Escolar Documentos

Profissional Documentos

Cultura Documentos

Equations: Hvac Equations, Data, and Rules of Thumb

Enviado por

zodedTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Equations: Hvac Equations, Data, and Rules of Thumb

Enviado por

zodedDireitos autorais:

Formatos disponíveis

Equations

5

PA RT

5

H VAC E Q UAT I O N S, DATA , A N D R U L E S O F T H U MB

C

o

p

y

r

i

g

h

t

e

d

M

a

t

e

r

i

a

l

Copyright 2000 by The McGraw-Hill Companies Retrieved from: www.knovel.com

36

PART 5

5.01 Cooling and Heating Equations

H

S

= 1.08 CFM T

H

S

= 1.1 CFM T

H

L

= 0.68 CFM W

GR.

H

L

= 4840 CFM W

LB.

H

T

= 4.5 CFM h

H

T

= H

S

+ H

L

H = U A T

SHR = =

LB. STM/HR =

H

S

= Sensible Heat (Btu/Hr.)

H

L

= Latent Heat (Btu/Hr.)

H

T

= Total Heat (Btu/Hr.)

T = Temperature Difference (F.)

W

GR.

= Humidity Ratio Difference (Gr.H

2

O/Lb.DA)

W

LB.

= Humidity Ratio Difference (Lb.H

2

O/Lb.DA)

h = Enthalpy Difference (Btu/Lb.DA)

CFM = Air Flow Rate (Cubic Feet per Minute)

U = U-Value (Btu/Hr. Sq. Ft. F.)

A = Area (Sq. Ft.)

SHR = Sensible Heat Ratio

H

FG

= Latent Heat of Vaporization at Design Pressure (1989 ASHRAE

Fundamentals)

5.02 R-Values/U-Values

R = = Thickness

U =

R = R-Value (Hr. Sq. Ft. F./Btu.)

U = U-Value (Btu./Hr. Sq. Ft. F.)

C = Conductance (Btu./Hr. Sq. Ft. F.)

K = Conductivity (Btu. In./Hr. Sq. Ft. F.)

R = Sum of the Individual R-Values

1

R

1

K

1

C

BTU/HR

H

FG

H

S

H

S

+ H

L

H

S

H

T

C

o

p

y

r

i

g

h

t

e

d

M

a

t

e

r

i

a

l

Copyright 2000 by The McGraw-Hill Companies Retrieved from: www.knovel.com

Equations

37

5.03 Water System Equations

H = 500 GPM T

GPM

EVAP.

=

GPM

COND.

=

H = Total Heat (Btu/Hr.)

GPM = Water Flow Rate (Gallons per Minute)

T = Temperature Difference (F.)

TONS = Air Conditioning Load (Tons)

GPM

EVAP.

= Evaporator Water Flow Rate (Gallons per Minute)

GPM

COND.

= Condenser Water Flow Rate (Gallons per Minute)

5.04 Air Change Rate Equations

=

CFM =

AC/HR. = Air Change Rate per Hour

CFM = Air Flow Rate (Cubic Feet per Minute)

VOLUME = Space Volume (Cubic Feet)

5.05 Mixed Air Temperature

T

MA

=

T

ROOM

T

OA

T

MA

=

T

RA

T

OA

CFM

SA

= Supply Air (CFM)

CFM

RA

= Return Air (CFM)

CFM

OA

= Outside Air (CFM)

T

MA

= Mixed Air Temperature (F)

T

ROOM

= Room Design Temperature (F)

T

RA

= Return Air Temperature (F)

T

OA

= Outside Air Temperature (F)

5.06 Ductwork Equations

TP = SP + VP

VP =

2

=

(V)

2

(4005)

2

V

4005

CFM

OA

CFM

SA

CFM

RA

CFM

SA

CFM

OA

CFM

SA

CFM

RA

CFM

SA

H

AC

R

VOLUME

60

CFM 60

VOLUME

AC

HR

TONS 30

T

TONS 24

T

C

o

p

y

r

i

g

h

t

e

d

M

a

t

e

r

i

a

l

Copyright 2000 by The McGraw-Hill Companies Retrieved from: www.knovel.com

38

PART 5

V = =

D

EQ

=

TP = Total Pressure

SP = Static Pressure, Friction Losses

VP = Velocity Pressure, Dynamic Losses

V = Velocity, Ft./Min.

Q = Flow through Duct (CFM)

A = Area of Duct (Sq. Ft.)

W = Width of Duct (Inches)

H = Height of Duct (Inches)

D

EQ

= Equivalent Round Duct Size for Rectangular Duct (Inches)

A = One Dimension of Rectangular Duct (Inches)

B = Adjacent Side of Rectangular Duct (Inches)

5.07 Fan Laws

=

=

2

=

2

=

3

=

3

=

1.5

BHP =

MHP =

CFM = Cubic Feet/Minute

RPM = Revolutions/Minute

SP = In. W.G.

BHP = Break Horsepower

Fan Size = Constant

Air Density = Constant

SP.GR. (Air) = 1.0

FAN

EFF.

= 6585%

M/D

EFF.

= 8095%

M/D = Motor/Drive

5.08 Pump Laws

=

=

2

=

2

RPM

2

RPM

1

GPM

2

GPM

1

HD

2

HD

1

RPM

2

RPM

1

GPM

2

GPM

1

BHP

M/D

EFF.

CFM SP SP.GR.

6356 FAN

EFF.

SP

2

SP

1

RPM

2

RPM

1

CFM

2

CFM

1

BHP

2

BHP

1

RPM

2

RPM

1

CFM

2

CFM

1

SP

2

SP

1

RPM

2

RPM

1

CFM

2

CFM

1

1.3 (A B)

0.625

(A + B)

0.25

Q 144

W H

Q

A

C

o

p

y

r

i

g

h

t

e

d

M

a

t

e

r

i

a

l

Copyright 2000 by The McGraw-Hill Companies Retrieved from: www.knovel.com

Equations

39

B

B

H

H

P

P

2

1

=

3

=

3

=

1.5

BHP =

MHP =

VH =

HD =

GPM = Gallons/Minute

RPM = Revolutions/Minute

HD = Ft. H

2

O

BHP = Break Horsepower

Pump Size = Constant

Water Density = Constant

SP.GR. = Specific Gravity of Liquid with Respect to Water

SP.GR. (Water) = 1.0

PUMP

EFF.

= 6080%

M/D

EFF.

= 8595%

M/D = Motor/Drive

P = Pressure in Psi

VH = Velocity Head in Ft.

V = Velocity in Ft./Sec.

g = Acceleration due to Gravity (32.16 Ft./Sec

2

)

5.09 Pump Net Positive Suction Head (NPSH) Calculations

NPSH

AVAIL

> NPSH

REQD

NPSH

AVAIL

= H

A

H

S

H

F

H

VP

NPSH

AVAIL

= Net Positive Suction Available at Pump (Feet)

NPSH

REQD

= Net Positive Suction Required at Pump (Feet)

H

A

= Pressure at Liquid Surface (Feet34 Feet for Water at Atmospheric

Pressure)

H

S

= Height of Liquid Surface Above (+) or Below () Pump (Feet)

H

F

= Friction Loss between Pump and Source (Feet)

H

VP

= Absolute Pressure of Water Vapor at Liquid Temperature (Feet1989

ASHRAE Fundamentals)

5.10 Air Conditioning Condensate

GPM

AC COND

=

GPM

AC COND

=

CFM W

GR.

