Escolar Documentos

Profissional Documentos

Cultura Documentos

RC Column Design BS8110

Enviado por

dantevarias0 notas0% acharam este documento útil (0 voto)

980 visualizações5 páginasDesign of Reinforced Concrete Column design using BS8110

Título original

RC COLUMN DESIGN BS8110

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDesign of Reinforced Concrete Column design using BS8110

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

980 visualizações5 páginasRC Column Design BS8110

Enviado por

dantevariasDesign of Reinforced Concrete Column design using BS8110

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 5

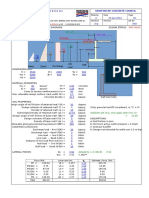

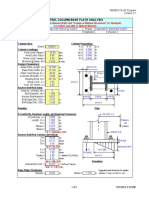

DESIGN OF UNBRACED RC COLUMN AND PEDESTAL Code : SS CP 65

Structure : Column Mark :

1. Design Loads Units : kN, kN-m

No. Condition LC # Beam # N* M

x

M

y

V

x

V

y Material Strength :

1 Max N 102 22 765.5 27.4 50.4 27.7 8.5

f

cu

= 30 Mpa

2 Min N 245 16 -14.2 132.1 2.2 4.6 27.4

f

y

= 460 Mpa

3 Max M

x 291 22 653.4 211.4 0.3 8.6 61.2

f

yv

= 460 Mpa

4 Min M

x

292 15 621.2 211.2 8.5 12.9 60.5

E

s

=

200000 Mpa

5 Max M

y 174 518 552.0 11.2 215.6 52.7 3.0

6 Min M

y 165 521 535.8 27.9 206.7 48.4 7.9

* (-) negative signs indicates tension force

2. End Condition and Effective Length (SS CP 65 Part 1 sec. 3.8.1.6)

12 - T20

Column Dimensions :

Top Bottom b = 550 mm

b

x

= 1.2 1 1 h = 550 mm

b

y

= 1.2 1 1 c.c. = 50 mm

l

ex

= b

x

(L

ox

)= 9900 mm l

ox

= 8250 mm

l

ey

= b

y

(L

oy

)= 9900 mm l

oy

= 8250 mm

L

ex

/h = 18 > 10 T13 @ 200

L

ey

/b = C2 > 10 Design as slender column.

3. Ultimate Design Moment

Units : kN-m, N/mm

2

No. M

addx

M

addy

M

tx

M

ty

M

tx

/h' M

ty

/b' M

u

M

u

/bh

2

M

u

/hb

2

N/bh

1 68.1 68.1 95.5 118.5 200.3 248.5 204.5 1.23 2.53

2 NA NA 132.1 2.2 276.9 4.6 134.3 0.81 -0.05

3 58.1 58.1 269.5 58.4 565.1 122.5 323.3 1.95 2.16

4 55.3 55.3 266.5 63.8 558.7 133.7 325.2 1.96 2.05

5 49.1 49.1 60.3 264.7 126.5 555.0 320.8 1.93 1.82

6 47.7 47.7 75.6 254.4 158.5 533.3 324.7 1.96 1.77

Formulas and Conditions for Ultimate Design Moment Calculation

Additional Moment (SS CP 65 Part 1 sec. 3.8.3)

Additional and Maximum Moment about X-axis Additional and Maximum Moment about Y-axis

k

x

= 1.0 e

miny

= 20 mm k

y

= 1.0 e

minx

= 20 mm

b

ax

= (l

ex

/b" )

2

/ 2000 b

ay

= (l

ey

/b" )

