Escolar Documentos

Profissional Documentos

Cultura Documentos

Hyprez Lapping Polishing

Enviado por

Margaret DaughertyDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Hyprez Lapping Polishing

Enviado por

Margaret DaughertyDireitos autorais:

Formatos disponíveis

System Compatibility

with Engis Equipment

All Engis machines and their supporting

components are engineered for maximum

system compatibility, elevating both

precision and performance.

Engis at lapping and polishing machines

bring high performance and economic

efciencies to your operation. Capable

of consistently and repeatedly generating

surface nishes to 0.5 nm Ra and surface

atness to 1/20 wavelength, Engis

systems are suitable for processing

virtually all solid materials, including

metals, ceramics, glass, semiconductor

substrates and electro-optical materials.

Engis offers the most comprehensive

choice of machine models designed

specically for advanced materials.

Operational Flexibility

with Hyprez Consumables

There is a Hyprez diamond product for

virtually every application.

Our powders, slurries, compounds and

pastes come in a wide variety of

micron sizes and carriers.

Engis offers the largest selection of lapping

plates in the industry. Hyprez composite

lapping plates are designed to maximize

the cutting characteristics of Hyprez

diamond slurries and compounds.

Parts carriers, conditioning rings, dispensing

accessories and other consumables are all

designed to optimize system compatibility

enabling more efcient and effective

performance, consistently and repeatedly.

Both special composite and natural

metal lapping plates are engineered

to maximize the cutting character-

istics and performance of diamond

superabrasives.

At Engis, we build the machines, congure the components

and formulate our compounds and slurries with one goal

in mind: to deliver a total system with the capabilities

you need in your at lapping and polishing operations

capabilities that include:

System Compatibility

Operational Flexibility

Consistent, Repeatable Performance

The Engis

Total System

Process Development

and Technical Support

Engis invests in its customers by making

available a wealth of diamond expertise

and technical support through our

process development labs.

The Hyprez Process Development Lab

enables customers to experiment with

various options and combinations of

machines, plates, compounds, lubricants

and processing parameters. The result is

a deep understanding of the capabilities

of your Hyprez system and an on-going

relationship with Engis engineers and

support personnel.

The Wafer Processing Lab is focused on

producing specialized slurries, processes

and machining parameters that boost

yields and throughput in the supernishing

of wafer substrates for the semiconductor

and compound semiconductor industries.

Engis lapping machines are

available in single and double

sided models, ranging from

15 table top models to

48 production oor models.

Totally Integrated Diamond Flat Lapping & Polishing Systems Only from Engis

2

Electronic precision dispensing

systems, conditioning rings, part

holders and other accessories are

designed by Engis to integrate

your lapping system with

maximum efciency.

Important Factors

in the Lapping Process

In order for supernishing processes to yield precise,

repeatable results, a complex set of factors must be

brought into balance and matched to the application

at hand.

Engis at lapping and polishing machining systems are

engineered to give you maximum control over these

crucial factors:

Precision dispensing and metering of slurries

Pressure on the workpiece

Speed of the plate (tool)

Plate material and characteristics

Plate surface conguration (grooves)

Type and size of abrasive particles

Type of carrier (vehicle) used, if applicable

Optimum operating temperatures

Plate atness requirements, methods of measurement

Requirements for lubricants, plus lubricant attributes

Consideration of plate ramp-up/ramp-down speeds

Consideration of ramping pressures for the workpiece

Method of charging and conditioning the plate

Conditioning/retaining ring in-process use

Diamond delivery system and positioning

Diamond Lapping Benets

Machining Problems Lapping - Benets

Clamping distortion Stress-free

Multiple machining steps Single step to nish

Brittle parts Low p.s.i. low losses

Composite/dissimilar materials Same stock removal

Non-metallic/magnetic materials Easily accommodated

Thermal distortion Eliminated water cooled

Thin part capability poor Less than 0.005

Engis manufactures a complete line of standard-sized conditioning rings and

part holders, as well as specialized controls, custom slurries, xturing and

other application-specic accessories.

Hyprez diamond powders,

slurries, compounds and lubri-

cants make up the broadest in

the industry, with micron sizes

and formulations for virtually

every application.

3

The case for using diamond superabrasives

rather than conventional abrasives in your

operations can be summed up in three

words. Diamond is faster, cleaner and

cost-efcient.

With diamond slurries, the lapping and

polishing phases of a nishing operation

can often be combined into one step. Plus,

less time is required for cleaning parts

and processing waste, so your throughput

increases, along with overall productivity.

