Escolar Documentos

Profissional Documentos

Cultura Documentos

DRA Book

Enviado por

DrGajanan Vaishnav0 notas0% acharam este documento útil (0 voto)

390 visualizações2 páginasDRA book

Título original

DRA book

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

DOCX, PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDRA book

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato DOCX, PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

390 visualizações2 páginasDRA Book

Enviado por

DrGajanan VaishnavDRA book

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato DOCX, PDF, TXT ou leia online no Scribd

Você está na página 1de 2

Q.1.

Write a short note on drug development notebooks

Pharmaceutical drug development notebooks are essential records of what was done in drug

development program. They have a complete and truthful record of what was observed and

how technical decisions were taken. Typically they are 100 to 200 pages hardbound notebooks

suitable for using in laboratory environment.

Issue and control of the laboratory notebooks is responsibility of documentation group. The

documentation group comes under corporate quality assurance department (CQA). When a

scientist is assigned a project, he gets a product (drug) development notebook issued on his

name. After the project is complete, the notebook is returned to documentation cell (doc cell)

and they archive it.

There is an elaborate SOP for issue, maintenance and archiving of product development

notebooks. A junior scientist working on a project has to obtain following signatures after each

days work.

1. Checked by: This signature is usually done by a peer scientist working in the same area.

The signature signifies that the work was indeed done and the concerned scientist did

the records meticulously.

2. Reviewed by: This signature is done by the group leader. The records as well as

conclusions are reviewed well and inferences highlighted. Future course of action is

discussed and documented.

Following signatures are taken weekly during preformulation/ formulation and monthly during

stability

3. Authorized by: This signature is done by the F&D head. A meeting is called with group

leader and concerned scientist. The results and progress are discussed and then

signatures made.

4. CQA countersign: The CQA person would check all the records. The raw material labels

should be pasted on LHS page. All weighing, sifting, mixing, granulation, drying,

lubrication, compression coating labels, and IPQC printouts should be pasted. Everything

that can be documented with proof must be preserved. A reserve sample of the latest

stage of the trial must be made available by the scientist. CQA person should check

some of the IPQC parameters to judge truthfulness of the records.

All preformulation and formulation trials should be recorded. A general rule is No product was

ever developed without a number of reject lots. All the failures must be truthfully recorded.

Key data are:

1. All ingredient lot numbers and expiry dates.

2. Active and excipient sources (supplier and batch numbers)

3. All preformulation data

4. All manufacturing methods used

5. Equipment used, speeds and times

6. All IPQC

7. All results and observervations

8. All tentative specifications

9. All finished product controls

10. Proposed stability specifications

11. All failed data, and abnormal results.

12. Investigations and conclusions

Você também pode gostar

- GMP Documentation ReviewDocumento7 páginasGMP Documentation Reviewanandhra2010Ainda não há avaliações

- Scale Up Manufacturing ProcessesDocumento53 páginasScale Up Manufacturing ProcessesJohmarie TanAinda não há avaliações

- Standard Operating Procedure (Sop) : Presented by GovindDocumento22 páginasStandard Operating Procedure (Sop) : Presented by GovindHarigovind GoliAinda não há avaliações

- Document Maintenance in Pharmaceutical Industry: General RequirementDocumento24 páginasDocument Maintenance in Pharmaceutical Industry: General RequirementDinesh SenathipathiAinda não há avaliações

- Unit IV - Complaints and DocumentsDocumento103 páginasUnit IV - Complaints and DocumentsIndu VattiAinda não há avaliações

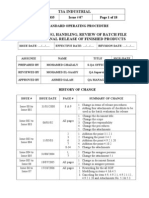

- Issuing, Handling, Revision of Batch File and Final Release of Finished Products For Sale and Distribution 07Documento18 páginasIssuing, Handling, Revision of Batch File and Final Release of Finished Products For Sale and Distribution 07ibrahimgomaaAinda não há avaliações

- Finished ProductDocumento4 páginasFinished ProductDilip ChaudharyAinda não há avaliações

- Quality Control Procedure in Pharmaceutical IndustryDocumento6 páginasQuality Control Procedure in Pharmaceutical IndustryMuhammad Masoom AkhtarAinda não há avaliações

- Validation Ensures Quality in Pharma IndustryDocumento7 páginasValidation Ensures Quality in Pharma Industryajitjoshi950Ainda não há avaliações