SpV 8.33 7000

CFM W

LB.

SpV 8.33

P 2.31

SP.GR.

V

2

2g

BHP

M/D

EFF.

GPM HD SP.GR.

3960 PUMP

EFF.

HD

2

HD

1

RPM

2

RPM

1

GPM

2

GPM

1

C

o

p

y

r

i

g

h

t

e

d

M

a

t

e

r

i

a

l

Copyright 2000 by The McGraw-Hill Companies Retrieved from: www.knovel.com

40

PART 5

GPM

AC COND

= Air Conditioning Condensate Flow (Gallons/Minute)

CFM = Air Flow Rate (Cu.Ft./Minute)

SpV = Specific Volume of Air (Cu.Ft./Lb.DA)

W

LB.

= Specific Humidity (Lb.H

2

O/Lb.DA)

W

GR.

= Specific Humidity (Gr.H

2

O/Lb.DA)

5.11 Humidification

GRAINS

REQD

=

ROOM AIR

SUPPLY AIR

POUNDS

REQD

=

ROOM AIR

SUPPLY AIR

LB. STM/HR = = CFM POUNDS

REQD

60

GRAINS

REQD

= Grains of Moisture Required (Gr.H

2

O/Cu.Ft.)

POUNDS

REQD

= Pounds of Moisture Required (Lb.H

2

O/Cu.Ft.)

CFM = Air Flow Rate (Cu.Ft./Minute)

SpV = Specific Volume of Air (Cu.Ft./Lb.DA)

W

GR.

= Specific Humidity (Gr.H

2

O/Lb.DA)

W

LB.

= Specific Humidity (Lb.H

2

O/Lb.DA)

5.12 Humidifier Sensible Heat Gain

H

S

= (0.244 Q T) + (L 380)

H

S

= Sensible Heat Gain (Btu/Hr.)

Q = Steam Flow (Lb.Steam/Hr.)

T = Steam Temperature Supply Air Temperature (F.)

L = Length of Humidifier Manifold (Ft.)

5.13 Expansion Tanks

CLOSED V

T

= V

S

OPEN V

T

= 2

V

S

1

3T

DIAPHRAGM V

T

= V

S

2

1

3T

P

P

1

2

2

1

3T

P

P

A

1

P

P

A

2

CFM GRAINS

REQD

60

7000

W

LB.

SpV

W

LB.

SpV

W

GR.

SpV

W

GR.

SpV

C

o

p

y

r

i

g

h

t

e

d

M

a

t

e

r

i

a

l

Copyright 2000 by The McGraw-Hill Companies Retrieved from: www.knovel.com

Equations

41

V

T

= Volume of Expansion Tank (Gallons)

V

S

= Volume of Water in Piping System (Gallons)

T = T

2

T

1

(F)

T

1

= Lower System Temperature (F)

Heating Water T

1

= 4550F Temperature at Fill Condi-

tion

Chilled Water T

1

= Supply Water Temperature

Dual Temperature T

1

= Chilled Water Supply Temperature

T

2

= Higher System Temperature (F)

Heating Water T

2

= Supply Water Temperature

Chilled Water T

2

= 95F Ambient Temperature (Design

Weather Data)

Dual Temperature T

2

= Heating Water Supply Temperature

P

A

= Atmospheric Pressure (14.7 Psia)

P

1

= System Fill Pressure/Minimum System Pressure (Psia)

P

2

= System Operating Pressure/Maximum Operating Pressure (Psia)

V

1

= SpV of H

2

O at T

1

(Cu. Ft./Lb.H

2

O) 1989 ASHRAE Fundamentals, Chapter 2,

Table 25 or Part 27, Properties of Air and Water

V

2

= SpV of H

2

O at T

2

(Cu. Ft./Lb.H

2

O) 1989 ASHRAE Fundamentals, Chapter 2,

Table 26 or Part 27, Properties of Air and Water

= Linear Coefficient of Expansion

STEEL

= 6.5 10

6

COPPER

= 9.5 10

6

System Volume Estimate:

12 Gal./Ton

35 Gal./BHP

System Fill Pressure/Minimum System Pressure Estimate:

Height of System +5 to 10 Psi OR 510 Psi, whichever is greater.

System Operating Pressure/Maximum Operating Pressure Estimate:

150 Lb. Systems 45125 Psi

250 Lb. Systems 125225 Psi

5.14 Air Balance Equations

SA = Supply Air

RA = Return Air

OA = Outside Air

EA = Exhaust Air

RFA = Relief Air

SA = RA + OA = RA + EA + RFA

If minimum OA (ventilation air) is greater than EA, then

OA = EA + RFA

If EA is greater than minimum OA (ventilation air), then

OA = EA RFA = 0

For Economizer Cycle

OA = SA = EA + RFA RA = 0

C

o

p

y

r

i

g

h

t

e

d

M

a

t

e

r

i

a

l

Copyright 2000 by The McGraw-Hill Companies Retrieved from: www.knovel.com

42

PART 5

5.15 Efficiencies

COP = =

EER =

Turndown Ratio = Maximum Firing Rate: Minimum Firing Rate

(i.e., 5:1, 10:1, 25:1)

OVERALL THERMAL EFF. = 100%

COMBUSTION EFF. = 100%

Overall Thermal Efficiency Range 75%90%

Combustion Efficiency Range 85%95%

5.16 Cooling Towers and Heat Exchangers

APPROACH

CTS

= LWT AWB

APPROACH

HES

= EWT

HS

LWT

CS

RANGE = EWT LWT

EWT = Entering Water Temperature (F)

LWT = Leaving Water Temperature (F)

AWB = Ambient Wet Bulb Temperature (Design WB, F)

HS = Hot Side

CS = Cold Side

5.17 Moisture Condensation on Glass

T

GLASS

= T

ROOM

(T

ROOM

T

OA

)

T

GLASS

= T

ROOM

(T

ROOM

T

OA

)

If T

GLASS

< DP

ROOM

Condensation Occurs

T = Temperature (F.)

R = R-Value (Hr. Sq.Ft. F./Btu.)

U = U-Value (Btu./Hr. Sq.Ft. F.)

IA = Inside Airfilm

OA = Design Outside Air Temperature

DP = Dew Point

5.18 Electricity

KVA = KW + KVAR

KVA = Total Power (Kilovolt Amps)

U

GLASS

U

IA

R

IA

R

GLASS

BTU INPUT BTU STACK LOSS

BTU INPUT

GROSS BTU OUTPUT

GROSS BTU INPUT

BTU OUTPUT

WATTS INPUT

EER

3.413

BTU OUTPUT

BTU INPUT

C

o

p

y

r

i

g

h

t

e

d

M

a

t

e

r

i

a

l

Copyright 2000 by The McGraw-Hill Companies Retrieved from: www.knovel.com

Equations

43

KW = Real Power, Electrical Energy (Kilowatts)

KVAR = Reactive Power or Imaginary Power (Kilovolt Amps Reactive)

V = Voltage (Volts)

A = Current (Amps)

PF = Power Factor (0.750.95)

BHP = Break Horsepower

MHP = Motor Horsepower

EFF = Efficiency

M/D = Motor Drive

A. Single Phase Power:

KW

1

=

KVA

1

=

BHP

1

=

MHP

1

=

B. 3-Phase Power:

KW

3

=

KVA

3

=

BHP

3

=

MHP

3

=

5.19 Calculating Heating Loads for Loading Docks, Heavily

Used Vestibules and Similar Spaces.