Among the many application benets

diamond superabrasives bring to lapping

and polishing operations are these:

Superior surface nish

Aggressive material removal

Lapping & polishing combined in one step

Uniform edge-to-edge atness

Process virtually any solid material

Surface nishes to .2 Ra

Flatness to 1/20

th

wavelength

Superior cleanability

Precise repeatability

Hyprez diamond slurries and lubricants

from Engis including our MultiTec

line for perfecting the surface nishes

of advanced materials outperform

conventional abrasives, generating

superior surface nishes, faster stock

removal rates and superior cutting

characteristics when processing hard

materials, such as ceramics.

4

Leadership in Diamond Technology

Lapping with Diamond The Benets

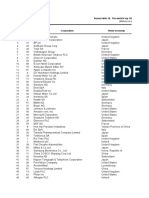

CERAMIC

Heat Sinks

Hybrid Substrates

Seals

Microwave Substrates

Sensing Devices

Valve Components

Read-Write Heads

Sapphire Windows

Ferrite Recording Heads

Ferrite Components

Capacitors

Thermoelectric Devices

Fiber Optic Connectors

CARBON

Seals

Pump Components

Carbon-Graphite Seals

Chemical Flow Components

Heart Valves

GLASS

LCD Glass

Optical Filters

Quartz Substrates

Camera Lenses

Fiber Optics

Copy Machine Mirrors

Video Disc Masters

Optical Flats

Optical Memory Discs

Glass Ornaments

Crystal Glassware

View Mirrors

Microscope Slides

PLASTIC

Contact Lenses

Fuel Pump Components

Engine Components

Printed Circuit Boards

METALS

Computer Components

Spacers

Gage Blocks

Fuel Injectors

Pump Components

Slitter Knives

Compressor Components

Cutting Inserts

Piston Rings

Valve Plates

Bearing Races

Heat Sinks

I.C. Boxes

Clipper Blades

Transmission Components

Brake Pads

Mechanical Seals

Power Stapler & Nailer

Components

Pump Housings

Valve Lifters

Compact Disc Molds

Pendants & Medals

Jewelry

Lapping Applications

Conventional Abrasive Costs

While diamond costs more, gram per

gram, you must buy substantially larger

volumes of conventional abrasives to

achieve the same results produced by

a single unit of diamond

Conventional Vehicle/Carrier

for Abrasive Costs

And when youre paying for more

conventional abrasives, youre also paying

for larger volumes of vehicle/carrier uids,

as well.

Shipping, Handling

& Storage Costs

Conventional abrasives are heavy and

typically stored in drums. Youre paying

more for shipping, on-site handling and a

larger storage footprint.

Spillage and Mixing Costs

Conventional abrasives have to be mixed

on-site with the vehicle/carrier to make

a lapping slurry. These messy operations

often lead to extra costs in spillage and

waste, as well as hidden costs created by

improper mixing ratios.

Cleaning Costs

Unlike diamond, conventional abrasives

require an extra cleaning step. In some

applications, both mechanical and an

ultrasonic cleaning process are required,

driving costs up and productivity down.

Disposal Costs

A major cost factor in using conventional

abrasives is the disposal of the large

volumes of spent slurry/swarf, as well

as disposal of empty abrasive & vehicle

containers. Diamond slurries generate

less waste by volume and are more

environmentally friendly.

5

Stock Removal and Surface Finish Generation

Diamond vs. Conventional Abrasives

Diamond is the Most Cost-Effective Solution

In terms of total cost-effectiveness, diamond easily outperforms conventional abrasives,

such as aluminum oxide and silicon carbide. Heres why:

6

Production Process Support

Hyprez

Process Development Lab

Located in our corporate headquarters, and staffed by some of the most seasoned experts in diamond at lapping and polishing,

there is one very important thing to keep in mind about the Hyprez Process Development Laboratory: This is your lab. Its purpose is

to solve your application problemstackle your toughest job requirementsmeet your most challenging performance criteria.

As an example, when you need advice on processing two or more dissimilar materials to uniform planes of atness Or new

technologies require you to attain higher tolerances in surface nish Or you are exploring ways to lap and polish a wider variety of

materials, while, at the same time, reducing costs

The Hyprez Process Development Laboratory

is your optimum resource. Through the lab, we

regularly assist customers by developing new

products, and processes that:

Shorten cycle times

Reduce the number of nishing steps

Lower nishing costs

Improve precision and performance

The wealth of Engis diamond nishing expertise is

available to you through this laboratory. If you have

a special application or processing problem, please

contact Engis. We will be glad to assist you in any

way we can.

7

Engis

LM Lapping/Polishing Systems

Setting a standard for rugged reliability and optimal processing exibility, the Engis LM Series of lapping

and polishing systems has been a mainstay, mission-critical supernishing solution for a wide variety of

industries and applications from aerospace to automotivedata storage to photonics.

Engis LM machines are in service the world over. Designed and engineered to

optimize the inherent superior nishing qualities of precision diamond abrasives,

Engis LM machines are available in both 15 benchtop congurations,

as well as oor standing models ranging in plate size from 24 to 42.