2

/ 2000 where : h' = effective depth along Y

= 0.162 = 0.162 = 477 mm

a

ux

= b

ax

k

x

h =

0.089 a

uy

= b

ay

k

y

b =

0.089 b' = Xeffective depth along Y

M

addx

= Na

ux

M

addy

= Na

uy = 477 mm

M

minx

= Ne

minx

M

miny

= Ne

miny b"= least column dimension

M

tx

= M

x

+ M

addx

> M

minx

M

ty

= M

y

+ M

addy

> M

miny

= 550 mm

Ultimate Design Moment for Biaxial Bending (Increase Moment about One Axis) (SS CP 65 Part 1 sec. 3.8.4.5)

when M

tx

/h' > M

ty

/b' , M

u

= M

tx

+ (bh'M

ty

) / b'

when M

tx

/h' < M

ty

/b' , M

u

= M

ty

+ (bb'M

tx

) / h' where : = 1 - 7/6 N / bh f

cu

> 0.3

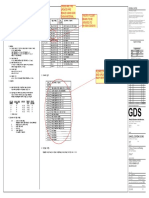

4. Arrangement of Reinforcement

Longitudinal Reinforcement

number of bar bar parallel to Y axis at one side n

y

= 4 , spacing = 134.7 mm <= 150.0

number of bar bar parallel to X at one side axis n

x

= 4 , spacing = 134.7 mm <= 150.0

Provide : 12 - T20 A

sc,min

= < Asc OK

A

sc

= 3,768.0 mm

2

A

sc

/bh =

1.25 %

Links Provided : T13 @200 mm no. of legs of links parallel to the Y axis = 2

no. of legs of links parallel to the X axis = 2

Minimum Diameter of Links : 6 mm satisfied Area of links parallel to Y axis A

svh

= 265.5

mm

2

Maximum Spacing of Links : 240 mm satisfied

Area of links parallel to X axis A

svb

=

265.5

mm

2

Table 3.22

1,210.0 mm

x

y

h

b

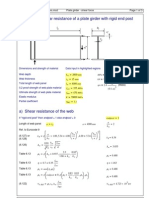

5. Capacity Analysis for N/bh - M

u

/bh

2

h' / h= 0.87

Capacity Check

No. N/bh M

u

/bh

2

Remarks

1 0 0

2 0 0

3 2.16 1.95 OK

4 2.06 1.96 OK

5 0 0

6 0 0

-10.00

-5.00

0.00

5.00

10.00

15.00

20.00

0.000 0.500 1.000 1.500 2.000 2.500 3.000 3.500 4.000

N

/

b

h

(

M

p

a

)

M

u

/bh

2

(Mpa)

INTERACTION CURVE N/bh - M

u

bh

2

CURVE

LOAD

6. Capacity Analysis for N/bh - M

u

/hb

2

b' / b= 0.87

BV

Capacity Check

No. N/bh M

u

/hb

2

Remarks

1 2.54 1.23 OK

2 0 0

3 0 0

4 0 0

5 1.83 1.93 OK

6 1.78 1.96 OK

-10.00

-5.00

0.00

5.00

10.00

15.00

20.00

0.000 0.500 1.000 1.500 2.000 2.500 3.000 3.500 4.000

N

/

b

h

(

M

p

a

)

M

u

/hb

2

(Mpa)

INTERACTION CURVE N/bh - M

u

hb

2

CURVE

LOAD

7. Check Of Shear Stress (sec. 3.8.4.6 SS CP65 Part 1)

Actual Concrete Shear Stress

Units : m , N/mm

2

No. M

x

/N Remarks M

y

/N Remarks V

x

/ hb' V

y

/ bh'

1 0.036 > 0.06h 0.066 > 0.06b 0.11 0.03

2 9.290 > 0.06h 0.155 > 0.06b 0.02 0.10

3 0.324 > 0.06h 0.000 > 0.06b 0.03 0.23

4 0.340 > 0.06h 0.014 > 0.06b 0.05 0.23

5 0.020 < 0.06h 0.300 < 0.06b 0.20 0.01

6 0.052 > 0.06h 0.300 > 0.06b 0.18 0.03

where :

0.6h = 0.033 m 0.6b = 0.033 m

Design Concrete Shear Stress (Table 3.9 of SS CP65 Part 1)

v

cy

= 0.84(100A

sy

/bh')

