-ring (1-22).

4.3.7 Using two thin 3/8-24 UNF-2B nuts as jam nuts on

the shaft (1-19) where Nut (1-9) was removed

above, remove Nut (1-9) and Washer (1-10)

retaining the outer Piston (1-11) from the Shaft (1-

19).

4.3.8 Remove Screws (1-17A) from the spring Guide (1-

17) to remove Seal (1-14) and O-ring (1-13) from

retainer. Discard O-ring (1-13).

4.4 Remove Screws (1-24) and then pull out Seal

Housing (1-25) and Seal Retainer (1-28) with

Seals (1-27) and O-rings (1-26). Discard Seals (1-

27) and O-rings (1-26).

Note: It is recommended the user upgrade to

the new seal cartridge. The new design with

the energized Seal (1-27) and O-Ring (1-26) are

included in the overhaul kit KD64080-1. These

seals will not work with the old-style cartridge.

Request a -4 kit for hardware items (1-25 & 1-

28) to complete the upgrade. This

configuration provides a more robust seal,

reducing leakage and frequency for overhaul

of the seal cartridge.

4.4.1 Older Units Seal Cartridge: Remove Screws (1-24)

and then pull out Seal Housing Retainer (1-25A).

Then remove and discard Seals (1-27A) and O-

rings (1-26) and (1-28A).

4.5 Using an Allen key, remove Orifice Screw (1-34)

and Spring (1-35).

4.6 Do not remove Plug(s) (1-36) from the Housing

unless replacement is needed.

4.7 It is not necessary to remove Relief Valve (1-37)

Option B (if equipped) from the Housing unless

replacement is needed.

4.8 64124- 4 VALVE ASSEMBLY Refer to Figure 2

for this operation.

4.8.1 Remove Check Valve Housing (2-29) followed by

Check Valve (2-32), O-ring (2-31) and Gasket (2-

30) and Spring (2-33). Discard O-ring (2-31) and

Gasket (2-30).

4.9 Rotate Outer Piston (2-11), if necessary to gain

access to the four Screws (2-7).

4.9.1 Screws (2-7) are a self locking type screw that

utilizes a nylon insert in the threads to affect the

resistance required to provide the locking. They

are designed to be reused a number of times

before losing their locking effectiveness. Using a

torque wrench, remove Screws (2-7) from the

Housing (2E-2J ) measuring the torque during

removal. If the torque is less than 2 in lb. (0.023 m

SM64080 September 2008

5

kg) discard the screw and replace it during

reassembly. Set aside Washers (2-8) for reuse.

4.9.2 Grasp Outer Piston (2-11) and remove the entire

piston/shaft assembly from the outlet of the unit.

4.9.3 Remove and discard O-rings (2-15) and (2-16)

from the shoulder and groove of the Piston

Retainer (2-12).

WARNING

Before proceeding further beware that the Outer

Piston and the attaching parts are heavily spring

loaded and a vise or similar should be used to

safely disassemble the piston assembly.

4.9.4 As indicated above, a vise or woodworkers clamp

is required to proceed further. Wood blocks

should be used to secure the piston.

Assemble such that an axial load is exerted yet

allows access to both Nuts (2-9).

CAUTION:

Be certain the piston assembly is securely held in

place and cannot slip, allowing the unit to forcibly

separate when the first nut (2-9) is removed.

Forcible separation may cause personal injury. Be

careful not to damage the sealing surface of the

inner or outer piston. Damage to these surfaces

will cause leakage and may cause regulator

malfunction.

NOTE:

Shaft (2-19) and nut (2-9) are both stainless steel.

Nut (2-9) also includes a locking element. Due to

this combination there is the possibility when these

items are disassembled that the threads may gall

or become damaged beyond repair. If it is

necessary to disassemble these items replace

both nuts (2-9) and consider replacing the shaft

(2-19).

4.9.5 With the assembly securely clamped in place,

carefully remove Nut (2-9) from the piston

assembly, use Lockease or similar as an aid in

removing the nut. Remove Washer (2-10) from

piston assembly. Slowly open the clamping device

allowing the spring force to cause the inner piston

assembly to follow the clamp until all spring force

is relieved. Then carefully remove the clamp and

lift the Inner Piston (2-23) from the Spring (2-18).

Remove the two bronze Washers (2-20) from the

Inner Piston (2-23) then remove Spring (2-18) and

Teflon Washer (2-17B) from the Guide (2-17).

Remove O-ring (2-22) and Washer (2-21) from the

end of Shaft (2-19). Discard O-ring (2-22).

4.9.6 Using two thin 3/8-24 UNF-2B nuts as jam nuts on

the shaft (2-19) where Nut (2-9) was removed

above, remove Nut (2-9) and Washer (2-10)

retaining the outer Piston (2-11) from the Shaft (2-

19).

4.9.7 Remove Screws (2-17A) from the spring Guide (2-

17) to remove Seal (2-14) and O-ring (2-13) from

retainer. Discard O-ring (2-13).

4.10 Remove and discard Seal (2-4) and O-ring (2-5).

4.11 Remove Screws (2-24) and then pull out Seal

Housing (2-25) and Seal Retainer (2-28) with

Seals (2-27) and O-rings (2-26). Discard Seals

(2-27) and O-rings (2-26).

Note: It is recommended the user upgrade to

the new seal cartridge. The new design with

the energized Seal (2-27) and O-Ring (2-26) are

included in the overhaul kit KD64124-1. These

seals will not work with the old-style cartridge.