Standard Features:

Bench Top Models

Variable speed drives for optimum feed travel

rates 0 120 RPMs

Robust drive systems

Digital Readout Cycle Timer (Fully adjustable,

with digital readout and auto-reset)

3 Ring Arms (Roller Yoke Type)

Dial Indicator Flatness Gauge (Model 15LM)

Floor Standing Models

Pneumatic pressure or hand weight systems

Individual pneumatic controls for each work station

Electronic controls Part of a two-hand control system

to toggle the pressure plate up and down

Plate cooling system controls (optional)

Applications:

Ceramic, Carbon, Glass, Plastic, Metals

Composite Lapping Plate

MiniMiser

Autostirrer

Machine Control Panel

Operator Control Panel

Pneumatic Pressure Plates

Large Work Table

Mounted on a swing arm, the main

control panel can be positioned by the

operator for optimum visibility and

maximum accessibility to the parts.

Part: CMP Ring Assembly

Material: PPS Plastic / Stainless Steel

Requirements: Single process for both sides of part. Plastic side required visually scratch free nish (with no abrasive contamination).

Stainless steel side required reective surface with uniform scratch pattern. Both sides required 0.0002 atness.

Process: Engis 28LM230VP single-side lapping system was used in a multiple step process using diamond slurry, composite lap

plates and polishing pads.

Results: A surface nish of 1.7 was achieved on SS side and a 1.5 (scratch free) nish was achieved on plastic side.

A atness of ~1 lightband was achieved on each side (far exceeding the requirement).

8

Engis

FL FastLap Systems

Versatility and speed are the hallmarks for Engis newest line

of lapping and polishing machines. The Engis FastLap Series

of oor-standing systems are designed to maximize the efciency

of diamond lapping processes while giving operators optimal speed

and control. The result greater per-piece-nished cost efciencies.

Engis FL machines are available in models utilizing 24, 28, 36, 42

and 48 lapping plates. Robust, durable, variable speed drive systems,

paired with touch-screen digital controls, give operators a range of

pressure and speed settings of up to 1,100 pounds per head and

90 RPMs, respectively. This makes the Engis FL system both fast

and exible, capable of processing a wide range of industrial-grade

materials within optimal timeframes.

Features:

Models for ve plate diameters 24 / 28 / 36 / 42 / 48

Soft start ramp up to protect parts during start up

Corrosion-resistant worktable, chrome pressure plates

Integrated slurry dispensing system

Protective enclosure system optional

Water cooling optional

Proface touch screen control

Customization packages available

Applications:

Mechanical Seals, Ceramics, Carbide, Glass, Optics

FL-24VP FastLap Machine

Part: Mechanical Seal

Material: Alinco V

Requirements: Flatness of 0.0000232 and reective nish of 4 or better. Customer was using a multi-step

conventional lapping process but was experiencing difculty meeting the quality and wanted to improve on productivity.

Process: The new process utilizes our Engis FL-24VP single-side lapping system with diamond slurry and

composite lap plates.

Results: The process was reduced to a single-step providing a 0.7 nish with a atness within 0.0000116.

Signicantly less waste is produced and production potential more than doubled.

9

Double Sided Lapping & Fine Grinding Systems

Available in three models, plus optional accessories, Engis Omni 3

double sided nishing systems can be used on a variety of materials

to achieve a high degree of accuracy in atness, parallelism and

surface nish. Designed for use with Engis diamond plates,

Engis Omni 3 double sided systems reduce processing times,

as well as overall costs.

This unique system is suitable for either double sided lapping

applications with free abrasive slurries or for ne grinding

processes with xed abrasive media.

Features:

Digital Size Controller assures reliability

Rigid body ensures no vibration for added accuracy

Real 3-way system features Upper and Lower Wheel drives.

Sun Gear is driven by independently geared motor with AC inverter

Soft Touch Screen makes operation simple and user friendly

Variety of applications for ne grinding, lapping and polishing

Pre, main and post load position is controlled by simple setting

Upper Wheel swivel provides operator with more space

for loading and unloading

Applications:

Tungsten Carbide, Sinter Metal, Hard Metal, Bronze, Aluminum, Quartz,

Crystal, Sapphire, Optical Glasses, MLCC, Ceramic Substrate, Zirconium,

Engineered Plastics, Composites, NTC Substrate, PZT Substrate,

Diamond Dicing Blade, Ferrite, Silicon Carbide and others.

Part: LASER WINDOW

Material: Calcium Fluoride

Requirements: The customer needed a process for rough sizing of parts. Current process was slow and labor intensive

and left excessive sub-surface damage.

Process: Parts were processed on our double-sided diamond pellet grinding system using a water based coolant.

