Escolar Documentos

Profissional Documentos

Cultura Documentos

Cost Estimate Membrane Cell Project

Enviado por

N PrasaddDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Cost Estimate Membrane Cell Project

Enviado por

N PrasaddDireitos autorais:

Formatos disponíveis

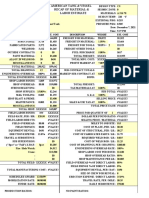

Sr

No

BC

(Current Density = 4.5KA/m2)

BC

(Current Density = 4.8KA/m2) BCCL

120 120 Conversion 225 TPD

I

1 Cost of land 0 0 0.00

2 Site development 45 45 15.00

3 Factory Building 553 553 590.05

4 Residential 120 120 109.96

718 718 715.01

II Plant & Machinery

a)

1994.36 1871.42 3468.83

b)

1 Brine Plant 691.00 691.00 753.70 For BC, though capacity is less , Primary brine is additional.

2 Salt Handling 79 79 27.00

3 Electrolyzer Plant 328 244.7 117.60

4 Caustic Concentration 0 0 690.59

5 De-Chlorination & Chlorate Destruction 200.00 200.00 72.45 Most of the exisitng facilities are considered in BCCL.

6 Hydrogen Handling & hook-up 239 239 11.00 In BC, Hydrogen compression is additional.

7 Catholyte Circulation 40.00 40.00 59.05

8 Chlorine treatment 62 62 69.00

9 Chlorine liquefaction 435 435 57.00 Existing facilities are considered for BCCL.

10 Chlorine evaporation 0 0 0.00

11 Chlorine Filling 35 35 10.00

12 Chlorine tonners 780 780 400.00

13 HCl Plant 359 359 7.90

14 Sodium Hypo 125 125 171.05

15 Utilities 192 192 114.21 Most of the exisitng facilities are considered for BCCL.

16 Piping & Valves and structurals 450 450 309.05

17 Electricals 995 963 1106.37

18 Instruments including DCS 548.2 545.8 322.45

19 Insulation & Painting 78 78 43.50

20 Miscellenous 24 24 24.00

21

Duties P&F transport, Insurance etc @ 10% of the

Indigenous items only. 566.02 554.25 436.59

6226.27 6096.80 4802.51

III

300.00 300.00 439.81

IV

426.03 413.41 435.56

V Pre-Operative Expenses

a) 46.47 46.47 43.56

b) 18.14 18.14 87.11

c) 18.14 18.14 15.00

d) 7.25 7.25 260.70

For BCCL: Estimate for fixed cost and customer retention cost during shut

down

VI

a) 219.48 213.52 336.19 Calculated actual

b) Working capital margin (25% of the net working capital) 120.0 120.0 110.00

VII Contingencies (5% of total cost before contingency) 504.71 491.16 535.71

10,598.84 10,314.30 11,249.99 GRAND TOTAL

Insurance

Start-up exp.

Travelling

Other

Others

Interest during construction period (3% of project cost)

CIVIL

Imported Equipment (Landed cost of proprietory

equipment including engineering.

Indigenous equipment

Total

Detailed Engg., Supervision, overseas travel (other than

engg. Know-how included in II (a)

Erection ( 5% of expenses excluding land & buildings

and civil cost)

BLOCK COMPARISON FOR MEMBRANE CELL PLANTS

Estimate in (Rs. In Lacs)

DESCRIPTION

Remarks

Plant Capacity (TPD)

A

S. No. Description

Birla Cellulosic 120 TPD (Kharach) BCCL (225 TPD)

Civil Work

1 Buildings

1.1 Salt godown 120.0 0 existing

1.2 Brine Plant 28.0 61.18

2 Electrolyser Room & Rectifier Room 180.0 201.9

3 Cl2 & H2 processing compression,

liquification & storage (Including filling

shed)

108.0 25.0

4 Utilities like Chilled water DM plant , Air,

boiler, etc (500 m2 @ Rs 6000 m2)

18.0 13.2

5 Foundations

5.1 For Storage tanks (Caustic,Cl2 & HCl ) 11 15.35

5.2 Other than considered in respective areas 5.0 34.00

5.3 Aux transformers & MCC etc. 11.0 41.50 **

6 Others (Sludge Pits, Drains , Sludge to

collection pits, Epoxy paints & pump etc.)

27.0 77.06

***

7 Caustic Concentration

Plant not required

76.45

8 Roads for Plant 30.0 25.02

9 RCC Pipe rack Column 15.0 19.33

Total 553.0 590.05

B Residential Building

1 Residential Building 120 109.96

** This also includes the control room.

*** This also includes the demercuriser.

Amounts in Lacs (INR)

Back

D6 Cell:

Area 2000 m2 @ Rs. 6000 / m2 Comment:

D7 Cell:

Area 400 m2 @ Rs 7000/m2 Comment:

E7 Cell:

Area 1107 m2 @ Rs 5740/m2 Comment:

D9 Cell:

Area 1500m2 @ Rs 12000/m2 Comment:

E9 Cell:

Area 2111m2 @ Rs 12075/m2 Comment:

D11 Cell:

Area 1440m2 @ Rs 7500/m2 Comment:

E11 Cell:

Area 350m2 @ Rs 7143/m2 Comment:

D13 Cell:

Area 300m2 @ Rs 6000/m2 Comment:

E13 Cell:

Area 264m2 @ Rs 488.5/m2 Comment:

C26 Cell:

35 Lacas for Jr block+85 Lacs for 2E Blocks + 30 Lacs for D block Comment:

D26 Cell:

35 Lacas for Jr block+85 Lacs for 2E Blocks + 30 Lacs for D block Comment:

E26 Cell:

16.85 - A type one block, 27.65 -B type one block, 20.18-C type one block, 19.31-W family one block, 26.00 Comment:

modification of guard barrack & A type.

