Escolar Documentos

Profissional Documentos

Cultura Documentos

Ep Petrochina Mangrove

Enviado por

StiveGrajalesDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Ep Petrochina Mangrove

Enviado por

StiveGrajalesDireitos autorais:

Formatos disponíveis

February 2013 | EPmag.

com

C

hallenging low-permeability oil reservoirs in the

Ordos basin in north-central China offer proof that

in-depth reservoir understanding, advanced design and

evaluation workflows, and appropriate completion and

fracturing techniques result in production increases of

as much as 80% to 100% over baseline. A pilot project

recently conducted in the basin set out to quantify

production improvements in two horizontal wells and

three vertical wells placed between two horizontal wells

equipped for real-time microseismic fracture monitoring.

An unconventional fracture model incorporating

geologically and geophysically defined natural fracture

patterns and mathematical interaction criteria for

hydraulic and natural fractures was used to optimize

treatment design. Real-time microseismic fracture

monitoring through a dual-monitoring well setup

was performed on a total 26 stages of fracturing treat-

ments. Simultaneous treatments pumped in four stages

were compared to other stages pumped in chronologi-

cal sequences.

Ordos basin challenges

Although historical field development in Ordos basin

tight oil reservoirs was considered economical, the

average production after hydraulic fracturing was low,

and most of the wells were producing only marginally.

Studies indicated that insufficient connected and con-

ductive fracture surface area induced by conventional

fracture completion techniques was the major reason

for low productivity.

Yet even by increasing the fracture treatment size and

proppant mass pumped into the formation, no obvious

incremental production gains were achieved using

conventional fracture design methodologies. This

pointed to the need to improve the understanding of

fracture mechanical propagation behavior and the

proppant distribution mechanism in the reservoir to

break through the production barrier status quo.

Pilot project in Chang-7 formation

To accomplish this objective, the pilot projects two

horizontal laterals were drilled orthogonal to maximum

horizontal stress orientation to enable propagating trans-

verse hydraulic fractures across the laterals as shown in

Figure 1. To obtain accurate microseismic data, dual

monitoring was established using two out of the three

monitoring wells simultaneously.

The horizontal wells were drilled in the lower Chang-7

formation, which is very fine sandstone grading to silt-

stone with average permeability of 0.24 mD and an

average porosity of 10.5%. Natural fractures are widely

distributed across the basin; however, their nature and

characteristics vary from formation to formation and

from block to block.

Optimized treatment design

shows promise

The first horizontal wells drilled in the Chang-7 formation deliver significant production

increases in Ordos basin tight oil reservoirs.

Yang Hua, Xu Yong Gao, Yang Ke Wen,

and Zhou Shu Xun, PetroChina Changqing Oilfield Co.;

Liu Hai and Luo Yin, Schlumberger

COVER STORY:

FRACTURING

FIGURE 1. The pilot projects horizontal laterals were drilled

orthogonal to maximum horizontal stress to fracture across

the laterals. (Images courtesy of Schlumberger)

EPmag.com | February 2013

The two horizontal wells were the first in this reservoir.

The vertical wells that were completed initially produced

31 b/d to 179 b/d after conventional fracturing treat-

ment with crosslinked gel and about 50 to 120 tons of

proppant placed. Production from the vertical wells

declined quickly in three months to fewer than 18 b/d

and could hardly produce economically afterward. From

previous post-closure pressure decline analysis it was

determined that effective permeability can be as low as

0.01 mD. Extremely low permeability and insufficient

fracture surface area for oil production were considered

the main causes for low production.

New simulation workflow

To achieve the objective of maximizing the reservoir-frac-

ture surface contact area in this basin, it was necessary to

have an accurate understanding of how the fracture was

penetrating into the reservoir, including complexity,

effective length, fracture containment within the pay

zone, and fracture conductivity for hydrocarbon produc-

tion. It is well known from other tight oil plays that reser-

voir contact area can be significantly improved with

multiple transverse fractures for horizontal wells. How-

ever, even with transverse fractures, the well potential

could only be maximized with contribution from all of

the pay intervals and optimized proppant distribution

along the lateral.