Request a -4 kit for hardware items (2-25 & 2-

28) to complete the upgrade. This

configuration provides a more robust seal,

reducing leakage and frequency for overhaul

of the seal cartridge.

4.11.1 Older Units Seal Cartridge: Remove Screws (2-

24) and then pull out Seal Housing Retainer (2-

25A). Then remove and discard Seals (2-27A)

and O-rings (2-26) and (2-28A).

4.12 Using an Allen key, remove Orifice Screw (2-34)

and Spring (2-35).

4.13 Do not remove Plug(s) (2-36) from the Housing

unless replacement is needed.

4.14 It is not necessary to remove Relief Valve (2-37)

Option B (if equipped) from the Housing unless

replacement is needed.

5.0 INSPECTION

5.1 It is recommended that all O-rings and Seals be

replaced upon every overhaul. Inspect all metal parts

for dings, gouges, abrasions, etc. On all parts except

Inner Piston (1-23 or 2-23) and Outer Piston (1-11 or

2-11), use 320 grit paper to smooth and remove

sharp edges. Carefully inspect the outer diameters of

both the Inner Piston (1-23 or 2-23) and Outer Piston

(1-11 or 2-11) for scratches and other damage that

will cause leakage. Check the "knife" edge of the

Outer Piston (1-11 or 2-11) where it comes in contact

with O-ring (1-16 or 2-16). This edge should be

smooth and free of dings and other imperfections.

The outer diameters of both the Inner Piston (1-23 or

2-23) and the Outer Piston (1-11 or 2-11) can be

polished to remove minor scratches by using a very

fine emery cloth while the parts are rotated. Do not

polish local areas of these diameters. By using the

Shaft (1-19 or 2-19) as a fixture, both pistons can be

installed in a portable drill held in a vise to achieve

rotation. Do not break through the hard-anodized

surface of the part. If scratches are too pronounced,

the parts should be replaced.

SM64080 September 2008

6

5.2 Nuts (1-9) or (2-9) should not be reused.

6.0 REASSEMBLY

Reassembly is accomplished in essentially the

reverse order of disassembly. A light coat of

petroleum jelly may be used during overhaul but do

not use any other type of lubricant, ONLY

PETROLEUM JELLY.

Note: Lightly lubricate all O-rings except O-Ring (1-

5) or (2-5) and O-Ring (1-28A) or (2-28A) [old seal

cartridge design] to be installed dry).

6.1 Make certain all components are clean and free

from oil, grease, or any other corrosion resistant

compound on all interior or exterior surfaces.

Wash all parts with cleaning solvent, Federal

Specification P-D-680, and dry thoroughly with a

clean, lint-free cloth or compressed air.

6.2 Use Vibra-Seal or equal on male threads during

reassembly. Do NOT use Teflon tape.

WARNING:

Use cleaning solvent in a well-ventilated area.

Avoid breathing of fumes and excessive

solvent contact with skin. Keep away from

open flame.

6.3 64080- 3 VALVE ASSEMBLY- Refer to Figure 1

for this operation.

6.3.1 Seal Cartridge older units: Place O-rings (1-26) into

the grooves of the Seal Housing Retainer (1-25A)

outside diameter. Install O-rings (1-28A) in O-ring

grooves on inside diameter of Housing. DO NOT

LUBRICATE. Next install Piston Seals (1-27A) in

inside diameter grooves over O-rings (1-28A) per

Figure 3A. Smooth the combination of the Seal and

O-ring (1-28A) with the finger to assure that they are

installed completely in the seal grooves. Apply a light

coat of lube and then insert the assembly into the

main Housing (1A-1D) with the notch on (1-25A)

oriented as shown on Figure 1 in the flow path for

the check valve port A.

6.3.2 Install Screws (1-24) and torque to 18 2 in.-lb.

(21 2 kg-cm). It will be necessary to condition

seals with seal run-in tool AF42208-1 as described

below.

Note: It is recommended the user upgrade to the

new seal cartridge. The new design with the

energized Seal (1-27) and O-Ring (1-26) are

included in the overhaul kit KD64080-1. These

seals will not work with the old-style cartridge.

Request a -4 kit for hardware items (1-25 & 1-28)

to complete the upgrade. This configuration

provides a more robust seal, reducing leakage

and frequency for overhaul of the seal cartridge

and does not require polishing.

6.3.3 It is recommended that seal "run-in" tool, AF42208-1,

be used to condition the Seals (1-27A) after

installation. The tool can be procured through your

Carter distributor. The tool can be used with a hand

drill to accomplish the run-in task as follows:

1. With the run-in tool attached to a hand drill,

carefully insert the tool into the first Inner Piston

Seal (1-27A) and using a low speed, push the tool

into the unit until the piston passes through the

second Inner Piston Seal (1-27A). The tool should

be kept such that the piston portion of the tool

makes contact only with the Seals (1-27A) in the

Housing (1A-1D) and does not make metal to

metal contact.

2. Carefully move the tool axially over a stroke of

about 0.50 inch (12.7 mm) in and out maintaining

contact with both Seals (1-27A) for about one

minute. The speed of the drill should be maintained

at a low to medium RPM.

3. Remove the tool.

6.3.4 Seal Cartridge newer units: O-rings (1-26) should

be fitted onto the grooves of Seal Retainer (1-28).

