Escolar Documentos

Profissional Documentos

Cultura Documentos

Application of Ductile Fiber

Enviado por

Andreea BadulescuTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Application of Ductile Fiber

Enviado por

Andreea BadulescuDireitos autorais:

Formatos disponíveis

Application of ductile ber reinforced cementitious composite in jointless

concrete pavements

Jun Zhang

, Zhenbo Wang, Xiancun Ju

Department of Civil Engineering, Tsinghua University, Beijing 100084, China

Key Laboratory of Safety and Durability, Education Ministry of China, Tsinghua University, Beijing 100084, China

a r t i c l e i n f o

Article history:

Received 9 October 2012

Received in revised form 22 January 2013

Accepted 3 February 2013

Available online 27 February 2013

Keywords:

A. Ceramicmatrix composites

B. Mechanical properties

D. Mechanical testing

Fiber reinforced cementitious composites

a b s t r a c t

This paper presents an experimental study on the potential applications of the ber reinforced engi-

neered cementitious composite with characteristic of low drying shrinkage (LSECC) in concrete pave-

ments for the purpose of eliminating joints that are normally used to accommodate temperature and

shrinkage deformation. It is found that a composite slab containing both plain concrete and LSECC, with

steel bars at the LSECC/concrete interface, and designed construction procedures, it is possible to localize

the tensile cracks into the LSECC strip instead of cracking in adjacent concrete slab. The crucial problem

that interfacial failure in composite slab was prevented by using reinforcing bars across the interfaces.

Due to the strain-hardening and high strain capacity of the LSECC, the overall strain capacity and the

integrity of the composite slab can be signicantly improved. The temperature and shrinkage deforma-

tions can be accommodated by adequate selection on the length ratio of LSECC strip and concrete slab.

2013 Elsevier Ltd. All rights reserved.

1. Introduction

Concrete pavements are popular for roads subjected to heavy

trafc loads due to their high load carrying capacity and low main-

tenance requirement compared to exible asphalt concrete pave-

ments. Several hundred thousand kilometers of Portland cement

concrete pavements had been built in China in the past decades

[1]. The average service life of a concrete pavement is determined

by many factors including initial design, material properties, traf-

c, environment, salt application, presence and effectiveness of

protective systems and maintenance practices. All these factors

inuence the development of cracks in concrete pavements during

service. It is well understood that concrete shrinkage and temper-

ature changes are the two major mechanisms leading to the initial

crack formation in concrete pavements. That is because pavement

has a much larger surface area compared with other structural

members, such as beams and columns. As a result, shrinkage and

temperature variation induced cracking in concrete pavements is

more obvious. In order to avoid cracking in concrete pavements,

the continuous pavement is normally pre-cut into separate slabs

with length of about 46 m in practice, and the cuts form the joints

of pavements. Due to the relatively short lengths of the jointed

slabs, shrinkage and temperature induced stresses should be lower

and cracking within the slab may be prevented. The joints open in

the winter and close in summer, and the difference of the joint

opening between winter and summer may achieve several milli-

meters. During service, the joint openings in pavements can lead

to concrete spalling and punchouts. Further, damage due to debris

accumulation within the joints can lead to leakage of water

through the joint or cracked pavement. Therefore, the areas close

to the joints are the places most frequently be damaged in practice,

which in turn, control the pavement life in general, as illustrated in

Fig. 1. In addition, due to the existence of joints, the running

uncomfortableness becomes another disadvantage for concrete

pavements compared with exible asphalt concrete pavements.

Thus, the prevention of the formation of joints in concrete pave-

ment is crucial, and the sequence of deterioration stages described

above has to be interrupted before nal pavement failure in order

to prolong the service life and improve the conformability of the

pavements.

In the present study, ductile strips of ber-reinforced cemen-

tious composites are investigated as replacements for conventional

joints in concrete pavements. The concept of using ductile strips in

concrete slabs was rst introduced by Zhang et al. [2]. In these

strips between regular concrete slabs, a special kind of ber rein-

forced cementitious composite (ECC), with strain-hardening and

high strain capacity compared to concrete is applied [3,4]. Through

proper material and structure designs, the temperature variation

and concrete shrinkage induced deformations may be compen-

sated by the formation of very ne cracks within the strips with

crack width less than 80 lm. ECC exhibits macroscopic strain-

hardening after rst crack. The strain energy produced by

1359-8368/$ - see front matter 2013 Elsevier Ltd. All rights reserved.

http://dx.doi.org/10.1016/j.compositesb.2013.02.007

Corresponding author at: Department of Civil Engineering, Tsinghua University,

Beijing 100084, China. Tel.: +86 10 62797422.

E-mail address: junz@tsinghua.edu.cn (J. Zhang).

Composites: Part B 50 (2013) 224231

Contents lists available at SciVerse ScienceDirect

Composites: Part B

j our nal homepage: www. el sevi er . com/ l ocat e/ composi t esb

shrinkage (under restrained condition) of hardened concrete and

temperature gradient can be released by the high deformation

within the ductile strips, and therefore, the damages occurred

around traditional joints in concrete pavement can be avoided.

Thus, the durability of concrete pavement can be improved, result-

ing in a longer service life. In addition, the running comfortable

problem normally occurred in jointed concrete pavements can be

overcome due to the replacement of joints with ductile strips.

Due to without coarse aggregate in ECC mixture, the drying shrink-

age of traditional ECC normally is much higher than concrete [5].

Such high shrinkage strain may lead longer strip requirement to

accommodate the deformations in the pavement and also may lead

un-expected shrinkage cracking inside of the strips. To implement

the concept of jointless concrete pavements and overcome the

problems that high drying shrinkage of traditional ductile material

may induced, an ECC with characteristics of low drying shrinkage

(LSECC) is used to form the ductile strips in the present paper

[5]. The cement used in LSECC has expansive property during hard-

ening and therefore the shrinkage of the composite can then be

compensated effectively, behavior as less shrinkage comparing

with traditional ECC. In addition, high early strength is another

mechanism for reducing drying shrinkage of the composite.

2. Design principles and experimental program

The target of present work is concentrating the deformation pro-

duced by temperature change and concrete shrinkage in adjacent

concrete pavement slabs into the strips placed between the two

slabs, to form a jointless concrete pavement system, as illustrated

in Fig. 2. To realize the above design concept, the tensile properties

of both concrete and LSECC material, as well as the interface be-

tween the two materials must be carefully tailored and designed.

