Escolar Documentos

Profissional Documentos

Cultura Documentos

Annual Repport 2012 13 MoT

Enviado por

Kali MuthuDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Annual Repport 2012 13 MoT

Enviado por

Kali MuthuDireitos autorais:

Formatos disponíveis

I

n

d

i

a

n

X

i

t

h

P

l

a

n

T

E

X

T

I

L

E

S

P

e

r

f

o

r

m

a

n

c

e

P

r

o

j

e

c

t

i

o

n

X

I

I

P

l

a

n

th

R

a

w

M

a

t

e

r

i

a

l

s

O

r

g

a

n

i

s

e

d

P

O

W

E

R

L

O

O

M

S

P

R

O

C

E

S

S

I

N

G

&

F

I

N

I

S

H

I

N

G

C

L

O

T

H

I

N

G

M

a

d

e

u

p

s

T

e

x

t

i

l

e

s

I

n

d

u

s

t

r

y

E

n

g

i

n

e

e

r

i

n

g

R

&

D

D

a

t

a

b

a

s

e

T

U

F

S

H

R

D

S

e

r

i

c

u

l

t

u

r

e

J

u

t

e

R

a

w

M

A

T

E

R

I

A

L

S

S

I

T

P

X

I

I

P

l

a

n

T

H

T

e

c

h

n

i

c

a

l

T

E

X

T

I

L

E

S

O

r

g

a

n

i

s

e

d

M

I

L

L

E

X

P

O

R

T

S

P

r

o

c

e

s

s

i

n

g

&

F

I

N

I

S

H

I

N

G

C

l

o

t

h

i

n

g

A

P

P

A

R

E

L

J

U

T

E

S

I

R

I

C

U

L

T

U

R

E

P

O

W

O

E

R

L

O

O

M

S

R

&

D

T

e

x

t

i

l

e

s

E

n

g

i

n

e

e

r

i

n

g

I

n

d

u

s

t

r

y

J

U

T

E

S

T

R

A

T

E

G

Y

S

IT

P

M

i

l

l

s

E

x

p

o

r

t

s

R

F

D

H

a

n

d

l

o

o

m

s

J

u

t

e

H

A

N

D

I

C

R

A

F

T

S

T

e

c

h

n

o

l

o

g

y

M

i

s

s

i

o

n

F

O

R

G

R

O

W

T

H

C

H

A

L

L

E

N

G

E

S

Annual Report

(2012-13)