1/3

(400/h')

1/4

/

m

(f

cu

/30)

1/2

= 0.53 N/mm

2

; <= vmax

v

cx

= 0.84(100A

sx

/bh')

1/3

(400/b')

1/4

/

m

(f

cu

/30)

1/2

= 0.53 N/mm

2

; <= vmax

v

max

= 4.4 Mpa

Condition : if M

x

/N < 0.06h, M

y

/N < 0.06b, V

x

/hb' < v

cx

, and V

y

/bh' < vcY', Shear Check is not required

Modification of the design concrete shear stress: Sec 3.4.5.12 of SS CP65 Part 1)

Units : N/mm

2

No.

v

y

h/M

x

v

x

b/M

y

v'

cy

v'

cx

1 0.17 0.3 0.79 0.99

2 0.11 1 0.51 0.5

3 0.16 1 0.74 1.19

4 0.16 0.83 0.73 1.17

5 0.15 0.13 0.69 0.67

6 0.16 0.13 0.70 0.67

where : v'

cy

= v

cy

+ 0.6NV

y

h' / (M

x

A

c

) <= vcy [1 + N/(A

c

v

cy

)]

0.5

v'

cx

= v

cx

+ 0.6NV

x

b' / (M

y

A

c

) <= vcx [1 + N/(A

c

v

cx

)]

0.5

v

cx

= V

x

/hb'

v

cy

= V

y

/bh'

condition : if (v

x

/v'

cx

) + (v

y

/v'

cy

) < 1.0, provided minimum reinforcement

Design of shear reinforcement

Unit : N/mm

2

, kN

No.

v"

cy

V'

cy

V

sy

V

y

- V'

cy Remarks v"

cx

V'

cx

V

sx

V

x

- V'

cx Remarks

1 0.19 49.85 292.2 -41.35 OK 0.76 199.386 292.16 -171.69 OK

2 0.44 115.43 292.2 -88.03 OK 0.07 18.3645 292.16 -13.76 OK

3 0.65 170.53 292.2 -109.33 OK 0.15 39.3525 292.16 -30.75 OK

4 0.60 157.41 292.2 -96.91 OK 0.21 55.0935 292.16 -42.19 OK

5 0.04 10.49 292.2 -7.49 OK 0.63 165.2805 292.16 -112.58 OK

6 0.10 26.24 292.2 -18.34 OK 0.58 152.163 292.16 -103.76 OK

Where :

v''

cx

= v'

cx

v

x

/ (v

x

+ v

y

)

v''

cy

= v'

cy

v

y

/ (v

x

+ v

y

)

V'

cx

= v''

cx

bh'

V'

cy

= v''

cy

hb'

V

sx

= 0.87f

yv

A

svb

h / S

V

sy

= 0.87f

yv

A

svh

b / S

Condition : if V

sy

> V

y

-V'

cy

and V

sx

> V

x

-V'

cx

, OK (shear reinforcement is adequate)

Condition : if V

sy

< V

y

-V'

cy

and V

sx

< V

x

-V'

cx

, NG (shear reinforcement is not adequate)

0.34

0.36

0.32

0.32

Remarks

< 1.0 ,provide minimum.

< 1.0 ,provide minimum.

< 1.0 ,provide minimum.

< 1.0 ,provide minimum.

(v

x

/v'

cx

) + (v

y

/v'

cy

)

0.15

0.24 < 1.0 ,provide minimum.

< 1.0 ,provide minimum.

Remarks

shear check is required

shear check is required

shear check is required

shear check is required

shear check is required

shear check is required

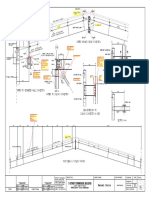

8. Biaxial Bending and Tension

Assuming that the lever arm to resist bending moment about each axis is the distance between the center of steel

reinforcement on each face.

a

x

= 404 mm, distance of center of steel reinforcement parallel at X axis

a

y

= 404 mm, distance of center of steel reinforcement parallel at Y axis

Unit : mm

2

No.

