Escolar Documentos

Profissional Documentos

Cultura Documentos

SKF Epb Pump en MM

Enviado por

Ebied Yousif Aly0 notas0% acharam este documento útil (0 voto)

168 visualizações4 páginaspump

Título original

12810 Skf Epb Pump en Mm

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentopump

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

168 visualizações4 páginasSKF Epb Pump en MM

Enviado por

Ebied Yousif Alypump

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 4

The SKF EPB pump is used in progressive, single-

line or dual-line industrial centralized lubrication systems.

The main purpose of the pump is to feed lubricant into

a centralized lubrication system.

SKF Electro-pneumatic Barrel

Pump EPB pump

for SKF MonoFlex, DuoFlex and ProFlex lubrication systems

SKF EPB pump

The SKF EPB pump is an electro-pneumatic

barrel pump, in which the traditional me-

chanical air motor valving has been replaced

with a solenoid valve. The pump is suitable

for 18 kg, 50 kg and 180 kg lubricant bar-

rels. With right equipment, it is possible to

use SKF EPB-pump with fluidbag.

The benefits of an electronic air motor con-

trol include:

The air motor of the pump is electroni-

cally controlled.

Electronic control allows accurate control

of the pump's output.

Lubrication-free air motor

Fewer mechanical components extend

the air motor's service life.

The pump comes with a self-diagnosing

system

There are two versions of the pump: ECO

and STA.

The ECO version is intended for use with

ECO lid sets, which are suitable for NLGI

grade 2 greases

The STA version is intended for use with

the following lid sets:

STA - greases in NLGI grades 1 and 2

LG - greases in NLGI grades 000-0

OS - oils

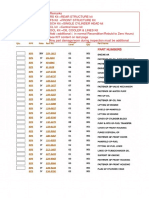

Quantity Value Unit Description

t 10 to +50 C Operating temperature range

p

max

390 bar Max. lubricant pressure

p

ratio

1:65 bar Pressure ratio

U 2032V DC V Operating voltage

P 1.5 W Power consumption

Q 850 grams/min Pump output

Q_p 5.5 grams/stroke Stroke output

V 18 kg = 1/8 kg Lubricant drum sizes

50 kg = 1/4

180 kg = 1/1

m 6.3 kg Weight, 1/8 pump

7.6 Weight, 1/4 pump

8.8 Weight, 1/1 pump

Aluminium, Plastic and Steel Body material

650x130x130 mm Dimensions, 1/8 pump

920x130x130 Dimensions, 1/4 pump

1020x130x130 Dimensions, 1/1 pump

IP65 Protection class

For all systems described in this bro-

chure, see important product usage

information on the back cover.

NOTE!

SKF EPB pump designations

Example:

SKF-EPB-PUMP-1/8-STA

SKF-EPB-PUMP

SKF-EPB-PUMP SKF Electro-pneumatic Barrel Pump

Drum capacity 1/1 = 180 kg

1/8 Lubricant barrel capacity: 18 kg

1/4 Lubricant barrel capacity: 50 kg

1/1 Lubricant barrel capacity: 180 kg

Lid set

STA The pumping unit is fixed on the lubricant barrel.

ECO The pumping unit is connected to a follower plate

placed inside the lubricant barrel. This allows

the pump to follow the lubricant level.

SKF-EPB-PUMP - 1/8 - STA

2

Capacity

The table on the left presents the key per-

formance values of the SKF EPB pump. The

table allows you to check the output of the

pump in the current counter pressure and

air pressure. The table also shows the air

consumption of the pump.

Example:

In Indication (1), the pressure air input is 6

bar, and the counter pressure (Indication 2)

is 285 bar, which gives a lubricant output of

330 g/min. (Indication 3). To determine the

air consumption, follow the 6 bar dashed

line to Indication 4 and draw a horizontal

line to the air consumption scale (Indication

5; 180 l/min).