The lubricated Inner Piston Seals (1-27) should be

installed on the inside diameter of the Seal

Retainer (1-28) per Figure 3B. Now insert the

retainer assembly into the main Housing (1A-1D)

then install Housing (1-25) with the notch on

oriented as shown on Figure 1 in the flow path for

the check valve port A. Be careful not to damage

the seals during installation.

6.3.5 Seat the Seal Housing (1-25) into the main

Housing (1A-1D) by installing Screws (1-24).

Torque Screws (1-24) to 18 2 in.-lb. (21 2 kg-

cm). When properly installed, it is not necessary to

polish the new type seals.

NOTE:

Shaft (1-19) and Nut (1-9) are both stainless steel.

Nut (1-9) also includes a locking element. Due to

this combination there is the possibility when these

items are disassembled that the threads may gall

or become damaged beyond repair. If it was

necessary to disassemble these items replace

both nuts (1-9) and consider replacing the shaft

(1-19).

6.4 Assemble Outer Piston (1-11) onto Shaft (1-19)

using Washer (1-10) and Nut (1-9). Use two thin

3/8-24 UNF-2B nuts as jam nuts on the opposite

end of the Shaft (1-19) while tightening Nut (1-9)

to 195 10 in.-lb. (225 12 kg-cm).

6.4.1 Install O-ring (1-13) on Seal (1-14) and install in

Retainer (1-12). The leg or hook end of the seal

should point toward the Outer Piston (1-11). Press

the seal into place very carefully in the retainer.

Install Screws (1-17A) through spring Guide (1-17)

and tighten screws equally.

SM64080 September 2008

7

6.4.2 Apply a light coat of lube to inside ID of Seal (1-

14) and slide the Retainer (1-12) onto Shaft (1-

19).

6.4.3 Install Teflon Washer (1-17B) on the shoulder of

the spring Guide (1-17).

6.4.4 Place Washer (1-21) over the end of the Shaft (1-

19) and install O-ring (1-22) above the washer.

6.4.5 Install Spring (1-18) onto Guide (1-17). Place the

two bronze Washers (1-20) on top of the spring

and hold them in place by placing the Inner Piston

(1-23) over Spring (1-18). Insert assembly into the

clamping device used during disassembly.

Compress the assembly and allow access to

install the Washer (1-10) and Nut (1-9) on the end

of the shaft and tighten to 195 10 in.-lb. (225

12 kg-cm).

6.4.6 Install the O-ring (1-15) into groove in Retainer (1-

12). Install O-ring (1-16) over the end of the

Retainer (1-12) to where it rests against the

retainers shoulder.

6.4.7 Victaulic Outlet- Install O-ring (1-3) on the shoulder

the Seal Housing (1-2B) and carefully insert into the

main Housing (1B or 1D) so as not to cut O-ring (1-

3). Rotate the Retainer (1-2B) to line up the six holes

with the mating holes in the housing and install

Screws (1-6B). Insert the non-lubricated O-ring (1-5)

into the groove between main housing and seal

housing. Install Seal (1-4) over O-ring (1-5) so the

flange end of the Seal (1-4) is on the outlet side with

the "leg" of the seal pointing toward the unit inlet.

Refer to Figure 4 for more detail.

6.4.8 Flange Outlet- Install O-ring (1-3) on the shoulder the

Seal Housing (1-2A) and carefully insert into the

main Housing (1A or 1C) so as not to cut O-ring (1-

3). Rotate the Retainer (1-2A) to line up the six holes

with the mating holes in the housing and install

Screws (1-6A). Insert the non-lubricated O-ring (1-5)

into the groove between main housing and seal

housing. Install Seal (1-4) over O-ring (1-5) so the

flange end of the Seal (1-4) is on the outlet side with

the "leg" of the seal pointing toward the unit inlet.

Refer to Figure 4 for more detail.

6.4.9 Insert piston assembly into the housing and rotate

Outer Piston (1-11) to line up the four holes with

the mating holes in the housing. Place O-rings (1-

8) over Screws (1-7) and tighten in a cross

manner.

6.5 Install Screw (1-34) and Spring (1-35) in Port D

using an Allen key to tighten Screw (1-34) to bottom

out. Then back out screw 3 - 4 complete turns. This

should adjust closing time to approximately 2.5 to 3

seconds. Finer adjustment may be necessary during

flow testing.

6.6 Install Spring (1-33) in port A. Place O-ring (1-31) in

groove of Check Valve (1-32) and install over Spring

(1-33). Place Gasket (1-30) over Check Valve

Housing (1-29) and thread into port A.

6.7 If either items (1-37) Option B or Plug(s) (1-36)

were removed during disassembly, reinstall at this

time.

6.8 64124- 4 VALVE ASSEMBLY- Refer to Figure 2

for this operation.

6.8.1 Seal Cartridge older units: Place O-rings (2-26) into

the grooves of the Seal Housing Retainer (2-25A)

outside diameter. Install O-rings (2-28A) in o-ring

grooves on inside diameter of Housing. DO NOT

LUBRICATE. Next install Piston Seals (2-27A) in

inside diameter grooves over O-rings (2-28A) per

Figure 3A. Smooth the combination of the Seal and

O-ring (2-28A) with the finger to assure that they are

installed completely in the seal grooves. Apply a light

coat of lube and then insert the assembly into the

main Housing (2E-2J ) with the notch on (2-25A)

oriented as shown on Figure 2 in the flow path for

the check valve port A.

