Escolar Documentos

Profissional Documentos

Cultura Documentos

Heater

Enviado por

boladelmundo123Descrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Heater

Enviado por

boladelmundo123Direitos autorais:

Formatos disponíveis

A Build It Yourself Dew Preventer

by

Dave McCarter

London Centre, RASC

Any observer knows that dew can quickly put an end to a promising evening, or at least force an intermission

as hair dryers are used to dry off fogged optics. In addition, dew may also carry harmful airborne chemicals

which attack mirror coatings. While the Kendrick Dew Remover system is very popular, many home brew

astronomers and ATM's might want to make their own Dew Preventer.

You don't have to remove dew if you prevent dew from forming in the first place by slightly warming the lens

or corrector plate above the dew point. The heater elements, small resistors or resistance wire to which

electrical power is applied, are housed inside a fabric shell and held around the lens or eyepiece by Velcro

tape. Power can be supplied from either a line operated transformer isolated power supply or 12 volt

rechargeable battery.

Only a few watts of heat are required to adequately warm a lens barrel or eyepiece. A heater control box is

used to regulate the amount of electrical current delivered to several plug in heater elements. This high speed

switching circuit, which does not waste excess power, extends the useful battery life and allows control over

the heat delivered to prevent overheated lenses.

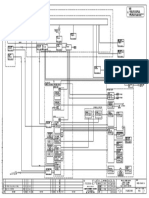

The Control Circuit

My dew zapper is really easy to put together if you enjoy experimentation with your telescope accessories,

and you are not intimidated by soldering small parts.

This circuit, based on the 555 timer IC, produces

a variable duty cycle signal to switch the heater

current for controllable lengths of time. The

longer the current is on, the more heating power

is delivered to the lens.

Circuit timing is controlled by the 50K

variable resistor and the timing capacitor

connected to IC pin 2 and 6, while the pair of

2.2K resistors set minimum and maximum

switching periods. The 1N914 diode ensures

that the switching duty cycle is symmetrical.

The 555 Integrated Circuit has limited current switching capability, so drives a high power enhancement mode

field effect transistor which switches the current with little loss and can easily supply up to fifty watts. A self

resetting plastic fuse, a RUE400, provides protection from shorted heaters or other calamities, while a red

LED indicates the unit is on and roughly the level of heating.

The circuit goes together quickly on my home made printed circuit board, see artwork below, but you could

use perf board or "dead bug" construction. The completed P.C. board, control pot, and connectors all fit into a

small Hammond type 1591A or 1591L plastic case.

Table 1: The Controller Parts List identifies the parts you need to obtain, and the figure below shows the

PC board component side layout, where each part fits into pre-drilled holes. The orientation of most parts on

the board are very important, and these have been identified with an * on the parts list. For example, the power

supply must be connected properly or the unit may be destroyed.

* 555 timer IC. may be marked MC1455P, NE555N, UA555P etc.

* IRF530A or similar N channel Power MOSFET, 50V @10A or better, eg: STD12N05, MTP3055E

* 470uF 16V electrolytic capacitor.

* 1N4001 silicon diode.

* 1N914 or 1N4148 silicon diode.

* Red LED light emitting diode.

* 50K linear potentiometer e.g.: P.E.C. type V6U5031

3 of 2200 1/4W resistors.

2 of 0.1uF 50 volt Monolithic ceramic capacitors.

RUE400 Raychem Polyswitch Fuse. May use RUE300 instead

1591A or 1591L Hammond plastic case

Plastic knob e.g.: Augat PKES-60B-1/4

4 or 5 chassis phono jacks e.g.: Switchcraft 3501FR.

4 or 5 phono plugs e.g.: Switchcraft 3507.

18G white two wire "Zip" cord, long enough to go from heater control to power supply, and from

phono plugs to heater elements,

Power Source: 12V car battery, gel cell, 10Ah or more.

Circuit Note:

This circuit works in series between the battery positive terminal (the in connection) and the resistive

heaters (to the out connection). There is no ground (battery negative terminal) on the printed circuit board!

The battery negative terminal only connects to the body of the heater connectors and to the cathode of the

LED. All circuit current

therefore goes through heater

elements, making the circuit

highly efficient.

The potentiometer, heater

connectors, and LED mount

into holes drilled into the case.

