Escolar Documentos

Profissional Documentos

Cultura Documentos

Work Pack - Guide For Reviewing Mechanical Engineering Work Packs - Rev1

Enviado por

mkash028100%(4)100% acharam este documento útil (4 votos)

2K visualizações8 páginasWork Pack Review Guide

Título original

Work Pack - Guide for Reviewing Mechanical Engineering Work Packs_Rev1

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoWork Pack Review Guide

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

100%(4)100% acharam este documento útil (4 votos)

2K visualizações8 páginasWork Pack - Guide For Reviewing Mechanical Engineering Work Packs - Rev1

Enviado por

mkash028Work Pack Review Guide

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 8

Engineering Work Pack

Engineering Project Work

Work Order/Project Code no:

Work Pack Title/Description:

Work Pack no: Unique (registered) number and associated revision number Page 1 of 8

FRM-MTC-QA-016 REV 5

MANAGEMENT OF CHANGE

MOC Approval to proceed or EHSMS 12 Appendix A MOC Form Part B checklist signed and attached?

Yes No MOC#: Date:

WORK PACK PURPOSE

This section must clearly describe the purpose of the work pack and be written on the

basis that the target audience may have little or no prior knowledge of the job.

QA/QC REQUIREMENTS

List relevant special conditions, testing requirements, and NDT requirements.

This section must list all the documentation required to ensure the work meets the minimum technical

and regulatory standards.

Santos Engineering or Maintenance FIC sheets and Technical Instructions relevant to the Work Pack

are to be listed in this section and copies attached to the Work Pack.

If specialist equipment or personnel (i.e. vendor commissioning engineer) are required they must be

listed in this section.

Approved Weld Procedure Specification(s) (WPS's) referenced

Appropriate NDT specified for all welds and joints (e.g. magnetic particle indication, dye penetrant,

visual, or radiography)

Hydrotest pressures and hold time specified for each Santos Piping specification used in the WP

Or equivalent data included for pneumatic test where approved by Principal Mechanical Engineer.

Qualification of personnel executing the job. e.g. Welding Inspector as per AS1796 Cert 10

Note indicating to sign and return workpack and all other relevant documentation to the person

originating this document.

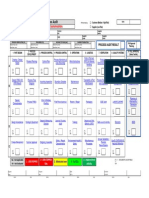

WORK PACK PREPARATION, REVIEW AND APPROVAL

Work Pack Type: Mechanical Instrumentation Electrical Structural Civil Piping

Title Print Name Signature Date

Prepared: Engineer Person developing the WP

Reviewed: Discipline Quality Control Moomba QA Welding Coordinator

Engineering Work Pack

Engineering Project Work

Work Order/Project Code no:

Work Pack Title/Description:

Work Pack no: Unique (registered) number and associated revision number Page 2 of 8

FRM-MTC-QA-016 REV 5

Reviewed: Senior Discipline Engineer Any Senior Discipline Engineer

included in the list of Approved

Reviewers (check with Principal

Mechanical Engineer)

If WP is developed by Service

Company then the reviewer should

be a Senior Discipline Engineer

from this company

Accepted by:

Insert extra line for Santos

Acceptance where Work Pack is

prepared by a Service Company

Approved: Engineering Team Leader

or Section Leader

Person responsible for issue of

Work Pack

WORK PACK DISTRIBUTION

Process Coordinator Production Coordinator Process/Production Permit Authority

Area Planner QC/Welding Coordinator Supervisor Tradesperson

Integrity Engineer Project Manager NDT Tech Other:

RELEVANT SPECIFICATIONS, DRAWINGS & DOCUMENTS

List all relevant documentation, including revision number and applicable Code/Standard as required. Attach a copy of all drawings

and/or field sketches.

Refer to The Well, Engineering, Santos Standards Index for List of applicable Specifications/Standards and include below.

Item No Document Type and Number. Revision

No.

