Escolar Documentos

Profissional Documentos

Cultura Documentos

HBL NCPP Leaflet

Enviado por

Sunil Kumawat0 notas0% acharam este documento útil (0 voto)

86 visualizações2 páginasHBL Battery

Título original

Hbl Ncpp Leaflet

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoHBL Battery

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

86 visualizações2 páginasHBL NCPP Leaflet

Enviado por

Sunil KumawatHBL Battery

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 2

Superior Features

HBL's Nickel Cadmium Pocket Plate Battery

designs are based on the superior Pocket

Plate technology of SABNIFE AB, Sweden.

The first electrode design for Nickel Cadmium

Batteries employed the pocket plate

construction which is still considered to be the

most reliable design.

The fully integrated modern factory,

supported by strong process management

and quality controls makes HBL one of the

best Nickel Cadmium Battery production

facilities in the world.

In HBLs Pocket Plate design, the active materials are

encapsulated between folded steel strips which are

perforated from both sides. This double perforation

method increases the effective surface area by 30%

and helps in better utilization of the active material

thereby making the battery more efficient. The

batteries are manufactured in 3 series designated as

H, M and L based on their performance capabilities.

The H series have thin plates to provide for high

discharge currents, the L series have thick plates to

provide lower currents for long durations and the M

series have an optimized plate thickness which is ideal

for medium discharge performance and durations.

These Batteries are available as Single cells of 1.2V or

in Blocks (individual cells thermally welded and

connected either in series or in parallel) of higher

voltages (2.4, 3.6V etc) and capacities.

Unsurpassed resistance to electrical and mechanical abuse.

Good charge retention.

Long and reliable service life.

Quick recharge capability.

Wide operating temperature range.

No emission of corrosive gases.

Flame-arresting vent protection.

Minimal maintenance requirements.

Long shelf life.

Nickel Cadmium Pocket Plate Batteries

NCPP

The Batteries are available in tough, fusion-welded polypropylene cell containers and lids. When placed on multi-step

battery racks, the electrolyte level in all the cells can be visually monitored to facilitate maintenance. For special

requirements, the containers can be offered in flame-retardant polypropylene, structural foam-moulded

polypropylene or stainless steel.

HBL's batteries are supplied with the electrolyte, inter-cell connectors and related hardware and accessories required

for normal operation and maintenance. Suitable battery racks are also offered as options.

HBL's batteries have been tested in accordance with the IEC/EN 60623 standard and certified by INTERTEK ETL

SEMKO. The batteries also conform to DIN 40771, BS 6260 and UIC 854R international standards.

Batteries can be selected from the above range for a given application. Contact HBL for your battery sizing requirements.

Pocket Plate

Cell Series

Typical Back-up Capacity Range

Ah

Typical Applications

Low rate

KPL (Single)

KBL (Block)

Above 3 hours 11 to 480

8 to 1540

Fire alarms, Emergency lightning, Telecom,

Railway signalling, Switchgear protection,

Photovoltaic, Cathodic protection.

Medium rate

KPM (Single)

KBM (Block)

60 minutes to 3 hours 10 to 395

12 to 1460

Switchgear protection, Emergency lighting,

Motive power, Train lighting, Instrumentation

and process control, UPS, Electric vehicles.

High rate

KPH (Single)

KBH (Block)

Below 60 minutes 10 to 265

9 to 930

Generator starting, UPS, Diesel

locomotive cranking, Aircraft/Helicopter

ground starting, Electro magnets.

IEC/EN 60623

HBL Power Systems Limited

Road # 10, Banjara Hills, Hyderabad - 500 034. INDIA

E-mail: contact@hbl.in

www.hbl.in

c

r

.

c

o

m

\

1

0

-

2

0

0

6

o

p

m

Você também pode gostar

- Supercapacitors 101: A home Inventors HandbookNo EverandSupercapacitors 101: A home Inventors HandbookNota: 5 de 5 estrelas5/5 (1)

- Piping Checklist For 30% 3D Model ReviewDocumento3 páginasPiping Checklist For 30% 3D Model Reviewcherif yahyaoui100% (5)

- Lmla NDP HDPDocumento4 páginasLmla NDP HDPJAY PARIKHAinda não há avaliações

- Engineering Guide Custom Battery PacksDocumento16 páginasEngineering Guide Custom Battery PacksAndrew PAinda não há avaliações

- Evolution of Oilfield BatteriesDocumento16 páginasEvolution of Oilfield BatteriesPasquale CutriAinda não há avaliações

- SICON-4000MZi in English (Rev1 8) PDFDocumento116 páginasSICON-4000MZi in English (Rev1 8) PDFAdjie89% (9)