Connections

Symbol Description

A Pressure air

P/C Power supply/Control

P Pressure

T Tank

20

20

20

20

100

120

140

160

180

200

220

240

260

280

300

320

340

360

380

400

0

0

25

50

75

100

125

150

175

200

225

250

275

300

325

l/min

3 bar

4 bar

1.

5 bar

6 bar

6

b

a

r

5

b

a

r

4

b

a

r

3

b

a

r

100 200

bar

300 400 500 600 700 800 900 1000g/min

2.

4.

3.

5.

EPB pump capacity

Output

Air

consumption

Lubricant pressure

3

SKF is a registered trademark of the SKF group.

SKF Group 2013

The contents of this publication are the copyright of the publisher and may not be reproduced (even extracts) unless prior written permis-

sion is granted. Every care has been taken to ensure the accuracy of the information contained in this publication but no liability can be

accepted for any loss or damage whether direct, indirect or consequential arising out of the use of the information contained herein.

PUB LS/P8 12810 EN January 2013

Printed in Sweden on environmentally friendly paper.

SKF lubrication systems

E-mail: skf-lube@skf.com

Bearings and units Seals

Lubrication

systems

Mechatronics Services

The Power of Knowledge Engineering

SKF brings innovative solutions to OEMs and production facilities in every major industry worldwide.

These solutions draw on five areas of competence and application-specific expertise amassed over 100

years.

These five competence areas include bearings and units, seals, lubrication systems, mechatronics

(combining mechanics and electronics into intelligent systems), and a wide range of services, from 3D

computer modelling to advanced condition monitoring and reliability and asset management services.

A global presence provides SKF customers with uniform quality standards and universal product

availability.

Model Prefix Product code

Pumps

SKF-EPB-PUMP-1/1-ECO VGBN 12381510

SKF-EPB-PUMP-1/4-ECO VGBN 12381520

SKF-EPB-PUMP-1/8-ECO VGBN 12381530

SKF-EPB-PUMP-1/1-STA VGBN 12381540

SKF-EPB-PUMP-1/4-STA VGBN 12381550

SKF-EPB-PUMP-1/8-STA VGBN 12381560

Installation kits

INSTALLATION KIT-ECO EPBP VGBV 12381354

INSTALLATION KIT-STA EPBP VGBV 12381353

Lid sets

MAX-LIDSET-1/1-ECO-EPBP VGBV 12381325

MAX-LIDSET-1/4-ECO-EPBP VGBV 12381315

MAX-LIDSET-1/8-ECO-EPBP VGBV 12381305

MAX-LIDSET-1/1-STA-EPBP VGBV 12381345

MAX-LIDSET-1/4-STA-EPBP VGBV 12381335

MAX-LIDSET-1/1-OS-EPBP VGBV 12381346

MAX-LIDSET-1/4-OS-EPBP VGBV 12381347

MAX-LIDSET-1/1-LG-EPBP VGBV 12381348

MAX-LIDSET-1/4-LG-EPBP VGBV 12381349

Pressure air regulator

MAXILUBE-SET-ECO-EPBP VGBV 12382677

MAXILUBE-SET-STA-EPBP VGBV 12382678

Power supply unit

EPBP-UNIPOWER 24V 0.63A 100-240V VGBV 12381505

!

Important information on product usage

All products from SKF may be used only for their intended purpose as described in this

brochure and in any instructions. If operating instructions are supplied with the products, they

must be read and followed.

Not all lubricants are suitable for use in centralized lubrication systems. SKF does offer an

inspection service to test customer supplied lubricant to determine if it can be used in a central-

ized system. SKF lubrication systems or their components are not approved for use with gases,

liquefied gases, pressurized gases in solution and fluids with a vapor pressure exceeding normal

atmospheric pressure (1 013 mbar) by more than 0,5 bar at their maximum permissible

temperature.

Hazardous materials of any kind, especially the materials classified as hazardous by European

Community Directive EC 67/548/EEC, Article 2, Par. 2, may only be used to fill SKF centralized

lubrication systems and components and delivered and/or distributed with the same after

consulting with and receiving written approval from SKF.