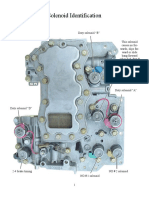

Rather than using traditional planar fracture models

based on a 1-D geomechanical model, the new Mangrove

reservoir-centric stimulation design software was intro-

duced for the pilot project. The software, which is a

plug-in for the Petrel E&P software platform, uses an

integrated reservoir-centric workflow to enable seismic

to simulation as well as optimal completion and stimu-

lation scenarios to enhance production from uncon-

ventional reservoirs. The design-execution-evaluation

cycle in this workflow is distinguished from previous

conventional capability by its ability to simulate com-

plex natural fracture and hydraulic fracture interaction

via new mathematical models in tight reservoirs.

For example, the 3-D geocellular earth model cap-

tures sedimentary, stratigraphic, and geomechanical

details in the reservoir and bounding layers. In the

past these models have been used solely for geologic

study and reservoir simulation. However, in the new

workflow the hydraulic fracture completion design

based on the 3-D geoceullar earth model is coupled

with production prediction based on the hydraulic

fracture gridded onto the upscaled reservoir model.

This enables the full usage of the model and a much

more realistic picture of hydraulic fracturing behavior

and its impact on well productivity.

For improved accuracy, model calibration plays an

important role in this workflow. While 3-D earth models

and complex fracture models provide details in real-

world dimensions with deliberate data inputs, model

accuracy is improved through fracture and production

behavior calibration.

Workflow steps are integrated into a single work

platform and can be implemented routinely for single

well or multiple well design. Calibration cycles are per-

formed during the fracture treatment if necessary. The

COVER STORY:

FRACTURING

FIGURE 2. By correlating the features from several well logs, the

structural variation along the laterals between the monitoring

wells was identified.

FIGURE 3. The surfaces extracted from well correlation show

structural variation.

COPYRIGHT HART ENERGY | 1616 S. VOSS, STE. 1000, HOUSTON, TX 77057 USA | +1 713 260 6400 | FAX +1 713 840 8585

COVER STORY:

FRACTURING

workflow is tailored according to how much data are

available, and the complexity of the 3-D models is cho-

sen to enable the capturing of adequate details with

acceptable computer time consumption.

In this pilot project, geostatistical well correlations to

reflect the detailed formation variation along the laterals

were established through the three vertical wells placed

between the two horizontal target wells. By looking at the

features from several well logs, a series of well tops

including the top and bottom of the target Chang-7 for-

mation was identified to reflect the structural variation

along the laterals. After building a structural model, a 3-D

zonal model was built according to the surfaces extracted

from well correlation. Geologic structure and reservoir

property variation were captured. Properties for each

zone were determined based upon the properties of the

monitoring wells along the laterals.

To capture the basic characteristic and quantitative

modeling of the natural fracture system in this area, a

discrete fracture network (DFN) approach was used

based on geologic knowledge. A manual DFN model was

initially created to represent the natural fractures. With

the DFN model and 3-D geomechanical model, the

unconventional fracture simulation result suggested

basic planar fractures with some simple fracture net-

works by opening natural fractures and creating new

fracture branches during the main fracture propagation.

The DFN model can be further calibrated according to

microseismic fracture monitoring results.

This unconventional fracture model can explicitly

model fracture propagation in 3-D. Hydraulic fracture-

natural fracture interaction, stress shadow effect

between nearby fractures, proppant transportation

in fracture networks, lateral stress, and property varia-

tions are considered.

New workflow results

in increased production

Initial production tests on both horizontal wells showed

783 b/d and 648 b/d, respectively, significantly higher

than all the wells completed in tight oil reservoirs in the

Ordos basin. Production normally varied from 31 b/d to

50 b/d in vertical wells and to 201 b/d for horizontal

wells, on average. The initial result showed substantial pro-

duction increase compared with the production from the

Chang-6 formation of the nearest offset reservoir as shown

in Figure 5, which actually had slightly better reservoir

quality. Compared with the best horizontal well, the initial

results showed an 80% to 100% production increase.

The stabilized production rates after three months

were 5.5 and 3.9 times those of the same vertical well.

Results showed more than a 50% increase compared

with the horizontal well completed in the same forma-

tion in the northern part of the basin.