- NCFPDocumento40 páginasNCFPJAY PARIKHAinda não há avaliações

- NCPP BlockDocumento36 páginasNCPP BlockSatya VasuAinda não há avaliações

- HBL BatteriesDocumento36 páginasHBL BatteriesDebnath Roychowdhury100% (1)

- Ni-Cad Pocket Plate BLOCK Brochure - Detailed PDFDocumento36 páginasNi-Cad Pocket Plate BLOCK Brochure - Detailed PDFogautierAinda não há avaliações

- HBL NCPP SingleDocumento31 páginasHBL NCPP SingleMagno100% (1)

- Ni CD BatteriesDocumento2 páginasNi CD BatteriesAVIJIT MITRAAinda não há avaliações

- Product Catalogue BatteryDocumento24 páginasProduct Catalogue BatteryPrakash SinhaAinda não há avaliações

- NCPP Single ManualDocumento32 páginasNCPP Single ManualtonyminarasAinda não há avaliações

- ALCAD HC185P DatasheetDocumento27 páginasALCAD HC185P DatasheetEn Faizul100% (1)

- AMCO Saft KP Range - Final Web - 0Documento24 páginasAMCO Saft KP Range - Final Web - 0Bao Le VietAinda não há avaliações

- AMCO Battery CatalogDocumento0 páginaAMCO Battery CatalogSanjeev DhariwalAinda não há avaliações

- KPL Low Rate: Dimensional and Electrical DataDocumento10 páginasKPL Low Rate: Dimensional and Electrical DataQazi M Asim WasimAinda não há avaliações

- Ni Cad Single Cell Data Sheet KPDocumento20 páginasNi Cad Single Cell Data Sheet KPVivekanand TripathiAinda não há avaliações

- Ni Cad Block KBH HighDocumento11 páginasNi Cad Block KBH Highruben egeaAinda não há avaliações

- KPM Medium Rate: Dimensional and Electrical DataDocumento10 páginasKPM Medium Rate: Dimensional and Electrical Datalokesh kumar singhAinda não há avaliações

- Ni Cad Block KBL LowDocumento11 páginasNi Cad Block KBL LowLino GabrielAinda não há avaliações

- Ni Cad KBM MediumDocumento11 páginasNi Cad KBM MediumRuzgardan AzizgizAinda não há avaliações

- Ni-Cad General Options (Pocket, Fibre & VRPP) PDFDocumento3 páginasNi-Cad General Options (Pocket, Fibre & VRPP) PDFogautierAinda não há avaliações

- Technical Manual: X3.3 April 2007Documento0 páginaTechnical Manual: X3.3 April 2007rajpre1213Ainda não há avaliações

- BatteriesDocumento16 páginasBatteriesLina M. Abd ElSalamAinda não há avaliações

- Ultracapacitor-Ppt 1Documento21 páginasUltracapacitor-Ppt 1Shijin Varghese100% (1)

- BatteriesDocumento30 páginasBatteriessunamisurendar123Ainda não há avaliações

- Faraz 2Documento37 páginasFaraz 2Hammad HashmiAinda não há avaliações

- Categories and Types of Batteries: Main ArticleDocumento3 páginasCategories and Types of Batteries: Main ArticleJdlgAinda não há avaliações

- SBLSBMSBH Datos PDFDocumento47 páginasSBLSBMSBH Datos PDFJose Joaquin Baeza VeluetaAinda não há avaliações

- Batteries: Performance Comparison of Rechargeable Batteries For Stationary Applications (Ni/MH vs. Ni-Cd and VRLA)Documento7 páginasBatteries: Performance Comparison of Rechargeable Batteries For Stationary Applications (Ni/MH vs. Ni-Cd and VRLA)Amey KhawaleAinda não há avaliações

- Super Capacitor 2018Documento25 páginasSuper Capacitor 2018Atlarn MoreAinda não há avaliações

- Supercapacitors 130206061102 Phpapp02Documento22 páginasSupercapacitors 130206061102 Phpapp02Brrijesh YadavAinda não há avaliações

- Kinds of BatteryDocumento32 páginasKinds of BatteryBalbon BonbonAinda não há avaliações

- Saft - SBL, SBM, SBH - NiCd Batteries-1Documento48 páginasSaft - SBL, SBM, SBH - NiCd Batteries-1miguelgg78Ainda não há avaliações

- The Handyman's Guide To CapacitorsDocumento4 páginasThe Handyman's Guide To CapacitorsiddrxAinda não há avaliações

- Categories and Types of Batteries 22Documento6 páginasCategories and Types of Batteries 22abdul ali munderAinda não há avaliações

- Btech EcDocumento52 páginasBtech EcAliAinda não há avaliações

- EverExceed Deep Cycle AGM Range VRLADocumento13 páginasEverExceed Deep Cycle AGM Range VRLAb.sumarsonoAinda não há avaliações