Installation kits

The installation kits contain components to

adapt the existing pneumatic and electrical

connections to the EPB-pump.

skf.com/lubrication

Você também pode gostar

- 008 Luis MoirerasDocumento35 páginas008 Luis Moirerasjaymuscat100% (1)

- 2 - 15B Ah-5vomDocumento1 página2 - 15B Ah-5vomMamiherintsoa Issaia RanaivoarimananaAinda não há avaliações

- C18 Industrial Engine SN WJH-WRH Part Book PDFDocumento200 páginasC18 Industrial Engine SN WJH-WRH Part Book PDFMuhammad Taupik KurrahmanAinda não há avaliações

- ISO 6743-2 - 1981 - Part. 2 - Family F - Spindle Bearings, Bearings and Associated ClutchesDocumento4 páginasISO 6743-2 - 1981 - Part. 2 - Family F - Spindle Bearings, Bearings and Associated ClutchesMassimiliano VolaAinda não há avaliações

- Astm d7720 PDFDocumento14 páginasAstm d7720 PDFRodrigo Andres Vallejo Castro100% (1)

- Franco Tosi MeccanicaDocumento15 páginasFranco Tosi MeccanicamassimocalviAinda não há avaliações

- Ceha PDFDocumento17 páginasCeha PDFMIGUELAinda não há avaliações

- Shims SKF TMAS Series Inch SizeDocumento2 páginasShims SKF TMAS Series Inch SizeFendyAinda não há avaliações

- PVWJ Open Loop Pumps: Bulletin 47085Documento24 páginasPVWJ Open Loop Pumps: Bulletin 47085CARLOS RAMIREZ100% (1)

- Ird 880 ManualDocumento97 páginasIrd 880 ManualEnrique Javier González HenríquezAinda não há avaliações

- 822882743-SC-EQ-0012 Bombas de MisturaDocumento98 páginas822882743-SC-EQ-0012 Bombas de MisturaKaren Katiuscia100% (1)

- ZZ5371VDMD30101specification TT SinotrukDocumento1 páginaZZ5371VDMD30101specification TT SinotrukJesus AlvarezAinda não há avaliações

- Model 7600: NDIR Infrared Gas AnalyzerDocumento126 páginasModel 7600: NDIR Infrared Gas Analyzerzulfiqar aliAinda não há avaliações

- Safe Seal ScanpumpDocumento4 páginasSafe Seal ScanpumpHector MaldonadoAinda não há avaliações

- 951 130 407 enDocumento26 páginas951 130 407 enli geneAinda não há avaliações

- Altronic Iii: Ignition System For Industrial EnginesDocumento4 páginasAltronic Iii: Ignition System For Industrial EnginesClever NegreteAinda não há avaliações

- Upa 150c Ing.Documento7 páginasUpa 150c Ing.Alfredo HerreraAinda não há avaliações

- Catalog HydrSeals PDE3350-GB Pgs63-66Documento4 páginasCatalog HydrSeals PDE3350-GB Pgs63-66claudioandrevalverdeAinda não há avaliações

- Maintenance Interval Schedule c15 MCW PDFDocumento3 páginasMaintenance Interval Schedule c15 MCW PDFVictor NunezAinda não há avaliações

- American Marsh 480seriesDocumento16 páginasAmerican Marsh 480seriesfabian blancoAinda não há avaliações

- 8008 ControlSwitches EK00 III enDocumento8 páginas8008 ControlSwitches EK00 III enLaurence Malanum100% (1)

- ISO 6743 - 1 - Total Loss SystemDocumento10 páginasISO 6743 - 1 - Total Loss SystemNokiabhre WijayaAinda não há avaliações

- Acople Nara CatalogDocumento48 páginasAcople Nara Catalogmarcelo castillo100% (1)