This article was prepared from SPE article 158268, presented

at the SPE Annual Technical Conference and Exhibition held

in San Antonio, Texas, Oct. 8-10, 2012.

FIGURE 4. The 3-D zonal model with minimum horizontal stress

was determined based upon properties from the monitoring

wells along the laterals.

FIGURE 5. The initial production result for both horizontal wells

(wells A and B) shows a substantial increase as compared to the

vertical well on the same pad.

Você também pode gostar

- Hydrocarbon Fluid Inclusions in Petroliferous BasinsNo EverandHydrocarbon Fluid Inclusions in Petroliferous BasinsAinda não há avaliações

- SPE-187682-MS Successful Hydraulic Fracturing Techniques in Shallow Unconsolidated Heavy Oil SandstonesDocumento6 páginasSPE-187682-MS Successful Hydraulic Fracturing Techniques in Shallow Unconsolidated Heavy Oil SandstonesAndre YudhistiraAinda não há avaliações

- Development of Volcanic Gas Reservoirs: The Theory, Key Technologies and Practice of Hydrocarbon DevelopmentNo EverandDevelopment of Volcanic Gas Reservoirs: The Theory, Key Technologies and Practice of Hydrocarbon DevelopmentAinda não há avaliações

- A Case Study On The Effect of Production Segmentation CompletionDocumento9 páginasA Case Study On The Effect of Production Segmentation CompletionSara Kamil Abd Al-RedahAinda não há avaliações

- Depositional History of Franchthi Cave: Stratigraphy, Sedimentology, and Chronology, Fascicle 12No EverandDepositional History of Franchthi Cave: Stratigraphy, Sedimentology, and Chronology, Fascicle 12Ainda não há avaliações

- Advanced Reservoir Characterization in Vaca Muerta PDFDocumento12 páginasAdvanced Reservoir Characterization in Vaca Muerta PDFojrfgmrfAinda não há avaliações

- Offshore Gas Hydrates: Origins, Development, and ProductionNo EverandOffshore Gas Hydrates: Origins, Development, and ProductionAinda não há avaliações

- SPE 185098 Gas Lift Production Benchmarking Using IPR Risked Inflow Modeling CaseDocumento21 páginasSPE 185098 Gas Lift Production Benchmarking Using IPR Risked Inflow Modeling CaseEdgar GonzalezAinda não há avaliações

- IPTC 16616 A Case Study: Innovative Open Hole Well Completion Provides Superior Results in Tight Gas Formation in Jilin District, ChinaDocumento12 páginasIPTC 16616 A Case Study: Innovative Open Hole Well Completion Provides Superior Results in Tight Gas Formation in Jilin District, ChinaAmr HegazyAinda não há avaliações

- 762id - Development of Cluster-7 Marginal Field Paper To PetrotechDocumento2 páginas762id - Development of Cluster-7 Marginal Field Paper To PetrotechSATRIOAinda não há avaliações

- IPTC 19608 AbstractDocumento14 páginasIPTC 19608 AbstractKeyner NúñezAinda não há avaliações

- SPE 0514 0032 JPT Matrix Acidizing Innovation SurpassesDocumento4 páginasSPE 0514 0032 JPT Matrix Acidizing Innovation SurpassesTrần Hoàng ChươngAinda não há avaliações

- Reservoir Management For Waterfloods R. Baker: This Article Begins On The Next PageDocumento6 páginasReservoir Management For Waterfloods R. Baker: This Article Begins On The Next PageHichem FakhfekhAinda não há avaliações

- Design Considerations When Rod Pumping Gas WellsDocumento12 páginasDesign Considerations When Rod Pumping Gas Wellssurakhi2011Ainda não há avaliações

- Iptc-19182-Ms An Innovative Reservoir Engineering Method To Identify Bypassed Oil and Derisk The Further Development of A Complex Mature FieldDocumento16 páginasIptc-19182-Ms An Innovative Reservoir Engineering Method To Identify Bypassed Oil and Derisk The Further Development of A Complex Mature FieldGilbert OmittaAinda não há avaliações

- Multilateral AsiaDocumento2 páginasMultilateral AsiaNazer CorleoneAinda não há avaliações