- Varun Kumar GDocumento5 páginasVarun Kumar GVarun KumarAinda não há avaliações

- Offshore CablesDocumento96 páginasOffshore Cableskutts76Ainda não há avaliações

- 2020 05 05 Lead Acid Batteries US Letter PDFDocumento16 páginas2020 05 05 Lead Acid Batteries US Letter PDFantonioAinda não há avaliações

- AEE - Automotive Electrical and ElectronicsDocumento78 páginasAEE - Automotive Electrical and ElectronicsKarthik BabuAinda não há avaliações

- Corrpro Magnesium AnodesDocumento4 páginasCorrpro Magnesium Anodeswhah11Ainda não há avaliações

- MiniDocumento40 páginasMiniShree KanthAinda não há avaliações

- FNC Catalogo BateriaDocumento8 páginasFNC Catalogo BateriaLuis ChonchisAinda não há avaliações

- Ultracapacitors: (A Revolutionary Technology)Documento18 páginasUltracapacitors: (A Revolutionary Technology)ranjith465Ainda não há avaliações

- EV and HEV - Unit 2 FinalDocumento63 páginasEV and HEV - Unit 2 FinalvenkateswarluvelisalAinda não há avaliações

- Atomic & Nuclear BatteryDocumento6 páginasAtomic & Nuclear BatteryIJAMTESAinda não há avaliações

- Types of BatteryDocumento22 páginasTypes of BatteryAppidi Sai Sushrith ReddyAinda não há avaliações

- (December 2010) : Citations VerificationDocumento27 páginas(December 2010) : Citations VerificationPraveen HalladmaniAinda não há avaliações

- PPT10-super and UltracapacitorDocumento22 páginasPPT10-super and UltracapacitorChaudhari Jainish100% (1)

- Advantages: CharacteristicsDocumento3 páginasAdvantages: CharacteristicsRick Jeyrald AbagatAinda não há avaliações

- Ultimate UltracapacitorsDocumento38 páginasUltimate UltracapacitorsvagasAinda não há avaliações

- LFC With Battery Energy Storage SystemDocumento9 páginasLFC With Battery Energy Storage SystemzahidAinda não há avaliações

- New Approaches to the Design and Economics of EHV Transmission Plant: International Series of Monographs in Electrical EngineeringNo EverandNew Approaches to the Design and Economics of EHV Transmission Plant: International Series of Monographs in Electrical EngineeringAinda não há avaliações

- Highly Integrated Gate Drivers for Si and GaN Power TransistorsNo EverandHighly Integrated Gate Drivers for Si and GaN Power TransistorsAinda não há avaliações

- Torque CalculationsDocumento1 páginaTorque CalculationsSunil KumawatAinda não há avaliações

- Electrical Clerance PDFDocumento4 páginasElectrical Clerance PDFSanjay RoutAinda não há avaliações

- 10 Unit ProtectionDocumento18 páginas10 Unit ProtectionSristick100% (1)

- Selection of Main CB and Branch CB 22-8-12Documento41 páginasSelection of Main CB and Branch CB 22-8-12Sunil KumawatAinda não há avaliações

- Cable Tray Manual: Based On The 2005 National Electrical CodeDocumento59 páginasCable Tray Manual: Based On The 2005 National Electrical CodeSunil KumawatAinda não há avaliações

- 11 Distance ProtectionDocumento22 páginas11 Distance ProtectionSristick100% (1)

- Lecture 09 - Transmission LinesDocumento55 páginasLecture 09 - Transmission LinesDorcas Jay B. RegaladoAinda não há avaliações

- DC Battery Bank Sizing PDFDocumento37 páginasDC Battery Bank Sizing PDFflyzalAinda não há avaliações

- KEI Cable CatalogueDocumento114 páginasKEI Cable CatalogueMousum100% (1)

- Nuclear Power in India - Sep 27-28, 2010Documento4 páginasNuclear Power in India - Sep 27-28, 2010Sunil KumawatAinda não há avaliações

- 05 High Voltage CablesDocumento27 páginas05 High Voltage Cablesdaegerte100% (5)

- Electrical Tender Document - 10MW CHADIYANA Package 20 and 9Documento56 páginasElectrical Tender Document - 10MW CHADIYANA Package 20 and 9Sunil KumawatAinda não há avaliações

- IS 2026 Part 1Documento46 páginasIS 2026 Part 1Narendra SinhaAinda não há avaliações

- Is 7113Documento9 páginasIs 7113Sunil KumawatAinda não há avaliações

- Non-Segregated Phase Bus Duct BR en 6 2012Documento8 páginasNon-Segregated Phase Bus Duct BR en 6 2012Aziddin GadingAinda não há avaliações

