Escolar Documentos

Profissional Documentos

Cultura Documentos

Candy Switch

Enviado por

vhrgmar09Descrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Candy Switch

Enviado por

vhrgmar09Direitos autorais:

Formatos disponíveis

CANDY SWITCH

!'

~

~

nl(~/.!..uti1~.." J !0 li{{~ liL!.lllZ[llU

~ (uliz ~l!I!lltlz

. .~. ~. ~

~

"

(01

~ !

.,

!

~~I

- Accurately adjust the timing of electrical or

electronic circuits-even while running.

a CANDY

~

CONTROLS

- Dwell length and the timing of the dwell are fully

adjustable from 0-360 degrees.

- Eliminate costly down time associated with trial

and error machine start-ups and changeovers.

DESCRIPTION

;:; ;:;

- -

The Candy Switch series is a full

line of adjustable-while-running

earn switches. These electro-

mechanical and solid-state

switches are used to adjust the

"on" and "off" points (or dwell

time) of electrical or electronic

circuits at any point during a

machine cycle. These variable

dwell devices are commonly used

to control glue guns, solenoids,

air and hydraulic cylinders, motors,

relays, clutch-brakes and many

other industrial devices.

Dwell control is just one function

of this earn-switch mechanism. It

is equally important to establish

the "trip-on point" or timing

within the machine cycle. The

Candy Switch series allows a

machine operator to advance or

retard this timing to ensure that

the dwell activates at the right

point. Like the dwell control, the

timing of the Candy Switch may

be adjusted while the machine

is running.

Since it is possible to alter both

dwell and timing, the Candy

switch becomes a unique tool

for the machine designer and

operator. The designer.no,ionger

has to calculate the rise and dwell

for cams which are exp~nsive to

.

fabricate and modify. The machine

operator no longer has to settle

for "good enough" timing. With

adjustable-while-running control,

optimal machine performance

becomes a reality.

PRINCIPLE OF

The Candy Switch series is

comprised of five major

components: an input shaft,

a rotating cam, a switching

mechanism, a dwell control

assembly and a timing control

assembly. The only components

which change depending on

the model of Candy Switch

(electro-mechanical or solid-state)

are the cam and the switching

mechanism.

To actuate the switch, the input shaft

must be coupled, in some manner,

to a rotating member of the parent

machine. The Candy Switch is a

1:1 unit, meaning that one full

revolution of the input shaft

represents one full cycle ofthe

dwell and timing set points. If

one revolution of the input shaft

does not match the machine cycle,

a ratio must be added between

the parent machine and the Candy

Switch, bringing these relationships

back to a 1:1 ratio.

Rotating the input shaft causes

the cam to rotate via a parallel-shaft

helical gear arrangement. In

electro-mechanical Candy Switches,

the cam has a physical, uniformly

increasing rise which rotates over

a snap action type switch or air

valve. When the nylon roller of the

switch hits the rise, the circuit

"trips on" until the cam rotates

and the nylon roller falls off the

rise, thus turning the circuit "off".

Solid-state Candy Switches employ

a solid cam wrapped with a two-tone

reflective material. The solid-state

cam rotates above a photo sensor

which is part of the solid-state

switching mechanism.

The switching mechanism activates

both the dwell and the timing by

opening or closing a circuit based

on the cam location. This

DWELL

To provide an infinitely adjustable dwell or "on-time" period, a

cam of uniformly increasing rise is employed to activate the switch.

Shifting the cam on its hex drive shaft alters the percentage of rise

area in contact with the switch roller. This design allows dwell time

to be varied from 0-360 even while running.

TIMING

To provide infinite timing adjustment of the switch "trip-on" point,

a pair of helical gears are arranged so that when the shorter gear

is shifted on its hex shaft, a rotary motion is imparted which causes

a change in phase relationship. Full travel allows over 3600 of phase

timing, even while running.

OPERATION

Carn

mechanism also serves as the

terminal block for incoming

and outgoing signals or voltages.

Electro-mechanical switches

typically incorporate a snap action

type micro switch or a two or three

way air valve. Solid-state switching

mechanisms are typically photo

sensor based boards which pick

up a reflective pattern off a

printed cam.

The unique internal design of the

Candy Switch permits on-the-fly

control of both circuit dwell and

timing. The dwell control assembly

increases or decreases the dwell by

moving the cam back and forth over

the switching mechanism. Circuit

timing is achieved by rotating the

cam on its axis over the switching

mechanism. Both adjustments are

actuated by the respective control

knobs on the front face of the

Candy Switch.