6.8.2 Install Screws (2-24) and torque to 18 2 in.-lb.

(21 2 kg-cm). It will be necessary to condition

seals with seal run-in tool AF42208-1 as described

below.

Note: It is recommended the user upgrade to the

new seal cartridge. The new design with the

energized Seal (2-27) and O-Ring (2-26) are

included in the overhaul kit KD64124-1. These

seals will not work with the old-style cartridge.

Request a -4 kit for hardware items (2-25 & 2-28)

to complete the upgrade. This configuration

provides a more robust seal, reducing leakage

and frequency for overhaul of the seal cartridge

and does not require polishing.

6.8.3 It is recommended that seal "run-in" tool,

AF42208-1, be used to condition the Seals (2-

27A) after installation. The tool can be procured

through your Carter distributor. The tool can be

used with a hand drill to accomplish the run-in task

as follows:

1. With the run-in tool attached to a hand drill,

carefully insert the tool into the first Inner Piston

Seal (2-27A) and using a low speed, push the tool

into the unit until the piston passes through the

second Inner Piston Seal (2-27A). The tool should

be kept such that the piston portion of the tool

makes contact only with the Seals (2-27A) in the

Housing (2E-2J ) and does not make metal to

metal contact.

2. Carefully move the tool axially over a stroke of

about 0.50 inch (12.7 mm) in and out maintaining

contact with both Seals (2-27A) for about one

minute. The speed of the drill should be

maintained at a low to medium RPM.

3. Remove the tool.

6.8.4 Seal Cartridge newer units: O-rings (2-26) should be

fitted onto the grooves of Seal Retainer (2-28). The

lubricated Inner Piston Seals (2-27) should be

installed on the inside diameter of the Seal Retainer

(2-28) per Figure 3B. Now insert the retainer

assembly into the main Housing (2E-2J ) then install

SM64080 September 2008

8

Housing (2-25) with the notch on (2-25) oriented as

shown on Figure 2 in the flow path for the check

valve port A. Be careful not to damage the seals

during installation.

6.8.5 Seat the Seal Housing (2-25) into the main

Housing (2E-2J ) by installing Screws (2-24).

Torque Screws (2-24) to 18 2 in.-lb. (21 2 kg-

cm). When properly installed, it is not necessary to

polish the new type seals.

NOTE:

Shaft (2-19) and Nut (2-9) are both stainless steel.

Nut (2-9) also includes a locking element. Due to

this combination there is the possibility when these

items are disassembled that the threads may gall

or become damaged beyond repair. If it was

necessary to disassemble these items replace

both nuts (2-9) and consider replacing the shaft

(2-19).

6.9 Assemble Outer Piston (2-11) onto Shaft (2-19)

using Washer (2-10) and Nut (2-9). Use two thin

3/8-24 UNF-2B nuts as jam nuts on the opposite

end of the Shaft (2-19) while tightening Nut (2-9)

to 195 10 in.-lb. (225 12 kg-cm).

6.9.1 Install O-ring (2-13) on Seal (2-14) and install in

Retainer (2-12). The leg or hook end of the seal

should point toward the Outer Piston (2-11). Press

the seal into place very carefully in the retainer.

Install Screws (2-17A) through spring Guide (2-17)

and tighten screws equally.

6.9.2 Apply a light coat of lube to inside ID of Seal (2-14)

and slide the Retainer (2-12) onto Shaft (2-19).

6.9.3 Install Teflon Washer (2-17B) on the shoulder of

the spring Guide (2-17).

6.9.4 Place Washer (2-21) over the end of the Shaft (2-

19) and install O-ring (2-22) above the washer.

6.9.5 Install Spring (2-18) onto Guide (2-17). Place the

two bronze Washers (2-20) on top of the spring

and hold them in place by placing the Inner Piston

(2-23) over Spring (2-18). Insert assembly into the

clamping device used during disassembly.

Compress the assembly and allow access to

install the Washer (2-10) and Nut (2-9) on the end

of the shaft and tighten to 195 10 in.-lb. (225

12 kg-cm).

6.9.6 Install the O-ring (2-15) into groove in Retainer (1-

12). Install O-ring (2-16) over the end of the

Retainer (2-12) to where it rests against the

retainers shoulder.

6.9.7 Victaulic or Flange Outlet- Insert O-ring (2-5) and

Seal (2-4) directly into main Body (2E-2J ). The

flange end of the Seal (2-4) shall be on the outlet

side with the "leg" of the seal pointing toward the

unit inlet. Refer to Figure 4 for more detail.

6.9.8 Insert piston assembly into the housing and rotate

Outer Piston (2-11) to line up the four holes with

the mating holes in the housing. Place O-rings (2-

8) over Screws (2-7) and tighten in a cross

manner.

6.9.9 Install Screw (2-34) and Spring (2-35) in Port D

using an Allen key to tighten Screw (2-34) to bottom

out. Then back out screw 3 - 4 complete turns. This

should adjust closing time to approximately 2.5 to 3

seconds. Finer adjustment may be necessary

during flow testing.

6.10 Install Spring (2-33) in port A. Place O-ring (2-31) in

groove of Check Valve (2-32) and install over Spring

(2-33). Place Gasket (2-30) over Check Valve

Housing (2-29) and thread into port A.

6.11 If either items (2-37) Option B or Plug(s) (2-36)

were removed during disassembly, reinstall at this

time.