Ministry of Textles

Government of India

I

n

d

i

a

n

X

i

t

h

P

l

a

n

T

E

X

T

I

L

E

S

P

e

r

f

o

r

m

a

n

c

e

P

r

o

j

e

c

t

i

o

n

X

I

I

P

l

a

n

th

R

a

w

M

a

t

e

r

i

a

l

s

O

r

g

a

n

i

s

e

d

P

O

W

E

R

L

O

O

M

S

P

R

O

C

E

S

S

I

N

G

&

F

I

N

I

S

H

I

N

G

C

L

O

T

H

I

N

G

M

a

d

e

u

p

s

T

e

x

t

i

l

e

s

I

n

d

u

s

t

r

y

E

n

g

i

n

e

e

r

i

n

g

R

&

D

D

a

t

a

b

a

s

e

T

U

F

S

H

R

D

S

e

r

i

c

u

l

t

u

r

e

J

u

t

e

R

a

w

M

A

T

E

R

I

A

L

S

S

I

T

P

X

I

I

P

l

a

n

T

H

T

e

c

h

n

i

c

a

l

T

E

X

T

I

L

E

S

O

r

g

a

n

i

s

e

d

M

I

L

L

E

X

P

O

R

T

S

P

r

o

c

e

s

s

i

n

g

&

F

I

N

I

S

H

I

N

G

C

l

o

t

h

i

n

g

A

P

P

A

R

E

L

J

U

T

E

S

I

R

I

C

U

L

T

U

R

E

P

O

W

O

E

R

L

O

O

M

S

R

&

D

T

e

x

t

i

l

e

s

E

n

g

i

n

e

e

r

i

n

g

I

n

d

u

s

t

r

y

J

U

T

E

S

T

R

A

T

E

G

Y

S

IT

P

M

i

l

l

s

E

x

p

o

r

t

s

R

F

D

H

a

n

d

l

o

o

m

s

J

u

t

e

H

A

N

D

I

C

R

A

F

T

S

T

e

c

h

n

o

l

o

g

y

M

i

s

s

i

o

n

F

O

R

G

R

O

W

T

H

C

H

A

L

L

E

N

G

E

S

I

n

d

i

a

n

X

i

t

h

P

l

a

n

T

E

X

T

I

L

E

S

P

e

r

f

o

r

m

a

n

c

e

P

r

o

j

e

c

t

i

o

n

X

I

I

P

l

a

n

th

R

a

w

M

a

t

e

r

i

a

l

s

O

r

g

a

n

i

s

e

d

P

O

W

E

R

L

O

O

M

S

P

R

O

C

E

S

S

I

N

G

&

F

I

N

I

S

H

I

N

G

C

L

O

T

H

I

N

G

M

a

d

e

u

p

s

T

e

x

t

i

l

e

s

I

n

d

u

s

t

r

y

E

n

g

i

n

e

e

r

i

n

g

R

&

D

D

a

t

a

b

a

s

e

T

U

F

S

H

R

D

S

e

r

i

c

u

l

t

u

r

e

J

u

t

e

R

a

w

M

A

T

E

R

I

A

L

S

S

I

T

P

X

I

I

P

l

a

n

T

H

T

e

c

h

n

i

c

a

l

T

E

X

T

I

L

E

S

O

r

g

a

n

i

s

e

d

M

I

L

L

E

X

P

O

R

T

S

P

r

o

c

e

s

s

i

n

g

&

F

I

N

I

S

H

I

N

G

C

l

o

t

h

i

n

g

A

P

P

A

R

E

L

J

U

T

E

S

I

R

I

C

U

L

T

U

R

E

P

O

W

O

E

R

L

O

O

M

S

R

&

D

T

e

x

t

i

l

e

s

E

n

g

i

n

e

e

r

i

n

g

I

n

d

u

s

t

r

y

J

U

T

E

S

T

R

A

T

E

G

Y

S

IT

P

M

i

l

l

s

E

x

p

o

r

t

s

R

F

D

H

a

n

d

l

o

o

m

s

J

u

t

e

H

A

N

D

I

C

R

A

F

T

S

T

e

c

h

n

o

l

o

g

y

M

i

s

s

i

o

n

F

O

R

G

R

O

W

T

H

C

H

A

L

L

E

N

G

E

S

CONTENTS

Sl. No. Chapter Page

I Highlights 1

II Functions & Organizational set-up 11

III The Organized Textiles Mill Industry 21

IV Exports 33

V Cotton 41

VI The J ute and J ute Textiles Industry 49

VII Sericulture and Silk Industry 63

VIII Wool & Woollen Textile Industry 77

IX Decentralised Powerloom Sector 85

X Handloom Industry 93

XI Handicrafts 115

XII Public Sector Undertakings 141

XIII Textile Research Associations 159

XIV Citizens/Clients Charter 167

XV Welfare of Scheduled Castes, Scheduled Tribes and Women 177

XVI Textiles in North East Region 183

XVII Human Resource Development 205

XVIII Gender J ustice 217

XIX Information and Communication Technology in Textiles 221

XX Vigilance Activities 225

XXI Persons with Disabilities 229

XXII Observations of the Comptroller and Auditor General of India 233

XXIII Results Framework Document 241

XXIV Goals Set-up for Procurement from Micro and Small 271

Enterprises and Achievements

I

n

d

i

a

n

X

i

t

h

P

l

a

n

T

E

X

T

I

L

E

S

P

e

r

f

o

r

m

a

n

c

e

P

r

o

j

e

c

t

i

o

n

X

I

I

P

l

a

n

th

R

a

w

M

a

t

e

r

i

a

l

s

O

r

g

a

n

i

s

e

d

P

O

W

E

R

L

O

O

M

S

P

R

O

C

E

S

S

I

N

G

&

F

I

N

I

S

H

I

N

G

C

L

O

T

H

I

N

G

M

a

d

e

u

p

s

T

e

x

t

i

l

e

s

I

n

d

u

s

t

r

y

E

n

g

i

n

e

e

r

i

n

g

R

&

D

D

a

t

a

b

a

s

e

T

U

F

S

H

R

D

S

e

r

i

c

u

l

t

u

r

e

J

u

t

e

R

a

w

M

A

T

E

R

I

A

L

S

S

I

T

P

X

I

I

P

l

a

n

T

H

T

e

c

h

n

i

c

a

l

T

E

X

T

I

L

E

S

O

r

g

a

n

i

s

e

d

M

I

L

L

E

X

P

O

R

T

S

P

r

o

c

e

s

s

i

n

g

&

F

I

N

I

S

H

I

N

G

C

l

o

t

h

i

n

g

A

P

P

A

R

E

L

J

U

T

E

S

I

R

I

C

U

L

T

U

R

E

P

O

W

O

E

R

L

O

O

M

S

R

&

D

T

e

x

t

i

l

e

s

E

n

g

i

n

e

e

r

i

n

g

I

n

d

u

s

t

r

y

J

U

T

E

S

T

R

A

T

E

G

Y

S

IT

P

M

i

l

l

s

E

x

p

o

r

t

s

R

F

D

H

a

n

d

l

o

o

m

s

J

u

t

e

H

A

N

D

I

C

R

A

F

T

S

T

e

c

h

n

o

l

o

g

y

M

i

s

s

i

o

n

F

O

R

G

R

O

W

T

H

C

H

A

L

L

E

N

G

E

S

I

n

d

i

a

n

X

i

t

h

P

l

a

n

T

E

X

T

I

L

E

S

P

e

r

f

o

r

m

a

n

c

e

P

r

o

j

e

c

t

i

o

n

X

I

I

P

l

a

n

th

R

a

w

M

a

t

e

r

i

a

l

s

O

r

g

a

n

i

s

e

d

P

O

W

E

R

L

O

O

M

S

P

R

O

C

E

S

S

I

N

G

&

F

I

N

I

S

H

I

N

G

C

L

O

T

H

I

N

G

M

a

d

e

u

p

s

T

e

x

t

i

l

e

s

I

n

d

u

s

t

r

y

E

n

g

i

n

e

e

r

i

n

g

R

&

D

D

a

t

a

b

a

s

e

T

U

F

S

H

R

D

S

e

r

i

c

u

l

t

u

r

e

J

u

t

e

R

a

w

M

A

T

E

R

I

A

L

S

S

I

T

P

X

I

I

P

l

a

n

T

H

T

e

c

h

n

i

c

a

l

T

E

X

T

I

L

E

S

O

r

g

a

n

i

s

e

d

M

I

L

L

E

X

P

O

R

T

S

P

r

o

c

e

s

s

i

n

g

&

F

I

N

I

S

H

I

N

G

C

l

o

t

h

i

n

g

A

P

P

A

R

E

L

J

U

T

E

S

I

R

I

C

U

L

T

U

R

E

P

O

W

O

E

R

L

O

O

M

S

R

&

D

T

e

x

t

i

l

e

s

E

n

g

i

n

e

e

r

i

n

g

I

n

d

u

s

t

r

y

J

U

T

E

S

T

R

A

T

E

G

Y

S

IT

P

M

i

l

l

s

E

x

p

o

r

t

s

R

F

D

H

a

n

d

l

o

o

m

s

J

u

t

e

H

A

N

D

I

C

R

A

F

T

S

T

e

c

h

n

o

l

o

g

y

M

i

s

s

i

o