- 95 Excel Tipsv 4Documento28 páginas95 Excel Tipsv 4Sunil KumawatAinda não há avaliações

- Heating Resistor LeafletDocumento2 páginasHeating Resistor LeafletNaqi Min GilAinda não há avaliações

- 2008 Product Catalogue PDFDocumento255 páginas2008 Product Catalogue PDFrenoyaboAinda não há avaliações

- Introduction To Marine MachineriesDocumento13 páginasIntroduction To Marine MachineriessrcattozziAinda não há avaliações

- Summer Training Report On Dadri Thermal Power StationDocumento11 páginasSummer Training Report On Dadri Thermal Power StationRamraj SinghAinda não há avaliações

- Design and Fabrication of Oil Skimmer RobotDocumento46 páginasDesign and Fabrication of Oil Skimmer RobotSathiya Udumalpet100% (2)

- Basics in Intrumentation in Mark-VDocumento11 páginasBasics in Intrumentation in Mark-VGnanaseharan ArunachalamAinda não há avaliações

- Haskel Air AaDocumento12 páginasHaskel Air AaJorge CastilloAinda não há avaliações

- ABB - OPR Lightning - p31-p31Documento1 páginaABB - OPR Lightning - p31-p31Indra WanAinda não há avaliações

- DLAB Centrifuges-Benchtop DM0636 ManualDocumento27 páginasDLAB Centrifuges-Benchtop DM0636 ManualServicio AHSAinda não há avaliações

- IEEE 1547 - Explicacion PDFDocumento11 páginasIEEE 1547 - Explicacion PDFAlejandro Gil RestrepoAinda não há avaliações

- GeneratePDF (1) - Proposal JU6H-UFDO - 144 HP@ 2100 RPMDocumento11 páginasGeneratePDF (1) - Proposal JU6H-UFDO - 144 HP@ 2100 RPMMaurilio Batista de LimaAinda não há avaliações

- SiemensPowerAcademyTD Catalog EN 2016 PDFDocumento14 páginasSiemensPowerAcademyTD Catalog EN 2016 PDFANINDA CHATTERJEEAinda não há avaliações

- Cadbury CSRDocumento14 páginasCadbury CSRAdwait KhareAinda não há avaliações

- Vacuum Distillation Colume: Mass Transfer Lab AssignmentDocumento4 páginasVacuum Distillation Colume: Mass Transfer Lab AssignmentMalik HamidAinda não há avaliações

- of Gatorade..Documento29 páginasof Gatorade..Jay ThakkarAinda não há avaliações

- Crankpin Failure Study PDFDocumento12 páginasCrankpin Failure Study PDFΑθανασιος ΜπεργελεςAinda não há avaliações

- CSB-F: Three-Phase Power Capacitor With Fuse ProtectionDocumento2 páginasCSB-F: Three-Phase Power Capacitor With Fuse ProtectionAbdul RafaeAinda não há avaliações

- Fundamentals of Engineering Thermodynamics (Solutions Manual) (M. J. Moran & H. N. Shapiro)Documento451 páginasFundamentals of Engineering Thermodynamics (Solutions Manual) (M. J. Moran & H. N. Shapiro)eltytanAinda não há avaliações

- Assignment#2, Potential, Capacitors, Magnetic Force and FieldDocumento5 páginasAssignment#2, Potential, Capacitors, Magnetic Force and FieldBilal KhalidAinda não há avaliações

- 2.627/2.626 Background Assessment QuizDocumento4 páginas2.627/2.626 Background Assessment QuizmusaAinda não há avaliações

- Ehad Hussainabad HvacDocumento4 páginasEhad Hussainabad Hvacashar jafferyAinda não há avaliações

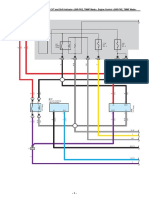

- Cruise Control, CVT and Shift Indicator, Engine ControlDocumento27 páginasCruise Control, CVT and Shift Indicator, Engine ControlRicardoAinda não há avaliações

- Parts C490BPGDocumento30 páginasParts C490BPGניקולאי איןAinda não há avaliações

- Level Sensor AnimationDocumento2 páginasLevel Sensor AnimationInstrumentation ToolsAinda não há avaliações

- BEKON Broschure en WebDocumento7 páginasBEKON Broschure en WebEko TjahjantokoAinda não há avaliações

- 092 M-002 Mechanical Symbols and LegendsDocumento1 página092 M-002 Mechanical Symbols and Legendseuri08Ainda não há avaliações

- Catalog - Regent RSV Ed 3Documento14 páginasCatalog - Regent RSV Ed 3Nyu123456Ainda não há avaliações

- Is 6547.1972Documento34 páginasIs 6547.1972rajmarathiAinda não há avaliações