Sr. No Description

BCCL (225 TPD)

At Current Density 4.8 KA/m2 At Current Density 4.5 KA/m2 At Current Density 4.8 KA/m2

1 Proprietary Equipment -

Electrolysers along with

associated components including

membrane

1871.42 1994.36 3468.83

Total 1871.42 1994.36 3468.83

3

Proprietary Equipment

Amount in lacs (INR)

Birla Cellulosic 120 TPD (Kharach)

Back

D6 Cell:

Current Density = 4.8 KA/m2 & 274 elements X Rs6.83 Lacs/ element (See backup for detail) Comment:

2 Electrolyzers -13 KA

E6 Cell:

Current Density = 4.5 KA/m2 & 292 elements X Rs6.83 Lacs/ element (See backup for detail) Comment:

3 Electrolyzers -13 KA

F6 Cell:

Current Density = 4.8 KA/m2 Comment:

& 508 elements @ Rs6.83Lacs

GRCD (For 50 Elements) BCCL 508 element

1 547500 5484150

2

27375

3

574875

4

57

4

50

5

11498

6

655358

7

32768

8

688125

9

110100

8

798225

9

110100

10

688125

11

13763

12

701888

13

7.02 6.830

14

0.90 0

7.92

6.83

Handling cost including transport @ 2%

Landed cost per element without membrane

Average cost per element in Rs Lacs

Membranes

Total per element

Total per element considered by BCCL (Refer Sheet BCCL Prop)

Add Duty @ 5%

Sub Total

CVD @ 16%

Sub Total

Less Modvat of CVD

Cost

Add frieght & Insurance @ 5%

Total

Exchange Rate

No of elements

Total cost per element ( In Euro at CIF Mumbai)

Total cost per element (In Rs at CIF Mumbai) @ 1E = Rs 57

Frame Gaskets

Gore-Tex sealing cord

Flange bolting system

Inlet & outlet hoses

Cost of elements

Break-up of an Element cost

Basis UHDE's Offer No. 05-96-50401/008 dt 27.10.2003

Cost of 50 Nos Uhde IIIrd generation element includes 50 Nos Anode half shells with coated electrodes 50 Nos

Cathode halfshells with coated electrodes 50 sets accessories, consisting of :

Spacers

Insert Pipes

Steel Frames

I15 Cell:

FOB 547,500 EURO at German sea port Comment:

J15 Cell:

EURO 5223000X105% at CIF India port including cost of membrane Comment:

ANNEXURE - I

Calculations for Element Cost Rs. In Lacs

A

1 3,180.81

2 3,212.62

3 160.63

4 539.72

5 117.39

6 539.72

7 10.00

3,468.83

B Imported Electrical Items (Isolators/Breakers/Shunts)

C

Total 3468.83

Cost per Element 6.83

Less ED

Travelling Expenses

SUB TOTAL - I

Indigenous Mechanical Estimate for Cell House, Cell Work Shop and

Rectifier Area

IMPORTED (508 Elements including Membrane)

License, Basic Engg and Proprietary supply including supervision (CIF Indian Port

basis) ( 5223000 X 105% Euro)XRs.58.00

Assessable Value @1% of 1

Custom duty @5% of 2

Excise duty @ 16% of (2+3+4)

Bank charges, custom clearance, inland transport and misc.@ 3% of (2+3+4+5+6)

Sr. No Description

Birla Cellulosic 120 TPD

(Kharach)

BCCL (225 TPD)

1

Brine Saturators 20

15.00

2

Reaction Tank 32

12.00

3

Agitator With motor 18

15.00

4

Air Blower for Agitation 4

not required

5

Reagent tanks with agitators for

BaCO3, Na2CO3, NaOH, HCl,

NaHSO3 & Alfa cellulose

12

8.00

6

Reagent Dosing pumps with motors

for BaCO3, Na2CO3, NaOH, HCl,

NaHSO3 & Alfa cellulose

10

6.00

7

Charging device for BaCO3,

Na2CO3, NaHSO3 & Alfa cellulose

8

manual

8

Water seal clarifier with accessories 70

75.00

9

Sludge Decanter (For 100 TPD) 30

existing

10

Slurry Pump with motor 2

existing

11

Clarified Brine Tank 8

8.00

12

Clarified Brine pump with motor 12

existing

Brine Filtration

13

Anthracite filters & piping 50

25.00

14

Filtered brine pump with motor 12

15.00

17

Polishing filters (Schumacher) 192

212.00

18

Polished brine pump with motor 12

16.00

19

Recuperator 16

22.00

Secondary Brine Purification

20

Ion Exchange column with all

accessories

90 225.00

21

Recovered brine pump with motor 2

existing

22

Pure brine head tank 3

3.60

23

Brine Heat Exchanger 13

existing

24

Alkaline Waste brine tank

7 9.00

25

Ion Exchange Effluent tank 8

10.00

26

Effluent Pump 1

1.00

27

Seal Pressurization pump 2

2.50

28

Seal water tank 1

1.50

29

Polishing Filter sludge tank 7

9.00

30

Ion Exchange Sludge pump 4

5.00

31

Cell Drain Tank 4

5.00

32

Cell Drain pump 1

1.00

33

Body Feed Tank 2

2.50

34

32% HCl head tank 2

3.00

35

UPSV Tank 3

4.00

36

H2 Condensate Tank 1

1.00

37

H2 Cooler 8

10.00

38

H2 Recuperator 10

14.00

39

Body Feed Pump 2

2.60

40

Precoat Pump 6

7.50

41

H2 Condensate Pump 2

2.50

42

Precoat Tank 4

5.00

43

Demercuriser 0

15.00

Total

691.00 753.70

Brine Plant

Amounts in Lacs (INR)

Back

Sr No Description

Birla Cellulosic120

TPD (Kharach)

BCCL (225 TPD)

1 Bucket Elevator with Gear

& motor (10 - 15 T/Hr)

16

19.00

2 Hopper (MOC SS) with

vibration feeder & its

power unit (10-15 T/hr)

8

6.00

3 Belt Conveyor

(Reversible)

2

existing

4 Platform 1

existing

5 Foundations 2

existing

6 Pay Loader 15

considered in P&B

7 Steel structures 5

2.00

8 Salt Godown conveyors

with trippers

30

existing

79 27

Salt Handling

Amount in Lacs (INR)

Back

Sr No Description

Birla Cellulosic

120 TPD (Kharach)

2 electrolysers

Birla Cellulosic

120 TPD (Kharach)

3 electrolysers

BCCL (225

TPD)

1 Catholyte Header (PP-FRP)

40 60

2 Anolyte Header (FRP-HT)

20 30

3 Anolyte Header / Catholyte feed header (PP)

8 12

4 Cell Rack ( MS / Copper Conductor)

46 69

5 Imported Valves (PFA)

43.2 64

6 Indegeneous Valves (MSRL)

6 9

7 Filters (PFA)

5 7.5

8 Cell Workshop items eg. Hoist, tables etc.

40 40

9

32% Caustic Cooler 4.5 4.5

6.00

10

Overhead Crane (EOT) 30 30

30.00

11

Cl2 Seal 2 2

2.00

Total 244.7 328 117.6

Cell House

Amount in Lacs (INR)

79.6

Back

Sr.

No.

Item MOC

Qty./

Electrolyser

Cost /

Electrolyser

(Rs. In Lacs)

Total

Qty.

Total Cost

(2 electrolysers)

(Rs. In Lacs)

Total Cost

(3electrolysers) (Rs.