- 2.7 SOP Reporting v2Documento9 páginas2.7 SOP Reporting v2trs220% (2)

- Process Validation-Aseptic Process For Pharmaceuticals (June 1, 2003)Documento24 páginasProcess Validation-Aseptic Process For Pharmaceuticals (June 1, 2003)อิอิ อิอิAinda não há avaliações

- DocumenttionDocumento6 páginasDocumenttionTejAinda não há avaliações

- Good Manufacturing Practice or GMPDocumento10 páginasGood Manufacturing Practice or GMPMuhammad Masoom AkhtarAinda não há avaliações

- 02good Laboratory Practice (GLP)Documento26 páginas02good Laboratory Practice (GLP)Ayalew DesyeAinda não há avaliações

- Procedure for release of Drug Substance and ProductsDocumento4 páginasProcedure for release of Drug Substance and Productsom shankar JhaAinda não há avaliações

- Equ10-04 Micro QC - Eqpt Maint SOPDocumento7 páginasEqu10-04 Micro QC - Eqpt Maint SOPpokhara144Ainda não há avaliações

- InterviewDocumento13 páginasInterviewPurwaning Nugroho WAinda não há avaliações

- Documentation Pharmaceutical IndustryDocumento102 páginasDocumentation Pharmaceutical IndustryRagulAinda não há avaliações

- QC MANUAL (Project Quality Plan) WisnuDocumento10 páginasQC MANUAL (Project Quality Plan) WisnuNovie DwiyantiAinda não há avaliações

- Covid-19 Post Lockdown Production Restart & Part Readiness ChecklistDocumento9 páginasCovid-19 Post Lockdown Production Restart & Part Readiness ChecklistSanjay KumarAinda não há avaliações

- Covid-19 Post Lockdown Production Restart & Part Readiness ChecklistDocumento9 páginasCovid-19 Post Lockdown Production Restart & Part Readiness ChecklistSanjay KumarAinda não há avaliações

- PROCESS VALIDATION CONCEPT GUIDEDocumento6 páginasPROCESS VALIDATION CONCEPT GUIDEYousifAinda não há avaliações

- Audit of Sterile Production and PackagingDocumento22 páginasAudit of Sterile Production and PackagingsjAinda não há avaliações

- Validation: Presented To: Prof. H.S. Keerthy Department of Pharmaceutics Mallige College of PharmacyDocumento26 páginasValidation: Presented To: Prof. H.S. Keerthy Department of Pharmaceutics Mallige College of PharmacyAfdal Naim100% (1)

- Quality assurance viewpoint on pharmaceutical validation overviewDocumento12 páginasQuality assurance viewpoint on pharmaceutical validation overviewNarongchai PongpanAinda não há avaliações

- Guidelines For Inspection of Facilities For Manufacture of Food ProductsDocumento14 páginasGuidelines For Inspection of Facilities For Manufacture of Food ProductsMercyclara IgweAinda não há avaliações

- Medical Device Validation RadhaDocumento27 páginasMedical Device Validation Radhas1a2d3f40% (1)

- Documentation in Pharmaceutical IndustryDocumento101 páginasDocumentation in Pharmaceutical Industrygeet55Ainda não há avaliações

- Control of Documentation in QC Laboratory - BlogDocumento2 páginasControl of Documentation in QC Laboratory - BlogBrassica Pharma Pvt Ltd PhaseAinda não há avaliações

- Internal Audit Checklist - QualityDocumento3 páginasInternal Audit Checklist - QualitySachin Ramdurg100% (1)

- Batch Records HandoDocumento39 páginasBatch Records HandoNiranjan SinghAinda não há avaliações

- Sop-Standard Operating Procedure: ObjectiveDocumento4 páginasSop-Standard Operating Procedure: ObjectiveDivyashree PatilAinda não há avaliações

- Nonconforming Material Containment:: Designated Area Away From The Production Workflow?Documento6 páginasNonconforming Material Containment:: Designated Area Away From The Production Workflow?Cande EscobedoAinda não há avaliações

- Control Sample SOP - SOP For Control Sample ManagementDocumento10 páginasControl Sample SOP - SOP For Control Sample ManagementdaribeefaAinda não há avaliações

- SOP Storage & Handling of Finished ProductDocumento1 páginaSOP Storage & Handling of Finished ProductUjwal C Kamble0% (1)