6.12 Option C (4 Flange Adapter Assembly) - If

equipped, replace Gasket (2-40) during

reinstallation of valve.

7.0 TEST

7.1 The following test procedures will be

accomplished after overhaul:

7.2 Test conditions

7.2.1 Test media shall be Stoddard Solvent (Federal

Specification P-D-680), J P-4 per MIL-J -5624D at

75 +15F, J et A or equivalent.

7.3 Functional Test

7.3.1 Flange both ends of the unit with shutoff valves,

connect a 0-300 psi test fluid source to the inlet of

the unit and to the Fuel Sense Port (A). Plug the

bleed port (B). Connect a 0-125 psi air reference

source to the unit, at port D, through a deadman

control valve.

Actuate the deadman control valve to apply 125 psi

air reference pressure to the air reference port.

Open the outlet shutoff valve and the bleed port

(B). Supply 300 psi test fluid pressure to the inlet

to fill the unit. Hold the unit such that the bleed

port (B) is up to facilitate bleeding of all air from

the inside of the unit.

Close the outlet valve, release the deadman valve

and maintain the 300 psi pressure for a minimum

of one minute while checking for external leakage.

Reduce the inlet pressure to 5 psi and repeat the

test. There shall be no evidence of external

leakage.

7.3.2 Open outlet valve to relieve pressure. Remove the

outlet flange. Rotate the unit such that the outlet is

on top. Cover the outlet to contain any fuel flow.

Apply 60 psi through the deadman valve. Release

and re-apply the deadman several times, while

observing the Outer Piston (1-11or 2-11). The

SM64080 September 2008

9

Outer Piston shall stroke fully open with each

application of the deadman and fully close when

the deadman is released.

WARNING!

Keep fingers clear of these moving parts.

Turn the unit over to drain the fluid from the outlet.

Increase the inlet pressure to 5 psi for one minute.

Increase the inlet pressure to 150 psi and measure

liquid leakage at the outlet. The maximum allowable

internal leakage is 10 cc/min.

7.3.3 Install the unit in a system capable of maintaining

a flow rate of 600 US gpm with a deadhead

pressure of 150 psi. The fuel sense port shall be

connected to a downstream sense point with a

gauge installed to determine control pressure. The

unit shall be installed such that the bleed port is

vertical and facing upwards. Start flow through the

system by actuating the deadman and flow for

approximately 2 minutes to bleed the main line of

the system. Partially close a valve downstream of

the sense point.

Open the bleed line valve to obtain a steady bleed

flow. Allow the line to bleed until all signs of air are

eliminated. Shutoff bleed line valve.

Open the downstream valve and actuate the

deadman, with 75 psi air pressure, to establish flow

of approximately 300 gpm with system deadhead

pressure of 120 psi. The unit should open and

assume a pressure control of approxi-mately 25-35

psi less than the air reference pressure (75 psi) at

the downstream control point.

While flowing 300 gpm, release the deadman and

measure the time required to reach zero flow. The

time required can be adjusted by repositioning

Orifice Screw (1-34 or 2-34) to 2-5 seconds. Factory

setting of a new unit for opening time is 3 .5

seconds. Overshoot, the volume of fuel passing

through the unit during closure shall not exceed 15

gallons at 300 gpm flow rate. If the overshoot

exceeds the allowable amount, the closing time can

be readjusted by turning Screw (1-34 or 2-34)

counter-clockwise to increase the orifice size.

Also measure the time required to re-open from

zero flow to 300 gpm. Opening time should be 5 -

10 seconds. The operating time will vary with

system setup and adjustments but should be

within the same range of times from unit to unit.

Establish a flow rate of 300 gpm and throttle down to

zero in about 5 increments to stabilize at each flow

rate. The stabilized pressure at the control point

should be 50 psi or less. The unit should maintain a

stable control at all times. Note that if the flow rate is

reduced too rapidly, the unit may shutoff at a

pressure higher than 50 psi. This is normal and is the

surge control function of the unit.

With zero flow, close the downstream valve and

apply the deadman. The locked-in pressure at the

outlet shall not exceed 75 psi.

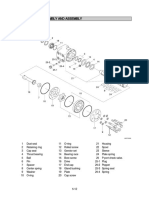

8.0 ILLUSTRATED PARTS CATALOG

Table 1.0 tabulates the parts and sub-assemblies

comprising the 64080 3 line mounted pressure

control valve. The item numbers of the table are

keyed to the exploded views of the unit

diagrammed in Figure 1.

Table 2.0 tabulates the parts and sub-assemblies

comprising the 64124 4 line mounted pressure

control valve. The item numbers of the table are

keyed to the exploded views of the unit

diagrammed in Figure 2.

TABLE 1.0

64080 3 Control Valve

Fig. Item Part Number Description

Units/

Assy

Valve

Option

Spares/10

Units/yr.

