Escolar Documentos

Profissional Documentos

Cultura Documentos

About The Industry - An Overview

Enviado por

Kp PrakashTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

About The Industry - An Overview

Enviado por

Kp PrakashDireitos autorais:

Formatos disponíveis

Rubber Industry

An Overview

Automotive Industry, globally, as well in India, is one of

the key sectors of the economy. The Indian Automotive

Industry comprising of the automobile and the auto

component sectors has recorded considerable growth

following the delicensing and opening up of the sector

to FDI in 1993. The unbundling of this industry from restrictive environment has, on the one hand,

helped in restructuring, absorbing new technologies, align itself to the global developments and realise

its potential with signifcant increase in industrys contribution to overall industrial growth in the country.

Due to its deep forward and backward linkages with several key segments of the economy, automotive

industry has a strong multiplier efect and acts as one of the drivers of economic growth. The well-

developed Indian automotive industry produces a wide variety of vehicles: passenger cars, light,

medium and heavy commercial vehicles, multi-utility vehicles such as jeeps, scooters, motor-cycles,

mopeds, three wheelers, tractors and other agricultural equipments etc.

It is envisaged that the opportunity landscape for the Indian auto industry would encompass

manufacture of vehicles and components for domestic sales and for exports. India would continue to

enjoy its eminent position of being the largest tractor and three wheeler manufacturer in the world and

the worlds second largest two wheeler manufacturer and would emerge as the worlds eighth/ninth

largest car producer and would retain 4th largest position in world truck manufacturing sector. Further,

by the end of decade, the automotive sector is likely to double its contribution to the countrys GDP

from current levels of 5% to 10%. It is estimated that the automotive sector requires an incremental

investment of Rs 11,000 - 12,000 crores per annum to realise its full growth potential.

Indian Auto Component industry is quite comprehensive with

around 500 firms in

Auto

the organised sector

producing practically all parts and more than 10,000

component

firms in small unorganised sector !he auto component sector has

been one of

Industry

the fastest growing segments of auto industry !he industry, over

the years,

developed the capability of manufacturing all components required to manufacture vehicles, which is

evident from the high levels of indigenisation achieved in the

vehicle industry as well as the components developed for the completely Indian made vehicles

"ver the last few years the Indian Auto Component Industry has created a robust capacity base and world#s

all ma$or manufacturers have set up their manufacturing unit in the country Indian auto component

manufacturing, currently constrained by lac% of large capacities, is slowly but steadily wor%ing on e&panding

capacities and automation levels !he Indian auto component industry is targeting for a bigger share of the

e&port mar%et and is in the process of ramping up its manufacturing capabilities to meet the capacity and

quality requirements !he auto component industry in India is e&pected to grow fourfold from the current

levels of '()*+ billion to over '()

110 billion by the year *0*0 and it would require an average investment of '() ,5 billion per annum

Automotive

Industry

Rubber-' . Rubber

Industry (tatics

Indian

Rubber Industry

(a!istics

(ince the establishment of the

first rubber goods

manufacturing unit in 1/*1 at

0ol%ata, the Indian rubber

industry has maintained its

forward march, particularly

during the post.independence period It has achieved overall e&pansion through increase in the range of

products manufactured, in the number of units, in technological sophistication and self.sufficiency 1esides

catering to the entire domestic demand, the industry is brea%ing new barriers on the e&port front It pro$ects

tremendous growth in the *1st century !he factors responsible for this phenomenal e&pansion are vast

internal mar%et, rapid industrialisation, on.going economic reforms, and improved living standards of the

masses

India is the fourth largest producer of natural rubber and second largest consumer of natural rubber2 and fifth

largest consumer of natural rubber and synthetic rubber together in the world India is the world#s largest

manufacturer of reclaim rubber India is first in productivity of natural rubber !he per capita consumption of

rubber in India is only //0 gms against / to 1+ %ilos in 3apan, '(A and 4urope !his envisages tremendous

growth prospects of the industry in the years to come

5ith around +000 units comprising ,0 large scale, ,00 medium scale and around 5+60 ((I 7 tiny sector

units, manufacturing ,5000 rubber products, employing directly -00 hundred thousand people, including

around **000 technically qualified support personnel !he Indian Rubber Industry plays a core sector role in

the Indian national economy !he industry has certain distinct advantages li%e . an e&tensive plantation