A

stx, required

A

stx, provided Remarks A

sty, required

A

sty, provided Remarks A

st, required

A

scor, required

A

scor, provided Remarks

1 0 1256 OK 0 1256 OK 0 0 314 no tension

2 817 1256 OK 14 1256 OK 36 217 314 OK

3 0 1256 OK 0 1256 OK 0 0 314 no tension

4 0 1256 OK 0 1256 OK 0 0 314 no tension

5 0 1256 OK 0 1256 OK 0 0 314 no tension

6 0 1256 OK 0 1256 OK 0 0 314 no tension

where :

Area of bars required on each face parallel to the x-axis: A

stx,required

= M

x

/ [ (f

y

a

x

/ 1.15) ]

Area of bars required on each face parallel to the y-axis: A

sty,required

= M

y

/ [ (f

y

a

y

/ 1.15) ]

Area of steel required for tension: A

st,required

= N / (f

y

/ 1.15)

Area of bars provided on each face parallel to the x-axis: A

stx,provided

Area of bars provided on each face parallel to the y-axis: A

sty,provided

Required area for one corner bar :

A

scor, required

= Astx,required / nx + Asty,required / ny + Ast,required / 4

Area of bar provided for one corner bar :

A

scor, provided

Você também pode gostar

- RCC61 Basement WallDocumento15 páginasRCC61 Basement WallMUTHUKKUMARAMAinda não há avaliações

- Load Combination and Flexural Design of Roof Deck BeamsDocumento123 páginasLoad Combination and Flexural Design of Roof Deck BeamsMarkAinda não há avaliações

- RC Beam Design (Cantilever)Documento7 páginasRC Beam Design (Cantilever)api-1975359867% (3)

- Staircase DesignDocumento45 páginasStaircase DesignHenRy Ngu 旭67% (3)

- Calculation On Sizing of SlabDocumento20 páginasCalculation On Sizing of SlabazhimsyammelAinda não há avaliações

- Beam Design To BS 8110Documento14 páginasBeam Design To BS 8110Gihan Chathuranga60% (5)

- Design of BeamsDocumento19 páginasDesign of BeamssnsatyanarayanaAinda não há avaliações

- Unbraced Short Column Design To BS 8110Documento8 páginasUnbraced Short Column Design To BS 8110Gihan Chathuranga100% (3)

- Design Procedure For Steel Frame Structures According To Bs 5950Documento46 páginasDesign Procedure For Steel Frame Structures According To Bs 5950Ali Gaffar100% (2)

- Inverted T FootingDocumento7 páginasInverted T FootingMohamed100% (2)

- Deflection Check (Beams BS 8110)Documento2 páginasDeflection Check (Beams BS 8110)dhanya1995Ainda não há avaliações

- PROKON - Plane Frame - Analysis - Example - BeamDocumento44 páginasPROKON - Plane Frame - Analysis - Example - BeamJames RamAinda não há avaliações

- Balcony Slab To BS 8110Documento5 páginasBalcony Slab To BS 8110gaza manAinda não há avaliações

- One Way Slab DesignDocumento4 páginasOne Way Slab DesignMario FeghaliAinda não há avaliações

- RCD Course Work PDFDocumento60 páginasRCD Course Work PDFSaciid LaafaAinda não há avaliações

- Slab With OpeningDocumento16 páginasSlab With OpeningTomislav Šimag100% (1)

- Column Design As Per BS 8110-1:1997: PHK/JSNDocumento16 páginasColumn Design As Per BS 8110-1:1997: PHK/JSNopulithe0% (1)

- Column Design BS8110Documento7 páginasColumn Design BS8110MinTzHo0% (1)

- RCC13 Punching ShearDocumento11 páginasRCC13 Punching ShearMUTHUKKUMARAMAinda não há avaliações

- 15 Footing DesignDocumento10 páginas15 Footing DesignLaura HernandezAinda não há avaliações