First, the cracking strength of LSECC must be lower than the

strength of the adjacent concrete slabs. Second, the interfacial bond

strength between ECC and concrete slab must be high enough to

conrmthe cracking should not occur at the interface. The strength

difference between LSECC and concrete can be satised relatively

easy by adjusting the mix proportions of the materials and/or cast-

ing the strips at later age that the concrete slab cast. The difculty to

achieve above target may be the enhancement on the interface of

the ductile strip and adjacent concrete slab. Because if the failure

under tensile or bending loads occurs at the interface, the potential

higher strain capacity of ECC completely cannot be used and no

improvement on the performance of the pavement can be expected

compared with conventional joint concrete pavements. Therefore,

present paper will focus on the interfacial design to prevent the

interfacial failure in the ECCconcrete composite pavements. Cer-

tainly, the tensile properties of concrete and LSECC are also be eval-

uated in order to satised the design requirements.

Three tests are involved in the experimental program. First, the

tensile properties of plain concrete and a kind of LSECC was exper-

imentally examined to guarantee the strength difference is satis-

ed the design requirement. Second, the drying shrinkage of the

selected LSECC used as ductile strips was examined in order to con-

rm the low shrinkage characteristic [5]. Third, the designed inter-

facial connection methods to enhance the interfacial bond between

the ECC strip and the concrete slab were evaluated by three points

bending tests on composite beams in order to learn the reliability

of the designs.

2.1. Materials

In the present investigation, two types of cements, ordinary

Portaland cement used for concrete and the newly developed com-

posite cement with low drying shrinkage characteristic used for

ECC matrix. Natural sand and crushed limestone with a maximum

particle size of 5 mm and 20 mm, respectively, were used as ne

and coarse aggregates in concrete. The concrete mixture propor-

tions are listed in Table 1. A superplasticizing admixture was used

in the mixtures to guarantee the three fresh concrete having a

slump of 120140 mm. For ECC, silica sand with average particle

size 0.1 mm were used to form the matrix. Polyvinyl Alcohol

(PVA) ber supplied by Kuraray Company in Japan was employed

as reinforcement and the ber properties are listed in Table 2. Mix-

ture proportions of the LSECC adopted in this study are given in

Table 3.

2.2. Specimens, curing and testing procedures

For drying shrinkage test of ECC, a prism shape specimen mea-

suring 40 40 160 mm with two embedded copper heads at the

Pavement

Existing joint or crack

Subgrade

Damage susceptible zone

Fig. 1. Illustration of formation of joints and damages susceptible zone under trafc

load.

Pavement

Existing joint

Subgrade

LSECC strip

Interfacial reinforcing bars

Fine cracks

Fig. 2. Ductile joints in concrete pavement.

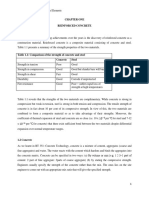

Table 1

Mix proportions of concrete, kg/m

3

.

Cement Water Sand Stone Fly ash

345 185 685 1090 85

Table 2

Properties of the PVA ber.

Density (g/

cm

3

)

Tensile strength

(MPa)

E

(GPa)

Diameter

(mm)

Length

(mm)

1.2 1620 42.8 0.039 12

Table 3

Mix proportions of LSECC.

Composite cement Water Sand Super plasticizer Fiber (volume, %)

1.0 0.35 0.3 0.012 1.7

J. Zhang et al. / Composites: Part B 50 (2013) 224231 225

two long ends for length measurement was used. After removing

from their molds (24 h after casting), the specimens were stored

in the room with constant temperature and relative humidity of

25 2 C and 60 1.5% for drying shrinkage deformation measure-

ment. The length measurement starts immediately after specimen

demolding until 28 days after casting.

The uniaxial tensile tests give tensile stressstrain performance

and related mechanical parameters, such as tensile strength and

strain of materials. Rectangular coupon specimens with size of

40 150 15 mm were used for LSECC to conduct uniaxial tensile

test. The molds used to cast the tensile specimens were made of

steel. After removing from their molds, the tensile specimens were

stored in water at 20 2 C for curing until tensile tests were car-

ried out. The tensile specimens were tested in uniaxial tension

with displacement control in a 250 kN capacity MTS 810 material

testing system with hydraulic wedge grips. Aluminum plates were

epoxy glued onto the ends of the specimens prior to loading at

least 6 h to enhance the ends for gripping. The actuator displace-

ment rate used for controlling the test was 0.0025 mm per second.

The strain was measured by two extensometers mounted on the

surface of the specimen. The measured gage length of extensome-

ter was 50 mm. The tensile test set-up and specimen with alumi-

num plates glued and extensometers mounted is shown in

Fig. 3a. For tensile tests of plain concrete, a loading holder devel-

oped by Li [4] was adopted (Fig. 3b). The holders were made of alu-

minum alloy. One was xed to the load cell and the other to the

actuator with standard MTS grips. The tensile load was transmitted

to the specimen by the anchor action between holders and the en-

larged ends of the specimen. To further prevent failure due to

stress concentration at the loaded ends of the concrete specimens,

two steel bolts with 6 mm diameter and 12 mm length were used

to reinforce the specimen ends. One end of each bolt was con-

nected with a nut and the other end was fastened to a

118 45 7 mm steel plate through another nut. Thus the failure

of the specimen under tensile load can be ensured to be within the

central position with a uniform cross section. The minimum cross

section of the specimen was 76 45 mm. The overall uniaxial ten-

sile strain was measured with two LVDTs, one on each side of the

specimen. The details of experimental set-up and geometry of the

test specimen are shown in Fig. 3b. The tensile tests were carried

out under displacement control with prescribed rate of 0.005 mm

per second in a 250 kN capacity MTS 810 material testing system.

The raw data of tensile tests consisted of time, load, position of the

piston and displacement from each extensometer. The tensile

behavior can then be determined from these test data.