Results: The nish achieved off the pellet plates was 18.5 (Ra) with a maximum stock removal rate of 0.0137/min.

The customer tested parts (after a nal polishing) for transmission degradation after 1 million laser shots and found

the results to be superior to their old process (attributed to less sub-surface damage).

10

MPC/AM Lapping/Polishing Systems

Maximum Process Control

Specically designed for unique polishing, delayering and planarization

applications where R&D, prototype and small volume processing is

required, Engis systems are available in both AM-15 bench top and

MPC oor-standing models.

Each MPC system provides the kinematics and control required

to develop processes that have 6-Sigma capability for material

removal, atness and surface nish generation. The menu-driven

microprocessor control allows any polishing, delayering or

planarization process to be fully optimized. The oscillation system

provides 3-axis motion for true CMP kinematics.

Finishing Systems for Advanced Materials

Features:

Ideal for universities and research labs, as well as commercial

enterprises with unique, application-specic requirements

A range of standard processes, developed by Engis, can be applied

Compatible with both Engis precision diamond CMP-D slurries,

as well as conventional abrasives, plates and other

consumables and accessories

Touch screen interface, fully customizable

Operator interface mounted on swivel-style pendant

All drives are programmable and reversible

Data acquisition and program stringing

Oscillation features are controlled from main input screen

Integrated slurry dispensing system controls

Digital readouts for all drive and pressure functions

Applications:

Silicon Carbide, Sapphire, metal foils, delayering planarization of SiO

2

and metalized depositions. Calcium Fluoride and Magnesium

Fluoride preparation.

MPC Lapping Machine

AM-15 BenchTop

Lapping Machine

Part: Wafer Epi-Polishing

Material: Indium Antiminide

Requirements: Achieve a sub-nanometer (nm) Ra surface nish.

Process: Three-step process utilized EHG-150 Horizontal Grinder, followed by stock removal

lapping and CMP polish on an Engis AM-15 lapping/polishing machine, P4 colloidal silica slurry

and polishing pad.

Results: Achieved a surface nish of 0.7nm Ra, at a material removal rate of 2.8 m/hr.

Engis designs specialized machines, part holders and

xtures for supernishing applications in the compound

semiconductor, MEMS and electro-optics industries.

Area Shown: X-282.75 m

Y-212.06 m

Ra-0.67 nm

Engis is the leading force in pioneering

new diamond superabrasive nishing

systems for the manufacturers of disk

drives and data storage components.

The Hyprez Wafer Processing Laboratory

(WPL), a new facility within the Engis

world headquarters complex in Wheeling,

Illinois, is specically designed to shorten

the time it takes to move new magnetic

and MR head technology into mass

production.

The Hyprez WPL collaborates with

research and development teams at

magnetic head manufacturers, developing

new production processes concurrently

with the creation of new head/disk

drive designs. Manufacturers who partner

with Engis are able to deliver new data

storage technology to the end user much

faster, with greater reliability.

The Hyprez WPL integrates Engis

diamond superabrasive technology with

its customers bar/slider manufacturing

technology. Engis has installed in the lab

actual production equipment used by

its customers. This enables Engis process

engineers to control all of the variables

in the production environment. These

variables include how the diamond is

micronized, how the slurry is formulated,

selecting and properly charging the

appropriate composite lapping plate,

and how each production cycle is

set up and run.

Advanced surface measuring systems are

used to analyze pole tip recession and other

factors inuenced by the lapping/polishing

process for magnetic heads and advanced

materials, such as MEMS, electro-optics,

and compound semiconductors.

Hyprez

Wafer Processing Lab

These two 3D model images illustrate

before (above) and after (below) results of

a nishing process for CaF

2

crystals to be

used in an optics application. A surface nish

of 0.5nm Ra is achieved, followed by a pitch

polish for excellent atness.

Results

Ra 0.49nm

Rq 0.62nm

Rv -2.84nm

Rt 7.57nm

SRz 3.22nm

Image

Size X 282.75m

Size Y 212.06m

Technology Development

11

12

Composite lapping plates are central to the superior performance of integrated diamond

lapping systems. Hyprez lapping plates are formulated specically to deliver optimum

performance when used with Hyprez Diamond Slurries. The composite material efciently

and rapidly removes stock, while producing high quality surface nish and atness with

diamond superabrasives in both large volume operations and smaller hand lapping and

polishing applications.

All lapping plates from Engis

can be retrotted to mount

on most commercially available

lapping machines.

Hyprez

Composite Lapping Plates

Special Composites

vs. Natural Metals

Special composite laps are made with

a unique blend of powdered metal or

ceramic, combined in a resin system. These

composite laps take a more uniform charge

of diamond, compared to pure metal plates.

The result is more consistent and controlled

performance. Composite plates are also

superior in applications where lapping and

polishing are combined into one step.