- Continuous BeamsDocumento450 páginasContinuous BeamssreenivasaeeAinda não há avaliações

- LECTURE NOTE 01 - RCC DesignDocumento14 páginasLECTURE NOTE 01 - RCC DesignMohamed AbdAinda não há avaliações

- Design of Inverted Strip Fdn. BeamDocumento7 páginasDesign of Inverted Strip Fdn. Beamakankwasa100% (4)

- One-Way Ribbed Slab Design As Per BS8110Documento5 páginasOne-Way Ribbed Slab Design As Per BS8110yusuf abdinasir100% (5)

- Unit 8 (SERVICEABILITY LIMIT STATE (SLS) )Documento26 páginasUnit 8 (SERVICEABILITY LIMIT STATE (SLS) )Zara Nabilah100% (2)

- BS8110 RC Beam DesignDocumento1 páginaBS8110 RC Beam DesignPcEng100% (1)

- Preliminary Structural DesignDocumento8 páginasPreliminary Structural Designaikaless100% (1)

- Column Design As Per BS 8110-1:1997: PHK/JSNDocumento16 páginasColumn Design As Per BS 8110-1:1997: PHK/JSNJennifer Tang100% (2)

- Structural Engineering - Slab Design To BS 8110Documento4 páginasStructural Engineering - Slab Design To BS 8110Gladson Js100% (2)

- Design of A UbDocumento8 páginasDesign of A UbGihan Chathuranga100% (1)

- British Standard Bs 8110Documento10 páginasBritish Standard Bs 8110م.عمرو عبداللهAinda não há avaliações

- One Ways Slab Design To BS 8110-1997Documento6 páginasOne Ways Slab Design To BS 8110-1997Gihan Chathuranga100% (9)

- Minimum Edge Distances As Identified in BS 5950Documento1 páginaMinimum Edge Distances As Identified in BS 5950Jagdish DhanuskarAinda não há avaliações

- Ribbed Slab Design TemplateDocumento4 páginasRibbed Slab Design Templateyusuf abdinasir75% (4)

- Two Way Design Slab To BS 8110Documento6 páginasTwo Way Design Slab To BS 8110Gihan Chathuranga100% (17)

- Slab DesignDocumento78 páginasSlab DesignWrishad Zia100% (25)

- Strap #1: Design AssumptionsDocumento27 páginasStrap #1: Design AssumptionsLeanna Abdul Wahab100% (4)

- Monolithic Staircase DesignDocumento5 páginasMonolithic Staircase DesignAzraiAzizAinda não há avaliações

- Design of Steel Baseplate To BS 5950 - PHILLIPS CONSULTING ENGINEERS LTDDocumento4 páginasDesign of Steel Baseplate To BS 5950 - PHILLIPS CONSULTING ENGINEERS LTDLavanyan SatchithananthanAinda não há avaliações

- BS8110 design of combined footingDocumento1 páginaBS8110 design of combined footingdantevarias83% (6)

- 2 - Portal FramesDocumento19 páginas2 - Portal FramesLesego Matojane100% (2)

- Unit 10 (TORSION)Documento22 páginasUnit 10 (TORSION)Zara Nabilah100% (3)

- Design of Beams To BS 8110Documento14 páginasDesign of Beams To BS 8110Kasun Karunaratne99% (76)

- Design Shear Resistance (Beams EC2)Documento2 páginasDesign Shear Resistance (Beams EC2)dhanya1995Ainda não há avaliações

- Design For RC Flat SlabsDocumento70 páginasDesign For RC Flat SlabsAil Aafaaq100% (3)

- Slab DesignDocumento28 páginasSlab DesignUlasi IfeanyiAinda não há avaliações

- Design of Lift Wall: Axial LoadDocumento3 páginasDesign of Lift Wall: Axial LoadSavithri Murthy50% (2)

- Lift Wall DesignDocumento4 páginasLift Wall DesignBajracharya A-sub25% (4)