Most models provide a full 3600

range for both timing and dwell.

The values for these setpoints may

be monitored from the reference

scale on top of the Candy Switch.

~

~\,~\~~~.~

~

"A.C.AM.

"

AM.

vou

""" "M"

D.T ST

2B 20 80

'0

25

12S 20 80 5 2.0

250 20 80 .2 .5

480 20 50

- -

600 5 10

- -

ELECTRO-MECHANICAL CANDY SWITCH MODELS

MODELS

There are two basic types of electro-mechanical Candy

Switches which can be determined by the switching

mechanism. The first type employs a snap action type

switch to open and close the circuit. The second

type uses a two or three-way air valve as the

switching mechanism.

The standard cam for all electro-mechanical

models is the CS-12. The CS-12 cam

provides a full 0-360' range for both

dwell and timing"

..

MODEL A

General Purpose Switch

A 20 amp, single pole, double throw, snap

action switch. Speed to 500 cpm. Switch

mechanical life- 10 million cycles.

""'O""""',",m""""""",",,,,,"

mo"""","""","'W,""""",,""",,,,,

ELECTRO-

MECHANICAL CAMS

CS-12

MODEL B ~~~p~:~~~;.~~AY

DOWN

t

UP t

~

/

Air Valve

PRESSURE 0300 PSI OUT-

A cam actuated popp

.

et

.

valve F~D

.

OWCFM@50 PSI OUT ~

=$ IN

~

.

."

.

suitable for air, vacuum and some 6'8CFM

@

100PS1

fluid applications. Barbed fittings for

1/8" plastic tubing. Specify: 2-way

or 3-way valve. .

'N

.

AIR FLOW I

Standard cam for clockwise

rotation. The CS-12 provides a

0-360' range for both dwell

and timing.

MODEL C

Heavy Duty, Double Break Switch

A 20 amp double-break, butterfly

switching mechanism. Tested

to over 20 million cycles

mechanical life. 1 HP @ 125 VAG.

2 HP@ 250 VAG.

MODEL D

Dual Circuit Control Switch

A 10 amp double-break switch for

multiple circuit control. 10 million

cycle mechanical life. 1/2 HP

@

125 VAG. 3/4 HP

@

250 VAG.

ELECTRICAL RATING"

S.P.O.T.-D.B

LINE'

-..L-

I~

~DU~

fl

...

~'G:=xJ

~N.O

N.C.

'FOR OPERATION ABOVE

125 VAC SEE NATleNAL.

'AD comONUOCS

AM"" 'AT LOCAL ELECTRIC CODES. ONOos

"AM. eos,"

0'

A

'"

.ow," CAOOR

D.P.O.T.-D.B.

"

ELECTRICAL RATING.

1OAMP,125/250VAC

'OAMP,2BVDC'RES,

'AMP,2BVDC"ND.' rP

::

'

~

~

~ILlGHT

Nr

INE LOAD

CURRENT SlNK'NGCIReU"

~

")~

LINE

MODEL K

Hall Effect, Solid-State Cam Operated Switch

An integrated circuit produces a digital

output, with no contacts (the output is

bounce freel. 100 million cycle life.

Specify: Model K5 (5VDC) or Model K16

16 to 16 VDC). Current sinking circuit.

REGULATOR, SHOWN BY DASHEO LNES

AVA<LAm ONLY ON 6.16 VOC C"CUIT

CS-12C

Optional cam for counter-

clockwise rotation. The CS-12C

provides a 0-360' range for

both dwell and timing.

TECHNICAL

CONSTRUCTION:

The Candy Switch housing

is a gasketed aluminum cast

providing a NEMA-12 dusttight,

drip proof rating. The input

shaft is steel with a black oxide

finish and is supported by

self-lubricating bushings. The

reference scale on top of each

unit is available in glass or

Lexan plastic. Each Candy

Switch model has (2)

1/2"

NPT outlets to accommodate

circuit connection.

INPUT DIRECTION:

It is important to determine the

direction of input as all models

are available with clockwise

and counterclockwise cams.

Candy Switches may operate

satisfactorily if run in the wrong

direction, however, the values

for the timing shown in the

reference scale will be reversed.