In Lacs)

1 Cell Catholyte Header PP/ FRP 1 Set 20.00 2 Set 40.00 60.00

2 Cell Anolyte Header FRP-HT 1 Set 10.00 2 Set 20.00 30.00

3 Brine & Catholyte Feed Header PP 1 Set 4.00 2 Set 8.00 12.00

4 Cell Rack MS/ Copper

Conductor

3 Nos 23.00 6 Nos. 46.00 69.00

5 Imported Valves PFA Lot 21.60 Lot 43.20 64.00

6 Indegeneous Valves MSRL Lot 3.00 Lot 6.00 9.00

7 Filters PFA 2 Nos. 2.50 4 Nos. 5.00 7.50

8 Cell Workshop 40.00 40.00

Grand Total 84.10 208.20 291.50

Estimate of Mechanical Items for Electrolyser

Sr. No Description

Birla Cellulosic 120

TPD (Kharach)

BCCL (225 TPD)

1

Anolyte tank (Depleted brine) 5

19.95

2

Vacuum Tank (Dechlorinator) 6

existing

3

Vacuum pumps with motors 13

12.00

4

Separator with cooler 1

1.50

5

Vapour Condenser (Dechlorination

Cooler)

7.0 6.0

6

Lean Brine pump with motor 12

existing

7

Chlorinated water pump (Condensate

) with motor

1

existing

8

Overhead tank for NaOH & NaHSO3 3

2.00

9

Chlorate Destruction tank 15

15.00

10

Chlorate feed Pump with motor 16

16.00

11

Pipe & Support for entire brine plant 33

12

Valves in brine areas other than

Secondary brine purification

13

13

Structures 25

Structurals Head

14

Foundations for various equipments

like saturator, purifier, clarifier, filters

etc.

50

Civil head

Total 200.00 72.45

Dechlorination

Amounts in Lacs (INR)

Piping & Valves

Head

Back

Sr No Description

Birla Cellulosic 120 TPD

(Kharach)

BCCL (225 TPD)

1 Gas Holder Buffer vessel is considered

in place of Gas holder

existing

2 Buffer Vessel 6

0

3 Safety Seal 1

1.00

4 Flame arrestor 2

2.00

5 Heat Exchanger 5

8.00

6 H2 Compressor with all associated

equipments & manifolds

225

0

Total 239 11

Hydrogen Handling

Amounts in Lacs (INR)

Back

E10 Cell:

15 manifoldsX 10 Lacs= 150 + 75 for piping, washing, foundation etc. Comment:

Total = 225 lacs

Sr. No Description

Birla Cellulosic 120

TPD (Kharach)

BCCL (225

TPD)

1

Catholyte Tank 6

16.00

2

Catholyte Pump 12

13.46

3

Caustic Heat Exchanger 16

20.00

4

Caustic OH tank for cell house 2

3.75

5

Intermediate Caustic Tanks 4

5.84

Total

40.00 59.05

Catholyte Circulation

Amounts in Lacs (INR)

Back

Sr No Description

Birla Cellulosic

120 TPD

(Kharach)

BCCL (225 TPD)

1 Absorption Towers complete with internals

25

2 Titanium Centrifugal pumps

15

3 Ti plate heat exchanger

5

4

Piping & Fittings

4.1 FRP

15

4.2 CS

3

5 Refrigeration System

7

6 Valves

11

4 Tanks

13.5

7 Insulation

3

8 Structural supports

2

9 Instruments - Lot

5

10 Electricals- Lot

8

11 Civil Work ( Building, Foundations, Brick lining

& other works)

7.5

12 Misc. & Contengencies

5

Total 125 0

Sodium Hypo

Amount in lacs (INR)

Back

Cost Estimation of Sodium Hypo Plant for Mercury Cell Plant.

In place of secondary tower existing lime scrubber will be used,therefore partial generetion of

Calcium Hypo will take place.

1 FRP absorption towers complete 5.00 In place of secondary tower existing lime scrubber

with internals, etc. - 1 No. will be used

2a Titanium centrifugal pumps - 2 Nos 4.75 One pump to be arranged in house

with motors.

2b Dilute caustic pump with motor- 2 nos. 0.00 Inhouse (CSF condensate water storage tank with

pump will be used)

2c Hypo transfer pump with motor-2 Nos. 1.43

2d Chilled water pump with motor- 2 nos 1.34

3a Titanium plate heat exchanger 1.67

- 1 Nos.

3b SS plate heat exchanger 0.31

- 1 Nos.

4 Piping & Fittings

FRP 6.00 For Cl2 service PVC piping considered.

CS 4.00

5 Refrigeration System 50 TR 0.00 Existing chilled water system considered.

- 1 Nos.

6 Valves 4.00 Tower, heat exchanger & dump tank

isolation valve not considered

7a Tanks FRP Hypo circulation for main 4.20

tower 2 nos

7b Tank FRP Hypo circulation for second 0.00 Not required

tower 1 nos

7c Tank hypo storage 1 No 3.25

7d Tank MS 1 No. 0.00 Inhouse (CSF condensate water storage tank with

pump will be used)

8 Insulation 3.00

9 Structural supports 2.00

10 Instruments - Lot 2.00

11 Electrical cables. - lot 4.00

MCC 2.30 Spare feeders not available

with existing MCC

12 Civil works,

Building 2.00 Minimized building cost

Foundations 1.50

Brick Lining & Other works 1.00

13 Misc. & contingencies 2.70

GRASIM INDUSTRIES LIMITED

CHEMICAL DIVISION

OPTION-2

S.No. Items

Amount

(Rs. in

Lakhs)

Remarks

Grand Total (1 to 13) 56.45

In place of secondary tower existing lime scrubber will be used,therefore partial generetion of

In place of secondary tower existing lime scrubber

One pump to be arranged in house

Inhouse (CSF condensate water storage tank with

For Cl2 service PVC piping considered.

Existing chilled water system considered.

Tower, heat exchanger & dump tank

isolation valve not considered

Inhouse (CSF condensate water storage tank with

Spare feeders not available

GRASIM INDUSTRIES LIMITED

CHEMICAL DIVISION

OPTION-2

Remarks

Sr No Description

Birla Cellulosic

120 TPD

(Kharach)

BCCL (225 TPD)

1 Heat Exchanger (Cl2 Gas / Brine) Shell & tube

16 22.00

2 Heat Exchanger (Cl2 Gas / Cooling Water)

Shell & tube

15 20.00

3 Heat Exchanger (Cl2 Gas / Chilled Water)

Shell & tube

10 12.00

4 Mist Eliminator

13 15.00

5 H2SO4 handling system inclusive of tanks &

pumps with motors & piping

8 existing

Total 62 69

Chlorine Treatment

Amount in lacs (INR)

Back

Sr No Description

Birla Cellulosic 115

TPD (Kharach)

BCCL (225 TPD)

1 Drying tower (5 Tray tower with

distributor, acid circulation pump, motor,

Acid cooler, acid separators, piping

valves & instruments etc.

existing

2 Chlorine compressor unit (Liquid ring

compressor, acid coolers, acid separators

, piping, valves & instruments etc.