A. Find volume of space to be heated (Cu.Ft.).

B. Determine acceptable warm-up time for space (Min.).

C. Divide volume by time (CFM).

D. Determine inside and outside design temperaturesassume inside space temper-

ature has dropped to the outside design temperature because doors have been

open for an extended period of time.

E. Use sensible heat equation to determine heating requirement using CFM and

inside and outside design temperatures determined above.

BHP

3

M/D

EFF.

3 V A PF DEVICE

EFF.

746

3 V A

1000

3 V A PF

1000

BHP

1

M/D

EFF.

V A PF DEVICE

EFF.

746

V A

1000

V A PF

1000

C

o

p

y

r

i

g

h

t

e

d

M

a

t

e

r

i

a

l

Copyright 2000 by The McGraw-Hill Companies Retrieved from: www.knovel.com

44

PART 5

5.20 Ventilation of Mechanical Rooms with Refrigeration

Equipment

A. For a more detailed description of ventilation requirements for mechanical rooms

with refrigeration equipment see ASHRAE Standard 15 and Part 9, Ventilation Rules

of Thumb.

B. Completely Enclosed Equipment Rooms:

CFM = 100 G

0.5

CFM = Exhaust Air Flow Rate Required (Cu.Ft./Minute)

G = Mass of Refrigerant of Largest System (Pounds)

C. Partially Enclosed Equipment Rooms:

FA = G

0.5

FA = Ventilation Free Opening Area (Sq.Ft.)

G = Mass of Refrigerant of Largest System (Pounds)

5.21 Equations for Flat Oval Ductwork

FS = MAJOR MINOR

A =

P =

D

EQ

=

1.55 (A)

0.625

(P)

0.25

( MINOR) + (2 FS)

12

(FS MINOR) +

( M

4

INOR

2

)

144

C

o

p

y

r

i

g

h

t

e

d

M

a

t

e

r

i

a

l

Copyright 2000 by The McGraw-Hill Companies Retrieved from: www.knovel.com

Equations

45

FS = Flat Span Dimension (Inches)

MAJOR = Major Axis Dimension [Inches (Larger Dimension)]

MINOR = Minor Axis Dimension [Inches (Smaller Dimension)]

A = Cross-Sectional Area (Square Feet)

P = Perimeter or Surface Area (Square Feet per Lineal Feet)

D

EQ

= Equivalent Round Duct Diameter

5.22 Pipe Expansion Equations

A. L-Bends:

L = 6.225 D

F = 500 LB./PIPE DIA. PIPE DIA.

L = Length of Leg Required to Accommodate Thermal Expansion or Contraction

(Feet)

= Thermal Expansion or Contraction of Long Leg (Inches)

D = Pipe Outside Diameter (Inches)

F = Force Exerted by Pipe Expansion or Contraction on Anchors and Supports (Lbs.)

See Tables in Part 32, Appendix D

B. Z-Bends:

L = 4 D

F = 200 500 LB./PIPE DIA. PIPE DIA.

C

o

p

y

r

i

g

h

t

e

d

M

a

t

e

r

i

a

l

Copyright 2000 by The McGraw-Hill Companies Retrieved from: www.knovel.com

46

PART 5

L = Length of Offset Leg Required to Accommodate Thermal Expansion or Contrac-

tion (Feet)

= Anchor to Anchor Expansion or Contraction (Inches)

D = Pipe Outside Diameter (Inches)

F = Force Exerted by Pipe Expansion or Contraction on Anchors and Supports (Lbs.)

See Tables in Part 32, Appendix D.

C. U-Bends or Expansion Loops:

L = 6.225 D

F = 200 LB./PIPE DIA. PIPE DIA.

L = 2H + W

H = 2W

L = 5W

L = Length of Loop Required to Accommodate Thermal Expansion or Contraction

(Feet)

= Anchor to Anchor Expansion or Contraction (Inches)

D = Pipe Outside Diameter (Inches)

F = Force Exerted by Pipe Expansion or Contraction on Anchors and Supports (Lbs.)

See Tables in Part 32, Appendix D.

5.23 Steam and Condensate Equations

A. General:

LBS. STM./HR. =

LB. STM. COND./HR. =

EDR =

LB. STM. COND./HR. =

LB. STM. COND./HR. =

CFM 60 D C

P

T

L

GPM 500 SP.GR. C

P

T

L

BTU/HR.

240

EDR

4

BTU/HR.

960

C

o

p

y

r

i

g

h

t

e

d

M

a

t

e

r

i

a

l

Copyright 2000 by The McGraw-Hill Companies Retrieved from: www.knovel.com

Equations

47

B. Approximating Condensate Loads:

LB. STM. COND./HR. =

LB. STM. COND./HR. =

LB. STM. COND./HR. =

STM. = Steam

GPM = Quantity of Liquid (Gallons per Minute)

CFM = Quantity of Gas or Air (Cubic Feet per Minute)

SP.GR. = Specific Gravity

D = Density (Lbs./Cubic Feet)

C

P

= Specific Heat of Gas or Liquid (Btu/Lb)

Air C

P

= 0.24 Btu/Lb

Water C

P

= 1.00 Btu/Lb

L = Latent Heat of Steam (Btu/Lb. at Steam Design Pressure)

T = Final Temperature minus Initial Temperature

EDR = Equivalent Direct Radiation

5.24 Steam and Steam Condensate Pipe Sizing Equations

A. Steam Pipe Sizing Equations:

P =

W = 60

W = 0.41667 V A

INCHES

D = 60 V A

FEET

D

V = =

P Pressure Drop per 100 Feet of Pipe (Psig/100 feet)

W Steam Flow Rate (Lbs./Hour)

ID Actual Inside Diameter of Pipe (Inches)

D Average Density of Steam at System Pressure (Lbs./Cu. Ft.)

V Velocity of Steam in Pipe (Feet/Minute)

A

INCHES

Actual Cross Sectional Area of Pipe (Square Inches)

A

FEET

Actual Cross Sectional Area of Pipe (Square Feet)

B. Steam Condensate Pipe Sizing Equations:

FS = 100

W

CR

= W

FS

100

H

S

SS

H

S

CR

H

L

CR

W

60 A

FEET

D

2.4 W

A

INCHES

D

P D ID

5

0.01306

1 +

3

ID

.6

(0.01306) W

2

1 +

3

ID

.6

3600 D ID

5

CFM(AIR) T

900

GPM(FUEL OIL) T

4

GPM(WATER) T

2

C

o

p

y

r

i

g

h

t

e

d

M

a

t

e

r

i

a

l

Copyright 2000 by The McGraw-Hill Companies Retrieved from: www.knovel.com

48

PART 5

FS Flash Steam (Percentage %)

H

SSS

Sensible Heat at Steam Supply Pressure (Btu/Lb.)