SAFETY

If the installation requires excavation work reference to the excavation Work

Pack is to be made in this section.

Reference the associated MOC (if applicable) .

Include all the relevant documents required by the Work Pack reviewer, planner

and construction personnel, e.g. P&IDs, New/Modified Equipment data, etc.

There is no need to attach the complete MOC document

Approved lift study (i.e. for cranage) referenced and attached (where applicable

per HSHS16 Appendix A)?

Engineering Work Pack

Engineering Project Work

Work Order/Project Code no:

Work Pack Title/Description:

Work Pack no: Unique (registered) number and associated revision number Page 3 of 8

FRM-MTC-QA-016 REV 5

Whenever piping demolition and/or Tie-Ins to existing systems are included

include reference to the following procedures:

- Moomba Plant: Operating Procedure 0003-60-001 (Identification and

Marking of Plant Piping prior to Demolition or Tie-ins) or

- Port Bonython Plant: Operating Procedure 2500-60-001 (Identification

and Marking of Plant Piping for Cutting, Welding or Abrasive blasting,

Mandatory in Moomba and Port Bonython plant only.

Risks associated with hazardous or toxic substances (e.g. mercury per

HSH08.4, asbestos) have been duly considered and MSDS(s) attached to

workpack (refer Chemwatch)?

If the persons executing the job might be exposed to hazardous or toxic

substances (e.g. Mercury, Asbesto, etc.) then include relevant MSDS(s) (refer

Chemwatch)

Also include reference to the relevant Santos EHS procedures (eg. HSH08.4 for

Mercury, HSHS08.1 for Asbestos, etc.)

DESIGN

All drawings which are required by the planning , construction and/or

maintenance departments in order to complete the Work Pack are to be listed in

this section and copies attached to the Work Pack.

Drawings must be provided on A4 or A3 sheets. Legible Mark-Ups from the

MOC documents are acceptable however preference is for back drafted

drawings.

Reference to Painting and appropriate coating specification (where applicable)

List data sheets for Mechanical equipment covered by the Work Pack in this

section. Copies of the datasheets are to be included in the Work Pack.

Where sections of specifications or standards are referenced which the installer

will need to refer to, the relevant section shall be copied and attached to the

Work Pack. Do not attach the full document.

Reference to all relevant Australian, International and Santos standards

WELDING / QAQC

Engineering Work Pack

Engineering Project Work

Work Order/Project Code no:

Work Pack Title/Description:

Work Pack no: Unique (registered) number and associated revision number Page 4 of 8

FRM-MTC-QA-016 REV 5

Approved Weld Procedure Specification(s) (WPS's) referenced and attached for

all welds

For golden welds or hot taps both approval in principle and notification /

acceptance forms have been approved

All necessary Inspection and Test Plans (ITP's) referenced and attached in

accordance with Work Pack Build Sheet

OTHERS

List any Work Packs for other disciplines which are directly related to this Work

Pack i.e. this Work Pack may say cover the Mechanical works for a new pump

skid. The I/E Work Pack for the installation of the pump skid must be referenced

in this section.

JOB INSTRUCTIONS

Notes: A detailed step by step set of instructions for work execution.

Item No Task Description

GENERAL

This section is to include all the steps in logical order necessary to implement the work

including the plant shutdown, isolation and permitting work which will normally be done by

Santos.

Workpack should cover a single engineering discipline only. In this context mechanical /

piping / civil / structural may be treated as one discipline i.e. don't mix these with

instrument or electrical workpacks.

Preference should be given to numbering each Job Instruction logical step as this makes

work tracking and referencing easier.

The use of sub-headings / sections is encouraged to maximise clarity.

Typical sections are:

1. Pre-start

2. Off-site works

3. Site works

4. Close-out

Colour photos should be included in the relevant steps in this section where they help to

identify work scope and or location.