The interfacial connection tests were used to evaluate the reli-

ability of the bond between the concrete slab and the ductile strips,

meanwhile to check the effectiveness of the replacement of con-

ventional joints with ductile strips. A composite beam with overall

dimension of 100 100 515 mm is employed with three bend-

ing load applied to the beam as a general loading condition. The

specimen is composed of two concrete blocks to simulate the

two adjacent concrete slabs and a ECC block with size of

100 50 300 mm placed in the top center of the beam to simu-

late the ductile strip. A steel bar with 10 mm diameter was used to

enhance the connection of concrete block and ECC strip. Two con-

necting steel bars having enlarged nut with outer diameter of 17

mm at ends, with different embedment length in concrete and/or

ECC, were placed at each interface. The detailed dimension of each

part of the composed beam is shown in Fig. 4. The concrete blocks

used for the composite beams were cast rst and designed steel

bars was embedded inside of concrete at prescribed locations.

75

120

1

6

5

1

8

0

1

6

5

45

Loading Hold

LVDT

Specimen

Unit: mm

Strengthen Element

(b)

(a)

Fig. 3. Test set-up and geometry of specimen of LSECC (a) plain concrete and (b) in tension.

226 J. Zhang et al. / Composites: Part B 50 (2013) 224231

The space left for ECC strip was formed by pre-placed wood block

with required dimensions in the mold. These concrete blocks were

cast and demolded 24 h after casting. After demolding, the blocks

were cured in moisture roomat 20 3 C and relative humidity lar-

ger than 95% for 2 weeks. Then the blocks were placed back into

the mold again and the empty space left for ECC strip was cast.

The composite beams were demolded 24 h after the ECC strip

was cast and were cured in the moisture room for another 2 weeks

before testing. As control, specimens without steel bars were cast

also at the same time. Conventional concrete and mortar mixers

were used to prepare the fresh materials. For plain concrete, the

mixing time was 5 min. For LSECC about 10 min mixing time was

used to ensure good ber distribution in the matrix.

Deection is carefully monitored during bending testing using a

reference beam attached to the top of the beam by three steel

blocks glued to the beam surface. A standard Toni linear variable

differential transducer (LVDT) is used for measuring the movement

of the actuator displacement. A extensometer mounted on the cen-

ter of the beam is used for measuring the deection. The loading

congurations for three point bending test is shown in Fig. 5. The

bending test is conducted at a prescribed deformation rate of

0.05 mm per minute using the signal from the LVDT as feedback.

All tests are carried out on a Toni testing machine equipped for

close-loop testing. The raw data consisted of time, load and dis-

placement reading from load cell, LVDT and extensometer respec-

tively. Data are recorded by the test machine and transferred to a

computer for further processing. All types of the composite beams

used in the experiments are summarized in Table 4.

3. Results and discussions

3.1. Drying shrinkage behavior of LSECC

The measured drying shrinkage up to 28 days of conventional

ECC using normal Portland cement in matrix [5] and LSECC made

by low shrinkage cementitious material is shown in Fig. 6. We

can clearly see that the drying shrinkage deformation of the com-

posites using the newcementitious material in matrix is greatly re-

duced. The shrinkage strain at 28 days is only 242 10

6

of the

new developed ECC. For traditional ECC, the shrinkage strain at

28 days is nearly 1200 10

6

that is almost ve times larger than

the shrinkage of LSECC. Further, the result indicates that the drying

shrinkage of the LSECC is even lower than that of normal concrete,

which normally has the magnitude of shrinkage strain of 400

600 10

6

at 28 days under the similar testing conditions. This

means that under the same or similar curing periods and environ-

mental conditions, as cracking does not occur in normal concrete

structure, the same or even higher no-cracking guarantee can be

provided as using LSECC to replace normal concrete in the struc-

ture. Therefore, after applying the LSECC as the ductile strip in con-

crete pavement, un-expected shrinkage cracking can be reduced

and the requirement on the overall deformation capacity to com-

pensate temperature strain produced by the adjacent concrete

slabs may become small and the required strip length may be

shorter than that when conventional ECC was used [2]. Further,

due to its low drying shrinkage strain, the shrinkage cracking along

the trafc direction should be able to be avoided that may happen

as using normal ECC as the ductile strips.

3.2. Uniaxial tensile behavior of LSECC and plain concrete

ECC is a cement based composite reinforced with short ran-

domly oriented bers. The composite has been micro-structurally

engineered to strain-harden via multiple cracking in uniaxial ten-

sion [3,4]. ECC exhibits macroscopic strain-hardening after rst

Fig. 4. Design of composite beam.

Fig. 5. Experimental set-up for composite beam under bending load.

Table 4

Interfacial details used in the composite beams.

Number of interfacial steel reinforcements Embedment length (mm)

No 0

Two 25

Two 50

Two 100

J. Zhang et al. / Composites: Part B 50 (2013) 224231 227

crack. During strain-hardening, multiple cracks develop with con-

tinuously reducing crack spacing until localization occurs at one of

these cracks. The fracture site is not necessary the rst crack site.

The evolution of multiple cracking appears to be a stochastic pro-

cess associated with distributed initial aw sizes [6].

As an important material property, the tensile behavior of

LSECC and plain concrete used in the composite beams is deter-

mined rst. Fig. 7 displays the tensile stressstrain curves of plain

concrete and LSECC at 28 days of moisture curing. From the tensile

results, rst we may clearly see that the tensile strength of plain

concrete is about two times higher than that of LSECC. Such behav-

ior can guarantee the cracking should occur inside of the ductile

strip in the composite structure under tensile or bending loads as

long as the bond between concrete slab and ECC strips is sufcient

high that the interfacial failure can be prevented. Second, the

LSECC can well maintain the strain-hardening and multiple crack-

ing performance along with tight crack width less than 0.05 mm

[5], that normal ECC displayed. This performance conrms that if

cracking can be leaded into the inserted strips, the deformation

of the structure due to temperature variation, live load, and shrink-

age can be accommodated effectively by the formation of micr-

cracks inside of the strip. Clearly, the success on the jointless

concrete pavement now depends on the interface of concrete slab

and ECC strip. This is crucial to realize the concept apart from the

material properties tailoring.

3.3. Bending performance of LSECCconcrete composite beams

The objective performing bending test on concreteECC com-

posite beams is to examine if the present interfacial design can

prevent the interfacial failure in current jointless concrete pave-

ment system. Such interfacial failure had been observed in the

experiments of ECC linked steel reinforced slab and the interfacial

transition zone was designed to overcome the interfacial failure in

ECC linked steel reinforced slab [7,8]. In present study, the ECC

concrete interface is simply enhanced by steel reinforced bars with

enlarged end nuts only. The simplicity in construction is important

for its application in jointless concrete pavements.