Ultra-Precision Tolerances

Hyprez lapping plates, used in combination

with Hyprez diamond slurries and compounds,

are capable of achieving surface nishes to

0.5 nm Ra and atness to a 1/20 wavelength

on many materials.

Features:

Accelerated stock removal

Ultra-precise atness and surface nish

Consistent, repeatable results

Diamond is a premium abrasive.

Economies of usage are critical, requiring

dispensing accessories that maximize the

effectiveness of diamond slurries while

minimizing waste.

Both the Hyprez Autostirrer and

MINIMISER have been engineered to

deliver precisely controlled amounts of

Hyprez diamond slurry and lubricants.

These systems are designed for optimal

use on all Hyprez lapping systems.

The Hyprez Autostirrer keeps diamond

completely dispersed during usage by

stirring the slurry with a magnetic spin bar.

The EMC -2 MINIMISER Electronic

Dispenser, with digital readout,

incorporates microprocessor based

circuitry to provide consistent and

repeatable performance, day in and

day out.

The MINIMISER can be set for an interval

cycle up to 999 seconds (16.65 min.) and

a spray duration range of 1 to 9 seconds

in increments of 1 second.

Both the Hyprez Autostirrer and

MINIMISER can be retrotted to all

commercially available lapping machines.

Working together, the MINIMISER and

Autostirrer deliver precisely timed and

metered amounts of slurry and lubricant,

minimizing waste and maximizing diamond

dispersion.

Hyprez MINIMISER

& Autostirrer Dispensing System

13

Hyprez lapping plates, when used with diamond, are ideal for nishing two or

more dissimilar materials to a uniform plane of atness. Engis process engineers

will work with you to establish the optimum combination of Hyprez plates,

diamond slurries and lubricants for nishing each multi-material part.

Plate Sizes & Patterns

Standard sizes are as follows: 6, 9, 12, 15, 16, 18, 24, 28, 36, 42 and 48

diameters. Special sizes are available on request. Square, spiral, concentric and

radial grooves, as well as custom patterns, are available.

Hyprez

HY Iron

Aggressive Stock Removal

Excellent primary/roughing lap plate,

with a long service life.

Often used as an alternative to cast

iron plates.

Produces a good surface nish on most

materials, especially metals and ceramics.

Typically used with coarse to medium

diamond sizes.

Uniform Finishing of Dissimilar Materials

Hyprez

TX-10A

Moderate Stock Removal

Composite tin plate. Offers a lead (Pb)

free working environment.

Provides superior surface nish prior

to CMP step.

Works with coarser diamond slurries

for fast stock removal while achieving

extraordinary ne surface nish.

Provides longer service life, low recondi-

tioning needs and rened surface nishes.

Hyprez

X08

Most Aggressive Stock Removal

This plate is used when rapid stock

removal is required.

Second hardest composite iron plate.

Provides excellent atness, longer service

life, low reconditioning needs and rened

surface nishes.

Often used as an alternative to cast

iron plates.

Produces good surface nish on most

materials, especially metals and ceramics.

Hyprez

Tin Antimony

Low/Very Low Stock Removal

Typical plate for head manufacturing

industry (kiss lap process).

Used in pre-polishing of hard materials,

SiC, GaN.

Resistant to temperature variations

during lapping.

Prevents changes in lubricant viscosity

during continuous lapping operation.

Hyprez

HY Copper

Moderate to Aggressive Stock Removal

Most widely used, universal composite

lap plate.

Excellent when primary and nishing lap

are combined in a one-step operation.

Suitable for virtually any solid material:

metal, ceramic, glass, carbon, plastic, etc.

Typically used with medium to ne

diamond sizes.

Minimizes fracturing and chipping tenden-

cies when lapping crystal components.

Hyprez

HY Ceramic

Moderate Stock Removal

Generally used to lap/polish ceramic parts

and other stain-sensitive materials.

Used in applications where metallic-type

contamination cannot be tolerated.

Affordable, more machineable alternative

to natural ceramic plates.

Very exible used with coarse to ne

diamond sizes.

14

Solid Ceramic Conditioning Rings

Ideal for use in the electronics, automotive, medical,

audio/visual and optical industries, these high quality, alumina

ceramic rings provide an unmatched level of control in the

nal nishing process. 12 serrations per ring. Available for

12 and 15 lap plates.

Stainless Steel-Backed Ceramic

Conditioning Rings

Backed with 304 stainless steel for greater tensile strength,

these rings are highly resistant to corrosion. Available for

12, 15, 24, 28, 36 and 42 lap plates.

Diamond-Plated Conditioning Rings

These diamond-plated rings are designed specically for

Hyprez Series HY composite lapping plates. Engineered

to consistently regenerate surface texture and atness of

composite lap plates, these rings eliminate varying results

usually associated with conventional abrasive reconditioning.