sector2 indigenous availability of the basic raw materials, li%e natural rubber, synthetic rubber, reclaim rubber,

carbon blac%, rubber chemicals, fatty acids, rayon, and nylon yarn and so on2 large domestic mar%et2

availability of cheap labour2 training facility in various technical institutes2 improved living standards of the

masses All these ground support help the Indian rubber industry to poise for an all round development and a

quantum $ump in production and technology up gradation in near future

!he wide range of rubber products manufactured by the Indian rubber industry comprises all types of heavy

duty earth moving tyres, auto tyres, tubes, automobile parts, footwear, beltings, hoses, cycle tyres and tubes,

cables and wires, camelbac%, battery bo&es, late& products, pharmaceutical goods, besides moulded and

e&truded goods for mass consumption !he products manufactured also cover hi.tech industrial items !he

important areas which the industry caters to include all the three wings of defence, civil, aviation,

aeronautics, railways, agriculture, transport as also te&tiles, engineering industries, pharmaceuticals, mines,

steel plants, ports, family planning programmes, hospitals, sports, ie practically to every conceivable field

India rubber industry is basically divided into two sectors . tyre and non.tyre !he tyre sector produces all

types of auto tyres, conventional as well as radial tyres and e&ports to advanced countries li%e '(A, 4' etc

!he non.tyre sector comprises the large, medium scale, small scale and tiny units It produces high

technology and sophisticated industrial products !he small.scale sector accounts for over 508 of production

of rubber goods in the non.tyre sector !he Indian rubber products have been e&ported to around 1/0

countries in the world including '(A, Russia, '0, 1angladesh, Italy, 9epal, :ermany, "man, ;rance, (audi

Arabia, 'A4, African countries etc and e&ports have gone up manifold

!he yardstic% to measure the growth rate of the industry is rubber consumption 1esides yearly consumption

of rubbers . natural, synthetic and reclaim, there are other raw materials li%e carbon blac%, rubber chemicals,

tyre cords, plastici<ers, process oils, <inc o&ide, stearic acid, titanium dio&ide, and other miscellaneous

chemicals which are mostly available indigenously !his apart, almost all types of ma$or rubber machinery

are being manufactured in the country

Rubber-' . Rubber Industry (tatics

Indian

Rubber

Industry

Indian

Rubber Industry

(a!istics

Natural Rubber is produced from the crop harvested from rubber

plantations both in the latex form as well as in the feld coagulam

form. Latex is a milky white dispersion of rubber in water and

feld coagulam is the auto coagulated latex on the tapping panel

(tree lace) and the collection cups (shell scrap and cuplumps).

Both the latex and feld coagulam harvested from rubber

plantations being highly susceptible to degradation by

contamination on keeping, have to be processed into marketable

forms that will allow safe storage and marketing. The most

important forms in which natural rubber is processed and

marketed are Sheets (RSS1 to RSS5), Crepes (Pale Latex

Crepes; Estae Brown Crepes; Thin Brown Crepes; Thick Blanket Crepes; Flat Bark Crepes; Pure

Smoked Blanket crepe), Block rubber, Technically specifed (SMR, SIR, STR, ISNR), Preserved latex

concentrates. Among these forms/types, the frst three are in the dry form and almost 90% of the total

natural rubber produced in the world is at present marketed in these 3 forms. Sheet rubber and block

rubber are the dominant types of dry natural rubber available in the world market and this dominance

reduced the number of grades used in any volume to the 10-15 within these types.