H

SCR

Sensible Heat at Condensate Return Pressure (Btu/Lb.)

H

LCR

Latent Heat at Condensate Return Pressure (Btu/Lb.)

W Steam Flow Rate (Lbs./Hr.)

W

CR

Condensate Flow based on percentage of Flash Steam created during condensing

process (Lbs./Hr.). Use this flow rate in steam equations above to determine con-

densate return pipe size.

5.25 Psychrometric Equations

W = 0.622

RH = 100%

RH = 100%

H

S

= m c

P

T

H

L

= L

V

m W

H

T

= m h

W =

W =

W = Specific Humidity (Lb.H

2

O/Lb.DA or Gr.H

2

O/Lb.DA)

W

ACTUAL

= Actual Specific Humidity (Lb.H

2

O/Lb.DA or Gr.H

2

O/Lb.DA)

W

SAT

= Saturation Specific Humidity at the Dry Bulb Temperature

W

SAT WB

= Saturation Specific Humidity at the Wet Bulb Temperature

P

W

= Partial Pressure of Water Vapor (Lb./Sq.Ft.)

P = Total Absolute Pressure of Air/Water Vapor Mixture (Lb./Sq.Ft.)

P

SAT

= Saturation Partial Pressure of Water Vapor at the Dry Bulb Temperature

(Lb./Sq.Ft.)

RH = Relative Humidity (%)

H

S

= Sensible Heat (Btu/Hr.)

H

L

= Latent Heat (Btu/Hr.)

H

T

= Total Heat (Btu/Hr.)

m = Mass Flow Rate (Lb.DA/Hr. or Lb.H

2

O/Hr.)

c

P

= Specific Heat (Air: 0.24 Btu/Lb.DA, Water: 1.0 Btu/Lb.H

2

O)

T

DB

= Dry Bulb Temperature (F.)

T

WB

= Wet Bulb Temperature (F.)

T = Temperature Difference (F.)

W = Specific Humidity Difference (Lb.H

2

O/Lb.DA or Gr.H

2

O/Lb.DA)

h = Enthalpy Difference (Btu/Lb.DA)

L

V

= Latent Heat of Vaporization (Btu/Lb.H

2

O)

(1093 0.556 T

WB

)(W

SAT WB

) (0.240)(T

DB

T

WB

)

(1093 + 0.444 T

DB

T

WB

)

(2501 2.381 T

WB

)(W

SAT WB

) (T

DB

T

WB

)

(2501 + 1.805 T

DB

4.186 T

WB

)

P

W

P

SAT

W

ACTUAL

W

SAT

P

W

P P

W

C

o

p

y

r

i

g

h

t

e

d

M

a

t

e

r

i

a

l

Copyright 2000 by The McGraw-Hill Companies Retrieved from: www.knovel.com

Equations

49

5.26 Swimming Pools

A. Sizing Outdoor Pool Heater:

1. Determine pool capacity in gallons. Obtain from Architect if available.

Length Width Depth 7.5 Gal/Cu.Ft. (If depth is not known assume an average

depth 5.5 Feet)

2. Determine heat pick-up time in hours from Owner.

3. Determine pool water temperature in degrees F. from the Owner. If Owner does not

specify assume 80F.

4. Determine the average air temperature onthe coldest monthinwhichthe pool will be used.

5. Determine the average wind velocity in miles per hour. For pools less than 900 square

feet and where the pool is sheltered by nearby buildings, fences, shrubs, etc., from the

prevailing wind an average wind velocity of less than 3.5 mph may be assumed. The sur-

face heat loss factor of 5.5 Btu/Hr/Sq.Ft.F. in the equation below assumes a wind veloc-

ity of 3.5 mph. If a wind velocity of less than 3.5 mph is used, multiply equation by 0.75;

for 5.0 mph multiply equation by 1.25; and for 10 mph multiply equation by 2.0.

6. Pool Heater Equations:

H

POOL HEATER

= H

HEAT-UP

+ H

SURFACE LOSS

H

HEAT-UP

=

H

SURFACE LOSS

= 5.5 BTU/HR. SQ. FT. F. T

WATER/AIR

POOL AREA

T

WATER

= T

FINAL

T

INITIAL

T

FINAL

= POOL WATER TEMPERATURE

T

INITIAL

= 50 F

T

WATER/AIR

= T

FINAL

T

AVERAGE AIR

H = Heating Capacity (Btu/Hr.)

T = Temperature Difference (F.)

5.27 Domestic Water Heater Sizing

H

OUTPUT

= GPH 8.34 LBS./GAL. T 1.0

H

INPUT

=

GPH = =

T = =

KW =

% COLD WATER =

% HOT WATER =

T

MIX

T

COLD

T

HOT

T

COLD

T

HOT

T

MIX

T

HOT

T

COLD

GPH 8.34 LBS./GAL. T 1.0

3413 BTU/KW

KW 3413 BTU/KW

GPH 8.34 LBS./GAL.

H

INPUT

% EFFICIENCY

GPH 8.34 LBS./GAL.

KW 3413 BTU/KW

T 8.34 LBS./GAL.

H

INPUT

% EFFICIENCY

T 8.34 LBS./GAL.

GPH 8.34 LBS./GAL. T

% EFFICIENCY

GALS. 8.34 LBS./GAL. T

WATER

1.0 BTU/LB.F.

HEAT PICK-UP TIME

C

o

p

y

r

i

g

h

t

e

d

M

a

t

e

r

i

a

l

Copyright 2000 by The McGraw-Hill Companies Retrieved from: www.knovel.com

50

PART 5

H

OUTPUT

= Heating Capacity, Output

H

INPUT

= Heating Capacity, Input

GPH = Recovery Rate (Gallons per Hour)

T = Temperature Rise (F.)

KW = Kilowatts

T

COLD

= Temperature, Cold Water (F.)

T

HOT

= Temperature, Hot Water (F.)

T

MIX

= Temperature, Mixed Water (F.)

5.28 Domestic Hot Water Recirculation Pump/Supply Sizing

A. Determine the approximate total length of all hot water supply and return piping.

B. Multiply this total length by 30 Btu/Ft. for insulated pipe and 60 Btu/Ft. for unin-

sulated pipe to obtain the approximate heat loss.

C. Divide the total heat loss by 10,000 to obtain the total pump capacity in GPM.

D. Select a circulating pump to provide the total required GPM and obtain the head

created at this flow.

E. Multiply the head by 100 and divide by the total length of the longest run of the

hot water return piping to determine the allowable friction loss per 100 feet of pipe.

F. Determine the required GPM in each circulating loop and size the hot water

return pipe based on this GPM and the allowable friction loss as determined above.

5.29 Relief Valve Vent Line Maximum Length

L = =

P

1

= 0.25 [(PRESSURE SETTING 1.1) + 14.7]

P

2

= [(PRESSURE SETTING 1.1) + 14.7]

L = Maximum Length of Relief Vent Line (Feet)

D = Inside Diameter of Pipe (Inches)

C = Minimum Discharge of Air (Lbs./Min.)