- PARTS LIST (Model EC4, ECT4, ECC4)Documento2 páginasPARTS LIST (Model EC4, ECT4, ECC4)Sajjad RasoolAinda não há avaliações

- Ahlstar: Process PumpsDocumento1 páginaAhlstar: Process Pumpsapi-3759223Ainda não há avaliações

- HH125 Smanual Completed - Master Updated 30-3-06Documento41 páginasHH125 Smanual Completed - Master Updated 30-3-06jacklyn ade putra0% (1)

- DM 7 Mfe 5BW 3S 37 Vogel DatasheetDocumento8 páginasDM 7 Mfe 5BW 3S 37 Vogel DatasheetMixailAinda não há avaliações

- RT10 Torque ChartDocumento2 páginasRT10 Torque ChartRoy Ramos100% (1)

- 318 100 - Falk UltraMax Type FC, FZ, Sizes 2040 2130 Gear Drives - Installation ManualDocumento14 páginas318 100 - Falk UltraMax Type FC, FZ, Sizes 2040 2130 Gear Drives - Installation Manualbasavaraj patil100% (1)

- Catalogo Filtros Coreanos - JHF QDDocumento7 páginasCatalogo Filtros Coreanos - JHF QDGabriel Escarcena RoblesAinda não há avaliações

- 25713-220-V2A-MPY0-00089 Manual Giw Español PDFDocumento271 páginas25713-220-V2A-MPY0-00089 Manual Giw Español PDFFERNANDA ARLETTIS TORRESAinda não há avaliações

- PH 474A-K - Synthetic Gear Oil - Extreme Pressure (EP)Documento4 páginasPH 474A-K - Synthetic Gear Oil - Extreme Pressure (EP)dfbdfbfdbfbAinda não há avaliações

- Spray Nozzle PlanoDocumento10 páginasSpray Nozzle Planor7510mAinda não há avaliações

- Rla / Rlva: Single-Stage Steam TurbineDocumento2 páginasRla / Rlva: Single-Stage Steam TurbineMauricio GuanellaAinda não há avaliações

- Rovalve PDFDocumento4 páginasRovalve PDFWilliam ValenciaAinda não há avaliações

- Catalogo de Conectores Hidraulicos PARKER PDFDocumento86 páginasCatalogo de Conectores Hidraulicos PARKER PDFgbobadillaAinda não há avaliações

- EXXI-4130-00-00-VD-MAN-5251 - 00x-Sellos MecanicosDocumento33 páginasEXXI-4130-00-00-VD-MAN-5251 - 00x-Sellos MecanicosrodolfostiAinda não há avaliações

- Durco 1K 1.5 X 1-82Documento9 páginasDurco 1K 1.5 X 1-82jame11inAinda não há avaliações

- Turbine RepfairDocumento2 páginasTurbine Repfairasanka136Ainda não há avaliações

- Mi Ether CatalogDocumento76 páginasMi Ether CatalogcirclelineAinda não há avaliações

- Pump ZM B PDFDocumento12 páginasPump ZM B PDFRamon PachecoAinda não há avaliações

- Gefico Brochure +UFDocumento40 páginasGefico Brochure +UF1zorro10% (1)

- Mobile Cylinder Div.: Dump Product & Quick Reference GuideDocumento56 páginasMobile Cylinder Div.: Dump Product & Quick Reference GuideMario JayaAinda não há avaliações

- Pieces de Rechange Pompe A Lobe Alfa Laval OptilobeDocumento13 páginasPieces de Rechange Pompe A Lobe Alfa Laval OptilobeMahmoud FathyAinda não há avaliações

- g3616 A4 Lehw0198 FinalDocumento4 páginasg3616 A4 Lehw0198 FinalVictor NunezAinda não há avaliações

- Sundyne Gearbox Reliability Upgrade KitDocumento2 páginasSundyne Gearbox Reliability Upgrade Kitjamil ahmedAinda não há avaliações

- DG Pump Catalague PDFDocumento20 páginasDG Pump Catalague PDFJonas ArifinAinda não há avaliações