n

F

O

R

G

R

O

W

T

H

C

H

A

L

L

E

N

G

E

S

CHAPTER I

HIGHLIGHTS

I

n

d

i

a

n

X

i

t

h

P

l

a

n

T

E

X

T

I

L

E

S

P

e

r

f

o

r

m

a

n

c

e

P

r

o

j

e

c

t

i

o

n

X

I

I

P

l

a

n

th

R

a

w

M

a

t

e

r

i

a

l

s

O

r

g

a

n

i

s

e

d

P

O

W

E

R

L

O

O

M

S

P

R

O

C

E

S

S

I

N

G

&

F

I

N

I

S

H

I

N

G

C

L

O

T

H

I

N

G

M

a

d

e

u

p

s

T

e

x

t

i

l

e

s

I

n

d

u

s

t

r

y

E

n

g

i

n

e

e

r

i

n

g

R

&

D

D

a

t

a

b

a

s

e

T

U

F

S

H

R

D

S

e

r

i

c

u

l

t

u

r

e

J

u

t

e

R

a

w

M

A

T

E

R

I

A

L

S

S

I

T

P

X

I

I

P

l

a

n

T

H

T

e

c

h

n

i

c

a

l

T

E

X

T

I

L

E

S

O

r

g

a

n

i

s

e

d

M

I

L

L

E

X

P

O

R

T

S

P

r

o

c

e

s

s

i

n

g

&

F

I

N

I

S

H

I

N

G

C

l

o

t

h

i

n

g

A

P

P

A

R

E

L

J

U

T

E

S

I

R

I

C

U

L

T

U

R

E

P

O

W

O

E

R

L

O

O

M

S

R

&

D

T

e

x

t

i

l

e

s

E

n

g

i

n

e

e

r

i

n

g

I

n

d

u

s

t

r

y

J

U

T

E

S

T

R

A

T

E

G

Y

S

IT

P

M

i

l

l

s

E

x

p

o

r

t

s

R

F

D

H

a

n

d

l

o

o

m

s

J

u

t

e

H

A

N

D

I

C

R

A

F

T

S

T

e

c

h

n

o

l

o

g

y

M

i

s

s

i

o

n

F

O

R

G

R

O

W

T

H

C

H

A

L

L

E

N

G

E

S

annual report 2012-13

3

I

n

d

i

a

n

X

i

t

h

P

l

a

n

T

E

X

T

I

L

E

S

P

e

r

f

o

r

m

a

n

c

e

P

r

o

j

e

c

t

i

o

n

X

I

I

P

l

a

n

th

R

a

w

M

a

t

e

r

i

a

l

s

O

r

g

a

n

i

s

e

d

P

O

W

E

R

L

O

O

M

S

P

R

O

C

E

S

S

I

N

G

&

F

I

N

I

S

H

I

N

G

C

L

O

T

H

I

N

G

M

a

d

e

u

p

s

T

e

x

t

i

l

e

s

I

n

d

u

s

t

r

y

E

n

g

i

n

e

e

r

i

n

g

R

&

D

D

a

t

a

b

a

s

e

T

U

F

S

H

R

D

S

e

r

i

c

u

l

t

u

r

e

J

u

t

e

R

a

w

M

A

T

E

R

I

A

L

S

S

I

T

P

X

I

I

P

l

a

n

T

H

T

e

c

h

n

i

c

a

l

T

E

X

T

I

L

E

S

O

r

g

a

n

i

s

e

d

M

I

L

L

E

X

P

O

R

T

S

P

r

o

c

e

s

s

i

n

g

&

F

I

N

I

S

H

I

N

G

C

l

o

t

h

i

n

g

A

P

P

A

R

E

L

J

U

T

E

S

I

R

I

C

U

L

T

U

R

E

P

O

W

O

E

R

L

O

O

M

S

R

&

D

T

e

x

t

i

l

e

s

E

n

g

i

n

e

e

r

i

n

g

I

n

d

u

s

t

r

y

J

U

T

E

S

T

R

A

T

E

G

Y

S

IT

P

M

i

l

l

s

E

x

p

o

r

t

s

R

F

D

H

a

n

d

l

o

o

m

s

J

u

t

e

H

A

N

D

I

C

R

A

F

T

S

T

e

c

h

n

o

l

o

g

y

M

i

s

s

i

o

n

F

O

R

G

R

O

W

T

H

C

H

A

L

L

E

N

G

E

S

CHAPTER I

HIGHLIGHTS

I

ndian Textile Industry has an

overwhelming presence in the

economic life of the country. Apart

from providing one of the basic

necessities of life, the textile industry

also plays a pivotal role through

its contribution to industrial output,

employment generation and the export

earnings of the country. It contributes

about 14% to the industrial production,

4% to the GDP and 11% to the countrys

export earnings. The textile sector is the

second largest provider of employment

after agriculture.

The Indian textiles industry is extremely

varied, with the hand-spun and

handwoven sector at one end of the

spectrum, and the capital intensive,

sophisticated mill sector at the other.

The decentralized powerlooms/ hosiery

and knitting sector form the largest

section of the Textiles Sector. The close

linkage of the Industry to agriculture and

the ancient culture, and traditions of the

country make the Indian textiles sector

unique in comparison with the textiles

industry of other countries. This also

provides the industry with the capacity

to produce a variety of products suitable

to the different market segments, both

within and outside the country.

The major sub-sectors that comprise

the textiles sector include the organized

Cotton/Man-Made Fibre Textiles Mill

Industry, the Man-Made Fibre/Filament

Yarn Industry, the Wool and woollen

Textiles Industry, the Sericulture and Silk

Textiles Industry, Handlooms, Handicrafts,

the J ute and J ute Textiles Industry, and

Textiles Exports.

TECHNOLOGY UPGRADATION

FUND SCHEME (TUFS)

The Technology Upgradation Fund

Scheme (TUFS) was launched on April 1,

1999, for a period of fve years, and was

Awards for Master Craftpersons & Weavers 2009, 2010

ministry of textiles

4

I

n

d

i

a

n

X

i

t

h

P

l

a

n

T

E

X

T

I

L

E

S

P

e

r

f

o

r

m

a

n

c

e

P

r

o

j

e

c

t

i

o

n

X

I

I

P

l

a

n

th

R

a

w

M

a

t

e

r

i

a

l

s

O

r

g

a

n

i

s

e

d

P

O

W

E

R

L

O

O

M

S

P

R

O

C

E

S

S

I

N

G

&

F

I

N

I

S

H

I

N

G

C

L

O

T

H

I

N

G

M

a

d

e

u

p

s

T

e

x

t

i

l

e

s

I

n

d

u

s

t

r

y

E

n

g

i

n

e

e

r

i

n

g

R

&

D

D

a

t

a

b

a

s

e

T

U

F

S

H

R

D

S

e

r

i

c

u

l

t

u

r

e

J

u

t

e

R

a

w

M

A

T

E

R

I

A

L

S

S

I

T

P

X

I

I

P

l

a

n

T

H

T

e

c

h

n

i

c

a

l

T

E

X

T

I

L

E

S

O

r

g

a

n

i

s

e

d

M

I

L

L

E

X

P

O

R

T

S

P

r

o

c

e

s

s

i

n

g

&

F

I

N

I

S

H

I

N

G

C

l

o

t

h

i

n

g

A

P

P

A

R

E

L

J

U

T

E

S

I

R

I

C

U

L

T

U

R

E

P

O

W

O

E

R

L

O

O

M

S

R

&

D

T

e

x

t

i

l

e

s

E

n

g

i

n

e

e

r

i

n

g

I

n

d

u

s

t

r

y

J

U

T

E

S

T

R

A

T

E

G

Y

S

IT

P

M

i

l

l

s

E

x

p

o

r

t

s

R

F

D

H

a

n

d

l

o

o

m

s

J

u

t

e

H

A

N

D

I

C

R

A

F

T

S

T

e

c

h

n

o

l

o

g

y

M

i

s

s

i

o

n

F

O

R

G

R

O

W

T

H

C

H

A

L

L

E

N

G

E

S

subsequently extended upto March 31,

2007. The Scheme provides for interest

reimbursement/capital subsidy/Margin

Money subsidy and has been devised

to bridge the gap between the cost of

interest and the capital component to

ease up the working capital requirement

and to reduce the transaction cost, etc.