5.30 Relief Valve Sizing

A. Liquid System Relief Valves and Spring Style Relief Valves:

A =

B. Liquid System Relief Valves and Pilot Operated Relief Valves:

A =

GPM G

36.81 K

V

P

GPM G

28.14 K

B

K

V

P

9 P

2

2

D

5

16 C

2

9 P

1

2

D

5

C

2

C

o

p

y

r

i

g

h

t

e

d

M

a

t

e

r

i

a

l

Copyright 2000 by The McGraw-Hill Companies Retrieved from: www.knovel.com

Equations

51

C. Steam System Relief Valves:

A =

D. Gas and Vapor System Relief Valves (Lb./Hr.):

A =

E. Gas and Vapor System Relief Valves (SCFM):

A =

F. Relief Valve Equation Definitions:

1. A = Minimum Required Effective Relief Valve Discharge Area (Square Inches)

2. GPM = Required Relieving Capacity at Flow Conditions (Gallons per Minute)

3. W = Required Relieving Capacity at Flow Conditions (Lbs./Hr.)

4. SCFM = Required Relieving Capacity at Flow Conditions (Standard Cubic Feet per

Minute)

5. G = Specific Gravity of Liquid, Gas, or Vapor at Flow Conditions

Water = 1.0 for most HVAC Applications

Air = 1.0

6. C = Coefficient Determined from Expression of Ratio of Specific Heats

C = 315 if Value is Unknown

7. K = Effective Coefficient of Discharge

K = 0.975

8. K

B

= Capacity Correction Factor Due to Back Pressure

K

B

= 1.0 for Atmospheric Discharge Systems

9. K

V

= Flow Correction Factor Due to Viscosity

K

V

= 0.9 to 1.0 for most HVAC Applications with Water

10. K

N

= Capacity Correction Factor for Dry Saturated Steam at Set Pressures

above 1500 Psia and up to 3200 Psia

K

N

= 1.0 for most HVAC Applications

11. K

SH

= Capacity Correction Factor Due to the Degree of Superheat

K

SH

= 1.0 for Saturated Steam

12. Z = Compressibility Factor

Z = 1.0 If Value is Unknown

13. P = Relieving Pressure (Psia)

P = Set Pressure (Psig) + Over Pressure (10% Psig) + Atmospheric

Pressure (14.7 Psia)

14. P = Differential Pressure (Psig)

P = Set Pressure (Psig) + Over Pressure (10% Psig) Back Pressure

(Psig)

15. T = Absolute Temperature (R = F. + 460)

16. M = Molecular Weight of the Gas or Vapor

G. Relief Valve Sizing Notes:

1. When multiple relief valves are used, one valve shall be set at or below the maximum

allowable working pressure, and the remaining valves may be set up to 5 percent over the

maximum allowable working pressure.

SCFM TGZ

1.175 C K P K

B

W TZ

C K P K

B

M

W

51.5 K P K

SH

K

N

K

B

C

o

p

y

r

i

g

h

t

e

d

M

a

t

e

r

i

a

l

Copyright 2000 by The McGraw-Hill Companies Retrieved from: www.knovel.com

52

PART 5

2. When sizing multiple relief valves, the total area required is calculated on an over-

pressure of 16 percent or 4 Psi, whichever is greater.

3. For superheated steam, the correction factor values listed below may be used:

a. Superheat up to 400 F.: 0.97 (Range 0.9790.998)

b. Superheat up to 450 F.: 0.95 (Range 0.9570.977)

c. Superheat up to 500 F.: 0.93 (Range 0.9300.968)

C

o

p

y

r

i

g

h

t

e

d

M

a

t

e

r

i

a

l

Copyright 2000 by The McGraw-Hill Companies Retrieved from: www.knovel.com

Equations

53

d. Superheat up to 550 F.: 0.90 (Range 0.9050.974)

e. Superheat up to 600 F.: 0.88 (Range 0.8820.993)

f. Superheat up to 650 F.: 0.86 (Range 0.8610.988)

g. Superheat up to 700 F.: 0.84 (Range 0.8410.963)

h. Superheat up to 750 F.: 0.82 (Range 0.8230.903)

i. Superheat up to 800 F.: 0.80 (Range 0.8050.863)

j. Superheat up to 850 F.: 0.78 (Range 0.7860.836)

k. Superheat up to 900 F.: 0.75 (Range 0.7530.813)

l. Superheat up to 950 F.: 0.72 (Range 0.7260.792)

m. Superheat up to 1000 F.: 0.70 (Range 0.7040.774)

4. Gas and Vapor Properties are shown in the table on the preceding page:

5.31 Steel Pipe Equations

A = 0.785 ID

2

W

P

= 10.6802 T (OD T)

W

W

= 0.3405 ID

2

OSA = 0.2618 OD

ISA = 0.2618 ID

A

M

= 0.785 (OD

2

ID

2

)

A = Cross-Sectional Area (Square Inches)

W

P

= Weight of Pipe per Foot (Pounds)

W

W

= Weight of Water per Foot (Pounds)

T = Pipe Wall Thickness (Inches)

ID = Inside Diameter (Inches)

OD = Outside Diameter (Inches)

OSA = Outside Surface Area per Foot (Square Feet)

ISA = Inside Surface Area per Foot (Square Feet)

A

M

= Area of the Metal (Square Inches)

5.32 English/Metric Cooling and Heating Equations Comparison

H

S

= 1.08 CFM T

H

SM

= 72.42 CMM T

M

H

L

= 0.68 CFM W

H

LM

= 177,734.8 CMM W

M

H

T

= 4.5 CFM h

H

TM

= 72.09 CMM h

M

Kg Min

Hr M

3

Lb Min

Hr Ft

3

KJ Min Kg DA

Hr M

3

Kg H

2

O

Btu Min Lb DA

Hr Ft

3

Gr H

2

O

KJ Min

Hr M

3

C

Btu Min

Hr Ft

3

F

C

o

p

y

r

i

g

h

t

e

d

M

a

t

e

r

i

a

l

Copyright 2000 by The McGraw-Hill Companies Retrieved from: www.knovel.com

54

PART 5

H

T

= H

S

+ H

L

H

TM

= H

SM

+ H

LM

H = 500 GPM T

H

M

= 250.8 LPM T

M

=

=

C =

F = 1.8 C + 32

H

S

= Sensible Heat (Btu/Hr.)

H

SM

= Sensible Heat (KJ/Hr.)

H

L

= Latent Heat (Btu/Hr.)

H

LM

= Latent Heat (KJ/Hr.)

H

T

= Total Heat (Btu/Hr.)

H

TM

= Total Heat (KJ/Hr.)

H = Total Heat (Btu/Hr.)

H

M

= Total Heat (KJ/Hr.)

T = Temperature Difference (F.)

T

M

= Temperature Difference (C.)

W = Humidity Ratio Difference (Gr.H

2

O/Lb.DA)

W

M

= Humidity Ratio Difference (Kg.H

2

O/Kg.DA)

h = Enthalpy Difference (Btu/Lb.DA)

h = Enthalpy Difference (KJ/Lb.DA)

CFM = Air Flow Rate (Cubic Feet per Minute)

CMM = Air Flow Rate (Cubic Meters per Minute)

GPM = Water Flow Rate (Gallons per Minute)

LPM = Water Flow Rate (Liters per Minute)

AC/HR. = Air Change Rate per Hour, English

AC/HR.