In 1/0/, a team headed by ;rit< =ofmann, wor%ing at the

1ayer laboratory in 4lberfeld, :ermany, succeeded in

polymeri<ing methyl isoprene, thereby creating the first

synthetic rubber !he first rubber polymer synthesi<ed from

butadiene was created by (ergei >asil$evich ?ebedev in

1/10 @ractical synthetic rubber grew out of studies

published in 1/,0 written independently by American

5allace Carothers, Russian scientist ?ebedev, and the

:erman scientist =ermann (taudinger !hese studies led in

1/,1 to one of the first successful

synthetic rubbers, %nown as

neoprene, which was developed at

Au@ont under the direction of 40

1olton 9eoprene is highly resistant to

heat and chemicals such as oil and

gasoline, and is used in fuel hoses

and as an insulating material in

machinery

(ynt

hetic

Rubb

er

In 1/,5, :erman chemists synthesi<ed

the first of a series of synthetic rubbers

%nown as 1una rubbers !hese were

copolymers, meaning the polymers were

made up from two monomers in

alternating sequence "ne such 1una

rubber, %nown as :R( B:overnment

Rubber (tyreneC, is a copolymer of

butadiene and styrene, was the basis for

'( synthetic rubber production during

5orld 5ar II After the war, natural

rubber plantations no longer had a

stranglehold on rubber supplies,

particularly after chemists learned to

synthesi<e isoprene

(tyrene.1utadiene Rubber B:R.(C

remains the primary synthetic rubber

for the manufacture of tyres

(ynthetic rubber is any

type of artificially made

polymer material, which

acts as an elastomer An

elastomer is a material

with the mechanical Bor

materialC property that it

can undergo much more

elastic deformation under

stress, than most

materials and still return to

its previous si<e without

permanent deformation

(ynthetic rubber serves as

a substitute for natural

rubber in many cases,

especially when improved

material

properties

are

needed

(yntheti

c rubber

can be

made

from the

polymeri

<ation of

a variety

of

monom

ers

includin

g

isopren

e B*.methyl.1,,.butadieneC, 1,,.

butadiene, chloroprene B*.chloro.

1,,.butadieneC, and isobutylene

BmethylpropeneC with a small

percentage of isoprene for cross.