The LED in series with the

2.2K current limiting

resistor is wired in parallel

with one of the heater

controllers. The PC board is cut so that it will slide into the special ridges on each side of the case. Try the

parts for fit to decide exactly where to cut the holes to ensure that everything will fit properly.

Printed Circuit Board Artwork

This is the solder side art for the heater controller. As seen here it is about twice finished size. The spacing

between IC pins is 1/10 inch, or 2.54mm.

Heaters

When the controller is complete the next task is to build some heaters. The local surplus electronics store

should have a stock of 330 or 470 1/4 watt resistors, hopefully on sale cheap, as quite a few are needed.

When a 330 resistor is supplied with 12 volts the resistor will dissipate 0.44 watt and get very hot, which is

usually not a problem on a chilly winter night. The 470 resistor will operate closer to the 0.25 watt safety

margin, but won't warm the lens as much when the mercury dips low. Of course, if you only need a small

amount of heat you turn down the controller.

To build a heater you solder in parallel

as many of these resistors as are

required to provide the desired level of

heat around the lens. I use a strip of

copper foil to connect the resistors

together, and transfer heat to the lens,

but a length of stranded or braided

copper wire works well too.

For a small finder or eyepiece 2 to 3

watts seems plenty, but for an eight

inch corrector plate a little more power is needed, maybe as much as 12 watts on a really cold night.

Experiment and determine what works for you. The heater resistors should be spaced evenly around the lens

cell. I typically place a resistor for each centimetre of circumference on finders and eyepiece heaters, spacing

resistors apart a little more for SCT corrector plates.

Lens heaters can be permanently installed on the lens cell, or packaged in a removable casing. My finder

objective lens and the finder eyepiece were always getting fogged either from dew or my breath, so I wrapped

resistors directly onto the plastic lens housings, and held them in place with electrical tape. The resistors must

be electrically insulated from a metal lens cell, and a few layers of adhesive vinyl electrical tape will work.

A short pair of wires, 18 to 20 AWG speaker wire for example, connects the heater element to the RCA phono

plug which plugs into the heater control box.

Keeping in the Heat.

Some form of insulation over the heaters should be used to prevent cold winter breezes from robbing those

watts. A piece of closed cell foam used for camping ground roll is formed into a tube large enough to wrap

around the front of the telescope. If made long enough the foam tube can also act as a lens hood to shield the

corrector lens from stray light.

Eyepieces

Eyepieces need to be warmed too, but it is often impractical to install heaters on each eyepiece. Flexible cloth

heater casings are easy to make. Finally, an astronomical use for that orphan black & fluffy wool sock, it's

twin lost to the clothes dryer! Follow the images on the next page to make this process clear.

To prepare the sock, cut off the foot at the ankle and retain the elastic leg portion. Make a heater element long

enough to circle your eyepiece and attach the lead wire, but don't solder the connector on just yet.

Thread the lead wire through the sock, from the outside to the inside at the same distance from the cut end as

the heater is wide. Fold the cut end over the heater, fold the finished end over the cut end, and sew the folds

together. Now two layers of cloth insulate the heater, while one layer will be between the heater and the

eyepiece. Easy!

The short length of sock, the finished and elasticised end, goes onto the eyepiece first to hold the heater

securely. The fluffy warm end of this contraption forms a comfortable eyecup which also keeps out stray light

and even keeps your eye from watering due to cold night breezes. To cosy up to a slightly warm eyepiece is a

true pleasure. You'll never do without after you've tried it once.

I have observed for several years with this heater system, and on the many occasions when the scope tube was

covered with a layer of dew or ice, all of the glass surfaces were clean and dry. Printed circuit boards, which

greatly ease construction, are sometimes available at minimal cost and I can be reached via the RASC mail list

for guidance in your construction effort.

Clear Skies & Warm observing!