M

= Air Change Rate per Hour, Metric

AC/HR. = AC/HR.

M

VOLUME = Space Volume (Cubic Feet)

VOLUME

M

= Space Volume (Cubic Meters)

KJ/Hr = Btu/Hr 1.055

CMM = CFM 0.02832

LPM = GPM 3.785

KJ/Lb = Btu/Lb 2.326

Meters = Feet 0.3048

Sq. Meters = Sq. Feet 0.0929

Cu. Meters = Cu. Feet 0.02832

Kg = Pounds 0.4536

F 32

1.8

CMM 60

M

H

i

r

n

VOLUME

M

AC

HR

M

CFM 60

M

H

i

r

n

VOLUME

AC

HR

KJ Min

Hr Liters C

Btu Min

Hr Gal F

C

o

p

y

r

i

g

h

t

e

d

M

a

t

e

r

i

a

l

Copyright 2000 by The McGraw-Hill Companies Retrieved from: www.knovel.com

Equations

55

1.0 GPM = 500 Lb. Steam/Hr.

1.0 Lb.Stm. /Hr = 0.002 GPM

1.0 Lb.H

2

O/Hr = 1.0 Lb.Steam/Hr.

Kg/Cu. Meter = Pounds/Cu. Feet 16.017 (Density)

Cu. Meters/Kg = Cu. Feet/Pound 0.0624 (Specific Volume)

Kg H

2

O/Kg DA = Gr H

2

O/Lb DA/7,000 = Lb. H

2

O/Lb DA

5.33 Cooling Tower Equations

C =

B =

E = GPM

COND.

R 0.0008

D = GPM

COND.

0.0002

R = EWT LWT

B = Blowdown (GPM)

C = Cycles of Concentration

D = Drift (GPM)

E = Evaporation (GPM)

EWT = Entering Water Temperature (F.)

LWT = Leaving Water Temperature (F.)

R = Range (F.)

5.34 Motor Drive Formulas

D

FP

RPM

FP

= D

MP

RPM

MP

BL = [(D

FP

+ D

MP

) 1.5708] + (2 L)

D

FP

= Fan Pulley Diameter

D

MP

= Motor Pulley Diameter

RPM

FP

= Fan Pulley RPM

RPM

MP

= Motor Pulley RPM

BL = Belt Length

L = Center-to-Center Distance of Fan and Motor Pulleys

E [(C 1) D]

(C 1)

(E + D + B)

(D + B)

C

o

p

y

r

i

g

h

t

e

d

M

a

t

e

r

i

a

l

Copyright 2000 by The McGraw-Hill Companies Retrieved from: www.knovel.com

Você também pode gostar

- Progress in Refrigeration Science and Technology: Proceedings of the XIth International Congress of Refrigeration, Munich, 1963No EverandProgress in Refrigeration Science and Technology: Proceedings of the XIth International Congress of Refrigeration, Munich, 1963Ainda não há avaliações

- HVAC Equations, Data, and Rules of Thumb, Third EditionNo EverandHVAC Equations, Data, and Rules of Thumb, Third EditionAinda não há avaliações

- MRI Formulas ConversionsDocumento1 páginaMRI Formulas ConversionsJoey ManlangitAinda não há avaliações

- Sizing Steps for an Air CoolerDocumento3 páginasSizing Steps for an Air CoolerRita YuliandaAinda não há avaliações

- Hvac Formulas and ValuesDocumento13 páginasHvac Formulas and ValuesRamadan RashadAinda não há avaliações

- Hvac Formulas PDFDocumento25 páginasHvac Formulas PDFSaraswatapalit0% (1)

- HVAC FormulasDocumento7 páginasHVAC Formulasisaiaspaula80Ainda não há avaliações

- ChE 305 Humidification Process OptimizationDocumento32 páginasChE 305 Humidification Process OptimizationTanvir AhmedAinda não há avaliações

- Humidification Load Calculation Armstrong PDFDocumento3 páginasHumidification Load Calculation Armstrong PDFsyedAinda não há avaliações

- Azucar HojaDocumento9 páginasAzucar HojaJorge PerezAinda não há avaliações

- AHU SizingDocumento8 páginasAHU Sizingmohammad hamdanAinda não há avaliações

- Cooling Tower Calc Efficiency Under 40Documento4 páginasCooling Tower Calc Efficiency Under 40Maman HakimAinda não há avaliações

- Heat Chap07 035Documento16 páginasHeat Chap07 035Kerem GönceAinda não há avaliações

- Experimentno.1:The Psychrometric Processes: Relative Humidity RH %Documento31 páginasExperimentno.1:The Psychrometric Processes: Relative Humidity RH %JayZx WayAinda não há avaliações

- Converting KW Ton To COP or EERDocumento2 páginasConverting KW Ton To COP or EERswsw2011Ainda não há avaliações

- Sizing calculations for BFW pumps, FD, SA and ID fans for 50,000 kg/hr boilerDocumento5 páginasSizing calculations for BFW pumps, FD, SA and ID fans for 50,000 kg/hr boilerMati Dalam Penantian CintamuAinda não há avaliações

- Evaporative CoolerDocumento8 páginasEvaporative Coolerbruce1312100% (1)

- Part 10. All-Air Systems - Chapter 4. Dual-Duct System: Table 1 Summarizes The Cooling Load Requirements of 2)Documento1 páginaPart 10. All-Air Systems - Chapter 4. Dual-Duct System: Table 1 Summarizes The Cooling Load Requirements of 2)Karthikeyan SankarrajanAinda não há avaliações

- SRL Diagnostics: Types of Cooling Tower - Cooling Tower Basic CalculationsDocumento13 páginasSRL Diagnostics: Types of Cooling Tower - Cooling Tower Basic CalculationssumitAinda não há avaliações

- Bry Air QuestionarysectionDocumento7 páginasBry Air Questionarysectionprashant_mahitkar4532Ainda não há avaliações

- Ref Pipe Sizing Ver 02 21 11Documento12 páginasRef Pipe Sizing Ver 02 21 11Ahmef100% (1)

- Cooling and Dehumidifying Heat Load Estimate FormDocumento4 páginasCooling and Dehumidifying Heat Load Estimate FormKaushikAinda não há avaliações

- Heat TransferDocumento1 páginaHeat TransferhuangjlAinda não há avaliações

- HTTP WWW - Bryair.com Manuals Man07Documento17 páginasHTTP WWW - Bryair.com Manuals Man07rama deviAinda não há avaliações

- FD Fan Sizing CalculationDocumento3 páginasFD Fan Sizing CalculationkumarananyarupeshAinda não há avaliações

- Average Sheet Temperature at Drying: Gloss Efficiency (Production Time / Maximum Time Available)Documento7 páginasAverage Sheet Temperature at Drying: Gloss Efficiency (Production Time / Maximum Time Available)Alexandre HugenAinda não há avaliações

- Geothermal HVAC: Shifting Performance Risk From Buyer To SellerDocumento5 páginasGeothermal HVAC: Shifting Performance Risk From Buyer To SellerKagitha TirumalaAinda não há avaliações