The bending performance of the composite beams with differ-

ent concreteLSECC interfacial enhancing bars is displayed in

Figs. 8 and 9 in terms of load and middle point deection diagrams.

The corresponded failure model of the beams are displayed in

Fig. 10, in which the smaller photographer present in the gure

displays the ner cracks formed inside of the ductile strip at side

Fig. 10b and top Fig. 10c faces respectively. From the results dis-

played in the gures, rst we can see that as without reinforcing

bars connecting the concrete slab and ECC strip (Fig. 8), the com-

posite beam behaviors immediate failure along the interface be-

tween concrete and LSECC. The load carry capacity of the beam is

simply controlled by the physical bond of LSECC and concrete

block, which is the weakest part in the composite system in the

current situation. The maximum exural stress achieved under

bending load is only about 4 MPa, which reects the magnitude

of exural strength of cold jointed concreteLSECC interface. The

loaddeection curves display apparent brittle nature behaving

as load carrying capacity suddenly drops after the peak load. No

ne cracks can be nd in the ECC strip. As using two reinforcing

bars at the interfacial zone to bridge the each interface, with

embedment length of 25 mm, 50 mm and 100 mm respectively,

the bending performance of the composite beams were completely

changed from interfacial failure to cracking inside of ECC strips, see

Fig. 10ac respectively for different embedment length of the steel

bars.

Flexural strain hardening behavior was occurred, along with

larger deformation and ductile failure characteristic. Meanwhile,

the bending strength of the beam is also signicantly increased

compared with the case of interfacial failure, for example, the

bending strength of the composite beams with interfacial failure

and ductile strip cracking are 4 MPa and 8 MPa respectively. The

0 7 14 21 28

Time (days)

0

400

800

1200

D

r

y

i

n

g

s

h

r

i

n

k

a

g

e

(

x

1

0

-

6

)

Traditional ECC

LSECC

Fig. 6. Drying shrinkage of LSECC and traditional ECC.

0.00 0.50 1.00 1.50 2.00 2.50 3.00

Tensile strain (%)

0.00

1.00

2.00

3.00

4.00

5.00

6.00

T

e

n

s

i

l

e

s

t

r

e

s

s

(

M

P

a

)

Plain Concrete

LSECC

Fig. 7. Tensile stressstrain curves of plain concrete and LSECC.

0.00 0.50 1.00 1.50 2.00 2.50 3.00

Deflection (mm)

0.00

1.00

2.00

3.00

4.00

5.00

6.00

7.00

8.00

9.00

10.00

F

l

e

x

u

r

a

l

s

t

r

e

s

s

(

M

P

a

)

L=450mm

No steel bars

No steel bars

Fig. 8. Bending performance of composite beam without interfacial reinforcing

bars.

228 J. Zhang et al. / Composites: Part B 50 (2013) 224231

load transferring ability of the interfaces is greatly improved,

which is an importance aspect needed to be considered in the de-

sign of conventional jointed concrete pavement. As expected, with

increase of embedment length of the steel bars, from 25 mm to

100 mm, the bending performance is improved, but it looks that

little difference can be found between embedment length of

50 mm and 100 mm. This means that the 50 mm embedment

length is sufcient to achieve the target of leading the cracking into

the LSECC strips. For the specimens with embedment length of

25 mm of the steel bars, the interface of LSECC and concrete failure

is still observed, but the bending behavior is improved compared

to the case without any reinforcement at interface, as shown in

Fig. 8. From the photographers attached in Fig. 10, we can clearly

see that the without steel reinforcing bars at interface, the interfa-

cial failure cannot be prevented and the cracking inside of the duc-

tile strip cannot occurs. By contrast, as using steel reinforcing bars

and with embedment length of 50 or 100 mm length, the interfa-

cial failure can be prevented and the ne cracks had been displayed

within the ductile strip.

3.4. Further discussions

3.4.1. Construction procedures for jointless concrete pavements

As state above, if the interfacial bond strength between ECC and

concrete slab is high enough and the interfacial failure can be pre-

vented, in order to realize the cracking occurs only inside of the

ductile strips, the cracking strength of LSECC must be lower than

the strength of the adjacent slabs. Such difference in cracking

strength can be realized by mix proportion design and/or casting

the strip later than the concrete cast. In practice, the pavements

may be constructed with traditional manners just at the location

where a joint notch should be cut, to put a prefabricated ller with

required steel bars in it and the thickness may be less than the

thickness of pavement, generally half of the pavement thickness

is sufcient to maintain a tight crack opening at pavement top after

the joint crack reecting into the ECC layer [9]. After concrete con-

struction, the ller is picked out and the space is left for ECC strips

cast that should be cast afterwards. In such construction proce-

dure, the weakest location in the continuously constructed pave-

ment is still at the place where the prefabricated ller is put in.

Several days after concrete cast, the joint crack should be formed

around the center of the prefabricated ller due to reection of

existing joint in the concrete slab. This predestined location of

existing joint crack is important also for completely avoid cracking

in adjacent concrete slab because the unsymmetrical joint cracking

in the base concrete may lead interfacial shear failure. After the

ECC strips were cast, the existing joint crack should reect into

the ECC layer in the manner of formation of many ne cracks, with-

out loss of load transferring capacity [9].

3.4.2. Strip length requirements to accommodate the deformation of

pavement

The strip length required to accommodate the deformation of

pavement depends on the strain capacity of the ductile material

and the space length between the strips, as well as local tempera-

ture variation and shrinkage of concrete. Assume a composite slab

is composed of two kinds of materials, LSECC and plain concrete

with length l

I

and l

II

respectively. The slab has the same cross sec-

tion along the length. Further assume that the two materials are

perfectly joined together without failure at the interface under ten-

sile load, above experimental study already demonstrates it is pos-

sible by simply introducing steel reinforcing bars at interfacial

zone. The general dimension of the slab and the corresponding

stressstrain relationship under tensile load of individual materials

are shown in Fig. 11, where the concrete tensile strength is higher

0.00 0.50 1.00 1.50 2.00 2.50 3.00

Deflection (mm)

0.00

2.00

4.00

6.00

8.00

10.00

F

l

e

x

u

r

a

l

s

t

r

e

s

s

(

M

P

a

)

L=450mm

R_L=25mm

R_L=25mm

(a)

0.00 0.50 1.00 1.50 2.00 2.50

Deflection (mm)

0.00

2.00

4.00

6.00

8.00

10.00

F

l

e

x

u

r

a

l

s

t

r

e

s

s

(

M

P

a

)

L=450mm

R_L=50mm

R_L=50mm

(b)

(c)

0.00 0.50 1.00 1.50 2.00 2.50 3.00

Deflection (mm)

0.00

2.00

4.00

6.00

8.00

10.00

F

l

e

x

u

r

a

l

s

t

r

e

s

s

(

M

P

a

)

L=450mm

R_L=100mm

R_L=100mm

Fig. 9. Bending performance of composite beam with interfacial reinforcing bars

and embedment length (a) 25 mm, (b) 50 mm and (c) 100 mm.