The Scheme is an important tool to infuse

fnancial support to the textiles industry

and help it capitalize on the vibrant and

expanding global and domestic markets,

through technology upgradation, cost

effectiveness, quality production, effciency

and global competitiveness. The progress

of TUFS is detailed at Chapter-3.

SCHEME FOR INTEGRATED

TEXTILES PARK (SITP)

Scheme for Integrated Textile Parks

(SITP): The Scheme for Integrated

Textile Parks (SITP) was Approved in the

10

th

Five Year Plan to provide the industry

with world-class infrastructure facilities

for setting up their textile units by merging

the erstwhile Apparel Parks for Exports

Scheme (APES) and Textile Centre

Infrastructure Development Scheme

(TCIDS).

SCOPE OF THE SCHEME:

The scheme targets industrial clusters/

locations with high growth potential, which

require strategic interventions by way

of providing world-class infrastructure

support. The project cost covers

common infrastructure and buildings for

production/support activities, depending

on the needs of the ITP. There will be

fexibility in setting up ITPs to suit the

local requirements.

This Scheme is implemented through

Special Purpose Vehicles (SPVs),

where. Industry Associations/Group of

Entrepreneurs are the main promoters

of the Integrated Textiles Park (ITP).

At each, ITP, there would be a separate

Special Purpose Vehicle (SPV) formed

with the representatives of local Industry,

Financial Institutions, State and Central

Government. SPV shall invariably be

a Corporate Body registered under the

Companies Act. Any different structure

for the SPV requires the approval of the

Project Approval Committee. The SPVs

shall have operational autonomy so that

they do not become surrogate Public

Enterprises or be controlled by Central/

State Governments. The details are at

Chapter-3.

TEXTILE WORKERS

REHABILITATION FUND SCHEME

(TWRFS)

The Textile Workers Rehabilitation Fund

Scheme came into force with effect from

15.09.1986 with the objective to provide

interim relief to textile workers rendered

unemployed as a consequence of

permanent closure of any particular portion

or entire textile unit. Assistance under

the Scheme is payable to eligible workers

only for the purpose of enabling them

to settle in another employment. Such

assistance is not heritable, transferable

or capable of being attached on account

of any other liabilities of the worker. The

workers eligibility shall cease if he takes

up employment in another registered or

licensed undertaking. The rehabilitation

assistance will not be curtailed if the

worker fxes himself in a self-employment

venture. The details are at Chapter-3.

TECHNICAL TEXTILES

Technical Textiles is the sunrise sector of

the textile industry in India, with a current

market size of Rs 57,000 crores and a

growth rate poised to take off from the

present 11%, to almost 20% during the

12th Five Year Plan. Technical Textiles

are material products used primarily

for their functional properties and have

annual report 2012-13

5

I

n

d

i

a

n

X

i

t

h

P

l

a

n

T

E

X

T

I

L

E

S

P

e

r

f

o

r

m

a

n

c

e

P

r

o

j

e

c

t

i

o

n

X

I

I

P

l

a

n

th

R

a

w

M

a

t

e

r

i

a

l

s

O

r

g

a

n

i

s

e

d

P

O

W

E

R

L

O

O

M

S

P

R

O

C

E

S

S

I

N

G

&

F

I

N

I

S

H

I

N

G

C

L

O

T

H

I

N

G

M

a

d

e

u

p

s

T

e

x

t

i

l

e

s

I

n

d

u

s

t

r

y

E

n

g

i

n

e

e

r

i

n

g

R

&

D

D

a

t

a

b

a

s

e

T

U

F

S

H

R

D

S

e

r

i

c

u

l

t

u

r

e

J

u

t

e

R

a

w

M

A

T

E

R

I

A

L

S

S

I

T

P

X

I

I

P

l

a

n

T

H

T

e

c

h

n

i

c

a

l

T

E

X

T

I

L

E

S

O

r

g

a

n

i

s

e

d

M

I

L

L

E

X

P

O

R

T

S

P

r

o

c

e

s

s

i

n

g

&

F

I

N

I

S

H

I

N

G

C

l

o

t

h

i

n

g

A

P

P

A

R

E

L

J

U

T

E

S

I

R

I

C

U

L

T

U

R

E

P

O

W

O

E

R

L

O

O

M

S

R

&

D

T

e

x

t

i

l

e

s

E

n

g

i

n

e

e

r

i

n

g

I

n

d

u

s

t

r

y

J

U

T

E

S

T

R

A

T

E

G

Y

S

IT

P

M

i

l

l

s

E

x

p

o

r

t

s

R

F

D

H

a

n

d

l

o

o

m

s

J

u

t

e

H

A

N

D

I

C

R

A

F

T

S

T

e

c

h

n

o

l

o

g

y

M

i

s

s

i

o

n

F

O

R

G

R

O

W

T

H

C

H

A

L

L

E

N

G

E

S

become a major industry segment

globally, leading to an improved quality

of life for citizens.

Technical Textiles are high performance

textiles which fnd application not only

in clothing but also in areas such as

agriculture, medical, infrastructure

development, automotive, aerospace,

sports, protective clothing, packaging,

etc. The global market size of Technical

Textile Industry in 2010 was estimated to

be Rs 5.72 trillion, which has grown at an

annual rate of approximately 3% since

2005. Based on the past trend of growth

and estimated end user segment growth,

the market size of Technical Textiles in

India is projected to Rs. 1.5 lakh crores

for the year 2016-17 with a growth rate of

20% per annum.

TECHNOLOGY MISSION ON TECHNICAL

TEXTILES (TMTT):

Technology Mission on Technical Textiles

(TMTT) has been launched with two

mini missions starting from 2010-11

to 2014-15 with a fnancial outlay of Rs.