Engineering Work Pack

Engineering Project Work

Work Order/Project Code no:

Work Pack Title/Description:

Work Pack no: Unique (registered) number and associated revision number Page 5 of 8

FRM-MTC-QA-016 REV 5

References to all associated Workpacks are included in the relevant Job Instructions

SAFETY

Permitting requirements (e.g. excavation, hot work, cold work) have been considered and

suitably referenced in job steps

Confined Space Entry (CSE) risks considered and factored into work methodology, CSE

risk assessment called up where appropriate (must involve Process/Production

representative)

Include reference to approved lift study (i.e. for cranage) in relevant Job Instruction (if

applicable)

Demolitions and Tie-Ins aspects of the job are clearly described in the pack. Include

instructions to mark the Tie-Ins and cut points as per the following procedures:

- Moomba Plant: Operating Procedure 0003-60-001 (Identification and Marking of

Plant Piping prior to Demolition or Tie-ins) or

- Port Bonython Plant: Operating Procedure 2500-60-001 (Identification and

Marking of Plant Piping for Cutting, Welding or Abrasive blasting)

NOTE: The use of these procedures is mandatory in Moomba and Port Bonython plants

only.

Relevant notifications to site personnel. Either because they will be directly involve with

the job or because they need to be aware that the job is taking place.

WORK DESCRIPTION

All piping field sketches match the relevant marked up (i.e. CDCR'd) P&ID(s)? i.e. pipe

specifications, pressure rating, valve specification(s), valve orientations, line slopes,

insulation, fire-proofing, venting / drainage requirements, applicable P&ID notes.

All relevant lines, equipment items, instruments, data sheets, and drawings (field

sketches, P&ID's, isometrics, equipment general arrangement drawings, plot plans etc)

have been fully referenced in the main body of the Workpack (i.e. with tag / number) and

at all appropriate job steps and attached

Engineering Work Pack

Engineering Project Work

Work Order/Project Code no:

Work Pack Title/Description:

Work Pack no: Unique (registered) number and associated revision number Page 6 of 8

FRM-MTC-QA-016 REV 5

This section must include steps to cover the QAQC checks as per the Piping Specs or

Vessel standard requirements for the work

Scaffolding requirements have been considered and suitably referenced in job steps

WorkPack includes fully specified Bill of Materials (including quantities, item descriptions,

pipe schedules, flange schedules, fitting ratings, material grades or specifications, Santos

valve specifications etc) for all necessary materials (whether it is on a field sketch or in

main workpack body). All the material specifications should be consistent with Santos

Standards, AS, ASME, ASTM or any other relevant Standard.

All the Tie-In points should be appropriately identified in the P&ID, Isometric and Photos.

Cross references should be made to the relevant Job Instructions.

Use HOLD POINTS to highlight a decision point by a Technical Person (e.g Integrity

Engineer, etc.)

In case of Repairs for which further investigation is required, include HOLD POINTS with

detailed explanation on how to preserve the relevant evidence.

Check that Isometric field sketches use appropriate drawing symbols (as per Santos

standard P&ID symbols drawing 1500-10-001)?

Location and orientation (i.e. "north" arrow) of all relevant piping, instruments, and

equipment are clearly referenced without any ambiguity or potential for confusion?

Isometric field sketches use solid lines for items to be fabricated or constructed, and

show adjacent piping or mechanical equipment (labelled with line or equipment number)

in dashed lines for context / clarity (tie-in points are thus clearly indicated by the transition

from solid to dashed lines)

Site measured dimensions (albeit to be confirmed later by job supervisor and

notwithstanding 40NB or less to be site run) shown where applicable on isometric and

general arrangement field sketches? e.g. to assist checking weld spacing (i.e. 6x wall

thickness or 50mm whichever is greater), requirement for pipe stressing, pipe run

allowance for instruments, adequacy of pipe supports / spans, and for materials ordering.