- Hypro Housing Fa-Mf3Documento4 páginasHypro Housing Fa-Mf3Roberto Torres ArancibiaAinda não há avaliações

- 1887 125HP Union TD 120 Triplex Sour Pump PackageDocumento11 páginas1887 125HP Union TD 120 Triplex Sour Pump PackageIvan Jojic100% (1)

- 3604 SMN-JWR PDFDocumento7 páginas3604 SMN-JWR PDFsaharaAinda não há avaliações

- J620V22 enDocumento4 páginasJ620V22 enMartin KratkyAinda não há avaliações

- Pump Engineering MSRODocumento2 páginasPump Engineering MSROLeonel RubioAinda não há avaliações

- WorthingtonCreyssensac Rollair 40-150E Leaflet en 6999010301-LRDocumento12 páginasWorthingtonCreyssensac Rollair 40-150E Leaflet en 6999010301-LRpragnesh prajapati100% (1)

- AISI 1045 Medium Carbon Steel - AZoMDocumento4 páginasAISI 1045 Medium Carbon Steel - AZoMLuis NunesAinda não há avaliações

- Chester Air Chain Hoist DataDocumento1 páginaChester Air Chain Hoist DataTheEnginnerdAinda não há avaliações

- SL020 PDFDocumento3 páginasSL020 PDFchidambaram kasiAinda não há avaliações

- PSI PumpsDocumento12 páginasPSI PumpsagiacomuzoAinda não há avaliações

- Keystone Atuador de Dupla Ação Pneumático PDFDocumento8 páginasKeystone Atuador de Dupla Ação Pneumático PDFdiforaAinda não há avaliações

- Piston Pumps Paste-Thickened Tailings PB-PPPT-0215 LowresDocumento10 páginasPiston Pumps Paste-Thickened Tailings PB-PPPT-0215 LowresMartin Lara100% (1)

- Plano Cat D6RDocumento2 páginasPlano Cat D6Redhuam100% (4)

- RENR5806Documento2 páginasRENR5806Ebied Yousif AlyAinda não há avaliações

- Senr 8570Documento2 páginasSenr 8570Ebied Yousif AlyAinda não há avaliações

- 16H Motor Grader Hydraulic System: 6ZJ1-UPDocumento2 páginas16H Motor Grader Hydraulic System: 6ZJ1-UPTino B OLAinda não há avaliações

- RENR5353Documento2 páginasRENR5353Ebied Yousif AlyAinda não há avaliações

- Iso 4260 1987 FR en PDFDocumento8 páginasIso 4260 1987 FR en PDFWilliam Orellana CarballoAinda não há avaliações

- Proth Psgs Manual PDFDocumento106 páginasProth Psgs Manual PDFBala SingamAinda não há avaliações

- Experiment 10 - Quantitative Determination of The Purity and Dissociation of Potassium Hydrogen Phthalate by Potentiometric Titration AtqDocumento3 páginasExperiment 10 - Quantitative Determination of The Purity and Dissociation of Potassium Hydrogen Phthalate by Potentiometric Titration AtqDoom RefugeAinda não há avaliações

- Merck Index Front MatterDocumento14 páginasMerck Index Front MatterCristian Meneguzzi100% (1)

- Thin Layer ChromatographyDocumento497 páginasThin Layer ChromatographyFrancimauroAinda não há avaliações

- Title, Abstract, Introduction, Literature Review-BogaDocumento20 páginasTitle, Abstract, Introduction, Literature Review-Bogaasheesh87Ainda não há avaliações

- Glazing A - IKA Group - Silicone Sealant Indonesia 1Documento4 páginasGlazing A - IKA Group - Silicone Sealant Indonesia 1Riry SuprianaAinda não há avaliações

- 1-6 Chemical Reactions of Alkanes and AlkenesDocumento2 páginas1-6 Chemical Reactions of Alkanes and AlkenesBryan100% (1)