~,:ri

//>co""

'oco",ro"

Schematic represents clockwise rotation

DWELL AND TIMING:

When setting up and adjusting the

Candy Switch, it should be

noted that the dwell and timing

are independent adjustments.

A change in the timing does

not affect the dwell. However,

a change in the dwell may

affect the timing, depending on

whether the dwell adjustment

is made on the leading edge

or trailing edge of the cam.

DATA

REFERENCE SCALE:

Each Candy Switch model has

a reference scale located on top

of the switch. This scale

defines relative values

for both dwell and

timing. Operators may

use this scale to define

limits of adjustment or

to return to a previously

established set of

values. Standard models

are shipped with glass

scales, however, Lexan

plastic scales are available when

glass is not suitable.

I

~

.l~'

I-'

~"

REPEATABILITY:

The Candy Switch series is

typically accurate to within

1/2 to 1% with slight variations

depending on the model and

operating speeds.

SPEED:

All Candy Switch models will

operate as specified up to 500

RPM. The input speed is directly

related to the life of the switch,

each model has a cycle rating

listed in the following sections.

Please consult the factory if an

application requires greater

operating speeds.

BANKING:

Any number of Candy Switches

may be banked together for

multiple circuit control. Different

models may be mixed in the bank

depending on application

requirements. Four (4) 1/4"-20

threaded rods are required as tie

rods through the bank. The CS-30

banking gears (one per switch)

may be used to gear the switches

together. In this arrangement,

Candy recommends that every

other switch be ordered to run

in the opposite direction as the

one before it.

An alternative to this banking

arrangement employs the CS-56

Idler Gear Unit between switches.

This serves to separate the Candy

Switches by 3/8" allowing for

a third gear in the train causing

each input shaft to rotate in the

same direction. See accessory

notes for more details.

MOUNTING!

I NST ALLA TION

The Candy Switch may be

mounted in any position and

may be driven in either the

clockwise or counterclockwise

direction. Most designers use

one of four methods to tie the

Candy Switch input shaft to

the parent machine's line

shaft or rotating member:

Direct coupling, chain drive,

belt drive or gear drive. It is

important to note that the

machine cycle must have a

1:1 relationship with the input

shaft of the Candy Switch.

Various accessories may be

used when installing a Candy

Switch. The CS-35, mounting

bracket may be used for a

standard foot mount

arrangement.The Candy Switch

may also be mounted to the

side frame of the machine using

the (4)

1/4" mounting holes

located in each corner of the

housing. The CS-30 Banking

Gears and the CS-56 Idler

Gear Unit may be used when

the Candy Switch is applied

in a bank.

~

~

..,

.,

,

.11>

-Direct coupling

~

~

'OJ

OJ

,

.~

liming belt

..

~

~

Gear drive

SWITCH/ OPERATING SWITCHED DWELL

MODEL

BOARD

CAM SCALE

ROTATION VOLTAGE VOLTAGE

TIME SPECIFY

A A CS.12 S CW 120VAC/DC N.D.

AlC A CS-12C R CCW 120VAC/DC N.D.

B B CS-12 S CW Pneumatic N.D. 2 or 3 way valve

c C CS-12 S CW 120VAC/DC N.D.

K K CS-12 S CW 5VDC or 6-16 VDC N.D. K5 or K16

N N N S CW 12VDC 12VDC N.D.

F F F S CW 12VDC 12VDC N.C.

G N G 0-10 either 12VDC 12VDC N/A

P

-

P S CW 10-30VDC 55mA@12V N.D. NPN or PNP

AT/12D AT N S CW 12VDC 5-400VAC N.D.

AT/24D AT N S CW 24VDC 5-400VAG N.D.

AT/90D AT N S CW 90VDC 5-400VAG N.D.

AT/120A AT N S CW 120VAC 5-400VAG N.D.

OT/120 AT N S CW 12VDC 90 VDC N.D.

OT1240 AT N S CW 24VDC 90 VDC N.D.

OT1900 AT N S CW 90 VDC 90 VDC N.D.

OT/120A AT N S CW 120 VAG 90 VDC N.D.

Please note that not all models are listed. Please contact the factory fol mOle Infolmatlon.

Scale: S=Standard. R=Reverse.

Dimensions and specifications are subject to change without notice.

ORDERING

When ordering a Candy Switch,

it is important to:

1. Decide whether an electro-

mechanical or solid-state

version is best suited for

the application.