Engineering Work Pack

Engineering Project Work

Work Order/Project Code no:

Work Pack Title/Description:

Work Pack no: Unique (registered) number and associated revision number Page 7 of 8

FRM-MTC-QA-016 REV 5

Uniquely numbered and registered field sketches of all relevant piping (i.e. isometrics)

and mechanical equipment (i.e. general arrangement drawings) have been created as

appropriate i.e. they are not merely substituted for by marked up photographs?

Any referenced photographs are contained in the formal Mechanical/Photo Data Sheet or

Scaffolding/Cranage/Rigging Data Sheet (where applicable - refer to QA/QC Build Sheet)

Risks associated with hazardous or toxic substances (e.g. mercury per HSH08.4,

asbestos) have been duly considered and MSDS(s) attached to workpack (refer

Chemwatch)?

Excavation risks considered, particularly potential underground services, and Excavation

Permit appropriately referenced in job steps.

Any machinery aspects of workpack have been reviewed and approved in writing by a

Senior Machinery Engineer?

Design is suitable for future operator or maintainer access and ergonomics

requirements? e.g. no tripping hazards introduced, adequate isolation blinds provided,

emergency escape access ok, valve / instrument / controls / buttons height and

orientation suitable, suitable drain valve outlet clearance provided, platforms and ladders

provided for access where required, suitable withdrawal clearance for adjacent

equipment such as filters and tube bundles, equipment / vehicle access ok for EWP's,

cranes, bundle pullers etc, suitable valve operator installed where required per Design

Guide 1515-50-G002.

No threaded joints in hydrocarbon service (other than for instrument tubing, instrument

connections, vents / drains, low pressure oil gathering systems, or GRE gathering

systems)?

CLOSE OUT

Include a section to close all the relevant documents associated with the Workpack, such

as:

Work Permits, ITPs, etc.

Instruction to compile all the Work Pack signed-off documentation and return it to the

originator.

WORKPACK COMPLETION

YES NO N/A

COMMENTS

Engineering Work Pack

Engineering Project Work

Work Order/Project Code no:

Work Pack Title/Description:

Work Pack no: Unique (registered) number and associated revision number Page 2 of 8

FRM-MTC-QA-016 REV 5

All work has been completed to

required standards/specifications

MAC Tagging is complete as per

the Mac Tag Procedure used on all

flanged connections

Materials / parts used were correct

for the job

An Electrical Certificate of

Compliance have been completed

Where alternate materials/parts

have been used, the MOC been

completed and approved.

All plant / equipment / instruments

/ covers / supports removed to

provide access to job have been

reinstated.

Site left in tidy condition. All tools,

surplus materials, and waste

removed.

All records including ITPs, FICs

etc completed as required?

NAME

(PRINTED)

SIGNATURE DATE

QC INSPECTOR

JOB SUPERVISOR

DISCIPLINE ENGINEER

Comments:

Você também pode gostar

- Ras Gas Work PackDocumento30 páginasRas Gas Work Packsanju021100% (1)

- Job Pack WP 509 e 001gDocumento91 páginasJob Pack WP 509 e 001gdwivedipramodkumarAinda não há avaliações

- Sample WorkpackDocumento9 páginasSample WorkpackKhairun Mohamad IshakAinda não há avaliações

- Toc-Ta Workpack Rev.1Documento2 páginasToc-Ta Workpack Rev.1anjangandak293250% (2)

- E100 Wash Water Tie-In (TAR)Documento128 páginasE100 Wash Water Tie-In (TAR)Murtadda MohammedAinda não há avaliações

- Sample Work PackDocumento24 páginasSample Work PackRoozbeh PAinda não há avaliações

- Mechanical Completion & Pre-Commissioning: Handover Process Key DeliverablesDocumento2 páginasMechanical Completion & Pre-Commissioning: Handover Process Key Deliverablescryovikas1975Ainda não há avaliações

- Piping Insulation Project Planned Schedule-Rev2Documento1 páginaPiping Insulation Project Planned Schedule-Rev2Anene EmmanuelAinda não há avaliações