J. Zhang et al. / Composites: Part B 50 (2013) 224231 229

Bottom face

(a)

(b) (d)

(c)

Fig. 10. Photographers of composite beams at ultimate failure, (a) without interfacial reinforcing bars, (b) embedment length 25 mm, (c) embedment length 50 mm and (d)

embedment length 100 mm.

(a)

(b)

ECC PC

l

l

I l

II

I

II

S

t

r

e

s

s

Strain

I

II

t,ECC

t,PC

fc,ECC

I-II

F F

Fig. 11. (a) A ECC/PC tensile bar and (b) schematic stressstrain behavior of ECC and concrete under uniaxial tensile load.

230 J. Zhang et al. / Composites: Part B 50 (2013) 224231

than that of ECC. Under uniaxial tension, the overall strain capacity

of the slab in length direction, e

c

, can be given by

e

c

e

I

l

I

l

e

II

l

II

l

1

where e

I

is the strain capacity of ECC and e

II

is the strain value of

plain concrete corresponding to the tensile load. l is the total length

of the slab. Therefore, the composite strain capacity, e

c

, is a function

of e

I

, e

II

and l

I

or l

II

. For given material properties, e

c

is inuenced

only by the individual element length l

I

or l

II

. For safety, we assume

e

I

is equal to 12%, which can easily achieved for ECC materials.

Fig. 12 displays the overall strain capacity, e

c

as a function of l

I

with

given strain capacity of ECC, e

I

of 1% and 2%. It shows that for a given

ECC element length the higher the strain capacity of ECC used, the

higher the overall strain capacity of the composite bar. Second, a

high composite strain capacity can also be obtained through adjust-

ing the length of the ECC strip.

On the demand side, the required strain capacity for the com-

posite slab is determined from the imposed strain mainly due to

the combined effect of thermal deformation and shrinkage of con-

crete, as shown in the following equation:

e

R

a

T

DT e

sh

2

where e

R

is the required total tensile strain. a

T

is the coefcient of

thermal expansion of concrete, generally equal to 0.001%/C. DT is

annual temperature variation, approximately 5060 C for Beijing

for example [10]. e

sh

is shrinkage strain of concrete, normally equal

to 0.06%. Using DT = 60 C and e

sh

= 0.06% in Eq. (2), we may obtain

e

R

= 0.12%. From Fig. 12, we may get the ratio of the length of ECC

strip to the total length of the composite pavement is about 0.05

and 0.10 for 2% and 1% tensile strain of ECC used respectively,

means for 6 m length slab, which is the general joint space in tradi-

tional concrete pavement [1], the required ductile strip is 0.60 and

0.30 meter for strain capacity of ECC of 1% and 2% respectively. It

should be noted that Eq. (2) does not take the effect of live load into

account. As live load is considered, the strip length may increase a

little.

Clearly, with a reasonable combination of plain concrete and

ECC strips, it is possible to achieve a prescribed strain capacity

requirement without a loss of load carrying capacity. In such situ-

ation, cracking can be avoided within the plain concrete section as

the structure is subject to tensile stress, such as shrinkage and tem-

perature stresses. Instead, the ECC strip plastically yields to

accommodate the imposed strain. In addition, the formation of

tight cracks within the ductile strips should form the base of crack

healing under moisture environments that should also be of great

interests for improvement of durability of concrete pavements and

prolong its service life. Further, such combination can still follow

the traditional construction procedures just leaving the required

space for the ductile strips which should be cast afterwards. Mean-

while remaining the total cost of the jointless concrete pavements

comparable with traditional jointed concrete pavements due to the

limited strip length required, but with super service ability and

long service life.

4. Conclusions and future work

This paper presents an experimental study on the potential

applications of the ber reinforced engineered cementitious com-

posite in concrete pavements for the purpose of eliminating joints

that normally used to accommodate temperature and shrinkage

deformation. It is found that a composite slab containing both plain

concrete and LSECC strips, with a simply enhancement at the

LSECC/concrete interfaces by using steel bars, and designed con-

struction procedures, it is possible to localize the tensile cracks into

the ductile strip instead of cracking in adjacent concrete slab. The

crucial problem that interfacial failure in composite slab of LSECC

and concrete was prevented by using reinforcing bars at the inter-

faces. Due to the strain-hardening performance of the ECC material

with high strain capacity, the overall strain capacity and the integ-

rity of the composite slab can be signicantly improved. The tem-

perature and shrinkage deformations can be accommodated by

adequate selection on the length ratio of ductile strip and concrete

slab. Further experiments with larger scale specimens are needed

in order to apply the concept explored in the present work in more

realistic eld situations.

Acknowledgments

Support from the National Science Foundation of China (Nos.

50878119, 51278278) and Twelfth Five-Year plan projects from

the National Science and Technology (No. 2011BAJ09B01) to Tsing-

hua University are gratefully acknowledged.

References

[1] Chinese specication for construction of concrete pavements. JTG F30-2003 [in

Chinese].

[2] Zhang J, Li VC, Nowak NS, Wang S. Introducing ductile strip for durability

enhancement of concrete slabs. ASCE J Mater Civil Eng 2002;14(3):25361.

[3] Li VC. From Micromechanics to structural engineering the design of

cementitous composites for civil engineering applications. JSCE J Struct Mech

Earthq Eng 1993;10(2):3748.

[4] Li VC. Engineered cementitious composites tailored composites through

micromechanical modelling. In: Banthia N, Bentur A, Mufti A, editors. Fiber

reinforced concrete: present and the future. Montreal: Canadian Society for

Civil Engineering; 1998. p. 6497.