- SOPDocumento5 páginasSOPJaime HinojosaAinda não há avaliações

- 16=Establish Quality Standards L=4 (2)Documento20 páginas16=Establish Quality Standards L=4 (2)EYOB AHMEDAinda não há avaliações

- Library Management System Test PlanDocumento14 páginasLibrary Management System Test PlanChun Chun0% (2)

- KVT Hsse Plan: Health, Safety, Security and Environment PlanDocumento9 páginasKVT Hsse Plan: Health, Safety, Security and Environment PlanLegend AnbuAinda não há avaliações

- SOP For Good Documentation PracticesDocumento5 páginasSOP For Good Documentation Practices王仁宏Ainda não há avaliações

- GMP Module - Data IntegrityDocumento46 páginasGMP Module - Data Integritydeepa_ragu5695Ainda não há avaliações

- QC& QaDocumento48 páginasQC& QaManohar KasdekarAinda não há avaliações

- Prospective, Concurrent and Retrospective Validation-GOOD ARTICLEDocumento8 páginasProspective, Concurrent and Retrospective Validation-GOOD ARTICLEraju1559405Ainda não há avaliações

- Standard Operating Procedures: Title: Document Controls Scope: Responsibility: PurposeDocumento2 páginasStandard Operating Procedures: Title: Document Controls Scope: Responsibility: PurposeEldaniz HasanovAinda não há avaliações

- 21002Documento10 páginas21002joeAinda não há avaliações

- Site Monitoring Plan TemplateDocumento5 páginasSite Monitoring Plan TemplaterajuAinda não há avaliações

- Clause 11Documento6 páginasClause 11Nor Adila Norhasmie hassanAinda não há avaliações

- Frequently Asked Questions About Pharmaceutical Quality AssuranceDocumento71 páginasFrequently Asked Questions About Pharmaceutical Quality AssuranceDipesh BardoliaAinda não há avaliações

- Quality Manual ExampleDocumento15 páginasQuality Manual ExampleHagit Givati100% (1)

- Batch Releas ProcedureDocumento4 páginasBatch Releas ProcedureSolomon Gamanuel100% (1)

- PROCESS VALIDATION PROTOCOL ExampleDocumento14 páginasPROCESS VALIDATION PROTOCOL ExampleNazia KabirAinda não há avaliações

- Sorces of Quality VariationsDocumento5 páginasSorces of Quality VariationsIndiraAinda não há avaliações

- 1 Objective: Packaging Validation Packaging Line/packaging RoomDocumento13 páginas1 Objective: Packaging Validation Packaging Line/packaging RoomAngel CvetanovAinda não há avaliações

- Frequently Asked Questions About Pharmaceutical Quality SystemsDocumento66 páginasFrequently Asked Questions About Pharmaceutical Quality Systemsshanmukha2007Ainda não há avaliações

- QC 22 03Documento12 páginasQC 22 03Yahia HassaanAinda não há avaliações

- Biosafety Sop 0027 Settle Plate Method Env MonitoringDocumento2 páginasBiosafety Sop 0027 Settle Plate Method Env MonitoringUjang KarnaAinda não há avaliações

- Method Statement Demolison and Site ClearanceDocumento7 páginasMethod Statement Demolison and Site ClearanceSasi Kumar100% (3)

- Laboratory Quality/Management: A Workbook with an Eye on AccreditationNo EverandLaboratory Quality/Management: A Workbook with an Eye on AccreditationNota: 5 de 5 estrelas5/5 (1)

- How To Make A "Loading Pen" How To Prepare PTLC: Draw Guideline by PencilDocumento2 páginasHow To Make A "Loading Pen" How To Prepare PTLC: Draw Guideline by PencilDrGajanan VaishnavAinda não há avaliações

- Introduction To Web Server and Server ProductsDocumento8 páginasIntroduction To Web Server and Server ProductsDrGajanan Vaishnav67% (3)

- Fire Extinguishers TypesDocumento1 páginaFire Extinguishers TypesDrGajanan VaishnavAinda não há avaliações

- NBA Departmental Files v3.0Documento11 páginasNBA Departmental Files v3.0DrGajanan Vaishnav89% (9)

- My L1 Antianginal DrugsDocumento22 páginasMy L1 Antianginal DrugsDrGajanan VaishnavAinda não há avaliações

- Fire Extinguishers TypesDocumento1 páginaFire Extinguishers TypesDrGajanan VaishnavAinda não há avaliações