1 1A 47202-1 3 sub-assembly, flanged both ends 1 Standard -

220801 3 Housing, flanged both ends 1 Standard -

1B 47204-2 3 sub-assembly, flanged inlet, Victaulic outlet 1 D -

220803 3 Housing, flanged inlet, Victaulic outlet 1 D -

1C 47204-3 3 sub-assembly, victaulic inlet, flanged outlet 1 E -

220802 3 Housing, Victaulic inlet, flanged outlet 1 E -

1D 47204-4 3 Sub-assembly, Victaulic both ends 1 DE -

220793 3 Housing, Victaulic both ends 1 DE -

2A 221193 Housing, Seal, flanged end 1 Standard, E -

2B 221191 Housing, Seal, Victaulic end 1 D, DE -

3 MS29513-042 O-ring 1 All 5

4 220665 Seal, Outer Piston 1 All 5

5 MS29513-151 O-ring 1 All 5

6A GF16997-18 Screw, flanged end 6 Standard, E -

6B GF16995-49 Screw, Victaulic end 6 D, DE -

SM64080 September 2008

10

Fig. Item Part Number Description

Units/

Assy

Valve

Option

Spares/10

Units/yr.

1 7 220685-1250 Screw 4 All -

8 MS29513-008 O-ring 4 All 20

15 MS29513-038 O-ring 1 All 5

16 201201-231 O-ring 1 All 5

9-14 &

17-23

47347-1 Piston Assembly 1 All -

9 38NST188 Nut 2 All -

10 GF960C616L Washer 2 All -

11 220666 Piston, Outer 1 All -

12 221607 Retainer, Piston Seal 1 All -

13 203565 O-ring 1 All 5

14 221595 Seal, Shaft 1 All 5

17 221594 Guide 1 All -

17A NAS1351C04-4 Screw 6 All -

17B 5610-381-50 Washer, Teflon 1 All -

18 200757 Spring 1 All -

19 202290 Shaft, Piston 1 All -

20 5720-158-25 Washer, Bronze 2 All -

21 202291 Washer 1 All -

22 MS29513-012 O-ring 1 All 5

23 200759 Piston, Inner 1 All -

24 GF16997-32L Screw 4 All -

Items 25A, 27A & 28A have been superseded by items 25, 27 & 28

25 222160 Housing, Seal 1 All -

25A 221307 Retainer, Housing, Seal 1 All -

26 MS29513-134 O-ring 2 All 10

27 222165 Seal, Inner Piston 2 All 5

27A 200758 Seal, Inner Piston 2 All 5

28 222161 Retainer, Seal 1 All -

28A MS29513-129 O-ring 2 All 5

29 205756-2 Housing, Check Valve 1 All -

30 MS29512-08 Gasket 1 All 5

31 MS29513-009 O-ring 1 All 5

32 205772 Check Valve 1 All -

33 200791 Spring 1 All -

34 220413 Control Screw 1 All -

35 220472 Spring 1 All -

36 5406-P-04 Plug 2 All (1 only on

Option B)

-

37 206B-1 Valve, Trapped Pressure Relief 1 B -

KD64080-1 Kit - Contains the parts needed to overhaul the 64080 valve assembly contains items 1-3,

1-4, 1-5, 1-8, 1-13, 1-14, 1-15, 1-16, 1-22, 1-26, 1-27, 1-30 and 1-31.

KD64080-2 Kit Contains Piston Assembly 47347-1 for 3 valve Contains items 1-9, 1-10, 1-11, 1-12,

1-13, 1-14, 1-17, 1-18, 1-19, 1-20, 1-21, 1-22 and 1-23.

KD64080-4 Kit Contains the housing and retainer necessary to upgrade to the now standard seal

cartridge design. Contains items 1-25 and 1-28.

Notes:

1. All part numbers beginning with "GF" are interchangeable with those beginning with either "AN" or "MS". If the

"GF" is followed by three numbers it is interchangeable with and "AN" part, otherwise it is interchangeable with

an "MS" part of the same number.

2. The recommended spare parts shown above are the number required to support 10 units for one year or

each overhaul whichever is sooner. These quantities do not include replacement spares for intermediate

replacement of parts required by abuse or misuse of the equipment. The recommended quantities are

based on the ratio of spare parts sold for each unit during a one-year period of time. The actual quantity

required will vary from location to location.

SM64080 September 2008

11

Figure 1

64080 3 Inline Valve

SM64080 September 2008

12

TABLE 2.0

64124 4 Control Valve

Fig. Item Part Number Description

Units/

Assy

Valve

Option

Spares/10

Units/yr.