200 crore. The objective the mission is

to remove the impediments hampering

the production of technical textiles in the

country to meet growing demand in the

domestic and export market. The details

are at Chapter-3.

EXPORTS

Indias textiles and clothing industry is one

of the mainstays of the national economy.

It is also one of the largest contributing

sectors of Indias exports worldwide. The

report of Working Group constituted by the

Planning Commission on boosting Indias

manufacturing exports during 12

th

Five

Year Plan (2012-17), envisages Indias

exports of Textiles and Clothing at USD

64.11 billion by the end of March 2017.

The textiles industry accounts for 14% of

industrial production, which is 4% of GDP;

employs 45 million people and accounts

for nearly 11% share of the countrys total

exports basket.

COTTON

Cotton is one of the principal crops of

the country and is the major raw material

for domestic textile industry. It provides

sustenance to millions of farmers as

also the workers involved in cotton

industry, right from processing to trading

of cotton. The Indian textile industry

consumes a diverse range of fbres and

yarn, but is predominantly cotton based.

The growth and all around development

of cotton and cotton industry has a vital

bearing on the overall development of

the Indian economy. The details are at

Chapter-5.

THE JUTE AND JUTE TEXTILES

INDUSTRY

The J ute industry occupies an important

place in the national economy of India. It

is one of the major industries in the eastern

region, particularly in West Bengal. J ute,

the golden fbre, meets all the standards

for safe packaging in view of being a

natural, renewable, biodegradable and

eco-friendly product. It is estimated that

that the jute industry provides direct

employment to 0.37 million workers in

organized mills and diversifed units

including tertiary sector and allied activities

and supports the livelihood of around 4.0

million farm families. In addition there are

a large number of persons engaged in the

trade of jute.

In the world perspective, India is the

major producer of both raw jute and jute

products. Out of the total world production

of Jute, Kenaf and allied fbre of 3.0 million

tonnes in 2007-08, India produced 1.8

million tonnes. In percentage terms India

accounted for 60 % of world production

in 2007-08. Global production of jute and

ministry of textiles

6

I

n

d

i

a

n

X

i

t

h

P

l

a

n

T

E

X

T

I

L

E

S

P

e

r

f

o

r

m

a

n

c

e

P

r

o

j

e

c

t

i

o

n

X

I

I

P

l

a

n

th

R

a

w

M

a

t

e

r

i

a

l

s

O

r

g

a

n

i

s

e

d

P

O

W

E

R

L

O

O

M

S

P

R

O

C

E

S

S

I

N

G

&

F

I

N

I

S

H

I

N

G

C

L

O

T

H

I

N

G

M

a

d

e

u

p

s

T

e

x

t

i

l

e

s

I

n

d

u

s

t

r

y

E

n

g

i

n

e

e

r

i

n

g

R

&

D

D

a

t

a

b

a

s

e

T

U

F

S

H

R

D

S

e

r

i

c

u

l

t

u

r

e

J

u

t

e

R

a

w

M

A

T

E

R

I

A

L

S

S

I

T

P

X

I

I

P

l

a

n

T

H

T

e

c

h

n

i

c

a

l

T

E

X

T

I

L

E

S

O

r

g

a

n

i

s

e

d

M

I

L

L

E

X

P

O

R

T

S

P

r

o

c

e

s

s

i

n

g

&

F

I

N

I

S

H

I

N

G

C

l

o

t

h

i

n

g

A

P

P

A

R

E

L

J

U

T

E

S

I

R

I

C

U

L

T

U

R

E

P

O

W

O

E

R

L

O

O

M

S

R

&

D

T

e

x

t

i

l

e

s

E

n

g

i

n

e

e

r

i

n

g

I

n

d

u

s

t

r

y

J

U

T

E

S

T

R

A

T

E

G

Y

S

IT

P

M

i

l

l

s

E

x

p

o

r

t

s

R

F

D

H

a

n

d

l

o

o

m

s

J

u

t

e

H

A

N

D

I

C

R

A

F

T

S

T

e

c

h

n

o

l

o

g

y

M

i

s

s

i

o

n

F

O

R

G

R

O

W

T

H

C

H

A

L

L

E

N

G

E

S

allied fbres is estimated to have increased

by 25 % to 3.0 million tonnes in 2007-08

compared to 2004-05 season. Production

in India has also increased by 28% to 1.8

million tonnes in 2007-08 over 2004-05.

There are 84 composite jute mills in India.

Out of the total 83 jute mills, 64 jute mills

are located in West Bengal, 3 each in

Bihar and U.P., 7 in Andhra Pradesh 2

each in Chattisgarh& Orissa and 1 each

in Assam and Tripura. Ownership- wise

division is:- 6 mills are under Government

of Indias P.S.U., 1 mill (Tripura) is under

State Government, 2 mills (Assam & New

Central) are in the co-operative sector and

70 are privately owned mills.

As on J anuary, 2012 total number of

looms installed in the jute industry stood

at 49,529 consisting of 21,122 Hessian

looms, 26,663 sacking looms, 903 C.B.C

looms and others at 841. The installed

spindles in jute mills other than 100%

export oriented units were 751,216

comprising of 628,678 fne spindles

and 122,538 coarse spindles. Installed

spindles in 100% export oriented units

stood at 9,088 with fne spindles at

6,580 and coarse spindles at 2,508. The

maximum installed capacity in jute mills

other than 100% export oriented units (on

the basis of 305 working days per year) is

estimated to be of 2641 thousand tonnes

per annum.

In exercise of the power conferred by

Sub-section (1) of section 3 of the J ute

Packaging Materials (Compulsory use in

Packing Commodities) Act, 1987, Ministry

of Textiles issued Notifcation dated

31.10.2012 stipulating that minimum of

90% of food grain and 40% of sugar to

be compulsorily packed in jute packaging

material.

HANDLOOMS

Handloom weaving is one of the largest

economic activities after agriculture

providing direct and indirect employment

to more than 43 lakh weavers and

allied workers. This sector contributes

nearly 15% of the cloth production in the

country and also contributes to the export

earnings of the country 95% of the worlds

handwoven fabric comes from India.

PRODUCTION IN THE HANDLOOM

SECTOR

Resultant to the developmental and welfare

measures initiated by the Government of

India, the declining trend in production in

the handloom sector had been arrested

and from the year 2004-05 (except the

year of recession in 2008-09) there in

fact has been a considerable growth in

production in the sector. Production in the

handloom sector recorded a fgure of 6900

million sq. meters in the year 2011-12,

which is about 25% over the production

fgure of 5493 million sq. meters recorded

in the year 2003-04.