- BrochureDocumento4 páginasBrochureDrGajanan VaishnavAinda não há avaliações

- (CHAPTER 9, PARA 9.4.3) Polling Agents / Relieving Agents Movement SheetDocumento1 página(CHAPTER 9, PARA 9.4.3) Polling Agents / Relieving Agents Movement SheetDrGajanan VaishnavAinda não há avaliações

- Lipids Fats&SteroidsDocumento11 páginasLipids Fats&SteroidsDrGajanan VaishnavAinda não há avaliações

- Movement Register For Polling AgentsDocumento8 páginasMovement Register For Polling AgentsDrGajanan VaishnavAinda não há avaliações

- Slips For Voters in Q at The End of Closing HoursDocumento1 páginaSlips For Voters in Q at The End of Closing HoursDrGajanan VaishnavAinda não há avaliações

- Graduate Pharmacy Aptitude Test 2019 (Gpat-2019) : Public NoticeDocumento1 páginaGraduate Pharmacy Aptitude Test 2019 (Gpat-2019) : Public NoticeDrGajanan VaishnavAinda não há avaliações

- Willy WonkaDocumento2 páginasWilly WonkaDrGajanan VaishnavAinda não há avaliações

- HPLCDocumento10 páginasHPLCamitrameshwardayalAinda não há avaliações

- Preparation For Obtaining NBA AccDocumento3 páginasPreparation For Obtaining NBA AccKanchana Krishna KaushikAinda não há avaliações

- Agar Media Is Required For ExperimentsDocumento1 páginaAgar Media Is Required For ExperimentsDrGajanan VaishnavAinda não há avaliações

- Moringa Oleifera Tablet FormulationDocumento31 páginasMoringa Oleifera Tablet FormulationDrGajanan VaishnavAinda não há avaliações

- HPLC 1Documento31 páginasHPLC 1DrGajanan Vaishnav0% (1)

- Q15 S21 of Ceiling ActDocumento2 páginasQ15 S21 of Ceiling ActDrGajanan VaishnavAinda não há avaliações

- Invention, My Dear Friends, Is 93% Perspiration, 6%Documento2 páginasInvention, My Dear Friends, Is 93% Perspiration, 6%DrGajanan Vaishnav0% (1)

- PCI B Pharm Syllabus PDFDocumento189 páginasPCI B Pharm Syllabus PDFDrGajanan Vaishnav100% (1)

- Pharmacology 2Documento13 páginasPharmacology 2DrGajanan VaishnavAinda não há avaliações

- Size Reduction NotesDocumento15 páginasSize Reduction NotesDrGajanan VaishnavAinda não há avaliações

- Notice Us 138Documento1 páginaNotice Us 138DrGajanan VaishnavAinda não há avaliações

- Appeals RevisionMLRC 1966Documento2 páginasAppeals RevisionMLRC 1966DrGajanan VaishnavAinda não há avaliações

- What Are PatentsDocumento1 páginaWhat Are PatentsDrGajanan VaishnavAinda não há avaliações

- DibenzalacetoneDocumento3 páginasDibenzalacetoneDrGajanan VaishnavAinda não há avaliações

- Kokate Forensic Pharmacy PDFDocumento201 páginasKokate Forensic Pharmacy PDFSouvik Saha100% (2)

- Ashraf M. Mahmoud, Saad A. Alqahtani: American Journal of Analytical Chemistry, 2016, 7, 179-191Documento13 páginasAshraf M. Mahmoud, Saad A. Alqahtani: American Journal of Analytical Chemistry, 2016, 7, 179-191DrGajanan VaishnavAinda não há avaliações

- Golden RuleDocumento2 páginasGolden RuleDrGajanan VaishnavAinda não há avaliações

- Karan Chawla and Joshua Lee November 21, 2016 MEDS 3020 - Fall 2016 Dr. Rosevear, Dr. Cartwright, Dr. LiebermanDocumento2 páginasKaran Chawla and Joshua Lee November 21, 2016 MEDS 3020 - Fall 2016 Dr. Rosevear, Dr. Cartwright, Dr. LiebermanJeremy DelaneyAinda não há avaliações

- Generate Ideas with TechniquesDocumento19 páginasGenerate Ideas with TechniquesketulAinda não há avaliações

- SFA160Documento5 páginasSFA160scamalAinda não há avaliações

- 1HMEE5013 Exam Q JAN2017 S14Documento5 páginas1HMEE5013 Exam Q JAN2017 S14kumar6125100% (1)