[5] Zhang J, Gong CX, Zhang MH, Guo ZL. Engineered cementitious composite with

characteristic of low drying shrinkage. Cem Concr Res 2009;39(4):30312.

[6] Wu HC, Li VC. Trade-off between strength and ductility of random

discontinuous ber reinforced cementitious composites. J Cem Concr

Compos 1994;16(1):239.

[7] Gilani A, Jansson P. Link slabs for simply supported bridges. Report no. MDOT

SPR-54181, Michigan Department of Transportation; June 2004. 129p.

[8] Qian S, Lepech MD, Kim Y, Li VC. Introduction of transition zone design for

bridge deck link slabs using ductile concrete. ACI Struct J 2009;106(1):96105.

[9] Zhang J, Li VC. Monotonic and fatigue performance of engineered ber

reinforced cementitious composite in overlay system. Cem Concr Res

2002;32(3):41523.

[10] Zhang J, Huang Z, Li Z, Yan P, Zhang P. Calculation and analyses of temperature

eld in external walls with different thermal insulation models. J Harbin Eng

Univ 2009;30(12):135665 [in Chinese].

I

0.00 0.04 0.08 0.12 0.16 0.20

l /l

0.00

0.10

0.20

0.30

0.40

0.50

O

v

e

r

a

l

l

s

t

r

a

i

n

c

a

p

a

c

i

t

y

(

%

)

=0.01%, = 2%, 1%

II

I

Fig. 12. Overall strain capacity of ECCconcrete composite bar as a function of ECC

strip length, l

I

.

J. Zhang et al. / Composites: Part B 50 (2013) 224231 231

Você também pode gostar

- Lecture Notes on Reinforced Concrete DesignNo EverandLecture Notes on Reinforced Concrete DesignAinda não há avaliações

- The Rheology of Cementitious MaterialsDocumento6 páginasThe Rheology of Cementitious MaterialsAi VietAinda não há avaliações

- Introduction of Transition Zone Design For Bridge Deck Link Slabs Using Ductile ConcreteDocumento10 páginasIntroduction of Transition Zone Design For Bridge Deck Link Slabs Using Ductile Concreteicv.xaviAinda não há avaliações

- Bendable ConcreteDocumento8 páginasBendable ConcreteAnees CalicutAinda não há avaliações

- Link Slab Deck JointsDocumento20 páginasLink Slab Deck JointsAnton Husen PurboyoAinda não há avaliações

- A Study On The Shrinkage Control of Fiber Reinforced Concrete PavementDocumento8 páginasA Study On The Shrinkage Control of Fiber Reinforced Concrete PavementShahid Lima KhanAinda não há avaliações

- Creep and Shrinkage of High-Performance Fiber-Reinforced Cementitious CompositesDocumento8 páginasCreep and Shrinkage of High-Performance Fiber-Reinforced Cementitious CompositesHenry BermeoAinda não há avaliações

- In Uence of Coarse Aggregate On The Permeation, Durability and The Microstructure Characteristics of Ordinary Portland Cement ConcreteDocumento9 páginasIn Uence of Coarse Aggregate On The Permeation, Durability and The Microstructure Characteristics of Ordinary Portland Cement ConcreteA M Yasin ArmanAinda não há avaliações

- Comparison of Performance of Standard Concrete and Fibre Reinforced Standard Concrete Exposed To Elevated TemperaturesDocumento7 páginasComparison of Performance of Standard Concrete and Fibre Reinforced Standard Concrete Exposed To Elevated TemperaturesAJER JOURNALAinda não há avaliações

- Relationship Between Cracking and Electrical Resistance in Reinforced and Unreinforced ConcreteDocumento8 páginasRelationship Between Cracking and Electrical Resistance in Reinforced and Unreinforced ConcreteMatthew SmithAinda não há avaliações

- Fibers, Percolation, and Spalling of High Performance ConcreteDocumento21 páginasFibers, Percolation, and Spalling of High Performance ConcretedddAinda não há avaliações

- Two Stage Method ConcreteDocumento5 páginasTwo Stage Method ConcreteReynhard WijayaAinda não há avaliações

- LWH Technical Paper 071219Documento12 páginasLWH Technical Paper 071219ahmad tarmiziAinda não há avaliações

- Comparative study of prestressed steel-concrete composite bridgesDocumento6 páginasComparative study of prestressed steel-concrete composite bridgesPreeti AgarwalAinda não há avaliações

- Reinforced Concrete BasicsDocumento12 páginasReinforced Concrete BasicshistorymakeoverAinda não há avaliações

- Applied SciencesDocumento17 páginasApplied SciencesDanielAinda não há avaliações

- Masonry Wall StrengtheningDocumento14 páginasMasonry Wall StrengtheningJ ChoyAinda não há avaliações

- Durability of Concrete With Differential Concrete Mix DesignDocumento10 páginasDurability of Concrete With Differential Concrete Mix Designshoyeeb ahmedAinda não há avaliações

- Innovation in Composite ConstructionDocumento6 páginasInnovation in Composite ConstructionnicholasAinda não há avaliações

- Self Compacting Concrete For Slip Form PavingDocumento7 páginasSelf Compacting Concrete For Slip Form PavingNaufal Pawa NajibAinda não há avaliações

- Enhancing Bond Strength Between Steel Fiber and Concrete Using Corrugated Fiber ShapeDocumento11 páginasEnhancing Bond Strength Between Steel Fiber and Concrete Using Corrugated Fiber ShapeDaniela Gonzalez BetancurAinda não há avaliações

- HB Assignment 2Documento11 páginasHB Assignment 2Himanshu BishnoiAinda não há avaliações

- 1.1 General Introduction: Experimental Behaviour On Engineered Cementitious CompositesDocumento41 páginas1.1 General Introduction: Experimental Behaviour On Engineered Cementitious CompositesChîrànjëêvï GøwđâAinda não há avaliações

- Behaviour of Hybrid Fibre Reinforced Concrete Beam Column Joints Under Reverse Cyclic Loads 2014 Materials and DesignDocumento8 páginasBehaviour of Hybrid Fibre Reinforced Concrete Beam Column Joints Under Reverse Cyclic Loads 2014 Materials and DesignAlper BuyukkaragozAinda não há avaliações