2. Choose the appropriate

Candy Switch model based

on desired dwell time,

direction of rotation,

operating and switching

voltages. The following

specification chart may

assist you in choosing the

most appropriate model

for your application.

Please note that all the

specifications in this chart

are based on the standard

cam for each unit.

DIMENSIONS

ACCESSORIES

CS-30

Banking Gear

,,-

"31'*

SETSCREW

"KEYW AY. I

,

/

~ me

:

EJ!jI~

\\ID

~

"

-'i1I

1

:~

'YoHUB

. . . . .

I

" Y.-I

li--'

no.

Yo "

2;<,,0.0.

24

~~LDN

BANKINGGEAR

r.

.200OPD.4BTDDIH

'0.

Locking Cover

OQ

rf

n ,

~

1v.

~

-"~._:~

2y/i~

'~.

11=,,)\/

8...

Q) L!

.-

J

"'"

ill'

i'

CS-56

Idler Gear Unit

~~%

~~~ll~

~CANDY

~

CONTROLS

Candy Mfg. Co., Inc.

5633 W. Howard St., Niles, IL 60714

Phone: (847) 588-2639

Fax: (847) 588-0055

email: Candymfgco@aol.com

www.candycontrols.com

@1998CandyControls. Printed In USA.

r

-

I So LID-STATE CANDY SWITCH MODELS:

I

- - - - -"--">~,--, --- ---

.,

MODELS

IC

GND

+12V +12V

WLA not ",ed

Model N

For applications that require higher switching speeds

and greater accuracy, Candy offers a complete line of

solid-state switches. This line employs a board

mounted photo scanner which reads a reflective

pattern from a printed cam.

The N cam is the standard cam for most

solid-state models. Alternative cams are

available with different operating

characteristics as described to the

lower right.

0""",

"0"'" 1>1"..

' Tnm,"'..

MODEL AT/DT

Conditioned, HighCurrent Signals

The AT/DT series is a general purpose AC or DC

solid-state switch. The AT prefix refers to an AC

switching voltage (10 amp max. current) and uses

an optically isolated triac controlled switching

mechanism. This triac is a zero crossing device.

The DT prefix, refers to applications involving a DC

switching voltage. The DT switch uses a transistor

controlled switching mechanism (4 amp max.

current). The standard cam for the AT/DT series is

the N cam.

MODEL N

Conditioned, LowCurrent Signals

The model N uses a photo sensor consisting of a light emitting diode and

a phototransistor. The N board contains an amplifier circuit allowing for

direct interface with pwgrammable controllers or other electronic devices. The Model N

provides both an active high and an active low output, providing complete flexibility in

meeting interface requirements. The active low output (WLA) features an operl collector

output allowing a'n external pull-up resistor to a voltage between 0 and + 25V. The

standard Model N is supplied with an N cam. Please specify 12V or 5V model when

ordering. Typical Custome"ntertace, 12-Volt Model Model N,S-Volt Model

Supply current

(excluding

output loading):

12- Volt Model-

25 mA, 5-Volt

Model-18mA.

'OIT"" Phooo

Troo,"'"

i --.

Gro"O' c"O"" Vo"'" AC..OC AC..DC

to TTL Input of

Gustome, equipment

10K

+5 VDC

Supply

G,ound GND

IC

Opto 22

01equlv,

not

u'ed

Suggested Circuit for TTL output, as shown, can drive 7 standard TTL inputs.

MODEL F

Unconditioned Signals

The Model F is primarily for voltage dependent circuits. The F board

contains only a terminal strip, a 1k limiting resistor and the photo scanner.

Additional circuitry must be provided by the user to suit specific applications.

The standard cam for this model is the F cam.

The biockdiogram is

a suggestion for use of

this scanner. in most

coses a forward

currento! 10 MAwili

provide sufficient

radiation from the

emlffer to generate

the on signal from the

sensor.

The electrical rating

for this device is:

Sensor

ON state

IcMln~ 100uA

@lf~40mA

@Vce~5V

IfContlnuous~40mAMax

Vf@40mA=1.6VMax

OFFstate

Collector-Emitter Breakdown:

50VMax