- Fise Tehnice Ue VRF FujitsuDocumento10 páginasFise Tehnice Ue VRF FujitsuMihaela CimpeanuAinda não há avaliações

- Cooling and Dehumidifying AirDocumento5 páginasCooling and Dehumidifying AirFaquruddin AliAinda não há avaliações

- Air Changes Per HourDocumento4 páginasAir Changes Per HourKg Chit ZawAinda não há avaliações

- Heatload Calculation 2Documento44 páginasHeatload Calculation 2Mustansir Pancha50% (2)

- Air Change RateDocumento18 páginasAir Change Ratemumbaimale20009776Ainda não há avaliações

- RTWD Series R (TM) 70-250 Ton Water-Cooled Chiller Dimension DrawingsDocumento2 páginasRTWD Series R (TM) 70-250 Ton Water-Cooled Chiller Dimension DrawingsJhon LewisAinda não há avaliações

- Psychrometric ProcessesDocumento14 páginasPsychrometric ProcessesKabin BoraAinda não há avaliações

- Psych Rome TricsDocumento46 páginasPsych Rome TricsDenitta D'RoseAinda não há avaliações

- Hardik Patel - Iciame2013 "RESEARCH PAPER-37"Documento31 páginasHardik Patel - Iciame2013 "RESEARCH PAPER-37"hardik10888Ainda não há avaliações

- Coil Selection ReportDocumento1 páginaCoil Selection ReportMohsin Shaikh100% (1)

- Vapour Compression RefrigerationDocumento11 páginasVapour Compression RefrigerationchinnuAinda não há avaliações

- Aircraft Flying Project (PRINT OUT)Documento24 páginasAircraft Flying Project (PRINT OUT)Priyanka KumariAinda não há avaliações

- Cooling Tower Data Sheet REV-00Documento12 páginasCooling Tower Data Sheet REV-00Anonymous ZnuMEWN1Ainda não há avaliações

- Basics of Refrigeration - EvaporatorsDocumento32 páginasBasics of Refrigeration - Evaporatorsfarazgazanfar-1Ainda não há avaliações

- Catalogue Water Cooled Scroll Uwl b5 1Documento48 páginasCatalogue Water Cooled Scroll Uwl b5 1rajeshwar sriramAinda não há avaliações

- Mollie ChartDocumento15 páginasMollie ChartKriz EarnestAinda não há avaliações

- Waste Heat Recovery System For RefrigeratorDocumento10 páginasWaste Heat Recovery System For RefrigeratorlalkrishnaAinda não há avaliações

- CFM and Capacity Calcs 4.5Documento9 páginasCFM and Capacity Calcs 4.5hvacrmedicAinda não há avaliações

- Air Leakage Through Automatic DoorsDocumento5 páginasAir Leakage Through Automatic DoorsstranfirAinda não há avaliações

- Expansion Vessel Sizing To UploadDocumento6 páginasExpansion Vessel Sizing To UploadsmcsamindaAinda não há avaliações

- Bell-Coleman Refrigeration Cycle ProblemsDocumento10 páginasBell-Coleman Refrigeration Cycle ProblemsBalvinderAinda não há avaliações

- Psychrometry. Heat Recovery Air Handling Unit (Ahu) - by Ömer Faruk DDocumento13 páginasPsychrometry. Heat Recovery Air Handling Unit (Ahu) - by Ömer Faruk DKarl WeierstrassAinda não há avaliações

- Cooling Tower UtilitasDocumento32 páginasCooling Tower UtilitasVlany DorisAinda não há avaliações

- Ch4 PsychrometricsDocumento102 páginasCh4 PsychrometricsJayant SisodiaAinda não há avaliações

- Cooling Towers & Desiccant Dehumidification GuideDocumento23 páginasCooling Towers & Desiccant Dehumidification Guideesojsuil_tgAinda não há avaliações

- EKC316 - Humidification Process Design and Psychrometric AnalysisDocumento95 páginasEKC316 - Humidification Process Design and Psychrometric AnalysisSathiswaran SelvamAinda não há avaliações

- Heat Gain From PeopleDocumento1 páginaHeat Gain From Peoplehasanadel88Ainda não há avaliações

- HVAC Thermal Load EstimatingDocumento28 páginasHVAC Thermal Load EstimatingIntisar Ali SajjadAinda não há avaliações

- Design of Hvac With VRF System For A Space House in AhmedabadDocumento7 páginasDesign of Hvac With VRF System For A Space House in AhmedabadIJSTEAinda não há avaliações

- Chiller Plant Efficiency ComputationDocumento28 páginasChiller Plant Efficiency ComputationhoangpalestineAinda não há avaliações

- Water-Cooled Series R (TM) RTHD Product ReportDocumento2 páginasWater-Cooled Series R (TM) RTHD Product ReporttrangocvuAinda não há avaliações

- Pressure drop computation for chilled water pump sizing in RKH Project, Saudi ArabiaDocumento17 páginasPressure drop computation for chilled water pump sizing in RKH Project, Saudi ArabiaabdullahAinda não há avaliações

- Heat ExchangerDocumento53 páginasHeat ExchangerNurulHidayahAinda não há avaliações

- Tirukkural MalayalamDocumento122 páginasTirukkural MalayalamAnil Sarngadharan100% (1)

- Hoar - Architects of Conspiracy - An Intriguing History (Conspiratorial View of US History) (1984)Documento360 páginasHoar - Architects of Conspiracy - An Intriguing History (Conspiratorial View of US History) (1984)doggydogAinda não há avaliações

- Proposed McCarthy and Stone Development Construction Method StatementDocumento17 páginasProposed McCarthy and Stone Development Construction Method StatementAddis MekuriaAinda não há avaliações

- New York City of Aspiration Middle Class ReportDocumento52 páginasNew York City of Aspiration Middle Class ReportLenard DatilesAinda não há avaliações

- Mathematics in Everyday Life - 1st Edition (2016)Documento164 páginasMathematics in Everyday Life - 1st Edition (2016)Adhitya Hidayat100% (3)

- 19 Rahasyatrayam PDFDocumento10 páginas19 Rahasyatrayam PDFzodedAinda não há avaliações

- Ultimate Field Guide To PhotographyDocumento23 páginasUltimate Field Guide To PhotographyIulian Oprea100% (1)

- Tantra and Its MisconceptionsDocumento14 páginasTantra and Its MisconceptionsPamela PaulikovaAinda não há avaliações

- Introduction To Modern Indian ArtDocumento41 páginasIntroduction To Modern Indian ArtzodedAinda não há avaliações

- The New MacBook A Guide For Beginners - Matthew HollinderDocumento10 páginasThe New MacBook A Guide For Beginners - Matthew HollinderzodedAinda não há avaliações

- 108 UpanishadsDocumento838 páginas108 UpanishadsHaindava Keralam100% (3)

- Tirukkural MalayalamDocumento122 páginasTirukkural MalayalamAnil Sarngadharan100% (1)

- Hoar - Architects of Conspiracy - An Intriguing History (Conspiratorial View of US History) (1984)Documento360 páginasHoar - Architects of Conspiracy - An Intriguing History (Conspiratorial View of US History) (1984)doggydogAinda não há avaliações