- Structural Glass Fiber Reinforced Concrete for Slabs on GroundDocumento7 páginasStructural Glass Fiber Reinforced Concrete for Slabs on GroundJayanth RaviAinda não há avaliações

- Colombo 2015Documento11 páginasColombo 2015Daania RasoolAinda não há avaliações

- Strength of GroutDocumento24 páginasStrength of Groutfaizal_7138Ainda não há avaliações

- Mechanical Properties of Bendable ConcreteDocumento25 páginasMechanical Properties of Bendable ConcreteVaidehi DesaiAinda não há avaliações

- Failure Mechanism of Fibre Reinforced Concrete Under Splitting Test Using Digital Image CorrelationDocumento14 páginasFailure Mechanism of Fibre Reinforced Concrete Under Splitting Test Using Digital Image CorrelationkashifAinda não há avaliações

- 6-Impact of Adhesive Thickness On The Capacity of The Surface Mounting Steel Plates Strengthening TechniqueDocumento9 páginas6-Impact of Adhesive Thickness On The Capacity of The Surface Mounting Steel Plates Strengthening TechniqueMr A. M. OlajumokeAinda não há avaliações

- Purpose of Provision of Concrete CoverDocumento17 páginasPurpose of Provision of Concrete CoverHiren DesaiAinda não há avaliações

- 22061-Microproject-Construction Management ProjectDocumento12 páginas22061-Microproject-Construction Management Projectaditya nimbalkarAinda não há avaliações

- 5 AmornpunyapatDocumento17 páginas5 Amornpunyapatmahdi najafzadehAinda não há avaliações

- A Ataei M Bradford 10thconferencepaperDocumento9 páginasA Ataei M Bradford 10thconferencepapermdkmlAinda não há avaliações

- Structural Glass Fiber Reinforced Concrete For Slabs On GroundDocumento8 páginasStructural Glass Fiber Reinforced Concrete For Slabs On GroundYusuf TrunkwalaAinda não há avaliações

- 22061-Microproject-Construction Management ProjectDocumento12 páginas22061-Microproject-Construction Management Projectv adamAinda não há avaliações

- Bond Behavior of Reinforcement in Self-Compacting ConcreteDocumento9 páginasBond Behavior of Reinforcement in Self-Compacting ConcreteSaif BayyariAinda não há avaliações

- High-Performance Warehouse Floors with Steel Fiber Reinforced ConcreteDocumento15 páginasHigh-Performance Warehouse Floors with Steel Fiber Reinforced ConcreteRainakAinda não há avaliações

- Gamma PDFDocumento19 páginasGamma PDFKarina DazaAinda não há avaliações

- 3.fiber Reinforced PlasticsDocumento34 páginas3.fiber Reinforced PlasticsMagdy BakryAinda não há avaliações

- MS - Unit 4Documento9 páginasMS - Unit 4sushant metriAinda não há avaliações

- Reinforced Concrete I: Lecture-1Documento54 páginasReinforced Concrete I: Lecture-1Temesgen BihonegnAinda não há avaliações

- Advantages and applications of steel fibre reinforced concrete (SFRCDocumento213 páginasAdvantages and applications of steel fibre reinforced concrete (SFRChamsanram100% (3)

- Feng 2021Documento19 páginasFeng 2021陈湘恒Ainda não há avaliações

- Effect of Fly Ash On Durability of Leightweight ConcreteDocumento10 páginasEffect of Fly Ash On Durability of Leightweight ConcreteRadna kurniasariAinda não há avaliações

- An Application of A Decision-Making Technique PDFDocumento19 páginasAn Application of A Decision-Making Technique PDFMudasserMuneerKhanAinda não há avaliações

- Final ProjectDocumento33 páginasFinal ProjectYuvresh BansalAinda não há avaliações

- Crystals 10 00928 v2Documento17 páginasCrystals 10 00928 v2ZU RehmanAinda não há avaliações

- Fiber Reinforcement ThesisDocumento5 páginasFiber Reinforcement Thesisbeckiroymanchester100% (2)

- Ferrado Et Al - Mec Comput 2016 BDocumento13 páginasFerrado Et Al - Mec Comput 2016 Bingenauta7282Ainda não há avaliações

- Influence of Stiffness of Dry Lean ConcrDocumento15 páginasInfluence of Stiffness of Dry Lean ConcrSai KrishnaAinda não há avaliações

- Wang S Li VC 07 Engineered Cementitous Composites With High-Volume+Documento9 páginasWang S Li VC 07 Engineered Cementitous Composites With High-Volume+Basil Baby-PisharathuAinda não há avaliações

- Performance Assessment of Glass Fiberreinforced Concrete BeamsDocumento11 páginasPerformance Assessment of Glass Fiberreinforced Concrete Beamsచిమ్ముల సందీప్ రెడ్డిAinda não há avaliações

- Impact of Crack Width On Bond Confined and Unconfined RebarDocumento10 páginasImpact of Crack Width On Bond Confined and Unconfined RebarbrahmabulAinda não há avaliações

- AAC-concrete Light Weight Precast Composite Floor SlabDocumento6 páginasAAC-concrete Light Weight Precast Composite Floor SlabSeifeldin Ali MarzoukAinda não há avaliações

- Fibre Reinforced ConcreteDocumento6 páginasFibre Reinforced ConcreteFranklyn GenoveAinda não há avaliações

- BT Searc Search SearchDocumento13 páginasBT Searc Search Searchdice tengayAinda não há avaliações

- JPNR - S07 - 611Documento12 páginasJPNR - S07 - 611Bien Thuy TranAinda não há avaliações

- Repair and Structural Performance of Initially Cracked RC SlabsDocumento9 páginasRepair and Structural Performance of Initially Cracked RC SlabsHari SankarAinda não há avaliações

- Ufc 4-023-03 Design of Buildings To Resist Progressive CollapseDocumento181 páginasUfc 4-023-03 Design of Buildings To Resist Progressive CollapseymordenverayAinda não há avaliações

- Finite Element Seismic Analysis of Guyed MastsDocumento166 páginasFinite Element Seismic Analysis of Guyed MastsseetaramayyaAinda não há avaliações

- En 1999 1 5 2007Documento67 páginasEn 1999 1 5 2007Daniel CojocaruAinda não há avaliações