- Report 7 Reservoir Management GE 4 مسائيDocumento67 páginasReport 7 Reservoir Management GE 4 مسائيعلي حميد زغيرAinda não há avaliações

- Spe 84497 MS PDFDocumento11 páginasSpe 84497 MS PDFShiyeng CharmaineAinda não há avaliações

- SPE-196631-MS Locate The Remaining Oil Ltro and Predictive Analytics Application For Development Decisions On The Z FieldDocumento24 páginasSPE-196631-MS Locate The Remaining Oil Ltro and Predictive Analytics Application For Development Decisions On The Z FieldMohamed SlimaniAinda não há avaliações

- Spe 104134 MS PDFDocumento8 páginasSpe 104134 MS PDFLeo Rojas DomAinda não há avaliações

- Kal War 2017Documento10 páginasKal War 2017khusnul9Ainda não há avaliações

- Otc 22963Documento14 páginasOtc 22963Rasheed YusufAinda não há avaliações

- Effective Laboratory Coreflood TestsDocumento15 páginasEffective Laboratory Coreflood TestsJj WeetlandAinda não há avaliações

- Spe 167350 Ms - Fast Screening ProcessesDocumento15 páginasSpe 167350 Ms - Fast Screening ProcessesAtrian RahadiAinda não há avaliações

- SPE 158059 MS Screening SurfDocumento11 páginasSPE 158059 MS Screening SurfAnonymous T32l1RAinda não há avaliações

- Asri Sunda BasinDocumento6 páginasAsri Sunda BasinGeologistAinda não há avaliações

- East JavaDocumento6 páginasEast JavaRennySaraSelvianiSipayungAinda não há avaliações

- SPE-188958-MS Successful Field Trials of Water Control in High Water Cut Wells Using An Improved Downhole Water Sink/Drainage SystemDocumento13 páginasSPE-188958-MS Successful Field Trials of Water Control in High Water Cut Wells Using An Improved Downhole Water Sink/Drainage SystemBa NeenAinda não há avaliações

- Completion Challenge PaperDocumento7 páginasCompletion Challenge Papergregorio2407Ainda não há avaliações

- Warrlich Et Al., 2019 (AAPG)Documento31 páginasWarrlich Et Al., 2019 (AAPG)redwanasisAinda não há avaliações

- OptimizingHorizontal PLT Open HoleDocumento5 páginasOptimizingHorizontal PLT Open HoleOmar RosarioAinda não há avaliações

- Eor Presentation SimgapDocumento22 páginasEor Presentation SimgapWasin SaengnumpongAinda não há avaliações

- HPWBM Exceeds SBMDocumento7 páginasHPWBM Exceeds SBMAnonymous JMuM0E5YOAinda não há avaliações

- 10 11648 J Ijsts 20150302 14 PDFDocumento10 páginas10 11648 J Ijsts 20150302 14 PDFBagus SetyaAinda não há avaliações

- Efficient Process Restores Flow To Sand - and Liquid-Loaded Well in Ameland Island - BJ Techline MagazineDocumento28 páginasEfficient Process Restores Flow To Sand - and Liquid-Loaded Well in Ameland Island - BJ Techline MagazineManuel S. NavarroAinda não há avaliações

- Ace 2018 Tpra 011618Documento100 páginasAce 2018 Tpra 011618BilboAinda não há avaliações

- A Three-Layer Modeling For Cuttings Transport With Coiled Tubing Horizontal DrillingDocumento14 páginasA Three-Layer Modeling For Cuttings Transport With Coiled Tubing Horizontal DrillingDavid OtálvaroAinda não há avaliações

- SPE-193121-MS - Integrated Prod Optim Workflow Provides Robust Platform For Significant Oil Gain To A Mature Field-UnlockedDocumento22 páginasSPE-193121-MS - Integrated Prod Optim Workflow Provides Robust Platform For Significant Oil Gain To A Mature Field-UnlockedadeeyoAinda não há avaliações