Available for lap plates from 12 up to 42.

Hyprez

Conditioning Rings & Pads

Hyprez Polishing Pads

In polishing operations, the holder of the abrasive is as important as the

abrasive itself. The choice and composition of this holder is determined by

the application and the materials being processed.

In extremely ne polishing operations you must use cloth, rather than, or

in addition to, composite plates. Polishing discs are divided into three broad

categories of fabric: woven, ocked and compressed.

Hyprez Polishing Cloth Discs are excellent for extremely high nishes on

a variety of materials. All cloths have a plastic barrier between the cloth

and the self-adhesive back. The plastic barrier not only provides a rm

backing but prevents excess loss of abrasives.

15

Specialty Machines

Wire Saw

Engis Corp. also represents wire saws and slurry re-claimers manufactured

by Yasunaga Corporation (based in Japan), a pioneer in the development

of wire saw machines. Yasunagas wire saws are designed for high-speed

and high-precision processing of crystal AT cutting, solar silicon and other

materials utilizing thinner wire and wire reciprocation.

Proling Machines

In addition to micronizing its diamond powders and formulating its

slurries, Engis also manufactures specialized lapping/polishing machines

for the data storage industry.

These machines feature an on-board plate facing device that shapes

and texturizes composite and natural metal lapping plates on two

separate axes, without the use of conditioning rings. Used in kiss,

or crown, lapping of bars/sliders, as well as other advanced operations,

the machine shortens cycle times and provides more precise, custom

processing options.

The 2-axis/3-axis, on-board plate

facing attachment generates at,

conical and spherical surface geometries.

Horizontal Grinding System Engis

EHG-180 AV

The Engis EHG-180AV Horizontal Grinding

Machine with vacuum chuck is designed for use

with our specialty diamond wheel. This unique

system is designed for surface grinding silicon

carbide, as well as backside grinding Sapphire LED

wafers to the highest levels of atness and surface

nish, economically, saving labor costs and time.

Engis, Hyprez, MINIMISER, Five Star, Hyprelube, Hyplicator and Electrogrip

are registered trademarks of Engis Corporation U.S.A.

2008 Engis Corporation. Printed in U.S.A.

Leaders in Superabrasive Finishing Systems

Engis Corporation

Wheeling, IL U.S.A.

Tel: (847) 808-9400

Fax: (847) 808-9430

Email: info@engis.com

Engis (UK) Ltd.

Henley-on-Thames

Oxfordshire, RG9 1DS ENGLAND

Tel: 44-1491-411117

Fax: 44-1491-412252

Email: sales@engis.uk.com

Engis Japan K.K.

Yokohama, JAPAN

Tel: 81-45-474-0666

Fax: 81-45-474-0677

Email: email@engis.co.jp

Engis Asia Pacic Pte. Ltd.

SINGAPORE

Tel: 65-6745-1923

Fax: 65-6745-2907

Email: sales @engis.com.sg

Engis (Hong Kong) Ltd.

Kwai Chung, HONG KONG

Tel: 852-26100903

Fax: 852-24234509

Email: sales@engis.com.hk

Engis of Canada Ltd.

Burlington, Ontario, CANADA

Tel: (905) 632-3016

Fax: (905) 632-4250

Email: engiscanada@engis.com

Engis (H.K.) Ltd., Beijing R.O.

Beijing, CHINA

Tel: 86-10-64848398

Fax: 86-10-64848396

Email: lianjie@engis.com.hk

Helical Lap & Mfg. Company

Fraser, MI U.S.A.

Tel: (586) 293-6900

Fax: (586) 293-6903

Email: info@helicallap.com

Engis Korea Co., Ltd.

Gyeong Gi-Do, KOREA

Tel: 82-31-354-1426

Fax: 82-31-354-1430

Email: mkkim@engis.co.kr

Engis

Lapping/Polishing Systems

Beginning-to-end at nishing systems

machines, plates, pads, diamond powders,

slurries, lubricants and other accessories

plus customized equipment, specialized

formulas, testing labs and technical support

for process and technology development.

Hyprez

DiaMold

Toolroom Products

Comprehensive line of diamond polishing

compounds, abrasive stones, sticks, bobs,

brushes and les plus powered hand

nishing systems for every toolroom

application.

Engis Single-Pass Bore Finishing Systems

Single-pass bore nishing systems standard

models and custom machines plus

diamond and CBN plated nishing tools,

parts holders/xtures and integrated

automation systems.

Electrogrip

Grinding Systems

Advanced superabrasive grinding, cutting

and dressing systems utilizing diamond

and CBN materials. Specializing in the

aerospace, medical, ceramic, automotive

and composite industries.