lin%ing !hese and other monomers

can be mi&ed in various desirable

proportions to be copolymeri<ed

for a wide range of physical,

mechanical, and chemical

properties !he monomers can be

produced pure and addition of

impurities or additives can be

controlled by design to give optimal

properties @olymeri<ation of pure

monomers can be better controlled

to give a desired proportion of cis

and trans double bonds

Rubber-' . Rubber Industr y (tatics

9atural

Rubber

ISO Code Technical Name- Common Names

BIIR Bromo Isobutylene Isoprene - Bromobutyl

BR Polybutadiene

CIIR Chloro Isobutylene Isoprene - Chlorobutyl, Butyl

CR Polychloroprene - Chloroprene, Neoprene

CSM Chlorosulphonated Polyethylene - Hypalon

ECO Epichlorohydrin - ECO, Epichlorohydrin, Epichlore, Epichloridrine

EP Ethylene Propylene

EPDM Ethylene Propylene Diene Monomer - EPDM, Nordel

FKM Fluoronated Hydrocarbon - Viton, Kalrez, Fluorel

FVQM Fluoro Silicone - FVQM

HNBR Hydrogenated Nitrile Butadiene - HNBR

IR Polyisoprene - (Synthetic) Natural Rubber

IIR Isobutylene Isoprene Butyl - Butyl

MVQ Methyl Vinyl Silicone - Silicone Rubber

NBR Acrylonitrile Butadiene - NBR, Nitrile, Perbunan, Buna-N

PU Polyurethane - PU, Polyurethane

SBR Styrene Butadiene - SBR, Buna-S, GRS

SI Polysiloxane - Silicone Rubber

XNBR Acrylonitrile Butadiene Carboxy Monomer - XNBR, Carboxylated Nitrile

Indian

Rubber Industry

(a!istics

(ynthetic rubber is a

by.product obtained

from petroleum

industry

Important sources are

styrene, acetylene and

butadiene !wo of the

most important types

of synthetic rubbers

are butyl rubber and

styrene.butadiene

rubber

Car

bon

Bla

ck

:enerally carbon blac% used in tyres

and rubber product is produced by a

process called furnace !yres and

rubber products represent the ma$or

end.use applications, accounting for

about /08 of global carbon blac%

mar%et !he growth of carbon blac%

is closely tied to the automotive

industry and the production of tyres

Consumption of carbon blac% in

tyres is e&pected to grow at a

compounded annual rate of ,+8

!he virgin carbon blac% industry is

li%ely to come under increased

pressure from governments and

environmental groups, as this

product is a significant greenhouse

gas emitter Aemand for carbon

blac% in paints, coatings and in%s

are e&pected to show upward trend

Aeveloping economies in Asia

@acific, Diddle 4ast7Africa and ?atin

America will emerge as the largest

and the most lucrative mar%ets in

the upcoming

years

Increasing level

of disposable

personal

income in these

regions is

e&pected to

generate

healthy demand

for automobiles

and other

consumer

applications,

translating into

higher demand

Asia.@acific

represents the

largest mar%et

for carbon blac%

in the world,

with a strong

hold of ,68

share

(ilica and other

silanes are

e&pected to

offer a serious

challenge to

carbon blac% in

the future and

are fast

emerging as

ma$or

substitutes to

carbon blac% due to better performance and

environmental friendly nature !hese products

reduce rolling resistance in tyres at the same time

improve fuel efficiency, hence they are increasingly

finding usage in tyres mar%et

(teady demand from %ey end.user industries

continues to provide sustainable business options

for active carbon blac% manufacturers :rowth in

automobile demand and the subsequent increase in

tyre manufacturing provide reasonable scope for

increase in volume consumption 5ith the global

automobile industry moving east to China, India and

4astern 4urope, the tyre industry has followed, and

with it the carbon blac% producers !he large

mar%ets of China and India will post particularly

impressive gains due to a continuing rapid

e&pansion in their respective motor vehicle and tyre

industries that will be driven by robust economic

growth in both nations

There is a potential for much higher

growth for whole spectrum of rubber

industry in the domestic market due to

the fact that the current car penetration

level in India is just 7 cars per thousand.

The tyre industry accounts for about

65% of carbon black demand in India

followed by 15% in rubber products and

20% is utilized by ink, printing and other

speciality chemicals etc. Carbon black

helps in conducting heat away from the

tread and belt area of the tyre, reducing

thermal damage and increasing the

durability of the tyre.

Rubber-' . Rubber Industry (tatics

Indian

Rubber Industry

!=4 R'114R 1"ARA

(a!istics

The Indian Rubber Board was constituted under the Rubber (Production and Marketing) Act, 1947. This act

was passed on the recommendation of an adhoc committee appointed by the Government of India in 1945

and it came into force on 19 April 1947. The Rubber Production and Marketing (Amendment)

Act of 1954 made certain changes in the constitution of the Board and amended its name as The

Rubber Board. This act came into force on 1st August 1955. The Rubber Act was further amended by

the Rubber Amendment Act 1960 which made certain alterations in the rate and procedure of collection

of cess on rubber. It was again amended by the Rubber (Amendment) Act 1982 to enable the Central

Government to appoint a part-time Chairman/whole time Chairman for the Board and an Executive

Director on whole time basis (if considered necessary by the Central Government) to exercise such

powers and perform such duties as may be prescribed or delegated to him by the chairman. This Act

came into force on 23rd October 1982.

The Chairman who is the administrative head of the Board, exercises control over all the nine departments.

Viz. Administration, Rubber Production, Research, Rubber Processing & Product Development, Statistics &

Planning, Finance & Accounts, Training, Market Promotion and Licensing & Excise duty. Publicity & Public

Relations, Planning, Internal Audit & Vigilance Divisions function directly under the Chairman.

The functions of the Board as defned under the Act are:

1. To promote by such measures as it thinks ft the development of the rubber industry.

2. Without prejudice to the generality of the foregoing provision the measures referred to therein may

provide for:

1) Undertaking, assisting or encouraging scientifc, technological or economic research.

2) Training students in improved methods of planting, cultivation, manuring and spraying.

3) The supply of technical advice to rubber growers.

4) Improving the marketing of rubber.

5) The collection of statistics from owners of estates, dealers and manufacturers.

6) Securing better working conditions and the provision and improvement of amenities and

incentives to workers.

7) Carrying out any other duties which may be vested with the Board as per rules made under this Act.

3. It shall also be the duty of the Board:

1) To advise the Central Government on all matters relating to the development of the rubber

industry, including the import and export of rubber.

2) To advise the Central Government with regard to participation in any international conference or

scheme relating to rubber.

3) To submit to the Central Government and such other authorities as may be prescribed, half

yearly reports on its activities and the working of this act, and

4) To prepare and furnish such other reports relating to the rubber industry as may be required by

the Central Government from time to time.