2 1E 27218-1 4 Sub-assembly flanged both ends 1 Standard -

220813 4 Housing, flanged both ends 1 Standard -

1G 47218-2 4 Sub-assembly, flanged inlet, Victaulic outlet 1 D -

220816 4Housing, flanged inlet & Victaulic outlet 1 D -

1H 47218-3 4 Sub-assembly, victaulic inlet, flanged outlet 1 E -

220814 4Housing, victaulic inlet & flanged outlet 1 E -

1J 47218-4 4 Sub-assembly, victaulic both ends 1 DE -

220815 4Housing, victaulic inlet & outlet 1 DE -

2-3 Left intentionally blank

4 200754 Seal, Outer Piston 1 All 5

5 MS29513-155 O-ring 1 All 5

6 Left intentionally blank

7 LP51958-64 Screw 4 All -

8 NAS620C10L Washer 4 All -

15 MS29513-149 O-ring 1 All 5

16 MS29513-240 O-ring 1 All 5

9-14 &

17-23

47351-1 Piston Assembly 1 All -

9 38NST188 Nut 2 All -

10 GF960C616L Washer 2 All -

11 202334 Piston, Outer 1 All -

12 221608 Retainer 1 All -

13 203565 O-ring 1 All 5

14 221595 Seal, Shaft 1 All 5

17 221594 Guide 1 All -

17A NAS1351C04-4 Screw 6 All -

17B 5610-381-50 Washer, Teflon 1 All -

18 200757 Spring 1 All -

19 202290 Shaft 1 All -

20 5720-158-25 Washer, Bronze 2 All -

21 202291 Washer 1 All -

22 MS29513-012 O-ring 1 All 5

23 200759 Piston, Inner 1 All -

24 GF16997-32L Screw 4 All -

Items 25A, 27A & 28A have been superseded by items 25, 27 & 28

25 222160 Housing, Seal 1 All -

25A 221307 Retainer, Housing, Seal 1 All -

26 MS29513-134 O-ring 2 All 10

27 222165 Seal, Inner Piston 2 All 5

27A 200758 Seal, Inner Piston 2 All 5

28 222161 Retainer, Seal 1 All -

28A MS29513-129 O-ring 2 All 5

29 205756-2 Housing, Check Valve 1 All -

30 MS29512-08 Gasket 1 All 5

31 MS29513-009 O-ring 1 All 5

32 205772 Check Valve 1 All -

33 200791 Spring 1 All -

34 220413 Control Screw 1 All -

35 220472 Spring 1 All -

36 5406-P-04 Plug 2 All (1 only on

Option B)

-

37 206B-1 Valve, Trapped Pressure Relief 1 B -

38 40766 Adapter Assembly 1 C -

39 210420 Adapter 1 C -

40 82154 Gasket 1 C 5

41 210421 Bolt 8 C -

SM64080 September 2008

13

Kit Number Description

KD64124-1 Kit - Contains the parts needed to overhaul the 64124 valve assembly contains items 2-4, 2-5, 2-13, 2-

14, 2-15, 2-16, 2-22, 2-26, 2-27, 2-30 and 2-31.

KD64124-2 Kit Contains Piston Assembly 47351-1 for 4 valve Contains items 2-9, 2-10, 2-11, 2-12, 2-13, 2-14,

2-17, 2-18, 2-19, 2-20, 2-21, 2-22 and 2-23.

KD64124-4 Kit Contains the housing and retainer necessary to upgrade to the now standard seal cartridge design.

Contains items 2-25 and 2-28.

Notes:

1. All part numbers beginning with "GF" are interchangeable with those beginning with either "AN" or "MS". If the

"GF" is followed by three numbers it is interchangeable with and "AN" part, otherwise it is interchangeable with

an "MS" part of the same number.

2. The recommended spare parts shown above are the number required to support 10 units for one year or each

overhaul whichever is sooner. These quantities do not include replacement spares for intermediate

replacement of parts required by abuse or misuse of the equipment. The recommended quantities are based

on the ratio of spare parts sold for each unit during a one-year period of time. The actual quantity required will

vary from location to location.

Figure 2

64124 4 Inline Valve

SM64080 September 2008

14

Table 3.0

Torque Specifications 64080 & 64124

Fig. Item Part Number Description Torque in.-lb.

1 or 2 24 GF16997-32L Screw(s) 18 2 in.-lb. (21 2 kg-cm)

1 or 2 9 38NST188 Nut(s) 195 10 in.-lb. (225 12 kg-cm)

SM64080 September 2008

15

Figure 4

Outer Piston Seal Installation

Figure 5

Inner Piston Seal Run-In Tool AF42208-1

Aerospace Group

Conveyance Systems Division

9650 Jeronimo Rd

Irvine, CA 92618

Ph (949) 452-9500

Fax (949) 452-9992

Você também pode gostar

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Acoplador de Hidrante PDFDocumento63 páginasAcoplador de Hidrante PDFHENKO7659Ainda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- SM 64250Documento20 páginasSM 64250HENKO7659Ainda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- SM60129 1Documento12 páginasSM60129 1HENKO7659100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- SM 61154Documento19 páginasSM 61154HENKO7659Ainda não há avaliações

- SM47013 PDFDocumento8 páginasSM47013 PDFHENKO7659Ainda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- SM 64349Documento32 páginasSM 64349HENKO7659Ainda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- SM64348 PDFDocumento24 páginasSM64348 PDFHENKO7659Ainda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- SM60427 PDFDocumento26 páginasSM60427 PDFHENKO7659Ainda não há avaliações

- SM64200 PDFDocumento20 páginasSM64200 PDFHENKO7659Ainda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- SM 60554Documento40 páginasSM 60554HENKO7659100% (1)

- SM 64900Documento48 páginasSM 64900HENKO7659Ainda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- SM 64348Documento24 páginasSM 64348HENKO7659Ainda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- JIG 58 Origin Accident Bulletin 1-2011Documento13 páginasJIG 58 Origin Accident Bulletin 1-2011HENKO7659Ainda não há avaliações

- SM 64055Documento20 páginasSM 64055HENKO7659Ainda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- SM 64250Documento20 páginasSM 64250HENKO7659Ainda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- SM 60700Documento54 páginasSM 60700HENKO7659Ainda não há avaliações

- SM 64800Documento63 páginasSM 64800HENKO7659Ainda não há avaliações

- SM 60427Documento26 páginasSM 60427HENKO7659Ainda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- SM 64200Documento20 páginasSM 64200HENKO7659Ainda não há avaliações

- 491 Manual ManutençãoDocumento90 páginas491 Manual ManutençãoHENKO7659Ainda não há avaliações

- SM 64250Documento20 páginasSM 64250HENKO7659Ainda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- ACO-Aquacon Velcon 140306Documento2 páginasACO-Aquacon Velcon 140306HENKO7659Ainda não há avaliações