- 10m R.C BEAM DESIGNDocumento3 páginas10m R.C BEAM DESIGNchris100% (1)

- Design of Timber Roof Truss To British Code - Solved Example - StructvilleDocumento9 páginasDesign of Timber Roof Truss To British Code - Solved Example - StructvilleDeRudy100% (3)

- Analysis and Design of SlabsDocumento3 páginasAnalysis and Design of Slabsdhanya1995100% (1)

- Design Strip FootingDocumento12 páginasDesign Strip FootingHenra HalimAinda não há avaliações

- Design steel column axial loadsDocumento2 páginasDesign steel column axial loadsGihan Chathuranga100% (1)

- Canal DesignDocumento35 páginasCanal DesignFranca-sp FrançaAinda não há avaliações

- CorbelDocumento6 páginasCorbelAsraf MuidinAinda não há avaliações

- Column Design - at Design OfficeDocumento56 páginasColumn Design - at Design OfficeShamen AmarasekaraAinda não há avaliações

- Ec9 Ex61 Shear No StiffenersDocumento3 páginasEc9 Ex61 Shear No StiffenersimotalpAinda não há avaliações

- Canal Trough DesignDocumento33 páginasCanal Trough DesignNageswar Pattem100% (10)

- RCC DESIGN CASE STUDYDocumento25 páginasRCC DESIGN CASE STUDYWHATS APP STATUSAinda não há avaliações

- Earthquakemodule 13Documento4 páginasEarthquakemodule 13dash1991Ainda não há avaliações

- Building Proposal To The MayorDocumento3 páginasBuilding Proposal To The MayordantevariasAinda não há avaliações

- FMM Novitiate Letter of Exemption To The MayorDocumento4 páginasFMM Novitiate Letter of Exemption To The MayordantevariasAinda não há avaliações

- FMM-BID-DOC-009 - Sworn Statement - R0Documento2 páginasFMM-BID-DOC-009 - Sworn Statement - R0dantevariasAinda não há avaliações

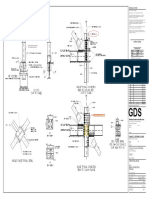

- Bracing Connection DetailDocumento1 páginaBracing Connection DetaildantevariasAinda não há avaliações

- 10.0 Tank FramingDocumento1 página10.0 Tank FramingdantevariasAinda não há avaliações

- FMM-BID-DOC-007 - Key Personnels Affidavit of Commitment To Work On The Contract - R0Documento2 páginasFMM-BID-DOC-007 - Key Personnels Affidavit of Commitment To Work On The Contract - R0dantevarias0% (1)

- Att-8 SPWS-7 Material SpecificationDocumento1 páginaAtt-8 SPWS-7 Material SpecificationdantevariasAinda não há avaliações

- SPWS-7 Structural Frame ConceptDocumento5 páginasSPWS-7 Structural Frame ConceptdantevariasAinda não há avaliações

- Att-1 SPWS-7 Structural Frame Overview and Canopy SizesDocumento1 páginaAtt-1 SPWS-7 Structural Frame Overview and Canopy SizesdantevariasAinda não há avaliações

- SPWS-7 Truss Design ResultDocumento5 páginasSPWS-7 Truss Design ResultdantevariasAinda não há avaliações

- SPWS-7 Load For Truss DesignDocumento3 páginasSPWS-7 Load For Truss DesigndantevariasAinda não há avaliações

- 5 STOREY GDS SCBF Connection DesignDocumento1 página5 STOREY GDS SCBF Connection DesigndantevariasAinda não há avaliações

- 12-S-01 General-ListDocumento1 página12-S-01 General-ListdantevariasAinda não há avaliações

- 14.0 RoofDetails - Drawing - Check - SHeetDocumento1 página14.0 RoofDetails - Drawing - Check - SHeetdantevariasAinda não há avaliações