THE ENGIS GROUP OF COMPANIES

HYC3-02-08

Você também pode gostar

- Performance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallNo EverandPerformance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallNota: 4 de 5 estrelas4/5 (8)

- Answer For Task 7 TransportDocumento2 páginasAnswer For Task 7 TransportAung Kyaw Moe86% (7)

- The Worlds Top 100 Non Financial MNEs Ranked by Foreign Assets 2018Documento8 páginasThe Worlds Top 100 Non Financial MNEs Ranked by Foreign Assets 2018Penguin_MaestroAinda não há avaliações

- Marine Superintendent - 2012Documento2 páginasMarine Superintendent - 2012Muhammad IsalAinda não há avaliações

- Bentonite Grinding MachineDocumento2 páginasBentonite Grinding MachineNickRuiAinda não há avaliações

- Ariana Afghan AirlinesDocumento14 páginasAriana Afghan AirlinesNawab AliAinda não há avaliações

- Loctite - 2011 - Design Guide For Bonding PlasticsDocumento100 páginasLoctite - 2011 - Design Guide For Bonding PlasticsPieter van der MeerAinda não há avaliações

- Rapid Manufacturing Sheet Metal DesignDocumento18 páginasRapid Manufacturing Sheet Metal Designniloy_67Ainda não há avaliações

- Super CatalogueDocumento8 páginasSuper CatalogueITL200_UAinda não há avaliações

- Casting: Shival Dubey Assistant Professor Mechanical EngineeringDocumento31 páginasCasting: Shival Dubey Assistant Professor Mechanical EngineeringChirag TaterAinda não há avaliações

- Den 348 PDFDocumento3 páginasDen 348 PDFTamer BidakAinda não há avaliações

- Hot Dip Galvanizing of Sheet Metal-SpangleDocumento6 páginasHot Dip Galvanizing of Sheet Metal-SpangleAgustine SetiawanAinda não há avaliações

- Der 671 Solid EpoxyDocumento3 páginasDer 671 Solid Epoxyvanhung680% (1)

- Product InformationDocumento3 páginasProduct Informationvanhung68Ainda não há avaliações

- Metal Injection MouldingDocumento1 páginaMetal Injection Mouldingkranthi1992Ainda não há avaliações

- Fit Tolerance For Plastic PartsDocumento16 páginasFit Tolerance For Plastic PartsA_JANNESAinda não há avaliações

- Proto Labs Whitepaper PDFDocumento15 páginasProto Labs Whitepaper PDFSugarboy3 SurAinda não há avaliações

- A Study of Casting Characteristics For Die Cast Aluminum Alloy-Anwar HussainDocumento23 páginasA Study of Casting Characteristics For Die Cast Aluminum Alloy-Anwar Hussainoquintero99100% (2)

- Brochure For HPDC ProcessDocumento4 páginasBrochure For HPDC Processramaswamykama786Ainda não há avaliações

- Squeeze Casting - An Overview PDFDocumento9 páginasSqueeze Casting - An Overview PDFDian Try SaputriAinda não há avaliações

- Waterjets:: AbrasiveDocumento4 páginasWaterjets:: AbrasiveAdel AbdelmaboudAinda não há avaliações

- DFM Guidebook Sheetmetal Design Guidelines Issue XVIII PDFDocumento11 páginasDFM Guidebook Sheetmetal Design Guidelines Issue XVIII PDFNandang KuroshakiAinda não há avaliações

- Casting ProcessDocumento50 páginasCasting ProcessPankajAinda não há avaliações

- Recommended Speed For Turning: Free Machining, Plain Carbon SteelsDocumento11 páginasRecommended Speed For Turning: Free Machining, Plain Carbon Steelsjsk_senAinda não há avaliações

- Eurotech 658 Lathes SeriesDocumento8 páginasEurotech 658 Lathes SeriesCNC SYSTEMSAinda não há avaliações

- Micro MachDocumento16 páginasMicro MachMukesh Muraleedharan NairAinda não há avaliações

- ECN Balzers 20april10 AC Falen PresterenDocumento76 páginasECN Balzers 20april10 AC Falen PresterenMiguelAinda não há avaliações

- Casting ChecklistDocumento4 páginasCasting Checklistmihai90Ainda não há avaliações

- Water Jet CutterDocumento16 páginasWater Jet CutterRex Delon50% (2)

- Plastics Today Extrusion Expert Webinarnb45 August 2010 v3Documento30 páginasPlastics Today Extrusion Expert Webinarnb45 August 2010 v3rahul_m57Ainda não há avaliações

- Drawdown Ratio and Draw Ratio Balance (DDR & DRB) : Outer LayerDocumento5 páginasDrawdown Ratio and Draw Ratio Balance (DDR & DRB) : Outer LayerItay100% (1)