- Spe 94941 MSDocumento8 páginasSpe 94941 MSLucas NunesAinda não há avaliações

- SPE 135669 Best Practices For Candidate Selection, Design and Evaluation of Hydraulic Fracture TreatmentsDocumento13 páginasSPE 135669 Best Practices For Candidate Selection, Design and Evaluation of Hydraulic Fracture TreatmentsJuan SueAinda não há avaliações

- Matereal Balance and Decline Curve Analysis To Prediction The Performance of Reservoir Using Mbal SoftwereDocumento95 páginasMatereal Balance and Decline Curve Analysis To Prediction The Performance of Reservoir Using Mbal SoftwerePedroAinda não há avaliações

- SPE 189134 Economic Optimization of Water and Gas Shut Off Treatment in Oil WellsDocumento16 páginasSPE 189134 Economic Optimization of Water and Gas Shut Off Treatment in Oil WellsEdgar GonzalezAinda não há avaliações

- Spe 184869 MSDocumento16 páginasSpe 184869 MSSS100% (1)

- Cambay 60Documento6 páginasCambay 60Sanjeev Singh NegiAinda não há avaliações

- IADC/SPE-180689-MS Samarang Well Intervention Performance Evaluation For Production Enhancement PortfolioDocumento11 páginasIADC/SPE-180689-MS Samarang Well Intervention Performance Evaluation For Production Enhancement PortfolioQaiser HafeezAinda não há avaliações

- Lecture 1 - 1 - Course Notes PDFDocumento67 páginasLecture 1 - 1 - Course Notes PDFFaraj NabiyevAinda não há avaliações

- Spe 120267 PPDocumento11 páginasSpe 120267 PPHeron Gachuz MuroAinda não há avaliações

- Waterflood in Basement Reservoirs - White TigerDocumento14 páginasWaterflood in Basement Reservoirs - White TigerIsmail Mohammed100% (1)

- Reservoir Surveillance......Documento51 páginasReservoir Surveillance......Nindy Sherli ParamitaAinda não há avaliações

- Evolving Khuff FormationsDocumento11 páginasEvolving Khuff FormationsrajkumarfAinda não há avaliações

- Well Optimisation: Stephanie Huber, EP-PDocumento3 páginasWell Optimisation: Stephanie Huber, EP-PStan AndreiAinda não há avaliações

- SPE-192670-MS Preserving Great Discoveries by Using Non-Damaging Killing Fluid During The Temporary Abandonment of HPHT Exploratory WellsDocumento9 páginasSPE-192670-MS Preserving Great Discoveries by Using Non-Damaging Killing Fluid During The Temporary Abandonment of HPHT Exploratory WellsAli mohammadAinda não há avaliações

- HardLock V6.1 Installation NotesDocumento5 páginasHardLock V6.1 Installation NotesRajpal ChouhanAinda não há avaliações

- SPE 158831 The Evolution of The NCMA Well Start-Up PhilosophyDocumento10 páginasSPE 158831 The Evolution of The NCMA Well Start-Up Philosophymatheus_moreira0990Ainda não há avaliações

- Spe 39437 MSDocumento14 páginasSpe 39437 MSAndrés Bojacá MatizAinda não há avaliações

- Downs2006 PDFDocumento10 páginasDowns2006 PDFTheNourEldenAinda não há avaliações

- A New Experimental Method To Prevent Paraffin-Wax FormationDocumento6 páginasA New Experimental Method To Prevent Paraffin-Wax FormationMichael MedinaAinda não há avaliações

- Spe 49165 MSDocumento16 páginasSpe 49165 MSamramazon88Ainda não há avaliações

- Spe 133268 MS PDFDocumento18 páginasSpe 133268 MS PDFPhuc TruongAinda não há avaliações

- FrontsimDocumento2 páginasFrontsimALEXANDER100% (1)

- Myron B. Allen III Auth. Collocation Techniques For Modeling Compositional Flows in Oil ReservoirsDocumento218 páginasMyron B. Allen III Auth. Collocation Techniques For Modeling Compositional Flows in Oil ReservoirsStiveGrajalesAinda não há avaliações

- 2011 WinProp TutorialDocumento58 páginas2011 WinProp TutorialoxcnvnAinda não há avaliações

- Steady-State Flow of Gas Through PipesDocumento71 páginasSteady-State Flow of Gas Through PipesAgustin SaezAinda não há avaliações