CAPEXIL

!he *Eth Darch 1/5E saw the emergence of an organi<ation with a mammoth tas% ahead !hat day, Cape&il

B;ormerly, Chemicals F Allied @roducts 4&port @romotion CouncilC, started off on the mission to further

the cause of Indian e&ports of chemical based and allied products

!he prime ob$ective of Cape&il is to offer value added services to its member e&porters and to promote

their products in the international mar%ets Cape&il has always lent its creative resources for e&port

promotion strategies !hese strategies include mar%et research, participation in trade fairs and buyers

seller meets, procurement of databases and trade information, publicity drives etc

CA@4GI? acts as Heyes F ears# of the :overnment in matters of e&port of the concerned industries and

thus, contributes to the formulation of national e&port policies

Rubber-' . Rubber Industry (tatics

Performance of Rubber Industry 201112

The global economic slowdown had afected the

Indian economy and Indian economy witnessed a

swift recovery. The impact of global slowdown was

more intense on industry, particularly the

manufacturing sector. The fscal and monetary

policy interventions, however, provided the stimulus

to the economy, leading to a recovery in the GDP

growth in 2011-12.

During 2011-12 period, Indian economy grew by 6.5%,

mainly due to poor performance of the manufacturing

sector, as against 7.8% in the previous fscal. However,

economic growth, as measured by the Gross Domestic

Product (GDP), decreased to 7.8% in 2011-12 from

8% in 2009-10 due to slowdown in farm output and

construction activities and fnancial services

performance.

The growth of manufacturing sector was fairly

aligned with the overall growth of industry and as

a dominant sector; it chartered the growth of

overall industry. Indias manufacturing sector

growth during year stood at 5.1%, which is one-

third of Chinas factory output of 15% and also

lower than the world average of 6.5%, according

to a UN report.

The IIP groups the industry into three broad

sectors like mining, manufacturing and electricity.

The performance of these three sectors indicates

that the mining sector have been able to maintain

the growth at about trend rates. The rate of

growth

wheelers were 76%, 15%, 4.5% and million tonnes as against 14.1 million

4.5% respectively. The growth rate tonnes in 2010.

recorded for domestic sales for 2011-12

was 12.24% amounting to 17,376,624 Global natural rubber consumption

vehicles. increased to 10.92 million tonnes in

The auto tyre sector registered a growth

2011 registering a growth of 1.4%

compared to 10.78 million tonnes in

of 3.7% as against 13.4% achieved 2010 due to low demand for vehicles

during 2010-11. The general rubber and tyres. Global synthetic rubber

goods sector recorded a negative growth consumption increased to 14.93

of 1.2% during 2011-12 compared to a million tonnes during 2011 from

negative growth of 1.2% registered during 14.09 million tonnes during 2010,

the previous year. According to the recording a growth of 6.0%. World

Automotive Tyre Manufacturers NR and SR consumption ratio during

Association, the average growth in tyre 2011 was 42:58.

production during the year 2011-12 was

22% compared to 13.4% in 2010-11. The Indian (cenario

truck & bus tyre production registered a Natural Rubber Production

growth of 3% during 2011-12 compared Production of natural rubber in India

to 3% achieved during 2010-11. The during 2011-12 was 903,700 tonnes

production passenger car tyre compared to 861,950 tonnes during

segments recorded 31% growth in 2011- 2010-11 and recorded a growth of 4.8%

12 as against 31% attained during 2010- compared to the previous year. The

productivity

during

CA!4:"RI.5I(4 @R"A'C!I"9 "; !IR4( F !'14( 2011-12 increased to

(Qty in 000 numbers) Tyres Tubes1841 kg/ha from 1806

Products 2011-12* 2010-11 2011-12* 2010-11kg/ha during 2010-11.

Truck & Bus 160857 15668 15404 14990The factors attributed

Tractor 5667 5423 2149 2006

to the growth in

Car 27141 26201 8363 9127

production were

Jeep 1595 1500 1857 1746

favourable weather LCV 6688 6029 5417 5232

Motor Cycles 44857 43118 45092 43156conditions and

Scooter+ 22195 20140 17177 16321intensive harvesting

A.D.V 293 311 166 198due to attractive price.

OTR 196 191 112 97

Industrial 681 616 100 74

Natural rubber

Total 125398 119197 95837 92947

Consumption

*: provisional, +including Moped

The consumption of

(Source: Automotive Tyre Manufacturers Association) natural rubber in

of manufacturing also improved

considerably in the last two

years and has been in double

digit. Electricity sector however,

have grown more at the trends

rates.