Leakage: 25 nA@ Vce~ 30V

ReverseVoltage~2VMax Emitter

ASchmifftrlggercircultls necessary to provide hysteresis between the light and darksurfaceofthe

earn. This eilminates any possible oscillations In a solid state output.

MODEL P

Proximity Sensor

The model P is a self contained proximity sensor

which reads a foil wrapped cam. The Model P is the

only switch in the solid-state family that is restricted

to one type of cam. The P cam offers a 0-3600 range

of adjustability for both dwell and timing. Specify

NPN or PNP.

Electrical Characteristics:

Suppiy voltage: 12-24 VDC

Max continuous load: 200 mA

Max current consumption

(excluding load): 10mA

@

12V

20mA

@

24V

RL min: @12V=68 ohms

@

24V=130 ohms

if

4

PHOTO

REFLECTIVE

SCANNER

SOLID STATE CAMS

I

'"

N CAM

0 to 360 Dwell & liming Cam

Rotation: Clockwise

Dwell: Normally open

I.,.

NC CAM

0 to 3600 Dwell & liming Cam

Rotation: Counterclockwise

Dwell: Normallyopen

F CAM

~

0 to 360 Dwell & liming Cam

Rotation: Clockwise

Dwell: Normally closed

FC CAM

,

0 to 360 Dwell & liming Cam

Rotation: Counterclockwise

Dwell: Normally closed

H CAM

.,

H Cam: 0 to 30 Dwell Cam

Rotation: Clockwise or counter-

clockwise

Dwell: 0-30

liming: Adjustable from 0-360

GCAM

Rotation: Clockwise or counter-

clockwise

Pulses: 0-10 equally spaced pulses

with a pulse duration of

approximately 22

Você também pode gostar

- Auma - Electric ActuatosDocumento44 páginasAuma - Electric ActuatosRakesh Karan Singh100% (1)

- Actuator Catalogue CompleteDocumento22 páginasActuator Catalogue Completeprashantsingh0450% (2)

- A Shop ManualDocumento93 páginasA Shop Manualhectorhernandez311Ainda não há avaliações

- Sinpac Cap Start Run Switches CVR - SeriesDocumento5 páginasSinpac Cap Start Run Switches CVR - SeriesstoragebinAinda não há avaliações

- Datasheet Electric Actuator IntroductionDocumento2 páginasDatasheet Electric Actuator IntroductionSenghy MaoAinda não há avaliações

- NOAH KatalogDocumento6 páginasNOAH KatalogtalayAinda não há avaliações

- SQK33.00 Autres Fiches en PDFDocumento6 páginasSQK33.00 Autres Fiches en PDFe-genieclimatique.comAinda não há avaliações

- Switch On To The Best: Cam Operated Rotary SwitchesDocumento32 páginasSwitch On To The Best: Cam Operated Rotary Switchesbagastc100% (1)

- Sequential Controller: SpecificationsDocumento1 páginaSequential Controller: SpecificationsscribdkhatnAinda não há avaliações

- Motor Operated Valve RotorkDocumento12 páginasMotor Operated Valve RotorkGeorge Asuncion100% (3)

- Sebon Chilled Water InvestigationDocumento4 páginasSebon Chilled Water InvestigationMark BraithwaiteAinda não há avaliações

- SG 1478LDocumento6 páginasSG 1478LcbarqueteAinda não há avaliações

- Technical Series 92 User ManualDocumento4 páginasTechnical Series 92 User ManualrandallshAinda não há avaliações

- Salzer CatalogueDocumento32 páginasSalzer CataloguebagastcAinda não há avaliações

- Conmutador KLDocumento16 páginasConmutador KLJefe de PlantaAinda não há avaliações

- Driller's Console Chapter 4Documento26 páginasDriller's Console Chapter 4Nmbvmbjhg Jgjkgj100% (4)

- Woodward Act.Documento108 páginasWoodward Act.Stoenescu Nicusor100% (3)

- Synchro Start CatalogbDocumento106 páginasSynchro Start CatalogbJames Greenwood67% (3)

- Electric SystemDocumento78 páginasElectric SystemHarry Wart Wart100% (2)

- 220 KV SwitchyardDocumento7 páginas220 KV SwitchyardIrfan UllahAinda não há avaliações

- Moog D633Documento16 páginasMoog D633Balu M100% (1)

- AUMADocumento24 páginasAUMAVenkatesh GangadharAinda não há avaliações

- Bul 36115 Servo Valve OperationDocumento12 páginasBul 36115 Servo Valve Operationrikkitech100% (1)

- Catalogo E210E Rango ADocumento12 páginasCatalogo E210E Rango Ael_apache10Ainda não há avaliações