- Introduction To Modern Indian ArtDocumento41 páginasIntroduction To Modern Indian ArtzodedAinda não há avaliações

- Physometric Chart SIDocumento1 páginaPhysometric Chart SIsuathayriAinda não há avaliações

- Headphones Buyer's Guide 2015Documento10 páginasHeadphones Buyer's Guide 2015Fazal AminAinda não há avaliações

- Best Quotes of All Time.Documento25 páginasBest Quotes of All Time.Abhi SharmaAinda não há avaliações

- Water Source Heat Pump Design ManualDocumento48 páginasWater Source Heat Pump Design Manualmnt6176Ainda não há avaliações

- Mathematics in Everyday Life - 1st Edition (2016)Documento164 páginasMathematics in Everyday Life - 1st Edition (2016)Adhitya Hidayat100% (3)

- 100 Internet Security Tips That John Would Never Follow - M MubasharDocumento24 páginas100 Internet Security Tips That John Would Never Follow - M MubasharOAAinda não há avaliações

- Control Valve Selection For Hydraulic SystemsDocumento7 páginasControl Valve Selection For Hydraulic SystemszodedAinda não há avaliações

- How I Became A HinduMalayalamDocumento261 páginasHow I Became A HinduMalayalamStalloneStalloneAinda não há avaliações

- ACAD12 Tips OnlineDocumento21 páginasACAD12 Tips OnlineEnrique ZGAinda não há avaliações

- AutoCAD ProductivityDocumento28 páginasAutoCAD ProductivityzodedAinda não há avaliações

- MB0050 Research Methodology Set 2Documento15 páginasMB0050 Research Methodology Set 2zodedAinda não há avaliações

- How To - Twelve Tips For Taking Better Photos On Your Nokia N8 or 808 PureVieDocumento12 páginasHow To - Twelve Tips For Taking Better Photos On Your Nokia N8 or 808 PureViezodedAinda não há avaliações

- Cablofil RussiaDocumento15 páginasCablofil RussiaSourav BhattacharyaAinda não há avaliações

- L Shape PDFDocumento20 páginasL Shape PDFJinesh PatelAinda não há avaliações

- SPLAT Expert Mode TipsDocumento11 páginasSPLAT Expert Mode TipsAndy HarcupAinda não há avaliações

- PostProcessor Reference Help enDocumento270 páginasPostProcessor Reference Help enHisham Hanafy100% (2)

- Window - Thermal TrendDocumento30 páginasWindow - Thermal TrendCC Cost AdvisoryAinda não há avaliações

- Look@LAN Setup LogDocumento3 páginasLook@LAN Setup LogAlexandre Canal SabariegoAinda não há avaliações

- Proposed Studio: 11 Reno RD, Sandringham, Vic 3191Documento11 páginasProposed Studio: 11 Reno RD, Sandringham, Vic 3191Engineer 1122Ainda não há avaliações

- General Structural/Construction Notes and Specifications: Proposed 4-Storey Residential Building W/FenceDocumento1 páginaGeneral Structural/Construction Notes and Specifications: Proposed 4-Storey Residential Building W/FenceWilbert ReuyanAinda não há avaliações

- Two Years of Jet-Grouting in British ColumbiaDocumento10 páginasTwo Years of Jet-Grouting in British ColumbiaabbidubbiAinda não há avaliações

- KOSORI Test Facilities-LeafletDocumento26 páginasKOSORI Test Facilities-LeafletRichard HollidayAinda não há avaliações

- Oracle XML Developer's Kit Programmer's Guide 12c Release 1 (12.1)Documento660 páginasOracle XML Developer's Kit Programmer's Guide 12c Release 1 (12.1)host2626Ainda não há avaliações

- IO SummaryDocumento8 páginasIO SummaryVineeth VKAinda não há avaliações

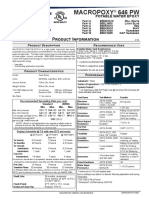

- Macropoxy 646 PW: Protective & Marine CoatingsDocumento4 páginasMacropoxy 646 PW: Protective & Marine CoatingsAnn HewsonAinda não há avaliações

- Isolated Footing: BY: Albaytar, Mark Joseph A. Billones, Joyce Anne CDocumento2 páginasIsolated Footing: BY: Albaytar, Mark Joseph A. Billones, Joyce Anne CMark JosephAinda não há avaliações

- VSAN Stretched Cluster & 2 Node GuideDocumento129 páginasVSAN Stretched Cluster & 2 Node GuideNedeljko MatejakAinda não há avaliações

- QualityStage - Investigate Stage Intro - PR3 Systems BlogDocumento6 páginasQualityStage - Investigate Stage Intro - PR3 Systems BlogMuraliKrishnaAinda não há avaliações

- Failover and Flashback Physical Standby for Testing Without Recreating ConfigDocumento4 páginasFailover and Flashback Physical Standby for Testing Without Recreating Configbaraka08Ainda não há avaliações

- Student ETH BrochureDocumento98 páginasStudent ETH BrochureabedinzAinda não há avaliações

- Section 23 21 14 - Underground Pre-Insulated Hydronic PipingDocumento7 páginasSection 23 21 14 - Underground Pre-Insulated Hydronic PipingaadsamudAinda não há avaliações

- 2279B Mod07la PDFDocumento6 páginas2279B Mod07la PDFJosé MarquesAinda não há avaliações

- Biblioteq Administrator Guide: Release - Notes. HTMLDocumento3 páginasBiblioteq Administrator Guide: Release - Notes. HTMLKostasAinda não há avaliações

- IS 15301: Installation and Maintenance of Fire Fighting Pumps - Code of PracticeDocumento13 páginasIS 15301: Installation and Maintenance of Fire Fighting Pumps - Code of Practiceashwani100% (1)

- Ed M 01.00 I 05Documento18 páginasEd M 01.00 I 05joseellargo100% (1)

- City Walk'-A Shopping Hub at Shaheed Udyan, Varanasi: SynopsisDocumento4 páginasCity Walk'-A Shopping Hub at Shaheed Udyan, Varanasi: SynopsisjioijAinda não há avaliações

- AVSystem Anjay BrochureDocumento4 páginasAVSystem Anjay BrochuresdlfkjldsfAinda não há avaliações

- KULT - Divinity Lost - Quickplay Scenario - Oakwood Heights PDFDocumento23 páginasKULT - Divinity Lost - Quickplay Scenario - Oakwood Heights PDFRafãoAraujoAinda não há avaliações

- C892Documento5 páginasC892dinhtung2210Ainda não há avaliações

- Larsen & Toubros 330MW Power Plant Footing DesignDocumento6 páginasLarsen & Toubros 330MW Power Plant Footing DesignAnand.5100% (1)

- Euthymius and His Monastery in The Judean DesertDocumento33 páginasEuthymius and His Monastery in The Judean DesertnurodaAinda não há avaliações

- Contemporary Architecture in Different Areas of The Arab World: Redefining Identity Through A New Built EnvironmentDocumento11 páginasContemporary Architecture in Different Areas of The Arab World: Redefining Identity Through A New Built EnvironmentakshiAinda não há avaliações