- Articulo GeomecanicaDocumento3 páginasArticulo GeomecanicaStiveGrajalesAinda não há avaliações

- Articulo GeomecanicaDocumento3 páginasArticulo GeomecanicaStiveGrajalesAinda não há avaliações

- OpenCV 3.0 Computer Vision With Java - Sample ChapterDocumento27 páginasOpenCV 3.0 Computer Vision With Java - Sample ChapterPackt PublishingAinda não há avaliações

- Model Building Intermediate: Exercise GuideDocumento64 páginasModel Building Intermediate: Exercise GuideDragos ZvincuAinda não há avaliações

- Performance CH 33Documento54 páginasPerformance CH 33Yasichalew sefinehAinda não há avaliações

- Casting Fabrication of Carbon Steel Pitman For Crusher Suppliers and Manufacturers China - Professional Factory - Zhengda HDocumento1 páginaCasting Fabrication of Carbon Steel Pitman For Crusher Suppliers and Manufacturers China - Professional Factory - Zhengda HCarlos Ediver Arias RestrepoAinda não há avaliações

- Promat Promapaint dc1 Hvac Ducts Technical Manual en 2019 12Documento6 páginasPromat Promapaint dc1 Hvac Ducts Technical Manual en 2019 12mohammad faldi fauziAinda não há avaliações

- 009-1137-00 HST-SMRTD Savant Smart Host Tech SpecDocumento6 páginas009-1137-00 HST-SMRTD Savant Smart Host Tech Specferna2420Ainda não há avaliações

- Barrett Light 50Documento23 páginasBarrett Light 50Zayd Iskandar Dzolkarnain Al-HadramiAinda não há avaliações

- Catalog07 PDFDocumento13 páginasCatalog07 PDFdeig15050% (2)

- CHAPTER 2 Eff Comm ModelsDocumento9 páginasCHAPTER 2 Eff Comm ModelsSubhash SoniAinda não há avaliações

- Managerial Communication - (MC) - SEM I-GTUDocumento93 páginasManagerial Communication - (MC) - SEM I-GTUkeyurAinda não há avaliações

- Installation & Stock Detail of Ignition Modules & Magnetos of Gas Compressor Units (All Fields)Documento4 páginasInstallation & Stock Detail of Ignition Modules & Magnetos of Gas Compressor Units (All Fields)Atiq_2909Ainda não há avaliações

- Adobe Transaction No 0991059129 20190125Documento2 páginasAdobe Transaction No 0991059129 20190125Mohamed WinnēriAinda não há avaliações

- Astm D979 12 PDFDocumento7 páginasAstm D979 12 PDFJohnCarlosGilAinda não há avaliações

- 816D Specalog (Small)Documento2 páginas816D Specalog (Small)Arvind HarryAinda não há avaliações

- 4 Ataxle PDFDocumento22 páginas4 Ataxle PDFAnonymous XTkln6H100% (1)

- Performance of Gesture Controlled DroneDocumento11 páginasPerformance of Gesture Controlled DroneKrishna SivaAinda não há avaliações

- Netbackup UsefulDocumento56 páginasNetbackup Usefuldnyan123Ainda não há avaliações

- English For Information Technology TEST 1 (Time: 90 Minutes)Documento30 páginasEnglish For Information Technology TEST 1 (Time: 90 Minutes)Lộc Ngô XuânAinda não há avaliações

- Design of Staircase by Limit State Method UNIT-5: C.risers Minus OneDocumento5 páginasDesign of Staircase by Limit State Method UNIT-5: C.risers Minus OneVAIJAYANTHI PAinda não há avaliações

- 4 10 59 08 Juni 2023Documento5 páginas4 10 59 08 Juni 2023ihor.vezhninAinda não há avaliações

- Aicte 2010 EVENDocumento105 páginasAicte 2010 EVENbalusharma1212Ainda não há avaliações

- Manual Yamaha Clavinova P100Documento69 páginasManual Yamaha Clavinova P100Nelon Rocha100% (1)

- CE Board Nov 2020 - Hydraulics - Set 11Documento1 páginaCE Board Nov 2020 - Hydraulics - Set 11Justine Ejay MoscosaAinda não há avaliações