- 2CV Series For 230 Vac Capacitor Start Motors and 2VR Series For 230 Vac Capacitor Start/Capacitor Run MotorsDocumento2 páginas2CV Series For 230 Vac Capacitor Start Motors and 2VR Series For 230 Vac Capacitor Start/Capacitor Run MotorsmachevallieAinda não há avaliações

- MV Vacuum Circuit Breakers LD and Shell Types: ISO 9001 and ISO 14001 CertificationDocumento4 páginasMV Vacuum Circuit Breakers LD and Shell Types: ISO 9001 and ISO 14001 CertificationEpsp MedAinda não há avaliações

- Technical Instructions: Document No. 155-517P25Documento28 páginasTechnical Instructions: Document No. 155-517P25chiita123Ainda não há avaliações

- AEE311L Experiment 7 8Documento8 páginasAEE311L Experiment 7 8Fe BaltazarAinda não há avaliações

- BELIMO LMX120-3 ActuadorDocumento5 páginasBELIMO LMX120-3 ActuadordcarunchioAinda não há avaliações

- Variable Fill Fluid CouplingsDocumento8 páginasVariable Fill Fluid CouplingsAnupam XessAinda não há avaliações

- Vac On Step EnglDocumento4 páginasVac On Step EnglTomuta StefanAinda não há avaliações

- VDCVS202 Ame435qmDocumento8 páginasVDCVS202 Ame435qmRoger RamosAinda não há avaliações

- Electro Hydraulics: Control Technology ConceptsDocumento98 páginasElectro Hydraulics: Control Technology Concepts@nshu_theachiever88% (8)

- El 200b ExcavadoraDocumento8 páginasEl 200b Excavadoradinny blancoAinda não há avaliações

- WP Series ManualDocumento9 páginasWP Series ManualSerfortec Cia LtdaAinda não há avaliações

- MAGNAVALVE Mod ACDocumento25 páginasMAGNAVALVE Mod ACdahora13Ainda não há avaliações

- Erth SwitchDocumento20 páginasErth SwitchPutraKurniawanAinda não há avaliações

- Paper Cutting MachineDocumento23 páginasPaper Cutting MachineManish Shetty100% (2)

- Auto Turn-Off For Water Pump With Four Different Time SlotsDocumento3 páginasAuto Turn-Off For Water Pump With Four Different Time SlotsKethavath Sakrunaik K100% (1)

- Auto Turn-Off For Water Pump With Four Different Time SlotsDocumento3 páginasAuto Turn-Off For Water Pump With Four Different Time SlotsKethavath Sakrunaik K0% (1)

- AMB24-SR - Installation InstructionsDocumento8 páginasAMB24-SR - Installation InstructionsatereñoneAinda não há avaliações

- Governor: BY Er. Tanuj Sharma Student of PGDC Hydro POWER PLANT (2010-11), NPTI NangalDocumento24 páginasGovernor: BY Er. Tanuj Sharma Student of PGDC Hydro POWER PLANT (2010-11), NPTI NangalTanuj SharmaAinda não há avaliações

- Dezurik Precision Electric Control Valves Ppe Technical 14-00-2Documento8 páginasDezurik Precision Electric Control Valves Ppe Technical 14-00-2gembirasekaliAinda não há avaliações

- Salzer Catalogue PDFDocumento32 páginasSalzer Catalogue PDFHeri SetyantoAinda não há avaliações

- VII. Electrical SystemDocumento2 páginasVII. Electrical SystemJoren PalminAinda não há avaliações

- Rotary Cam SwitchDocumento16 páginasRotary Cam Switchkvp0107100% (1)

- Electropneumatic Belt Conveyor 2015Documento3 páginasElectropneumatic Belt Conveyor 2015Chockalingam AthilingamAinda não há avaliações

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1No EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Nota: 2.5 de 5 estrelas2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Ainda não há avaliações

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGAinda não há avaliações

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNo EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNota: 2 de 5 estrelas2/5 (1)

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNo EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetAinda não há avaliações

- 110 Waveform Generator Projects for the Home ConstructorNo Everand110 Waveform Generator Projects for the Home ConstructorNota: 4 de 5 estrelas4/5 (1)