REVIVAL, REFORM AND

RESTRUCTURING PACKAGE

The Finance Minister in Budget of 2011-

12, in acknowledgement of economic

stress being faced by handloom weavers

and societies due to inability to repay

debts, announced a fnancial package

for handloom sector. Pursuant to this, the

Government of India approved a scheme

called Revival, Reform and Restructuring

Package for handloom sector. The

scheme includes one time waiver of

overdue loans and interest of eligible

handloom cooperative societies and

handloom weavers and provides fresh

credit with interest subsidy of 3% for 3

years with credit guarantee. The scheme

is currently beneftting about 5250 eligible

cooperative societies and around 50,000

handloom weavers. Further relaxation

of the norms of the scheme is under

consideration of the Government to widen

the benefciary coverage of the scheme.

annual report 2012-13

7

I

n

d

i

a

n

X

i

t

h

P

l

a

n

T

E

X

T

I

L

E

S

P

e

r

f

o

r

m

a

n

c

e

P

r

o

j

e

c

t

i

o

n

X

I

I

P

l

a

n

th

R

a

w

M

a

t

e

r

i

a

l

s

O

r

g

a

n

i

s

e

d

P

O

W

E

R

L

O

O

M

S

P

R

O

C

E

S

S

I

N

G

&

F

I

N

I

S

H

I

N

G

C

L

O

T

H

I

N

G

M

a

d

e

u

p

s

T

e

x

t

i

l

e

s

I

n

d

u

s

t

r

y

E

n

g

i

n

e

e

r

i

n

g

R

&

D

D

a

t

a

b

a

s

e

T

U

F

S

H

R

D

S

e

r

i

c

u

l

t

u

r

e

J

u

t

e

R

a

w

M

A

T

E

R

I

A

L

S

S

I

T

P

X

I

I

P

l

a

n

T

H

T

e

c

h

n

i

c

a

l

T

E

X

T

I

L

E

S

O

r

g

a

n

i

s

e

d

M

I

L

L

E

X

P

O

R

T

S

P

r

o

c

e

s

s

i

n

g

&

F

I

N

I

S

H

I

N

G

C

l

o

t

h

i

n

g

A

P

P

A

R

E

L

J

U

T

E

S

I

R

I

C

U

L

T

U

R

E

P

O

W

O

E

R

L

O

O

M

S

R

&

D

T

e

x

t

i

l

e

s

E

n

g

i

n

e

e

r

i

n

g

I

n

d

u

s

t

r

y

J

U

T

E

S

T

R

A

T

E

G

Y

S

IT

P

M

i

l

l

s

E

x

p

o

r

t

s

R

F

D

H

a

n

d

l

o

o

m

s

J

u

t

e

H

A

N

D

I

C

R

A

F

T

S

T

e

c

h

n

o

l

o

g

y

M

i

s

s

i

o

n

F

O

R

G

R

O

W

T

H

C

H

A

L

L

E

N

G

E

S

SETTING UP OF WEAVERS SERVICE

CENTERS (WSCS)

As per budget announcement 2012-

13, three new WSCs are to be set up in

the States of J harkhand, Mizoram and

Nagaland under Central Sector. The SFC

has approved setting up of three new

WSCs on 14.12.2012.

INSTITUTIONAL CREDIT/ WEAVER

CREDIT CARD SCHEME

For fresh loans, Government has also

introduced Institutional Credit for

Handloom Sector, which is implemented

under Integrated Handloom Development

Scheme. The interventions include (i)

issuance of Weaver Credit Cards(WCCs)

(ii) interest subvention @ 3% for 3 years on

fresh loans sanctioned, (iii) margin money

assistance @ Rs.4200 per individual

weaver and (iv) credit guarantee for 3

years.

In order to make the weavers aware of the

scheme and also to collect applications

from the weavers for issue of WCC,

674 camps were organized across the

country involving the State Governments,

lead banks, WSCs. The scheme was

also popularized using All India Radio.

Three jingles were broadcasted during

16.8.2012 to 15.09.12 all over India in 9

regional languages (Tamil, Telgu, Oriya,

Assamese, Kannada, Malayalam, Bengali,

Manipuri, Dogri) and in hindi in 3 slots (8

am, 2 pm and 8 PM). As per information

available from 24 States, 24257 WCCs

have been issued by the banks, with a

sanction and disbursal loans of Rs.7952

lakh and Rs.4128 lakh respectively till

15.02.13.

10% SUBSIDY ON HANK YARN

In order to provide cheap yarn to the

handloom weavers, 10% subsidy on

hank yarn has been approved. Against

the target of issuance of pass books

for covering 6.14 lakh handlooms, 2.61

lakh handlooms have been covered till

16.11.12.

610 HANDLOOM CLUSTERS TAKEN

UP FOR DEVELOPMENT.

The Integrated Handlooms Development

Scheme(IHDS) has been launched

with a view to develop holistically and

comprehensively the weavers clusters

throughout the country. Under this scheme,

610 handloom clusters have been taken

up during XIth Plan (upto March, 2012)

and fnancial assistance of Rs 213.53

crore has been released to various

Implementing agencies through the State

Government for various components like

skill upgradation, setting up of CFC/dye

house, marketing, formation of consortium

etc.

82 LAKH WEAVERS COVERED

UNDER HEALTH INSURANCE

SCHEME

The Health Insurance Scheme provides

health care facilities to the handloom

weavers and their families. 81.89 lakh

weavers have been covered/enrolled

during the XIth Plan under this scheme

which extends beneft to more than 327

lakh persons including spouse and two

children of the weaver covered.

YARN SUPPLY UNDER THE MILL

GATE PRICE SCHEME

788 yarn depots, covering all the

handloom clusters, have been set up by

the NHDC to ensure steady and timely

supply of requisite yarn at mill gate price

to the handloom weavers.