- SM 64348Documento28 páginasSM 64348HENKO7659Ainda não há avaliações

- In 64800Documento7 páginasIn 64800HENKO7659Ainda não há avaliações

- Mechanical SealDocumento121 páginasMechanical Sealxtremewhiz100% (1)

- Electronic Parts Catalog - Option DetailDocumento4 páginasElectronic Parts Catalog - Option DetailMohamedAinda não há avaliações

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Reda Cables BRDocumento24 páginasReda Cables BRÜmitByrktr67% (3)

- ERIKS - O-Ring Datasheet - FKM 75-Compound 514322 BlackDocumento1 páginaERIKS - O-Ring Datasheet - FKM 75-Compound 514322 Blackseeralan_1986Ainda não há avaliações

- PD X Caliber ManualDocumento20 páginasPD X Caliber ManualToha PutraAinda não há avaliações

- OM Manual AHL Pump PDFDocumento20 páginasOM Manual AHL Pump PDFinok stingerAinda não há avaliações

- Checkball Piston Pumps Pf1000 Series, 10 Design PF1 10: Service Parts ListDocumento3 páginasCheckball Piston Pumps Pf1000 Series, 10 Design PF1 10: Service Parts ListMiguel Vlntìn100% (1)

- Al4 Oil Leak PDFDocumento2 páginasAl4 Oil Leak PDFandylesxAinda não há avaliações

- Subconn Catalouge 2ndedt Web PDFDocumento120 páginasSubconn Catalouge 2ndedt Web PDFAzmee Syamsul NizamAinda não há avaliações

- Secoroc YSP 45 Stoper: Secoroc Rock Drilling ToolsDocumento20 páginasSecoroc YSP 45 Stoper: Secoroc Rock Drilling ToolsOscar Alberto Jáuregui AquinoAinda não há avaliações

- Sistema de DireccionDocumento30 páginasSistema de DireccionCarlos Gomez100% (1)

- ALS Series: Exd Limit Switch BoxDocumento4 páginasALS Series: Exd Limit Switch BoxNabeel MohammedAinda não há avaliações

- Hercules Production Solutions CatalogDocumento28 páginasHercules Production Solutions CatalogRiza Calleidoscope100% (1)

- RIVIT RIV504 Manual Eng It Comp WMDocumento13 páginasRIVIT RIV504 Manual Eng It Comp WMLeonardo AlexAinda não há avaliações

- Flowmaster Rotary Driven Hydraulic Pump Models: 85480, 85481, 85482, 85483, Series B Models: 85247, 85610, 85586 Series ADocumento11 páginasFlowmaster Rotary Driven Hydraulic Pump Models: 85480, 85481, 85482, 85483, Series B Models: 85247, 85610, 85586 Series ASIDI ahmedou yahyaAinda não há avaliações

- 93091p009 Zurcon Roto Glyd Ring SDocumento32 páginas93091p009 Zurcon Roto Glyd Ring SRiyan AprilliyanAinda não há avaliações

- STG190C-8 Sany Motor Grader: Equipment No - PY5819BH0289Documento249 páginasSTG190C-8 Sany Motor Grader: Equipment No - PY5819BH0289ngoun mara100% (1)

- D31PX-21 S/N 50001-50499 (For North America)Documento1 páginaD31PX-21 S/N 50001-50499 (For North America)Mbahdiro KolenxAinda não há avaliações

- MMPX 304SGP-11 - Parts - 1996Documento44 páginasMMPX 304SGP-11 - Parts - 1996Centrifugal Separator100% (1)

- Surface Vehicle Standard: (R) Hydraulic Hose FittingsDocumento34 páginasSurface Vehicle Standard: (R) Hydraulic Hose FittingsLUCIANO SOTOAinda não há avaliações

- Kawasaki 1100 STX DI Service ManualDocumento288 páginasKawasaki 1100 STX DI Service Manualnoname618483% (12)

- F7000 / 8000 SERIES Pilot-Operated Safety Relief Valve: Installation, Operation, & Maintenance ManualDocumento43 páginasF7000 / 8000 SERIES Pilot-Operated Safety Relief Valve: Installation, Operation, & Maintenance ManualMoe MozhganAinda não há avaliações

- Travel Drive FAT 350P059: Installation ManualDocumento34 páginasTravel Drive FAT 350P059: Installation ManualŁukasz Adamczak100% (1)

- C3000N PM en 09Documento103 páginasC3000N PM en 09SARAMQRAinda não há avaliações

- DTH - Martillo Zandvik TodozDocumento39 páginasDTH - Martillo Zandvik TodozedwinAinda não há avaliações

- Spare Parts ListDocumento17 páginasSpare Parts ListRodrigues de OliveiraAinda não há avaliações

- Fox Shocks Float and Float 2 RebuildDocumento22 páginasFox Shocks Float and Float 2 RebuildJules De MontignyAinda não há avaliações

- Hydrant ValveDocumento48 páginasHydrant ValvephuongAinda não há avaliações

- 5-3 Group 3 Disassembly and AssemblyDocumento25 páginas5-3 Group 3 Disassembly and Assemblystefan corjucAinda não há avaliações

- Analog Design and Simulation Using OrCAD Capture and PSpiceNo EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceAinda não há avaliações

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tNo EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tNota: 4.5 de 5 estrelas4.5/5 (27)