- Mitosis Quiz: Answers Each Question. Write The Answer On The Sheet ProvidedDocumento5 páginasMitosis Quiz: Answers Each Question. Write The Answer On The Sheet ProvidedJohn Osborne100% (1)

- Graphs & Charts SummariesDocumento20 páginasGraphs & Charts SummariesMaj Ma Salvador-Bandiola100% (1)

- Ubc 2015 May Sharpe JillianDocumento65 páginasUbc 2015 May Sharpe JillianherzogAinda não há avaliações

- UntitledDocumento21 páginasUntitledRoberto RamosAinda não há avaliações

- Informed Consent: Ghaiath M. A. HusseinDocumento26 páginasInformed Consent: Ghaiath M. A. HusseinDocAxi Maximo Jr AxibalAinda não há avaliações

- Money MBA 1Documento4 páginasMoney MBA 1neaman_ahmed0% (1)

- What Are Your Observations or Generalizations On How Text/ and or Images Are Presented?Documento2 páginasWhat Are Your Observations or Generalizations On How Text/ and or Images Are Presented?Darlene PanisaAinda não há avaliações

- ZJJ 3Documento23 páginasZJJ 3jananiwimukthiAinda não há avaliações

- LTC2410 Datasheet and Product Info - Analog DevicesDocumento6 páginasLTC2410 Datasheet and Product Info - Analog DevicesdonatoAinda não há avaliações

- Kashmira Karim Charaniya's ResumeDocumento3 páginasKashmira Karim Charaniya's ResumeMegha JainAinda não há avaliações

- Pengkondisian Kesiapan Belajar Untuk Pencapaian Hasil Belajar Dengan Gerakan Senam OtakDocumento9 páginasPengkondisian Kesiapan Belajar Untuk Pencapaian Hasil Belajar Dengan Gerakan Senam OtakSaadah HasbyAinda não há avaliações

- Topographic Map of Blooming GroveDocumento1 páginaTopographic Map of Blooming GroveHistoricalMapsAinda não há avaliações

- About Topsøe - and What We DoDocumento20 páginasAbout Topsøe - and What We DoAbhishek ChaudharyAinda não há avaliações

- 2022 - J - Chir - Nastase Managementul Neoplaziilor Pancreatice PapilareDocumento8 páginas2022 - J - Chir - Nastase Managementul Neoplaziilor Pancreatice PapilarecorinaAinda não há avaliações

- Makerwys - Exe Version 4.891: by Pete Dowson © 2019 InstructionsDocumento11 páginasMakerwys - Exe Version 4.891: by Pete Dowson © 2019 InstructionsRafrol RamonAinda não há avaliações

- Flight Instructor Patter Ex17Documento1 páginaFlight Instructor Patter Ex17s ramanAinda não há avaliações

- Cat IQ TestDocumento3 páginasCat IQ TestBrendan Bowen100% (1)

- List of SQAC DQAC SISC DISC 2019 20Documento39 páginasList of SQAC DQAC SISC DISC 2019 20Shweta jainAinda não há avaliações

- Laser Engrave Co2 System BJ-1390Documento5 páginasLaser Engrave Co2 System BJ-1390Sasa TodorovicAinda não há avaliações

- Ips 350:400:450:500:600 07:05 PDFDocumento124 páginasIps 350:400:450:500:600 07:05 PDFRandall PettersonAinda não há avaliações

- A Laboratory Experiment in Crystals and Crystal Model Building ObjectivesDocumento7 páginasA Laboratory Experiment in Crystals and Crystal Model Building ObjectivesrajaaAinda não há avaliações

- Family Preparedness PlanDocumento6 páginasFamily Preparedness PlanSabrinaelyza UyAinda não há avaliações

- Appraisal Sample PDFDocumento22 páginasAppraisal Sample PDFkiruthikaAinda não há avaliações

- User Manual - Numrolgy SoftwareDocumento14 páginasUser Manual - Numrolgy SoftwareComputershastriNoproblem0% (1)

- Pankaj Screener 10 Oct 2014Documento127 páginasPankaj Screener 10 Oct 2014Sadul Singh Naruka100% (1)

- 2021.01.28 - Price Variation of Steel Items - SAIL Ex-Works Prices of Steel - RB-CivilDocumento2 páginas2021.01.28 - Price Variation of Steel Items - SAIL Ex-Works Prices of Steel - RB-CivilSaugata HalderAinda não há avaliações