SANT KABIR AWARD

This award has been conferred since

2009 to outstanding handloom weavers

ministry of textiles

8

I

n

d

i

a

n

X

i

t

h

P

l

a

n

T

E

X

T

I

L

E

S

P

e

r

f

o

r

m

a

n

c

e

P

r

o

j

e

c

t

i

o

n

X

I

I

P

l

a

n

th

R

a

w

M

a

t

e

r

i

a

l

s

O

r

g

a

n

i

s

e

d

P

O

W

E

R

L

O

O

M

S

P

R

O

C

E

S

S

I

N

G

&

F

I

N

I

S

H

I

N

G

C

L

O

T

H

I

N

G

M

a

d

e

u

p

s

T

e

x

t

i

l

e

s

I

n

d

u

s

t

r

y

E

n

g

i

n

e

e

r

i

n

g

R

&

D

D

a

t

a

b

a

s

e

T

U

F

S

H

R

D

S

e

r

i

c

u

l

t

u

r

e

J

u

t

e

R

a

w

M

A

T

E

R

I

A

L

S

S

I

T

P

X

I

I

P

l

a

n

T

H

T

e

c

h

n

i

c

a

l

T

E

X

T

I

L

E

S

O

r

g

a

n

i

s

e

d

M

I

L

L

E

X

P

O

R

T

S

P

r

o

c

e

s

s

i

n

g

&

F

I

N

I

S

H

I

N

G

C

l

o

t

h

i

n

g

A

P

P

A

R

E

L

J

U

T

E

S

I

R

I

C

U

L

T

U

R

E

P

O

W

O

E

R

L

O

O

M

S

R

&

D

T

e

x

t

i

l

e

s

E

n

g

i

n

e

e

r

i

n

g

I

n

d

u

s

t

r

y

J

U

T

E

S

T

R

A

T

E

G

Y

S

IT

P

M

i

l

l

s

E

x

p

o

r

t

s

R

F

D

H

a

n

d

l

o

o

m

s

J

u

t

e

H

A

N

D

I

C

R

A

F

T

S

T

e

c

h

n

o

l

o

g

y

M

i

s

s

i

o

n

F

O

R

G

R

O

W

T

H

C

H

A

L

L

E

N

G

E

S

who have made valuable contribution

in keeping alive the handloom heritage.

Each award consists of one mounted

gold coin, one shawl and a citation. In

addition, fnancial assistance to the extent

of Rs. 6.00 lakh is also given to each of

the Sant Kabir awardee to innovate and

create 10 new products of high level of

excellence, of high aesthetic value and

high quality. 10 handloom weavers for

the year 2009 and 8 handloom weavers

for the year 2010 have been conferred

for Sant Kabir Award by the President of

India in a function held on 9th November,

2012 at Vigyan Bhawan, New Delhi.

BRAND BUILDING THROUGH

HANDLOOM MARK:

Handloom Mark: The Handloom Mark has

been launched to serve as a guarantee

to the buyer that handloom product being

purchased is a genuine handwoven

product and not a powerloom or mill

made product. The Textiles Committee

is Implementing agency for promotion of

Handloom Mark. As on 31st J an 2013, 3.13

crore (cumulative) handloom mark labels

have been sold to 10118 stakeholders.

813 retail outlets are selling handloom

goods with handloom mark label.

Handloom Week: To promote, popularize

and create awareness about the handloom

products Handloom Week is celebrated

every year from 21st to 27th December.

During the Handloom Week, number of

promotional and awareness programmes,

publicity through newspapers, magazines,

outdoor publicity, through electronic media

is undertaken.

Marketing Events: The marketing events

of various levels i.e. from district level,

State level to national Level is organized

by the State Governments to provide

opportunity to handloom weaver and their

agencies. During the year 2011-12, 740

marketing events were sanctioned During

the current year as on 20th Feb, 2013,

443 marketing events and 06 craft melas

have been approved for dissemination of

technological developments. Besides, 22

appropriate technology exhibitions have

also been approved for dissemination of

technological development.

HANDICRAFTS

The Handicrafts Sector plays a

signifcant & important role in the

countrys economy. It provides

employment to a vast segment of craft

persons in rural & semi urban areas and

generates substantial foreign exchange

for the country, while preserving its

cultural heritage. Handicrafts have

great potential, as they hold the key for

sustaining not only the existing set of

millions of artisans spread over length

and breadth of the country, but also for

the increasingly large number of new

entrants in the crafts activity. Presently,

handicrafts contribute substantially to

employment generation and exports.

The Handicraft sector has, however,

suffered due to its being unorganized,

with the additional constraints of lack of

education, low capital, poor exposure to

new technologies, absence of market

intelligence, and a poor institutional

framework.

The sector is estimated to employ Rs 68.86

lakh artisans at present and the export

of handicrafts including handmade carpet

upto November 2012 has been 12157.21

crores which shows an increase of 34.19%

over the same period in fnancial year

2011-12, and the plan allocation during

2012-13 is Rs. 177.00 crores.

During the 2012-13 the Government of

India implemented six generic central

sector schemes for holistic growth and

development of handicrafts sector in the

country. The details are at Chapter-11.

annual report 2012-13

9

I

n

d

i

a

n

X

i

t

h

P

l

a

n

T

E

X

T

I

L

E

S

P

e

r

f

o

r

m

a

n

c

e

P

r

o

j

e

c

t

i

o

n

X

I

I

P

l

a

n

th

R

a

w

M

a

t

e

r

i

a

l

s

O

r

g

a

n

i

s

e

d

P

O

W

E

R

L

O

O

M

S

P

R

O

C

E

S

S

I

N

G

&

F

I

N

I

S

H

I

N

G

C

L

O

T

H

I

N

G

M

a

d

e

u

p

s

T

e

x

t

i

l

e

s

I

n

d

u

s

t

r

y

E

n

g

i

n

e

e

r

i

n

g

R

&

D

D

a

t

a

b

a

s

e

T

U

F

S

H

R

D

S

e

r

i

c

u

l

t

u

r

e

J

u

t

e

R

a

w

M

A

T

E

R

I

A

L

S

S

I

T

P

X

I

I

P

l

a

n

T

H

T

e

c

h

n

i

c

a

l

T

E

X

T

I

L

E

S

O

r

g

a

n

i

s

e

d

M

I

L

L

E

X

P

O

R

T

S

P

r

o

c

e

s

s

i

n

g

&

F

I

N

I

S

H

I

N

G

C

l

o

t

h

i

n

g

A

P

P

A

R

E

L

J

U

T

E

S

I

R

I

C

U

L

T

U

R

E

P

O

W

O

E

R

L

O

O

M

S

R

&

D

T

e

x

t

i

l

e

s

E

n

g

i

n

e

e

r

i

n

g

I

n

d

u

s

t

r

y

J

U

T

E

S

T

R

A

T

E

G

Y

S

IT

P

M

i

l

l

s

E

x

p

o

r

t

s

R

F

D

H

a

n

d

l

o

o

m

s

J

u

t

e

H

A

N

D

I

C

R

A

F

T

S

T

e

c

h

n

o

l

o

g

y

M

i

s

s

i

o

n

F

O

R

G

R

O

W

T

H

C

H

A

L

L

E

N

G

E

S

INTEGRATED SKILL DEVELOPMENT

SCHEME (ISDS)

The Integrated Skill Development Scheme

(ISDS) was introduced as a pilot scheme

in the last two years of the 11

th

Five year

Plan with an outlay of Rs. 272 crore

including Rs. 229 crore as Government

contribution with a physical target of 2.56

lakh persons. The scheme is part of a

Government wide focus on creating skill

that is needed to enhance the competition

advantage of India in the manufacturing

and Textiles sector. It is proposed to

continue the scheme during the 12th Plan.