- SOP - 02 - Progress Measurement ProcedureDocumento5 páginasSOP - 02 - Progress Measurement ProcedureSuci YatiningtiyasAinda não há avaliações

- TOC Mechanical Complation DossierDocumento3 páginasTOC Mechanical Complation DossierMiftah Masrur0% (1)

- Completion Manager Job DesDocumento2 páginasCompletion Manager Job DesjrladduAinda não há avaliações

- Piping NDT Request Quality Control and Inspection FormDocumento1 páginaPiping NDT Request Quality Control and Inspection FormEdison WalitAinda não há avaliações

- PETA-7.2 Step DescriptionDocumento74 páginasPETA-7.2 Step DescriptionNack Abd RauofAinda não há avaliações

- 14 Communication ProcedureDocumento6 páginas14 Communication ProcedureHisham YousriAinda não há avaliações

- Method Statement For Decommissioning of Existing Gas ScrubberDocumento8 páginasMethod Statement For Decommissioning of Existing Gas ScrubberAzeta RobertAinda não há avaliações

- Flange Management Register PDFDocumento1 páginaFlange Management Register PDFsudeesh kumar100% (1)

- Method Statement of Lowerin inDocumento9 páginasMethod Statement of Lowerin inahmed08839494Ainda não há avaliações

- Organization Chart For Pipe Line Project 01Documento1 páginaOrganization Chart For Pipe Line Project 01MaherAinda não há avaliações

- Z 007 5913722 PDFDocumento56 páginasZ 007 5913722 PDFLegend AnbuAinda não há avaliações

- LZ-PC-B01 - Subcontractor's Mang - Site Coordination ProcedureDocumento15 páginasLZ-PC-B01 - Subcontractor's Mang - Site Coordination ProcedurecivilmechanicAinda não há avaliações

- Pipe Fabrication and Installation Work Procedure Rev-01Documento21 páginasPipe Fabrication and Installation Work Procedure Rev-01Dilshad Ahemad50% (4)

- SBU1 TLD G PR 002 Rev.B Document Control ProcedureDocumento49 páginasSBU1 TLD G PR 002 Rev.B Document Control ProcedureAndreas SchlagerAinda não há avaliações

- Workpack TEMANA ShutdownDocumento23 páginasWorkpack TEMANA ShutdownYusmin Mat Jusoh100% (2)

- 3.2 Develop The Material Control PlanDocumento9 páginas3.2 Develop The Material Control Planjesus_bs100% (1)

- MOC2145672 FormDocumento7 páginasMOC2145672 FormPersonal GmailAinda não há avaliações

- Procedure of Document ControlDocumento5 páginasProcedure of Document ControlNguyễn Văn GiápAinda não há avaliações

- Work PackDocumento8 páginasWork Packudhayasankars100% (2)

- DOSH Shutdown RolesDocumento4 páginasDOSH Shutdown RolesEric TingAinda não há avaliações

- Installtion of Lact Unit, Gas Metering Skid and Their Interconnecting Piping. CostDocumento2 páginasInstalltion of Lact Unit, Gas Metering Skid and Their Interconnecting Piping. CostAtty AttyAinda não há avaliações

- D12 - Workpack Challenge Rev.1Documento179 páginasD12 - Workpack Challenge Rev.1anjangandak2932100% (4)

- SPIE Document Deliverable Register Commisioning (10-Jan-2018)Documento139 páginasSPIE Document Deliverable Register Commisioning (10-Jan-2018)BalasubramanianAinda não há avaliações

- 220802DBQA50001 - EXCO04 - 56 Project Quality PlanDocumento56 páginas220802DBQA50001 - EXCO04 - 56 Project Quality PlanZainal Abidin100% (1)

- Logistic & Material Management Procedure - Ke01 A1 000 NC J PR 0001 000 c01Documento18 páginasLogistic & Material Management Procedure - Ke01 A1 000 NC J PR 0001 000 c01masahin100% (1)