- SISTO - Maintenance-Free Diaphragm Valves With and Without LiningDocumento2 páginasSISTO - Maintenance-Free Diaphragm Valves With and Without LiningsharemwAinda não há avaliações

- Bilge and Ballast PipingDocumento9 páginasBilge and Ballast PipingAwalia SulastriAinda não há avaliações

- Matrices, Retainers, Wedge Placement. Separation of The Teeth. The Protective Role of Liners and BasesDocumento42 páginasMatrices, Retainers, Wedge Placement. Separation of The Teeth. The Protective Role of Liners and BasesFatimah DewiAinda não há avaliações

- SERIES 7000 Paste Slakers: Fully Automated Lime Slaking SystemsDocumento4 páginasSERIES 7000 Paste Slakers: Fully Automated Lime Slaking Systemssoumyarm942Ainda não há avaliações

- Quintessence of The PhilosophersDocumento32 páginasQuintessence of The PhilosopherstravellerfellowAinda não há avaliações

- Solid Waste Management For HouseholdDocumento70 páginasSolid Waste Management For HouseholdsonAinda não há avaliações

- Energy Notes 1Documento4 páginasEnergy Notes 1api-491081853Ainda não há avaliações

- 1 s2.0 S2213453022000052 MainDocumento12 páginas1 s2.0 S2213453022000052 MainIsraa MustafaAinda não há avaliações

- Inoxpran Coffee MakerDocumento4 páginasInoxpran Coffee MakerelvisandmickAinda não há avaliações

- Analysis of Trihalomethanes: and Related Pentane-Extractable Organic HalidesDocumento33 páginasAnalysis of Trihalomethanes: and Related Pentane-Extractable Organic HalidesaviantaraAinda não há avaliações

- Chapter-6 Tissues-Full NotesDocumento12 páginasChapter-6 Tissues-Full NotesAdithya VinodAinda não há avaliações

- SK017 Paper2 Sem1 0708Documento3 páginasSK017 Paper2 Sem1 0708shehdilanunAinda não há avaliações

- 2004 - JMS - Jain & GuptaDocumento17 páginas2004 - JMS - Jain & GuptasemantAinda não há avaliações

- ASTM C1240-15Microsilica Specification 硅灰Documento7 páginasASTM C1240-15Microsilica Specification 硅灰杨过Ainda não há avaliações

- Ver 3.0 - Test Series - NEET - Schedule (XII & RM) - Code-A - BDocumento3 páginasVer 3.0 - Test Series - NEET - Schedule (XII & RM) - Code-A - BCorona virusAinda não há avaliações

- Classics in Chemical Neuroscience: Diazepam (Valium) : Nicholas E. Calcaterra and James C. BarrowDocumento8 páginasClassics in Chemical Neuroscience: Diazepam (Valium) : Nicholas E. Calcaterra and James C. BarrowEga Trikuntianti100% (1)

- CHEM 141 Lab 3 (Stoichiometry) ProcedureDocumento5 páginasCHEM 141 Lab 3 (Stoichiometry) ProcedureKiersten RobertsAinda não há avaliações

- Aerospace Material Specification: (R) Gas Nitriding of Low-Alloy Steel PartsDocumento10 páginasAerospace Material Specification: (R) Gas Nitriding of Low-Alloy Steel PartsVIJAY YADAVAinda não há avaliações

- Thesis On Plastic Waste ManagementDocumento7 páginasThesis On Plastic Waste Managementhwxmyoief100% (1)

- SMC EIA Final Report - Baseline ReportDocumento54 páginasSMC EIA Final Report - Baseline ReportGary JopsonAinda não há avaliações

- Anchor Bolt For Brick MasonryDocumento11 páginasAnchor Bolt For Brick MasonryEdmond Chow100% (1)

- MCAT Topic Focus Biology Electrophoresis and Blotting FSQ DrillDocumento1 páginaMCAT Topic Focus Biology Electrophoresis and Blotting FSQ DrillAnjalie GulatiAinda não há avaliações