32.00

3 Chlorine Liquification unit (Screw

compressors , Oil cooler, Oil Separators ,

Refrigerant condenser, Refrigerant

receiver, Cl2 Liquefier , Surge Drum,

22.00

4 Chilled Water Unit / VAM ( Chilled water

tank, pumps , valves & piping with

instruments

44 3.00

5 Chlorine storage tank (60 T) 100 existing

6 Chlorine valves for Cl2 storage tanks

(Calobri-Italy or Descote - France)

41

not required

Total

435 57

Chlorine Liquifacation

Amount in lacs (INR)

250

Back

E5 Cell:

1x45 TPD Liq. Cl2 capacity. Comment:

F5 Cell:

2x50TPD liq. Cl2 capacity Comment:

E9 Cell:

3 tanks are considered Comment:

F9 Cell:

4 tanks are considered Comment:

Sr No Description

Birla Cellulosic 120 TPD

(Kharach)

BCCL (225

TPD)

1 Filling Post with auto

weighing

15 5.00

2 Cranes 20 5.00

Total

35 10

Filling Station

Amount in lacs (INR)

Back

Sr No Description

Birla Cellulosic 120 TPD

(Kharach)

BCCL (225 TPD)

1 Chlorine tonners 780 400

Total

780 400

Chlorine Tonners

Amount in lacs (INR)

Back

C4 Cell:

RK SHAH: Comment:

100 TPD NaOH =45TPD Liquid Cl2 =50Tonners per day =1000Tonners required.

D4 Cell:

1) 100 TPD NaOH = 45 TPD Liq Cl2 prodn & 45 TPD HCl Prodn)= 50 Tonner per day = 1500 tonners Comment:

required

2) Rotation / month = 1

3) Cost / Tonner= Rs 44,000

E4 Cell:

1) 120 TPD NaOH = 86.25 TPD Liquid Cl2 = 96 tonners per day = 1950 tonners required Comment:

2) Rotation / Month = 1.5

3) Cost / tonner = Rs 40000

F4 Cell:

1000 Nos. @ Rs 40000 Comment:

Sr No Description

Birla Cellulosic

120 TPD

(Kharach)

BCCL (225 TPD)

1 Furnace with all

accessories with civil cost

of plant

350

existing

2 Acid transferring pump 3

existing

3 DM water tank 3 4.50

4 DM water pumps 3 3.40

Total

359 7.9

HCl Plant

Amount in Lacs (INR)

Back

F5 Cell:

2 furnace of 50 TPD Comment:

G5 Cell:

2 furnace of 50 TPD Comment:

H5 Cell:

2 furnace of 25 TPD Comment:

Sr No Description

Birla Cellulosic

120TPD (Kharach) BCCL (225 TPD)

1 DM water plant 55 53.00

2 Cooling tower (Additional cell, Cold water

pump, Piping , Valve & motor

30 19.36

3 Air Compressor with motor 16 12.00

4 Air Drying Unit 4 2.50

5 Nitrogen Unit 5 8.00

TANK FARM

1 Caustic storage tank (MS) 30 existing

2 Caustic Transfer Pump with motor 4 5.00

3 HCl storage tank (FRP) 26 existing

4 HCl Transfer pump with motor 5 existing

5 DM water supply pump 2 2.35

6 DM water Storage tank (MSRL) 15 12.00

Total

192 114.21

UTILITIES

Amt in Lacs (INR)

Back

E13 Cell:

4 tanks considered Comment:

F13 Cell:

4 tanks considered Comment:

G13 Cell:

2 tanks considered Comment:

Sr. No. Description

Birla Cellulosic 120

TPD (Kharach)

BCCL (225 TPD)

1 Pipe Rack - Structural Steel

50 Civil Head

2 Piping for Brine , Caustic, Cl2, HCl

including cell house except

individual cell headers

350 295.05

3 Piping for Air , N2, Water, steam

etc.

50 14.00

Total 450 309.05

General Piping

Amount in Lacs (INR)

Back

Sr No Description

Birla Cellulosic 120 TPD

(2electrolyser)

Birla Cellulosic 120 TPD

(3electrolyser)

BCCL (225 TPD)

1 Rectiformer with associated accessories

and DC bus bars, breakers, isolators, pol.

Rectifier, voltage monitoring systems etc.

688.00 720.00 909.38

2 Breaker Panel 35 35

37.80

3 Aux. Transformer 10 10

existing

4 Control Cables, Push button station, panel

etc

16 16

5.25

5 Cable for I/C Rectifier , Aux. Transformer 27 27

21.00

6 Main DB 27 27

21.59

7 Bus Duct - 2 Nos. 5 5

not required

8 MCCs 50 50

41.00

9 L.T. Cables for MCCs & power & control

cables for motors

40 40

26.25

10 Misc. (Earthing , Cable trays, structures,

insulators, lighting & protection system)

25 25

31.50

11 Capacitor Bank for Power factor

improvement

10 10

12.60

12 Harmonic Filter 15 15

integeral part of 11

13 Emergency power - 500 KVA DG Set 10 10

existing

14 Telephones & PA System 5 5

existing

Total 963 995 1106.37

Electrical

Amount in Lacs (INR)

Back

C5 Cell:

( 33 KV 50 Hz. 3 Ph & 30- KA, 400 V DC Thyrister type ) with Bus Bars, Isolators etc. (Including Polarisation rectifier if required) Comment:

D5 Cell:

( 33 KV 50 Hz. 3 Ph & 40- KA, 400 V DC Thyrister type ) with Bus Bars, Isolators etc. (Including Polarisation rectifier if required) Comment:

E5 Cell:

(11 KV, 50 Hz, 3 Ph & 2x20 KA , 400 V DC thyrister type) with bus bars, isolators etc. Comment:

F5 Cell:

(11 KV, 50 Hz, 3 Ph & 2x20 KA , 400 V DC thyrister type) with bus bars, isolators etc. Comment:

G5 Cell:

(22 KV, 50 Hz, 3 Ph & 2x30 KA , 430 V DC thyrister type) with bus bars, isolators etc. Comment:

C6 Cell:

33 KV , 6 Nos Comment:

D6 Cell:

33 KV , 6 Nos Comment:

E6 Cell:

11 KV , 4 nos Comment:

C7 Cell:

1000 KVA- 2 nos Comment:

D7 Cell:

1000 KVA- 2 nos Comment:

E7 Cell:

1600 KVA - 2nos Comment:

1x 40 KA 2 x 20 KA 1x 40 KA 2 x 20 KA

Rectiformer 350.00 550.00 350.00 550.00

DC Halmar System 14.00 16.00 14.00 16.00

DC Breaker Isolator & Shunt 36.00 36.00 24.00 24.00

Copper/Aluminium Bus bar flexible 60.00 66.00 40.00 46.00

Voltage monitoring system 25.00 25.00 25.00 25.00

DC Battery station 3.00 3.00 3.00 3.00

Polarisation rectifier 2.00 2.00 2.00 2.00

Air washery system 5.00 7.00 5.00 7.00

Mulsifire fire/Fire Hydrant 10.00 15.00 10.00 15.00

Total 505.00 720.00 473.00 688.00

ESTIMATE FOR RECTIFORMER

Rs. In lacs

Birla Cellulosic

11 KV

3Electrolyzers

Birla Cellulosic

11 KV

2Electrolyzers

Sr No Description

Birla Cellulosic

120TPD (2

electrolysers)

Birla Cellulosic

120TPD (3

electrolysers)

BCCL (225 TPD)

1 Instruments other than considered in respective

areas (DCS, Control Valves, Load cells, pressure

gauges, temperature gauges, level gauge,

transmitters, rotameters, pH meters, Gas detector,

Safety valves, Cables etc.

548 545.8 322.45

Total

548.2 545.8 322.45

Instruments & DCS

Amounts in Lacs (INR)

Back

Sno Description Qty Unit Price Total

1 I/P Converter 25 0.150 3.75

2 Temperature Transmitters 13 0.400 5.20

3 Pressure & Level switch 20 0.100 2.00

4 Rotameters(Glass Tube) 16 0.100 1.60

5 Magnetic Flow Meter (+2) 8 1.750 14.00

6 PH & ORP Transmittters 5 1.000 5.00

7 Density Transmiter 1 7.000 7.00

8 Control Valves( Chemtrol & Xomox) 29 0.700 20.30

9 On-Off Butterfly control valves 2 1.900 3.80

10 Metal tube Rotameter with Transmitter( 3 electroly) 6 1.000 6.00

11 Metal tube Rotameter without Transmitter 10 0.700 7.00

12 Pressure & Level Transmitters 34 1.250 42.50

13 Pressure Gauges 65 0.050 3.25

14 Air Headers 12 0.200 2.40

15 Imported Control valves 33(On/off)+8(Control Valves) 41 1.650 67.65

16 Dial Thermometer 43 0.015 0.65

17 Thermowell 48 0.050 2.40

18 Manometers 35 0.075 2.63

19 24X1.5 mm2 Armoured cable @ Rs.125/- 5000 125 6.25

20 12 pair X 0.75 Armoured shielded cable @ Rs.125/- 3000 125 3.75

21 2 pair x 0.75 mm2 armoured cable@ Rs. 60.00 2160 60.000 1.30

22 I pair x 0.75 mm2 Unarmoured shielded cable @ Rs.25/- 2000 25 0.50

23 I pair x 0.75 mm2 Armoured shielded cable @ Rs.35/- 4500 35 1.58

24 3 core x 1.5 mm2 Unarmoured cable @ Rs.30/- 500 30 0.15

25 3 core x 1.5 mm2 Armoured cable @ Rs.45/- 3000 45 1.35

26 1x0.2 mm2 wire @ Rs.2.5 1000 2.5 0.03

27 Steel for cable trays 35 0.3 10.50

28 Fitings (ss & brass) Lot 0.75

29 Copper tube 2000 50 1.00

30 SS Tubing 500 75 0.38

31 DCS & its accessories Lot 150.00

32 Erection & Mislenious Lot 12.00

33 UPS for control (Redundant) 18.00

34 Primary brine Transmitter (Level & pressure) 6 1.5 9.00

35 Temp.Transmitters (+1) 3 0.4 1.20

36 Ph Transmitters 1 1 1.00

37 Control Valves (0-100%) 5 1.5 7.50

38 On-Off control valves for 3 filters 18 1 18.00

39 Pressure gauges & Rotameters 40 0.05 2.00

40 Junction Boxes 30 0.15 4.50

447.84

41 65 TPD Compressor scheme ( 3 Cl2 + 2 Freaon) Lot 30.00

42 25x2 Tpd HCl Furnace (2 Nos) Lot 68.00

545.84 Lacs 322.45

0

GRAND TOTAL 2 Electrolysers

322.45

0

Instrumentation Cost

BCCL

BCCL's estimate is

prepared by

technology supplier

Sr. No. Description

Birla Cellulosic

120 TPD

(Kharach)

BCCL (225 TPD)

1

Insulation for Cl2

Liqufication & storage units,

steam lines & Boiler piping.

38 30.00

2

Painting 40 13.50

Total 78 43.5

Painting & Insulation

Amount in Lacs (INR)

Back

Sr No Description

Birla Cellulosic

120 TPD

(Kharach)

BCCL (225 TPD)

1 Safety appliances

8 6

2 Other Items (Vehicles, Stores/ Office furniture

/Equipments, etc)

5

5

3 Laboratory

11 13

4 Weigh bridge

0 existing

5 Fire Fighting

0 existing

Total

24 24

MISCELLANEOUS EQUIPMENT

Amounts in Lacs (INR)

Back

Sr. No Description

Birla Cellulosic 120 TPD (2

electrolysers)

Birla Cellulosic 120 TPD

(3electrolysers)

BCCL (225 TPD)

IEC FABCHEM

(5 TPD)