- Site Acceptance Test Contract No.: 537856: 863013-VPS-PQM-E-DS-0002Documento16 páginasSite Acceptance Test Contract No.: 537856: 863013-VPS-PQM-E-DS-0002Andry YanuarAinda não há avaliações

- PSSR Pre-Commissioning SafetyDocumento6 páginasPSSR Pre-Commissioning SafetymanuAinda não há avaliações

- Field Engg Change ControlDocumento9 páginasField Engg Change Controlmoytabura96Ainda não há avaliações

- 03-01 Material TraceabilityDocumento1 página03-01 Material TraceabilityAngel AngeleyeAinda não há avaliações

- Csp21 - Upstream Facilities Handover Manual Rev1Documento155 páginasCsp21 - Upstream Facilities Handover Manual Rev1Iskandar Musa88% (8)

- PETA-7.1 Step DescriptionDocumento44 páginasPETA-7.1 Step DescriptionNack Abd RauofAinda não há avaliações

- 076551C 000D Sow 9000 001 - R0Documento37 páginas076551C 000D Sow 9000 001 - R0ikenn100% (1)

- Mechanical Completion Procedure PDFDocumento69 páginasMechanical Completion Procedure PDFDoctorOberman100% (3)

- F-CD-19 Pipe and Weld Book 26-Abr-19Documento84 páginasF-CD-19 Pipe and Weld Book 26-Abr-19Jorge Isaac Lara RamosAinda não há avaliações

- Work Pack ChecksheetDocumento1 páginaWork Pack ChecksheetjaberbahariAinda não há avaliações

- Iraq Gates Contracting Company: Kaz 12.2 Rehabilitation ProjectDocumento8 páginasIraq Gates Contracting Company: Kaz 12.2 Rehabilitation ProjectAhmedAinda não há avaliações

- Models From NCTC - Construction Execution PlanDocumento40 páginasModels From NCTC - Construction Execution PlanSherif Mohsen100% (1)

- Traceability ProcedureDocumento9 páginasTraceability ProcedureRoshan Aravinth100% (2)

- Transmittal SampleDocumento1 páginaTransmittal SamplekokocdfAinda não há avaliações

- Valve Engineering - Shell TAT - TAMAP DiscussionDocumento3 páginasValve Engineering - Shell TAT - TAMAP Discussiontilakthakar10% (1)

- GI For Mechanical CompletionDocumento44 páginasGI For Mechanical CompletionRana Asif100% (1)

- Petronas Technical Standards: Specification For Pipeline Valves (Amendments / Supplements To API 6D & API 6DSS)Documento29 páginasPetronas Technical Standards: Specification For Pipeline Valves (Amendments / Supplements To API 6D & API 6DSS)tang weng wai100% (1)

- Work Method of Statement Site SurveyDocumento10 páginasWork Method of Statement Site Surveyahmed08839494Ainda não há avaliações

- Sl. No Item Description Mechanical: PSSR Package Documents and RequirementsDocumento6 páginasSl. No Item Description Mechanical: PSSR Package Documents and Requirementsli xianAinda não há avaliações

- Project Quality Plan Rev 00 1 ADocumento55 páginasProject Quality Plan Rev 00 1 AAhamed Naufal CaAinda não há avaliações

- SOP - 01 - Structure Organization ChartDocumento10 páginasSOP - 01 - Structure Organization ChartSuci YatiningtiyasAinda não há avaliações

- 02DEC2022 Progress MeasurementDocumento83 páginas02DEC2022 Progress Measurementjing aytonaAinda não há avaliações

- Fabrication and InstallationDocumento6 páginasFabrication and Installations33d_2010Ainda não há avaliações

- MAI 07 - Control of Insp Measuring and Testing Equipment - DJ - v1Documento9 páginasMAI 07 - Control of Insp Measuring and Testing Equipment - DJ - v1IT Support - FernanAinda não há avaliações