Dave McCarter

Dave V

R.A.S.D.

dmccarter@sympatico.ca

http://www.rasd.ca

This document available at:

http://www.astro.uwo.ca/~rasc/HEATER.pdf

Você também pode gostar

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Build Your Own EMP GeneratorDocumento22 páginasBuild Your Own EMP GeneratorMark Reichfeld100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- UniGear ZS1 Training1Documento191 páginasUniGear ZS1 Training1eyachachinAinda não há avaliações

- Break Down Panel PDFDocumento7 páginasBreak Down Panel PDFsaipul970Ainda não há avaliações

- 1 Outdoor Substation CalculationDocumento52 páginas1 Outdoor Substation Calculationpaolo sangalangAinda não há avaliações

- Multiple Choice Question (MCQ) of D.C. MachinesDocumento26 páginasMultiple Choice Question (MCQ) of D.C. Machineskibrom atsbha100% (2)

- Volvo-Wiring Diagram FL6 PDFDocumento144 páginasVolvo-Wiring Diagram FL6 PDFAnonymous OrZIZ1Bpg93% (14)

- 325 and 325 L Excavator Electrical SystemDocumento2 páginas325 and 325 L Excavator Electrical SystemRichard Savina100% (1)

- Kone LCE Fault CodesDocumento28 páginasKone LCE Fault Codesalberto peña100% (1)

- How To Calculate Burden of CTDocumento8 páginasHow To Calculate Burden of CTMiguel Alfredo Perez OrtizAinda não há avaliações

- Qdoc - Tips - 330c Electrical SchematicDocumento2 páginasQdoc - Tips - 330c Electrical SchematicAbdelbagiAinda não há avaliações

- Product Detail PhilipsDocumento109 páginasProduct Detail PhilipsDewanto WicaksonoAinda não há avaliações

- 245 Wiring Diagram For Electronic Ignition Switch (EIS) Control UnitDocumento5 páginas245 Wiring Diagram For Electronic Ignition Switch (EIS) Control UnitRosli YaacobAinda não há avaliações

- Telemecanique LC1F265 DatasheetDocumento28 páginasTelemecanique LC1F265 DatasheetRAUL ORTIZAinda não há avaliações

- Lecture 2 TransformersDocumento35 páginasLecture 2 TransformersRaza SikandarAinda não há avaliações

- History and Working Principles of Tunnel DiodesDocumento15 páginasHistory and Working Principles of Tunnel DiodesMahy MagdyAinda não há avaliações

- Reference Designator Symbol Legend: NotesDocumento106 páginasReference Designator Symbol Legend: NotesVU ingenieriaAinda não há avaliações

- ElectricasDocumento1 páginaElectricasAngel Lazarte DueñasAinda não há avaliações

- 3RV20111GA20 en PDFDocumento6 páginas3RV20111GA20 en PDFkotvasilevAinda não há avaliações

- Beacon 410A ManualDocumento80 páginasBeacon 410A ManualSebassdeAinda não há avaliações

- Cummins wiring harness repair kit parts listingDocumento6 páginasCummins wiring harness repair kit parts listingSugeng Ariyadi100% (1)

- Checklist for 66 KV underground cable completion reportsDocumento2 páginasChecklist for 66 KV underground cable completion reportsManojAinda não há avaliações

- CSD30N40 Data Sheet V1.2Documento6 páginasCSD30N40 Data Sheet V1.2Elec ThaihoaAinda não há avaliações

- Inverter From 12V-230V Irf3205: Testing A MosfetDocumento2 páginasInverter From 12V-230V Irf3205: Testing A MosfetMahmud MusaAinda não há avaliações

- EPC bid document electrical equipment price summaryDocumento64 páginasEPC bid document electrical equipment price summaryVimal Singh0% (1)

- Push Pull Transformer DesigneDocumento4 páginasPush Pull Transformer DesigneKrishna InamdarAinda não há avaliações

- II Mech - 03 - EE8353 - EDC - Unit 3 PDFDocumento4 páginasII Mech - 03 - EE8353 - EDC - Unit 3 PDFPraveena GopiAinda não há avaliações

- 9N80 UnisonicTechnologiesDocumento6 páginas9N80 UnisonicTechnologiesJlavieraAinda não há avaliações

- Datasheet Ordering Vibration Switch Metrix Model 5550Documento1 páginaDatasheet Ordering Vibration Switch Metrix Model 5550KUSNOAinda não há avaliações

- SSP 45 N 20 ADocumento6 páginasSSP 45 N 20 AJosué Daniel SotoAinda não há avaliações

- Products l3 Oskf Ansi 71503 v1 enDocumento4 páginasProducts l3 Oskf Ansi 71503 v1 enSergiu Aparatu100% (2)