The details are at Chapter-17.

POWERLOOM SECTOR

The decentralised powerloom sector

is one of the most important segments

of the Textile Industry in terms of fabric

production and employment generation.

It provides employment to 57.44 Lakh

persons and contributes 62 percent to

total cloth production in the Country.

60% of the fabrics produced in the

powerloom sector is of man-made. More

than 60% of fabric meant for export is

also sourced from powerloom sector.

The readymade garments and home

textile sectors are heavily dependent

on the powerloom sector to meet their

fabric requirement.

There are approximately 5.24 Lakh

Powerloom Units with 23.24 Lakh

Powerlooms as on 30.09.2012. The

technology level of this sector varies from

obsolete plain loom to high tech shuttle-

less looms. There are approximately

1,05,000 shuttleless looms in this sector.

It is estimated that more than 75% of the

shuttle looms are obsolete and outdated

with a vintage of more than 15 years and

have virtually no process or quality control

devices / attachments. However, there

has been signifcant upgradation in the

technology level of the powerloom sector

during the last 5-6 years.

POWERLOOM MEGA CLUSTERS

Comprehensive Powerloom Cluster

Development Scheme was formulated in

the year 2008-09 to enable implementation

of the announcement made by the Finance

Minister in his Budget Speech 2008-09

to develop Bhiwandi (Maharashtra) and

Erode (Tamil Nadu) as Powerloom Mega

Clusters. Subsequently, Government has

announced development of Powerloom

Mega Clusters in Bhilwara (Rajasthan)

in budget 2009-10 and Ichalkaranji

(Maharashtra) in Budget 2012-13.

The guiding principles underlying the

design of clusters is to create world-

class infrastructure and to integrate

the production chain in a manner that

caters to the business needs of the local

Small and Medium Enterprises (SMEs)

to boost production and export. The

broad objectives of the Mega cluster

approach Scheme is to enhance the

competitiveness of the clusters in terms

of increased market share and ensuring

increased productivity by higher unit value

realization of the products. The Scheme

provides requisite support / linkages

in terms of adequate infrastructure,

technology, product diversifcation,

design development, raw material

banks, marketing & promotion, credit,

social security and other components

that are vital for sustainability of weavers

engaged in the decentralized powerloom

sector.

Government funds to the tune of Rs.30

crore (approx..) was released for

implementation of the Powerloom Mega

Clusters till December, 2012.

Details of Mega Clusters are given at

table 1.

ministry of textiles

10

I

n

d

i

a

n

X

i

t

h

P

l

a

n

T

E

X

T

I

L

E

S

P

e

r

f

o

r

m

a

n

c

e

P

r

o

j

e

c

t

i

o

n

X

I

I

P

l

a

n

th

R

a

w

M

a

t

e

r

i

a

l

s

O

r

g

a

n

i

s

e

d

P

O

W

E

R

L

O

O

M

S

P

R

O

C

E

S

S

I

N

G

&

F

I

N

I

S

H

I

N

G

C

L

O

T

H

I

N

G

M

a

d

e

u

p

s

T

e

x

t

i

l

e

s

I

n

d

u

s

t

r

y

E

n

g

i

n

e

e

r

i

n

g

R

&

D

D

a

t

a

b

a

s

e

T

U

F

S

H

R

D

S

e

r

i

c

u

l

t

u

r

e

J

u

t

e

R

a

w

M

A

T

E

R

I

A

L

S

S

I

T

P

X

I

I

P

l

a

n

T

H

T

e

c

h

n

i

c

a

l

T

E

X

T

I

L

E

S

O

r

g

a

n

i

s

e

d

M

I

L

L

E

X

P

O

R

T

S

P

r

o

c

e

s

s

i

n

g

&

F

I

N

I

S

H

I

N

G

C

l

o

t

h

i

n

g

A

P

P

A

R

E

L

J

U

T

E

S

I

R

I

C

U

L

T

U

R

E

P

O

W

O

E

R

L

O

O

M

S

R

&

D

T

e

x

t

i

l

e

s

E

n

g

i

n

e

e

r

i

n

g

I

n

d

u

s

t

r

y

J

U

T

E

S

T

R

A

T

E

G

Y

S

IT

P

M

i

l

l

s

E

x

p

o

r

t

s

R

F

D

H

a

n

d

l

o

o

m

s

J

u

t

e

H

A

N

D

I

C

R

A

F

T

S

T

e

c

h

n

o

l

o

g

y

M

i

s

s

i

o

n

F

O

R

G

R

O

W

T

H

C

H

A

L

L

E

N

G

E

S

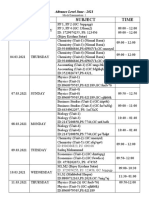

Table 1

Handloom Sector

(6 Mega Clusters)

Handicraft Sector

( 5 Mega Clusters)

Powerloom Sector

(4 Mega Clusters)

1. Varanasi (U.P).

2. Sivsagar (Assam).

3. Murshidabad (W.B.).

4. Virudhunagar (T.N)).

5. Guntur &PrakashamDistt. (A.P).*

6. Godda& Neighboring* Distt. (J harkhand)*

7. Moradabad (U.P.)

8. Narasapur (A.P.).

9. Bhdohi-Mirzapur (U.P.).

10. Srinagar (J &K).

11. J odhpur (Rajasthan)

12. Bhiwandi (Maharastra).

13. Erode (Tamil Nadu).

14. Bhilwara (Rajasthan).

15. Ichalkaranji (Maharashtra)*

*Announced in Budget 2012-13.

*****

ACTIVITIES RELATED TO

PROGRESSIVE USE OF OFFICIAL

LANGUAGE

Hindi is the Offcial Language of the Union

of India and the policy of the Government

aims at progressive use of Hindi in offcial

work. Effective steps have been taken