The Automotive production data for

2011-12 shows a production growth

of 13.83% over previous year. The

industry produced 20,366,432

million vehicles of which share of

two wheelers, passenger vehicles,

commercial

vehicles

and three

11. Export of tyres also

increased by

22% even though truck

& bus tyre exports

declined by 2%.

5orld Rubber

(cenario

According to the

International Rubber

Study Group (IRSG),

the world natural rubber

production increased by

5.5% to 10.97 million

tonnes in

2011,

compared

to a growth

of 7.3%

during

2010.

Global

synthetic

rubber

production

during

2011

registered

a growth

of 7.3 % to

15.1

2011-12

was

964,415

tonnes

with a

growth of

1.76% as

against

947,715

tonnes

during

2010-11.

Consu

mption of Natural Rubber

(Qty in Tonnes) 2010-11 2011-12Gr %

Tyres & Tubes 597623 631410 5.7

General Goods 350092 333005 -4.9

Total NR 947715 9644151.76

Rubber- ' . Rubber Industry (tatics

Import & Export of NR

As per the statistics published by

the Directorate General of

Commercial Intelligence &

Statistics (DGCI&S), India has

imported 205,433 tonnes of

natural rubber during 2011-12

against the import of 190,674

tonnes during 2010-11.

Exporters have utilized the

advantage of price diferential

between domestic and international

price during the initial and terminal

months and exported 27,145

tonnes of natural rubber during

2011-12 compared to 29,851

tonnes exported during the

previous year.

The stock of natural rubber as on

31st March 2012 was at 236,275

tonnes.

Synthetic Rubber Production

The Synthetic rubber production

increased to 110,599 tonnes

during 2011-12 from 110,340

tonnes recorded during 2010-11,

registering a growth of 0.2% as

against a growth of 3.4% during

2010-11.

Synthetic Rubber

Consumption

Synthetic rubber consumption

increased

to 423,350 tonnes during 2011-12

registering a growth of 2.8% as

against 411,830 tonnes consumed

during 2010-11. The automotive tyre

sector consumed 307,365 tonnes of

synthetic rubber during 2011-12 as

against 298,414 tonnes during 2010-

11, recording a growth of 3%. The

consumption ratio of natural and

synthetic rubber in India changed to

69:31 during 2011-12 from 70:30

during 2010-11.

Consumption of Synthetic

Rubber

(Qty in Tonnes) 2010-11 2011-12 Gr%

Tyres & Tubes 298414 307365

General Goods 113416 115985

Total SR 411830 423350

Consumption of NR & SR

(Qty in Tonnes) 2010-11 2011-12Gr%

Tyres & Tubes 896037 938775

General Goods 463508 448990

Total NR & SR 1359545 1387765

Import & Export of SR

Import of synthetic rubber by the

user industry during 2011-12

increased to 327,625 tonnes

compared to 302,030 tonnes

during 2010-11.

India

n

Rubber Industry

(a!istics

Price of Natural Rubber

During the year 2011-12, natural

rubber prices in the domestic and

international markets have been

ruling high. The surge in price was

due to tight supply, rise in crude oil

price, climatic factors, currency

movements, futures market

movements etc. Annual average

price for domestic RSS-4 grade

rubber for the year 2011-12 was Rs

208.05 per kg compared to

Rs.190.03 per kg in 2010-11.

The average international price for

RSS-3 grade was Rs.209.15 per kg

for the year 2011-12 and for the year

2010-11 the average price was

Rs.195.55 per kg.

;orecast

According to Rubber Board, the

production of natural rubber for the year

2012-13 is projected at 9.42 lakh

tonnes with a growth rate of 4.2% and

the projected consumption for the year

2012-13 is 10.06 lakh tonnes with a

growth of 4.4%.

Society of Indian Automotive

Manufacturers has forecasted the sales

growth of 11-13% for the fscal 2012-

13.