- 13.0 BEAM Connection DetailsDocumento1 página13.0 BEAM Connection DetailsdantevariasAinda não há avaliações

- BASEPLT9.xls Program Version 3.7 Steel Column Base Plate AnalysisDocumento1 páginaBASEPLT9.xls Program Version 3.7 Steel Column Base Plate AnalysisNagender Kumar0% (1)

- Framing Plan 1Documento1 páginaFraming Plan 1dantevariasAinda não há avaliações

- 0.2 STeel Take - OFF - 36ksi - June19'16Documento1 página0.2 STeel Take - OFF - 36ksi - June19'16dantevariasAinda não há avaliações

- Load Combination For RC BuildingDocumento1 páginaLoad Combination For RC BuildingdantevariasAinda não há avaliações

- 34 S 23 VB1 - Check - SheetDocumento1 página34 S 23 VB1 - Check - SheetdantevariasAinda não há avaliações

- V5 Floor PlanDocumento1 páginaV5 Floor PlandantevariasAinda não há avaliações

- Column Splice Detail - June 28'16Documento1 páginaColumn Splice Detail - June 28'16dantevariasAinda não há avaliações

- Sample Load Calculation For 3 Sto BuildingDocumento1 páginaSample Load Calculation For 3 Sto BuildingdantevariasAinda não há avaliações

- Proposed 3-Storey Residential Building: 2.5.2 Tie Beam Design (Tb1) DesignDocumento1 páginaProposed 3-Storey Residential Building: 2.5.2 Tie Beam Design (Tb1) DesigndantevariasAinda não há avaliações

- Sample Analysis ModelDocumento1 páginaSample Analysis ModeldantevariasAinda não há avaliações

- ASCE 702 Wind Load AnalysisDocumento3 páginasASCE 702 Wind Load AnalysisdantevariasAinda não há avaliações

- Proposed 3-Storey Residential Building: 2.5 Reinforced Concrete DesignDocumento1 páginaProposed 3-Storey Residential Building: 2.5 Reinforced Concrete DesigndantevariasAinda não há avaliações

- Wind Load For Low Rise BuildingDocumento3 páginasWind Load For Low Rise BuildingdantevariasAinda não há avaliações

- WIND LOADING ANALYSIS - Roof Components and CladdingDocumento3 páginasWIND LOADING ANALYSIS - Roof Components and CladdingdantevariasAinda não há avaliações

- Wind Load For Building With All HeightDocumento4 páginasWind Load For Building With All HeightdantevariasAinda não há avaliações

- ASTM D430 06 - Standard Test Methods For Rubber Deterioration-Dynamic FatigueDocumento10 páginasASTM D430 06 - Standard Test Methods For Rubber Deterioration-Dynamic FatigueAndre Rodriguez SpirimAinda não há avaliações

- The Catholic Diocese of Satesme St. Joachim Boys'S Secondary School Form Three Physics Midterm Test 0ctober 2020Documento5 páginasThe Catholic Diocese of Satesme St. Joachim Boys'S Secondary School Form Three Physics Midterm Test 0ctober 2020Eddie Michael RwegasiraAinda não há avaliações

- Biplots of Compositional Data: University of Glasgow, UKDocumento18 páginasBiplots of Compositional Data: University of Glasgow, UKStefhany ArdilaAinda não há avaliações

- MIT18 05S14 Class26-SolDocumento20 páginasMIT18 05S14 Class26-SolYuvraj WaleAinda não há avaliações

- Projectile Motion Lab ReportDocumento6 páginasProjectile Motion Lab ReportThu Phuong LeAinda não há avaliações

- Modul Sesion 14: Lecturer: Dra. Hariani, M.PDDocumento11 páginasModul Sesion 14: Lecturer: Dra. Hariani, M.PDMfatanj100% (1)

- Lecture 3-ME2617 Forced Vibration of SDOF SystemsDocumento53 páginasLecture 3-ME2617 Forced Vibration of SDOF SystemsHamzah QadriAinda não há avaliações