- Process AuditDocumento15 páginasProcess Auditdesurkarb100% (2)

- Anexo 06 - PA - Process Audit v1.1Documento19 páginasAnexo 06 - PA - Process Audit v1.1BalajiAinda não há avaliações

- ACT Report - Goulburn TRS Insulation - Jemena Gas NetworksDocumento17 páginasACT Report - Goulburn TRS Insulation - Jemena Gas Networksmkash028Ainda não há avaliações

- Corrosol VE GP - TDS - Rev 4 - Feb 19Documento2 páginasCorrosol VE GP - TDS - Rev 4 - Feb 19mkash028Ainda não há avaliações

- ATCO Gas STOPAQ-Vinylester Procedure Rev0Documento45 páginasATCO Gas STOPAQ-Vinylester Procedure Rev0mkash028Ainda não há avaliações

- Product Data Booklet Fibertec Ultimate HDD Coating SystemDocumento8 páginasProduct Data Booklet Fibertec Ultimate HDD Coating Systemmkash028Ainda não há avaliações

- Application Procedure Onto StopaqDocumento6 páginasApplication Procedure Onto Stopaqmkash028Ainda não há avaliações

- Safe Work Method Statement For Survey Work: CMS Surveyors Pty LTD ABN: 79 096 240 201Documento18 páginasSafe Work Method Statement For Survey Work: CMS Surveyors Pty LTD ABN: 79 096 240 201mkash028100% (1)

- Design Brief - Security Fence UpgradeDocumento1 páginaDesign Brief - Security Fence Upgrademkash028Ainda não há avaliações

- SPE Write A PaperDocumento3 páginasSPE Write A Papermkash028Ainda não há avaliações

- Sump Tank DrawingDocumento1 páginaSump Tank Drawingmkash028Ainda não há avaliações

- Monitoring Illustration Glasteel II Double Wall TankDocumento5 páginasMonitoring Illustration Glasteel II Double Wall Tankmkash028Ainda não há avaliações

- FEED Integrity Checks AIMS-PI-PROC-0408 Rev 1Documento15 páginasFEED Integrity Checks AIMS-PI-PROC-0408 Rev 1mkash028Ainda não há avaliações

- Air Cooled Heat Exchanger Inspection and Test Plan SampleDocumento4 páginasAir Cooled Heat Exchanger Inspection and Test Plan Samplemkash028Ainda não há avaliações

- Society of Petroleum Engineers Publications Style GuideDocumento40 páginasSociety of Petroleum Engineers Publications Style Guidemkash028Ainda não há avaliações

- Portfolio Report Zarin Tasnim Tazin 1920143 8Documento6 páginasPortfolio Report Zarin Tasnim Tazin 1920143 8Fahad AlfiAinda não há avaliações

- Exoskeleton ArmDocumento5 páginasExoskeleton Armc214ocAinda não há avaliações

- Question Bank For Vlsi LabDocumento4 páginasQuestion Bank For Vlsi LabSav ThaAinda não há avaliações

- Introduction To Wireless and Mobile Systems 4th Edition Agrawal Solutions ManualDocumento12 páginasIntroduction To Wireless and Mobile Systems 4th Edition Agrawal Solutions Manualethelbertsangffz100% (34)

- Guidelines Use of The Word AnzacDocumento28 páginasGuidelines Use of The Word AnzacMichael SmithAinda não há avaliações

- QCM Part 145 en Rev17 310818 PDFDocumento164 páginasQCM Part 145 en Rev17 310818 PDFsotiris100% (1)

- MEMORANDUMDocumento8 páginasMEMORANDUMAdee JocsonAinda não há avaliações

- MWG Installation 7.6.2 IG INSTALLATION 0516 en - PDDocumento64 páginasMWG Installation 7.6.2 IG INSTALLATION 0516 en - PDjbondsrAinda não há avaliações