10 TPD

1 Salt Handling 79.00 79.00 27.00 19.75

2 Brine Plant 691.00 691.00 753.70 172.8

3 Catholyte Circulation 40.00 40.00 59.05 10

4 Dechlorination 200.00 200.00 72.45 50

5 Proprietory equipment 1871.42 1994.36 3468.83 460.4 553.4971

6 Cell House 244.70 328.00 117.60 61.2

7 Cl2 Treatment 62.00 62.00 69.00 0

8 Cl2 Liquifaction 435.00 435.00 57.00 0

9 Cl2 Filling 35.00 35.00 10.00 0

10 Cl2 tonners 780.00 780.00 400.00 0

11 H2 Handling 239.00 239.00 11.00 59.8

12 HCl 359.00 359.00 7.90 0

13 Sodium Hypo 125.00 125.00 171.05 31.25

14 Caustic Concentrator Plant 0.00 0.00 690.59 0

15 CSF Plant 0.00 0.00 0.00 0

16 General Piping 450.00 450.00 309.05 112.5

17 Electrical 963.00 995.00 1106.37 240.8

18 Instruments + DCS 545.84 548.24 322.45 136.5

19 Utilities 192.00 192.00 114.21 49.6

20 Misc Equipment 24.00 24.00 24.00 6

21 Paint & Insulation 78.00 78.00 43.50 19.5

Total 7413.96 7654.60 7834.75 1354.78

Total 10% of Indigenous Part 554.25 566.02 436.59

61.78300833 63.78834167 34.82111556

15.59516667 16.61966667 15.41702222 92.078 55.34971

FREIGHT, FORWARDING, INSURANCE, HANDLING CHARGES & DUTIES

Amt in lacs (INR)

Back

Sr No Description

Birla Cellulosic

120 TPD (Kharach)

BCCL (225 TPD)

1 Supervisory fee

2 Basic Engineering & Know How

3 Detailed engineering fee

Total 300.00 439.81

Detailed Engg, Supervision

Amount in Lacs (INR)

300.00 439.81

Back

Sr No Description

Birla Cellulosic 120

TPD (2 electrolysers)

Birla Cellulosic 120

TPD (3electrolysers)

BCCL (225 TPD)

1 Salt Handling

79 79

27.00

2 Brine Plant

691.00 691.00

753.70

3 Catholyte Circulation 40.00 40.00 59.05

4 Dechlorination 200.00 200.00 72.45

5 Cell House 244.7 328 117.60

6 Proprietory Equipment 1871.42 1994.36 3468.83

7 Cl2 Treatment 62 62 69.00

8 Cl2 Liquifaction 435 435 57.00

9 Cl2 Filling 35 35 10.00

10 Cl2 tonners 780 780 400.00

11 H2 Handling 239 239 11.00

12 HCl 359 359 7.90

13 Sodium Hypo 125 125 171.05

14 Caustic Concentrator Plant 0 0 690.59

15 CSF Plant 0 0 0.00

16 General Piping 450 450 309.05

17 Electrical 963 995 1106.37

18 Instruments + DCS 545.841 548.241 322.45

19 Utilities 192 192 114.21

20 Misc Equipment 24 24 24.00

21 Paint & Insulation 78 78 43.50

22 Packing & Forwarding 554.25 566.02 436.59

23

Detailed Engg , Supervision &

Travelling expenses

300.00 300.00 439.81

Total 8268.22 8520.63 8711.15

Erection Charges @ 5% 413.41 426.03 435.56

ERECTION EXPENSES

Amount in Lacs (INR)

Back

Sr No Description

Birla Cellulosic

120TPD (Kharach)

BCCL (225 TPD)

1 Insurance 46.47 43.56

2 Travelling 18.14 15.00

3 Start up 18.14 87.11

4 Other 7.25 260.70

Total 90.00 406.37

Preoperation

Amount in Lacs (INR)

Back

Description Amount in Lacs (INR)

Imported Items

Furnace along with accessories like

preheater, gas train, burner etc. 175

Flaker & Flaker Vat 125

Custom duty , freight , Insurance etc @10

% of 300 30

Sub Total 330

Critical Ni Items

HE-01 50

EV-01 30

HE-02 60

EV-02 45

EV-03 30

Double Syphon with Piping 15

HE-03 35

HE-04 8

HE-06 15

HE-08 10

Molten Salt Tank 10

Molten Salt Pump 35

Interstage Pump 15

Various Level Pots 3

Seal Pots 5

EV-03 Outlet Pipe 5

Break Tank, Sugar Tank,Sugar

Preparation Tank, Condensate Tank 6

Ni Piping 20

Sub Total 397

Indigenous Equipment

Air Fan (2 Nos) 3

H2 Blowers 2 nos 4

Air Compressors 2 nos 4

Cooling tower 1 no Bigger size 15

Air Drying Unit 2

HE-801 5

Cranes 2 nos 5

DM Water Pumps (1 no) 0.5

Caustic & condensate pumps ( 8 nos) 4

Vacuum Pumps (2 nos) 3

Sugar Dosing pump (2 nos) 1

Effluent Pump (2 nos) 1

Cold Water Pumps (2 Nos) 1

Screw conveyor with bagging system 10

Stitching machine 3

Caustic storage tanks 25

Air Recievers (2 nos) 4

Fuel Oil Tanks (2 nos) 10

Sniff blower with motor (2 nos) 0.5

Prilling Tower 534.00

CSF PLANT (50 TPD)

44

Description Amount in Lacs (INR)

Sub Total 635

Piping Valves & Structures

SS Piping 10

MS Piping (Air, Water, Cooling Tower,

Natural Gas) 25

Molten Salt piping 20

Steam Piping ( HP) 6

Valves 15

Structures, Primary supports, Pipe racks

etc. 15

Insulation 15

Painting 15

Lab Equipment & Molten salt 8

Sub Total 129

Electricals

Motors (33 Nos) 9.75

MCC 9

Emergency MCC 2

Cables 10.2

Cables for Emergency Power 11

Push Buttons 0.75

Steel Strucures 5

Labours 4.8

Lightening 0.5

Sub Total 53

Civil

Civil Bldg. 18 MtrX12MtrX4 floors &

foundation for tanks, equipment & pipe

rack etc.

75

Instruments 40

Duties, P&F, Transport, insurance etc

@ 10% for indigenous items

125.4

Detailed Engg, Superviison, travel

5

Erection( 5% excluding land, bldg &

civil cost.