ESTIMATED

PRODUCTI

ON OF KEY

INDUSTRIES

IN THE

NON-SSI SECTOR

ITEM GROUPS

Adhesives

Auto Ancillary & Parts

Bicycles

Cable, Rubber Insulated

Carbon Black

Commerical Vehicles

Complete Tractors

Condoms

Fatty Acid

Hose Pipe

Motor Cycles

Passenger Cars

Rubber Chemical

Rubber Flaps

Rubber Transmission & V BeltsRs.Crore

Rubber Tread

ITEM GROUPS ACOUNTING

Scooter and Mopeds Numbers

Sports Goods, Rubber Th. Numbers

Synthetic Resins

Synthetic Rubber

Three-Wheelers Numbers

Tube, Cycle/Rickshaw

Tube, Truck

Tyre, Car/Cab

Tyre, Cycle/Rickshaw

Tyre, Jeep (Incl. Suv, Muv)

Tyre, Motor Cycle

Tyre, Tractor Front

Tyre, Tractor, Rear Numbers

Tyre, Tractor, Trailer Numbers

Tyre, Truck/Bus Th. Numbers

Utility/Multi-Purpose Vehicles Numbers

NOTE: Figures likely

to undergo change

based on factual

reporting.

Rubber- ' . Rubber Industry (tatics

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Catálogo de Pruebas Estándar IEEE para Transformadores Tipo SecoDocumento83 páginasCatálogo de Pruebas Estándar IEEE para Transformadores Tipo SecoBanner Ruano100% (2)

- CESC Dhariwal 300 MW - ChandrapurDocumento10 páginasCESC Dhariwal 300 MW - Chandrapurramnadh803181Ainda não há avaliações

- Study On Customer's Perception With Special Reference To Garnier Hair Care Products"Documento1 páginaStudy On Customer's Perception With Special Reference To Garnier Hair Care Products"Kp PrakashAinda não há avaliações

- To Whom So Ever It May Concern: Ref: JCRES/ADM/CS/17/18 Date: 15/05/2018Documento1 páginaTo Whom So Ever It May Concern: Ref: JCRES/ADM/CS/17/18 Date: 15/05/2018Kp PrakashAinda não há avaliações

- A Study On Employee'S Absenteeism in Mannan Spinning Mill PVT - LTDDocumento1 páginaA Study On Employee'S Absenteeism in Mannan Spinning Mill PVT - LTDKp PrakashAinda não há avaliações

- MilkDocumento7 páginasMilkKp PrakashAinda não há avaliações

- GSM Based Vehicle Fuel Monitoring System: A Major Project Report OnDocumento218 páginasGSM Based Vehicle Fuel Monitoring System: A Major Project Report OnKp PrakashAinda não há avaliações

- Drury Hotel Application and Interview UsaDocumento2 páginasDrury Hotel Application and Interview UsaKp PrakashAinda não há avaliações

- Rework DetailsDocumento106 páginasRework DetailsKp PrakashAinda não há avaliações

- JJ Spinning Mills CompletedDocumento1 páginaJJ Spinning Mills CompletedKp PrakashAinda não há avaliações

- Group 2a Answer KeysDocumento14 páginasGroup 2a Answer KeysKp PrakashAinda não há avaliações

- Shriram Value Service1Documento1 páginaShriram Value Service1Kp PrakashAinda não há avaliações

- Chapter 1 IntroductionDocumento3 páginasChapter 1 IntroductionKp PrakashAinda não há avaliações

- Unit 1Documento40 páginasUnit 1Kp PrakashAinda não há avaliações

- Adr Polymers (P) LTD CertificateDocumento1 páginaAdr Polymers (P) LTD CertificateKp PrakashAinda não há avaliações

- Adr Polymers Acceptance CertificateDocumento1 páginaAdr Polymers Acceptance CertificateKp PrakashAinda não há avaliações

- JJ Spinning Mills AcceptanceDocumento1 páginaJJ Spinning Mills AcceptanceKp PrakashAinda não há avaliações

- Front PageDocumento6 páginasFront PageKp PrakashAinda não há avaliações

- Front PageDocumento6 páginasFront PageKp PrakashAinda não há avaliações

- Unitedtech (P) LTD CertificateDocumento1 páginaUnitedtech (P) LTD CertificateKp PrakashAinda não há avaliações

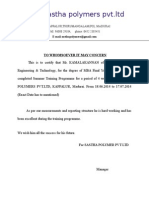

- Sastha Polymers PVT - LTD: To Whomsoever It May ConcernDocumento2 páginasSastha Polymers PVT - LTD: To Whomsoever It May ConcernKp PrakashAinda não há avaliações

- Front PageDocumento6 páginasFront PageKp PrakashAinda não há avaliações

- Quality Knit Wears CertificateDocumento1 páginaQuality Knit Wears CertificateKp PrakashAinda não há avaliações