- African Music Re-Examined in The Light of New Materials From The Belgian Congo and Ruanda Urundi Akab P Merriam African Music Re-ExaminedDocumento9 páginasAfrican Music Re-Examined in The Light of New Materials From The Belgian Congo and Ruanda Urundi Akab P Merriam African Music Re-Examinedberimbau8Ainda não há avaliações

- Digital Filter DesignDocumento102 páginasDigital Filter Designjaun danielAinda não há avaliações

- Shyla Jennings Ebook FinalDocumento17 páginasShyla Jennings Ebook FinalChye Yong HockAinda não há avaliações

- Seismic Assessment of RC Building According To ATC 40, FEMA 356 and FEMA 440Documento10 páginasSeismic Assessment of RC Building According To ATC 40, FEMA 356 and FEMA 440sobah assidqiAinda não há avaliações

- Anothr System Definition FacilityDocumento90 páginasAnothr System Definition FacilityllllllluisAinda não há avaliações

- DWDM Optical Power DebuggingDocumento17 páginasDWDM Optical Power DebuggingJuancarlos ArrietaAinda não há avaliações

- Internet and Java ProgrammingDocumento4 páginasInternet and Java ProgrammingsharmaarakeyshAinda não há avaliações

- Mechanical Engineering Manufacturing.149Documento1 páginaMechanical Engineering Manufacturing.149Anonymous QvIxEazXGdAinda não há avaliações

- It Implementation-Issues, Opportunities, Challenges, ProblemsDocumento9 páginasIt Implementation-Issues, Opportunities, Challenges, ProblemsAnnonymous963258Ainda não há avaliações

- POCLP010101 Wood PelletsDocumento1 páginaPOCLP010101 Wood PelletsPratiwi CocoAinda não há avaliações

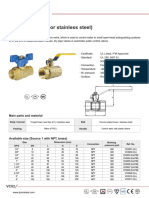

- VC02 Brass Ball Valve Full Port Full BoreDocumento2 páginasVC02 Brass Ball Valve Full Port Full Boremahadeva1Ainda não há avaliações

- Ad and AVM l1Documento54 páginasAd and AVM l1Rahul Tiwari67% (3)

- Msds Diesel PDFDocumento11 páginasMsds Diesel PDFSooraj PoochaliAinda não há avaliações

- BCS 031 Solved Assignments 2016Documento15 páginasBCS 031 Solved Assignments 2016Samyak JainAinda não há avaliações

- SAP LandscapeDocumento4 páginasSAP LandscapeSiddharth PriyabrataAinda não há avaliações

- Rit Fol Pegelmessung en WebDocumento4 páginasRit Fol Pegelmessung en WebPrimo BluesAinda não há avaliações

- Papa Jew SkiDocumento33 páginasPapa Jew Skiazimr157Ainda não há avaliações

- Netflix - WikipediaDocumento3 páginasNetflix - WikipediaHanako ChinatsuAinda não há avaliações

- Laporan Beton 1Documento80 páginasLaporan Beton 1Seulgi BearAinda não há avaliações

- York R410ADocumento2 páginasYork R410AArabiat76Ainda não há avaliações

- API 620 Vs API 650Documento5 páginasAPI 620 Vs API 650govimanoAinda não há avaliações

- Ansi C37.72-1987 PDFDocumento25 páginasAnsi C37.72-1987 PDFIvanAinda não há avaliações

- Corning SMF-28 DatasheetDocumento2 páginasCorning SMF-28 DatasheetsusyheunaAinda não há avaliações

- Process Safety BeaconDocumento1 páginaProcess Safety BeaconRaul tejadaAinda não há avaliações

- SP25Y English PDFDocumento2 páginasSP25Y English PDFGarcia CruzAinda não há avaliações

- Factors Affecting Grade 12 Students To Use Internet During Class HourDocumento39 páginasFactors Affecting Grade 12 Students To Use Internet During Class HourJerric Brandon FalconiAinda não há avaliações

- Prospects of Bulk Power EHV and UHV Transmission (PDFDrive)Documento20 páginasProspects of Bulk Power EHV and UHV Transmission (PDFDrive)Prashant TrivediAinda não há avaliações

- LZQJXC Dab e 3.10Documento2 páginasLZQJXC Dab e 3.10alageshvijayAinda não há avaliações

- 378 and 378 HT SeriesDocumento2 páginas378 and 378 HT SeriesTim Stubbs100% (2)

- EHB02 Technical Specifications: 1. External DimensionsDocumento5 páginasEHB02 Technical Specifications: 1. External DimensionsArmandoCalderonAinda não há avaliações