- Income Tax Calculator 2023Documento50 páginasIncome Tax Calculator 2023TARUN PRASADAinda não há avaliações

- Conflict WaiverDocumento2 páginasConflict WaiverjlurosAinda não há avaliações

- Interest Rates and Bond Valuation: All Rights ReservedDocumento22 páginasInterest Rates and Bond Valuation: All Rights ReservedAnonymous f7wV1lQKRAinda não há avaliações

- Different Software Life Cycle Models: Mini Project OnDocumento11 páginasDifferent Software Life Cycle Models: Mini Project OnSagar MurtyAinda não há avaliações

- RetrieveDocumento8 páginasRetrieveSahian Montserrat Angeles HortaAinda não há avaliações

- Effects of Organic Manures and Inorganic Fertilizer On Growth and Yield Performance of Radish (Raphanus Sativus L.) C.V. Japanese WhiteDocumento5 páginasEffects of Organic Manures and Inorganic Fertilizer On Growth and Yield Performance of Radish (Raphanus Sativus L.) C.V. Japanese Whitepranjals8996Ainda não há avaliações

- Icom IC F5021 F6021 ManualDocumento24 páginasIcom IC F5021 F6021 ManualAyam ZebossAinda não há avaliações

- 87 - Case Study On Multicomponent Distillation and Distillation Column SequencingDocumento15 páginas87 - Case Study On Multicomponent Distillation and Distillation Column SequencingFranklin Santiago Suclla Podesta50% (2)

- BreezeAIR 8000 Data SheetDocumento2 páginasBreezeAIR 8000 Data Sheetalfasukarno100% (1)

- V Series: Three Wheel, Counterbalanced Lift TruckDocumento126 páginasV Series: Three Wheel, Counterbalanced Lift TruckВиктор МушкинAinda não há avaliações

- Intelligent Smoke & Heat Detectors: Open, Digital Protocol Addressed by The Patented XPERT Card Electronics Free BaseDocumento4 páginasIntelligent Smoke & Heat Detectors: Open, Digital Protocol Addressed by The Patented XPERT Card Electronics Free BaseBabali MedAinda não há avaliações

- Mercury 150HPDocumento5 páginasMercury 150HP이영석0% (1)

- Vicente, Vieyah Angela A.-HG-G11-Q4-Mod-9Documento10 páginasVicente, Vieyah Angela A.-HG-G11-Q4-Mod-9Vieyah Angela VicenteAinda não há avaliações

- Scope: Provisional Method - 1994 © 1984 TAPPIDocumento3 páginasScope: Provisional Method - 1994 © 1984 TAPPIМаркус СилваAinda não há avaliações

- SettingsDocumento3 páginasSettingsrusil.vershAinda não há avaliações

- MCoal Coal July Investor SlidesDocumento26 páginasMCoal Coal July Investor SlidesMCoaldataAinda não há avaliações

- Home Guaranty Corp. v. Manlapaz - PunzalanDocumento3 páginasHome Guaranty Corp. v. Manlapaz - PunzalanPrincess Aliyah Punzalan100% (1)

- Acevac Catalogue VCD - R3Documento6 páginasAcevac Catalogue VCD - R3Santhosh KumarAinda não há avaliações

- Outage Analysis of Wireless CommunicationDocumento28 páginasOutage Analysis of Wireless CommunicationTarunav SahaAinda não há avaliações

- Dr. Najeebuddin Ahmed: 969 Canterbury Road, Lakemba, Sydney, NSW, Australia, 2195Documento2 páginasDr. Najeebuddin Ahmed: 969 Canterbury Road, Lakemba, Sydney, NSW, Australia, 2195Najeebuddin AhmedAinda não há avaliações

- Bea Form 7 - Natg6 PMDocumento2 páginasBea Form 7 - Natg6 PMgoeb72100% (1)

- DR-2100P Manual EspDocumento86 páginasDR-2100P Manual EspGustavo HolikAinda não há avaliações