- JEE Main 2021 - 24th February - Morning Shift - PaperDocumento14 páginasJEE Main 2021 - 24th February - Morning Shift - Paperjashan shuklaAinda não há avaliações

- Design of SHS PDFDocumento56 páginasDesign of SHS PDFAnonymous ptLRLiNNAinda não há avaliações

- I. Objectives:: Detailed Lesson Plan in Physics Grade 8Documento5 páginasI. Objectives:: Detailed Lesson Plan in Physics Grade 8Phranxies Jean BlayaAinda não há avaliações

- Micro-Proppant ReviewDocumento27 páginasMicro-Proppant ReviewMartin RylanceAinda não há avaliações

- PASAY CC9 - Q1 - Week 1Documento28 páginasPASAY CC9 - Q1 - Week 1SybieAinda não há avaliações

- GRP in Bypass Conditions and Temperatures Up To 300 CDocumento20 páginasGRP in Bypass Conditions and Temperatures Up To 300 CksshashidharAinda não há avaliações

- Lab 1 - Experiment On ElectrostaticsDocumento5 páginasLab 1 - Experiment On ElectrostaticsAbdoul BinJimAinda não há avaliações

- Leaks Using Bubble Emission Techniques: Standard Practice ForDocumento4 páginasLeaks Using Bubble Emission Techniques: Standard Practice Forsantiago barrionuevoAinda não há avaliações

- Haven 2018Documento16 páginasHaven 2018Antonios NaderAinda não há avaliações

- The Stone Age: (2.5 Mya - 3,000 BC)Documento6 páginasThe Stone Age: (2.5 Mya - 3,000 BC)KEVIN PALMEROAinda não há avaliações

- Electrical Internal Daily Report: Climate Information in The Site Tasks InformationDocumento3 páginasElectrical Internal Daily Report: Climate Information in The Site Tasks InformationJabel Oil Services Technical DPT100% (1)

- Plane and Spherical TrigonometryDocumento1 páginaPlane and Spherical TrigonometryJeff LaycoAinda não há avaliações

- Web TVGT 5064 PDFDocumento101 páginasWeb TVGT 5064 PDFDannyChaconAinda não há avaliações

- Xi Test Schedule 2023-24Documento4 páginasXi Test Schedule 2023-24SHIVAM INDERPAL YADAVAinda não há avaliações

- Mte 482 Final Project - First StepsDocumento13 páginasMte 482 Final Project - First Stepsapi-532488404Ainda não há avaliações

- SudaisDocumento3 páginasSudaisamirbadshahAinda não há avaliações

- Retaining Wall Design (Final)Documento6 páginasRetaining Wall Design (Final)ifylasyAinda não há avaliações

- ELECTIVE MATHEMATICS 10 Module Equation of Circle Part 1Documento17 páginasELECTIVE MATHEMATICS 10 Module Equation of Circle Part 1Rosuel Aslie ValeAinda não há avaliações

- FKM 595 elastomer properties and testing resultsDocumento3 páginasFKM 595 elastomer properties and testing resultsPillar ManufacturingAinda não há avaliações

- Research Highlights: Gel Cracks Brick Using Plants' Neat Trick Sugar-Eating Microbes Help Make Greener NylonDocumento1 páginaResearch Highlights: Gel Cracks Brick Using Plants' Neat Trick Sugar-Eating Microbes Help Make Greener NylonFacundo PainetruAinda não há avaliações

- DGA - TANGEDCO's procedure for transformer oil analysisDocumento7 páginasDGA - TANGEDCO's procedure for transformer oil analysischandranmuthuswamyAinda não há avaliações

- Efficiency of Broadband Four-Wave Mixing Wavelength Conversion Using Semiconductor Traveling-Wave AmplifiersDocumento3 páginasEfficiency of Broadband Four-Wave Mixing Wavelength Conversion Using Semiconductor Traveling-Wave AmplifiersАйбек АйбековAinda não há avaliações