- MIT16 842F15 Ses1SE Ovr VWDocumento64 páginasMIT16 842F15 Ses1SE Ovr VWDilshanAinda não há avaliações

- Zenith Cooling FanDocumento2 páginasZenith Cooling Fanraza239Ainda não há avaliações

- Agile Project Plan Template Excel - awp3fO7DZjfxukIDocumento25 páginasAgile Project Plan Template Excel - awp3fO7DZjfxukIAlex Orlando Castillo CentenoAinda não há avaliações

- Feasibility Analysis of 5MW Osmanabad Solar PV Power ProjectDocumento52 páginasFeasibility Analysis of 5MW Osmanabad Solar PV Power ProjectAnkur PathakAinda não há avaliações

- Jurnal QFDDocumento25 páginasJurnal QFDsuryaniAinda não há avaliações

- PdsDocumento3 páginasPdsEnrico SaviraAinda não há avaliações

- Re-Drawing Sukowati - Document Control SheetDocumento5 páginasRe-Drawing Sukowati - Document Control SheetHSE TrihascoAinda não há avaliações

- Megaworld CanopyDocumento6 páginasMegaworld CanopyNanam ZaerAinda não há avaliações

- March 19, 2013 PMDocumento251 páginasMarch 19, 2013 PMOSDocs2012Ainda não há avaliações

- Mumbai Port Trust: Civil Engineering DepartmentDocumento96 páginasMumbai Port Trust: Civil Engineering Departmentsuji91Ainda não há avaliações

- Egr Sensor St9972Documento2 páginasEgr Sensor St9972Elias Nassif GomezAinda não há avaliações

- The National Academies Press: Guidebook For Addressing Aircraft/Wildlife Hazards at General Aviation Airports (2010)Documento189 páginasThe National Academies Press: Guidebook For Addressing Aircraft/Wildlife Hazards at General Aviation Airports (2010)ERRAMESH1989Ainda não há avaliações

- Geometric White Paper Critical Chain Project Management CCPM3Documento21 páginasGeometric White Paper Critical Chain Project Management CCPM3tushar2001Ainda não há avaliações

- SAP MM Quick Guide PDFDocumento222 páginasSAP MM Quick Guide PDFKhadeer AhamedAinda não há avaliações

- Ska, Monthly Report Januari 2018Documento60 páginasSka, Monthly Report Januari 2018Muhammad Ma'mumAinda não há avaliações

- Abcd EfghDocumento11 páginasAbcd EfghDisha MehtaAinda não há avaliações

- Sample Welding Summary FormatDocumento1 páginaSample Welding Summary Formatalex sanjanAinda não há avaliações

- Thimmaiah B C - Asst Registrar - Patent 13Documento2 páginasThimmaiah B C - Asst Registrar - Patent 13THIMMAIAH B CAinda não há avaliações

- Chapter 1 - Introduction To Production ManagementDocumento12 páginasChapter 1 - Introduction To Production ManagementRohit BadgujarAinda não há avaliações

- Jane Clark Evolution ITIL Service Management Presentation Sept07Documento11 páginasJane Clark Evolution ITIL Service Management Presentation Sept07Rohan SatputeAinda não há avaliações

- Oracle UnifierDocumento16 páginasOracle UnifierahhanyAinda não há avaliações

- Unit 3 - Consumer Behaviour (For SA1)Documento5 páginasUnit 3 - Consumer Behaviour (For SA1)lovellmenezesAinda não há avaliações

- Space Efficiency in High-Rise Office BuildingsDocumento21 páginasSpace Efficiency in High-Rise Office BuildingsSrvt Snr100% (1)

- Archmodels Vol 105 Garden Hardscape SoftscapeDocumento18 páginasArchmodels Vol 105 Garden Hardscape SoftscapegombestralalaAinda não há avaliações

- OEKO Tex StandardDocumento2 páginasOEKO Tex StandardWahyuPurboSuasanaAinda não há avaliações

- Rejection Handling ProcessDocumento4 páginasRejection Handling ProcessSangeeth BhoopaalanAinda não há avaliações

- IADC Safety Alert Mud Pumps GDDocumento1 páginaIADC Safety Alert Mud Pumps GDlucas ronaldo coronel mendozaAinda não há avaliações

- KP2 KP3 GB 10-08 01Documento20 páginasKP2 KP3 GB 10-08 01Jas SumAinda não há avaliações