- The Mpeg Dash StandardDocumento6 páginasThe Mpeg Dash Standard9716755397Ainda não há avaliações

- Ford Fiesta Specifications: Exterior DimensionsDocumento2 páginasFord Fiesta Specifications: Exterior DimensionsBuhuntuUhuAinda não há avaliações

- Hydro DepartmentDocumento5 páginasHydro DepartmentaminkhalilAinda não há avaliações

- Transport ModellingDocumento37 páginasTransport ModellingRiza Atiq Abdullah Rahmat100% (6)

- Lec 2 - Tall Building Criteria and Loading-2003Documento30 páginasLec 2 - Tall Building Criteria and Loading-2003JibonGhoshPritomAinda não há avaliações

- A01 04 Assessmentk UndercarriageDocumento7 páginasA01 04 Assessmentk UndercarriageMARIO DEL PINO MUÑOZAinda não há avaliações

- Tutorial 2 What Is The Output of The Below Program?Documento2 páginasTutorial 2 What Is The Output of The Below Program?Sunitha BabuAinda não há avaliações

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseNo EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseNota: 3.5 de 5 estrelas3.5/5 (69)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingNo EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingNota: 5 de 5 estrelas5/5 (5)

- Alex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessNo EverandAlex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessAinda não há avaliações

- The Other End of the Leash: Why We Do What We Do Around DogsNo EverandThe Other End of the Leash: Why We Do What We Do Around DogsNota: 5 de 5 estrelas5/5 (65)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingNo EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingNota: 3.5 de 5 estrelas3.5/5 (34)

- Fire Season: Field Notes from a Wilderness LookoutNo EverandFire Season: Field Notes from a Wilderness LookoutNota: 4 de 5 estrelas4/5 (142)

- The Big, Bad Book of Botany: The World's Most Fascinating FloraNo EverandThe Big, Bad Book of Botany: The World's Most Fascinating FloraNota: 3 de 5 estrelas3/5 (10)

- The Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionNo EverandThe Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionNota: 4 de 5 estrelas4/5 (811)

- World of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsNo EverandWorld of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsNota: 4 de 5 estrelas4/5 (223)

- Wayfinding: The Science and Mystery of How Humans Navigate the WorldNo EverandWayfinding: The Science and Mystery of How Humans Navigate the WorldNota: 4.5 de 5 estrelas4.5/5 (18)

- Spoiled Rotten America: Outrages of Everyday LifeNo EverandSpoiled Rotten America: Outrages of Everyday LifeNota: 3 de 5 estrelas3/5 (19)

- The Lives of Bees: The Untold Story of the Honey Bee in the WildNo EverandThe Lives of Bees: The Untold Story of the Honey Bee in the WildNota: 4.5 de 5 estrelas4.5/5 (44)

- Why Fish Don't Exist: A Story of Loss, Love, and the Hidden Order of LifeNo EverandWhy Fish Don't Exist: A Story of Loss, Love, and the Hidden Order of LifeNota: 4.5 de 5 estrelas4.5/5 (699)

- When You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsNo EverandWhen You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsNota: 3.5 de 5 estrelas3.5/5 (13)

- The Rise and Fall of the Dinosaurs: A New History of a Lost WorldNo EverandThe Rise and Fall of the Dinosaurs: A New History of a Lost WorldNota: 4 de 5 estrelas4/5 (593)

- The Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorNo EverandThe Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorNota: 4.5 de 5 estrelas4.5/5 (137)

- Come Back, Como: Winning the Heart of a Reluctant DogNo EverandCome Back, Como: Winning the Heart of a Reluctant DogNota: 3.5 de 5 estrelas3.5/5 (10)

- When the Sahara Was Green: How Our Greatest Desert Came to BeNo EverandWhen the Sahara Was Green: How Our Greatest Desert Came to BeNota: 4.5 de 5 estrelas4.5/5 (6)

- Last Child in the Woods: Saving Our Children From Nature-Deficit DisorderNo EverandLast Child in the Woods: Saving Our Children From Nature-Deficit DisorderNota: 4 de 5 estrelas4/5 (283)