62.7

Intrest during construction period @

3% of project cost

56

Contingency @ 5% of total cost before

contingency

93

Grand Total 2000

45

Você também pode gostar

- Plant Cost EstimateDocumento29 páginasPlant Cost EstimateKevin J. MillsAinda não há avaliações

- Chlor Alkali Production CostsDocumento2 páginasChlor Alkali Production Costsemre_bozkurtAinda não há avaliações

- 5 - Equipment Cost EstimateDocumento8 páginas5 - Equipment Cost EstimateJose Yebra DeaunaAinda não há avaliações

- Capital Cost EstimatorDocumento14 páginasCapital Cost Estimatoramirho3einAinda não há avaliações

- Best Value Bid Weighting CalculatorDocumento28 páginasBest Value Bid Weighting Calculatormuhammad iqbalAinda não há avaliações

- WELCOME To Cost & Evaluation Workbook by Peters, Timmerhaus and West. Accompanying Plant Design and Economics For Chemical Engineers, 5th EditionDocumento15 páginasWELCOME To Cost & Evaluation Workbook by Peters, Timmerhaus and West. Accompanying Plant Design and Economics For Chemical Engineers, 5th Editionxhche7Ainda não há avaliações

- Dippr DataDocumento15 páginasDippr DataRussel BalinoAinda não há avaliações

- Haldor Topse SpecDocumento13 páginasHaldor Topse SpecRafiAinda não há avaliações

- Capital Cost Quinckly Calculated PDFDocumento8 páginasCapital Cost Quinckly Calculated PDFLeo Jiménez Montes100% (1)

- Easy-Pro Estimator v8 5Documento256 páginasEasy-Pro Estimator v8 5Franc Grošelj100% (1)

- Date: Project No: Purpose: Procedure: FeedDocumento5 páginasDate: Project No: Purpose: Procedure: FeedRogger Renato Salinas LopezAinda não há avaliações

- Equipment Cost Index Available I Exclusively From Marshall & SwiftDocumento2 páginasEquipment Cost Index Available I Exclusively From Marshall & Swiftrubench6Ainda não há avaliações

- Research Project ReportDocumento21 páginasResearch Project ReportinternationalbankAinda não há avaliações

- Jacobs Calculations 1Documento47 páginasJacobs Calculations 1BhattAinda não há avaliações

- Cost CurvesDocumento40 páginasCost CurvesNRK Ravi Shankar CCBMDO - 16 BatchAinda não há avaliações

- Pipe ScheduleDocumento2 páginasPipe Schedulepenny412100% (1)

- Est. Lbs. Est. Cost Description Weight Est. CostDocumento38 páginasEst. Lbs. Est. Cost Description Weight Est. Costsamy7354Ainda não há avaliações

- Molychem Pricelist 20192021 PDFDocumento160 páginasMolychem Pricelist 20192021 PDFPritish BiswalAinda não há avaliações

- LPG Physical PropertiesDocumento6 páginasLPG Physical PropertiesMugeshAinda não há avaliações

- Distillation CalculationDocumento9 páginasDistillation Calculationraviralagiri020% (1)

- NAWCPF-MSBI-NCPF-000-CV-RFQ-31072 - 001 - CPF-Civil Works-SOWDocumento45 páginasNAWCPF-MSBI-NCPF-000-CV-RFQ-31072 - 001 - CPF-Civil Works-SOWMouhebAinda não há avaliações

- Capcost 2008Documento15 páginasCapcost 2008Paulina BarrientosAinda não há avaliações

- Son My 1 Master ScheduleDocumento1 páginaSon My 1 Master ScheduleGaurav DuttaAinda não há avaliações

- Flujo de Caja - Costos de ProducciónDocumento11 páginasFlujo de Caja - Costos de ProducciónDanielIgnacioLuengoCordovaAinda não há avaliações

- Exothermic Dilution of Sulfuric AcidDocumento3 páginasExothermic Dilution of Sulfuric AcidAlvaro Benatti100% (1)

- TR CapexDocumento1 páginaTR Capexrahul281081Ainda não há avaliações

- WL130 PE4710 FM Approved Pipe: IPS & DIPS Pipe Sizes - Class 150, 200 & 267Documento3 páginasWL130 PE4710 FM Approved Pipe: IPS & DIPS Pipe Sizes - Class 150, 200 & 267Tanwir AhmadAinda não há avaliações

- Pipe Schedule PDFDocumento1 páginaPipe Schedule PDFMehmet YılmazAinda não há avaliações

- Bills ConversionsDocumento20 páginasBills ConversionssudhirbmaliAinda não há avaliações

- DAP & PAP Project Cost EstimateDocumento8 páginasDAP & PAP Project Cost EstimateSantosh JayasavalAinda não há avaliações

- D.M.Plant OperatorsDocumento5 páginasD.M.Plant OperatorsTiu TonAinda não há avaliações

- Costing Sheet For PlantDocumento84 páginasCosting Sheet For PlantmembranesAinda não há avaliações

- The Colors and Markings in This Workbook Have The Following MeaningsDocumento22 páginasThe Colors and Markings in This Workbook Have The Following Meaningsvvenkat123Ainda não há avaliações

- Cost Estimation of Fixed Roof (Cone) Carbon Steel Storage Tanks - CheresourcesDocumento3 páginasCost Estimation of Fixed Roof (Cone) Carbon Steel Storage Tanks - CheresourcesjkAinda não há avaliações

- Predict MIddle Distillate PropertiesDocumento8 páginasPredict MIddle Distillate PropertiesKumarAinda não há avaliações

- Detailed Unit Rate Estimating in Aspen Capital Cost EstimatorDocumento12 páginasDetailed Unit Rate Estimating in Aspen Capital Cost EstimatorOsama El-ShafieyAinda não há avaliações

- Piping CalculationDocumento19 páginasPiping CalculationYusri Fakhrizal100% (1)

- E0001 OverallDocumento30 páginasE0001 OverallkamlAinda não há avaliações

- Bw0404a Sc7 BurnDocumento96 páginasBw0404a Sc7 Burnoverlord5555Ainda não há avaliações

- Cepci 2008 2015Documento2 páginasCepci 2008 2015Chaerul AmienAinda não há avaliações

- Typical Project SequenceDocumento11 páginasTypical Project SequenceFrancisco Pires TavaresAinda não há avaliações

- Labor Cost For PipingDocumento148 páginasLabor Cost For PipingHenry San PedroAinda não há avaliações

- Copper 2010 ProgramDocumento44 páginasCopper 2010 ProgramCecilia Iter100% (1)

- Heat Exchanger RatingDocumento10 páginasHeat Exchanger RatingAnand BhiseAinda não há avaliações

- Ammonia Plant Selection, Sizing and Troubleshooting, Kolmetz Handbook of Process Equipment DesignDocumento24 páginasAmmonia Plant Selection, Sizing and Troubleshooting, Kolmetz Handbook of Process Equipment DesignHelena AdamAinda não há avaliações

- Reactor DesignDocumento31 páginasReactor DesignMortada OthmanAinda não há avaliações

- Capex Depreciation: #REF! Projec T'S ReqmtDocumento2 páginasCapex Depreciation: #REF! Projec T'S Reqmtjam mallillinAinda não há avaliações

- Project Cost EstimateDocumento6 páginasProject Cost EstimateVarun MalhotraAinda não há avaliações

- How To Prevent Caking in NPK Fertilizer Production ProcessDocumento2 páginasHow To Prevent Caking in NPK Fertilizer Production Processluna leAinda não há avaliações