- Guidelines For Design of Wind Turbines Copenhagen PDFDocumento294 páginasGuidelines For Design of Wind Turbines Copenhagen PDFVíctor Hugo Reséndiz EstradaAinda não há avaliações

- Composite Frame StructuresDocumento14 páginasComposite Frame StructuresAndreea Badulescu100% (1)

- Zucchini&Lourenco-Homogenization of Masonry Using A Micro Mechanical ModelDocumento11 páginasZucchini&Lourenco-Homogenization of Masonry Using A Micro Mechanical ModelAndreea BadulescuAinda não há avaliações

- Nonlinear Behavior of Steel Coupling BeamsDocumento10 páginasNonlinear Behavior of Steel Coupling BeamsAndreea BadulescuAinda não há avaliações

- CHENG Ming LU Xilin 64-ChinaDocumento8 páginasCHENG Ming LU Xilin 64-ChinaAndreea BadulescuAinda não há avaliações

- 2619Documento8 páginas2619Kevin Becerra DiazAinda não há avaliações

- Behaviour of Wall-Frame StructuresDocumento276 páginasBehaviour of Wall-Frame StructuresAndreea BadulescuAinda não há avaliações

- A Finite Element For The Interaction of Frames and Shear WallsDocumento10 páginasA Finite Element For The Interaction of Frames and Shear WallsAndreea BadulescuAinda não há avaliações

- Behavior of Couplimg BeamsDocumento10 páginasBehavior of Couplimg BeamsAndreea BadulescuAinda não há avaliações

- DMM 1Documento2 páginasDMM 1Madhu SagarAinda não há avaliações

- Tensile Strength of PaperDocumento11 páginasTensile Strength of Papertsvmpm1765Ainda não há avaliações

- Reinforced Concrete Design by Professor Anthony Kwame DansoDocumento131 páginasReinforced Concrete Design by Professor Anthony Kwame DansoBadu Evans NyiayeAinda não há avaliações

- Steel Material PropertiesDocumento1 páginaSteel Material PropertiesHendra93100% (1)

- Is 5424Documento14 páginasIs 5424girish1950% (2)

- 355.2_Chapter1-6Documento15 páginas355.2_Chapter1-6gradosana20Ainda não há avaliações

- 88 m37Documento8 páginas88 m37Mohammed Essam ShatnawiAinda não há avaliações

- Tension Testing of Metallic Foil: Standard Test Methods ofDocumento5 páginasTension Testing of Metallic Foil: Standard Test Methods ofNilton SantillanAinda não há avaliações

- Alloy SteelDocumento7 páginasAlloy SteelRavinJohnAinda não há avaliações

- D 229 - 96 - Rdiyos05ngDocumento16 páginasD 229 - 96 - Rdiyos05ngValeria Orannel Lopez MorilloAinda não há avaliações

- Guide To Using In-Situ Tensile Pull-Off Tests To Evaluate Bond of Concrete Surface MaterialsDocumento12 páginasGuide To Using In-Situ Tensile Pull-Off Tests To Evaluate Bond of Concrete Surface MaterialsMauricio Javier León TejadaAinda não há avaliações

- Rubber Products in Automotive Applications: Standard Classification System ForDocumento53 páginasRubber Products in Automotive Applications: Standard Classification System ForKhimeshAinda não há avaliações

- Pressure Equipment - : Part 4: Establishment of Technical Delivery Conditions For Metallic MaterialsDocumento48 páginasPressure Equipment - : Part 4: Establishment of Technical Delivery Conditions For Metallic MaterialsAhmed Hussien50% (2)

- Astm C709Documento3 páginasAstm C709정호철Ainda não há avaliações

- Iglidur Bearings For High TemperaturesDocumento46 páginasIglidur Bearings For High TemperaturesigusukAinda não há avaliações

- Aisi 304L PDFDocumento10 páginasAisi 304L PDFTony TonyAinda não há avaliações

- Smit Bracket Holding Power Strength CalculationsDocumento7 páginasSmit Bracket Holding Power Strength Calculationsnavalzero910100% (1)

- Sliding Wear of Cast Zinc-Based Alloy Bearings UndDocumento12 páginasSliding Wear of Cast Zinc-Based Alloy Bearings Undsafat parAinda não há avaliações

- Topic 6 Egf 4043Documento21 páginasTopic 6 Egf 4043hanis izzatiAinda não há avaliações

- Tube 2018 MAKLADA SA Paper Witu2018.2565651 3qbMLicwQLavC11TAtb5gwDocumento7 páginasTube 2018 MAKLADA SA Paper Witu2018.2565651 3qbMLicwQLavC11TAtb5gwMuhammad ArifAinda não há avaliações

- Various Types of Shear Connectors in Composite StructuresDocumento15 páginasVarious Types of Shear Connectors in Composite StructuresYasser OryassoAinda não há avaliações

- Construction Material and Testing: Psalms 127:1Documento47 páginasConstruction Material and Testing: Psalms 127:1Xam AcostaAinda não há avaliações

- Lesson 1 and 2-1 PDFDocumento22 páginasLesson 1 and 2-1 PDFDenver NieverasAinda não há avaliações

- ALLOY C19010: Exceptional Performance Versatile Product Global AvailabilityDocumento8 páginasALLOY C19010: Exceptional Performance Versatile Product Global Availabilitystrip1Ainda não há avaliações

- Mechanical Properties of Structural SteelDocumento17 páginasMechanical Properties of Structural SteelphairyAinda não há avaliações

- ERIKS - Datasheet - FKM 75-Compound 514010 WhiteDocumento1 páginaERIKS - Datasheet - FKM 75-Compound 514010 WhiteDarkedgeAinda não há avaliações

- Formability of Al Alloys - A ReviewDocumento26 páginasFormability of Al Alloys - A ReviewVigneshwaran Soundararaja perumal100% (1)

- Study of The Microstructure and Mechanical CharactDocumento14 páginasStudy of The Microstructure and Mechanical CharactRenuAinda não há avaliações

- 4 - Anchor - Bolts - Base - Plate - DD1-2 - Updated Shear KeyDocumento38 páginas4 - Anchor - Bolts - Base - Plate - DD1-2 - Updated Shear Keytitir bagchiAinda não há avaliações

- 04 Penyokong Atas 7Documento13 páginas04 Penyokong Atas 7Lukman SarifuddinAinda não há avaliações