- Econonmic Analysis in The Optimization of Belt Conveyor SystemsDocumento22 páginasEcononmic Analysis in The Optimization of Belt Conveyor SystemsTimber RamAinda não há avaliações

- FS - K.HILL BATTERY-GRADE MANGANESE PROJECT - K-Hill-FS-11142022Documento482 páginasFS - K.HILL BATTERY-GRADE MANGANESE PROJECT - K-Hill-FS-11142022girl2wise100% (1)

- DIPPR Thermophysical Properties Rev1Documento6 páginasDIPPR Thermophysical Properties Rev1Shailesh GhediyaAinda não há avaliações

- Cpi 2013Documento1 páginaCpi 2013Miguel Magat JovesAinda não há avaliações

- Design CalDocumento19 páginasDesign CalneelAinda não há avaliações

- Article Low Cost and Reliable Sulphur Recovery PDFDocumento4 páginasArticle Low Cost and Reliable Sulphur Recovery PDFpsnmurthy333Ainda não há avaliações

- VA1 DEC 00100 M M1D PHL 8202 - RevD PDFDocumento42 páginasVA1 DEC 00100 M M1D PHL 8202 - RevD PDFAnonymous JtYvKt5XEAinda não há avaliações

- Bkf4143-Process Engineering Economics 11213 PDFDocumento11 páginasBkf4143-Process Engineering Economics 11213 PDFJeevanNairAinda não há avaliações

- Work Done On Today: DCDB (220V-1No &48V-1No) ErectionDocumento47 páginasWork Done On Today: DCDB (220V-1No &48V-1No) ErectionGhritachi PaulAinda não há avaliações

- Sample 2x50MW Coal Fired Thermal Power Plant Proposal and QuotationDocumento6 páginasSample 2x50MW Coal Fired Thermal Power Plant Proposal and Quotationiwan_renaldiAinda não há avaliações

- 5 (EFC) Ujhani NPP PPT (Final)Documento11 páginas5 (EFC) Ujhani NPP PPT (Final)ATHARSBGAinda não há avaliações

- Quiz HMT Question PaperDocumento2 páginasQuiz HMT Question Papersutha_me20098282Ainda não há avaliações

- HV 60/125 Manifolds/Collectors For 2 and 3 Heating CircuitsDocumento1 páginaHV 60/125 Manifolds/Collectors For 2 and 3 Heating CircuitsHutan CatalynAinda não há avaliações

- D RP Heat Transfer Fluid: OwthermDocumento24 páginasD RP Heat Transfer Fluid: Owthermhmudassir_1Ainda não há avaliações

- Installation Instructions Spool Type Elastomer Expansion JointsDocumento2 páginasInstallation Instructions Spool Type Elastomer Expansion JointsAmina TaissaAinda não há avaliações

- Chapter 4 Molecular Diffusion in SolidsDocumento16 páginasChapter 4 Molecular Diffusion in SolidsrushdiAinda não há avaliações

- Mechanics of Materials: Shearing Stresses in Beams and Thin-Walled MembersDocumento26 páginasMechanics of Materials: Shearing Stresses in Beams and Thin-Walled MembersBeny FiriyaAinda não há avaliações

- Epiv Ultrasonic Tech DocumentationDocumento29 páginasEpiv Ultrasonic Tech DocumentationDaniel FigueiredoAinda não há avaliações

- Chapter Four Ogee SpillwayDocumento21 páginasChapter Four Ogee SpillwayhabtamuAinda não há avaliações

- Practice Problem Turbine Fans and Blower and CompressorDocumento3 páginasPractice Problem Turbine Fans and Blower and CompressorRey Regaspi Tuyay50% (2)

- Coring&Core AnalysisDocumento156 páginasCoring&Core AnalysisVi Dang100% (1)

- Vitas Check Valves Full OpeningDocumento4 páginasVitas Check Valves Full OpeningMina MagdyAinda não há avaliações

- UASB Upflow Anaerobic Sludg..Documento2 páginasUASB Upflow Anaerobic Sludg..Devendra BansalAinda não há avaliações

- Triaxial Test SoilDocumento26 páginasTriaxial Test SoilrockyminAinda não há avaliações

- Assignments Solution 1 PDF FinalDocumento10 páginasAssignments Solution 1 PDF FinalAliya A KhanAinda não há avaliações

- 10 Steps To A Better Rheological Measurement PDFDocumento44 páginas10 Steps To A Better Rheological Measurement PDFHílary VpbAinda não há avaliações

- Moving Bed ProcessorsDocumento11 páginasMoving Bed ProcessorsWaqar AhmedAinda não há avaliações

- Eden Project Case StudyDocumento2 páginasEden Project Case StudyTiara KusumaningtyasAinda não há avaliações

- CHAPTER 5 HydrotreatingDocumento41 páginasCHAPTER 5 HydrotreatingNurfarhana JelenAinda não há avaliações

- Practice Exercise - Elements - Terms #2 - Attempt ReviewDocumento12 páginasPractice Exercise - Elements - Terms #2 - Attempt ReviewDessa GuditoAinda não há avaliações

- Nachi Vane PumpDocumento10 páginasNachi Vane PumpengineermarkAinda não há avaliações

- Spe 120449 PaDocumento8 páginasSpe 120449 PaTECH JSC FHDAinda não há avaliações

- Continuum HypothesisDocumento2 páginasContinuum HypothesisS.h. Fahad FiazAinda não há avaliações

- PCS Ferguson Multi Stage Plunger Lift PresentationDocumento16 páginasPCS Ferguson Multi Stage Plunger Lift Presentationawise118750% (2)

- Pressure Surges: Resulting FromDocumento7 páginasPressure Surges: Resulting Fromshan07011984Ainda não há avaliações

- 7.1 Brief Introduction To Valves: 5Xeehu6Hdohg Dwh9DoyhDocumento7 páginas7.1 Brief Introduction To Valves: 5Xeehu6Hdohg Dwh9Doyhttplan800Ainda não há avaliações

- Vacuum Sewers 101Documento30 páginasVacuum Sewers 101George MustataAinda não há avaliações

- Expansion Joint CatalogDocumento84 páginasExpansion Joint CatalogAnonymous 7vljJzHAinda não há avaliações

- Ashrae Ic 90.1-2016-1Documento2 páginasAshrae Ic 90.1-2016-1widiantoekoAinda não há avaliações

- Modeling Arterial Blood Flow With Navier-StokesDocumento15 páginasModeling Arterial Blood Flow With Navier-Stokesapi-358127907100% (1)

- Automated Gas Permeameter: Core Analysis EquipmentDocumento2 páginasAutomated Gas Permeameter: Core Analysis EquipmentJean Carlos VillegasAinda não há avaliações