- PEEK-OPTIMA Processing Guide SecuredDocumento0 páginaPEEK-OPTIMA Processing Guide SecuredAngel LagrañaAinda não há avaliações

- Broach and Form ToolDocumento20 páginasBroach and Form Toolsonu kumarAinda não há avaliações

- Design For Mouldability-UK092010Documento16 páginasDesign For Mouldability-UK092010mjobson100% (1)

- Get A Free Injection Molded Part Quote From Proto Labs - ProtoQuote DemoDocumento4 páginasGet A Free Injection Molded Part Quote From Proto Labs - ProtoQuote DemoДушан ТомићAinda não há avaliações

- Mini Review On Desiging of Press Tools For Sheet Metal PartsDocumento11 páginasMini Review On Desiging of Press Tools For Sheet Metal Partsdhananjaya_eeeAinda não há avaliações

- ProCAST CapabilitiesDocumento3 páginasProCAST Capabilitiesvdmoorthy123Ainda não há avaliações

- 3form Varia Fabrication Manual Rev007Documento6 páginas3form Varia Fabrication Manual Rev007api-220610298Ainda não há avaliações

- TaegoTech - PG BroshureDocumento11 páginasTaegoTech - PG Broshurealexl5892Ainda não há avaliações

- Cartridge Type Boring BarDocumento4 páginasCartridge Type Boring BarvishalAinda não há avaliações

- PM DesignTip EssentialsDocumento20 páginasPM DesignTip EssentialsPurece EugenAinda não há avaliações

- CNC Machining Designing For SpeedDocumento9 páginasCNC Machining Designing For SpeedjaimeAinda não há avaliações

- Possible Simulation Techniques in Metal FormingDocumento23 páginasPossible Simulation Techniques in Metal FormingrikiAinda não há avaliações

- AT0020-0311 - Tech Briefs - Mold Polishing MoldMAX and PROtherm PDFDocumento2 páginasAT0020-0311 - Tech Briefs - Mold Polishing MoldMAX and PROtherm PDFrobin parmarAinda não há avaliações

- C2C Getting StartedDocumento24 páginasC2C Getting StartedKok MunAinda não há avaliações

- Advantages of LPDCDocumento2 páginasAdvantages of LPDCSuhas KrishnaAinda não há avaliações

- Overview Rubber ProcessDocumento36 páginasOverview Rubber ProcessYudoWijayantoAinda não há avaliações

- Opportunities and Limits of 2k Injection MouldingDocumento22 páginasOpportunities and Limits of 2k Injection Mouldingsa_arunkumarAinda não há avaliações

- Brochure Carbon Additives For PolymersDocumento24 páginasBrochure Carbon Additives For PolymersTUNGAinda não há avaliações

- Ecor WoodDocumento27 páginasEcor Woodxavier668Ainda não há avaliações

- Water Jet CuttingDocumento3 páginasWater Jet Cuttingnatrajan-ram-379Ainda não há avaliações

- High Ductility Aluminum Alloy Made From Powder by Friction ExtrusionDocumento6 páginasHigh Ductility Aluminum Alloy Made From Powder by Friction ExtrusionRaistlin1Ainda não há avaliações

- Zinc Nickel Plating: Platings & Coatings For IndustryDocumento1 páginaZinc Nickel Plating: Platings & Coatings For IndustryyağmurAinda não há avaliações

- Sensors For Process Monitoring - Casting and Powder MetallurgDocumento29 páginasSensors For Process Monitoring - Casting and Powder MetallurgJorge BandaAinda não há avaliações

- Lapmaster Catalogue1Documento20 páginasLapmaster Catalogue1Hicham HrslAinda não há avaliações

- Micro MFG BrochureDocumento8 páginasMicro MFG BrochureDeringer-Ney Inc.Ainda não há avaliações

- Coolants - RhenusDocumento26 páginasCoolants - RhenusFLMAinda não há avaliações

- Sealing Solutions For The Machine Tool Industry - Customized Machined Seals and Engineered Plastic PartsDocumento22 páginasSealing Solutions For The Machine Tool Industry - Customized Machined Seals and Engineered Plastic PartsJurun_BidanshiAinda não há avaliações

- SKF Economos SteelDocumento22 páginasSKF Economos SteelJurun_BidanshiAinda não há avaliações

- Cutting and Forming Machine Tools: Customised Machined Seals and Engineered Plastic PartsDocumento22 páginasCutting and Forming Machine Tools: Customised Machined Seals and Engineered Plastic Partsfiroz2404Ainda não há avaliações

- Cmti 1228918957257618 1Documento32 páginasCmti 1228918957257618 1Nhan LeAinda não há avaliações

- Gear Hobbing Dry Vs Wet Hobbing Manufacturing ProcessDocumento1 páginaGear Hobbing Dry Vs Wet Hobbing Manufacturing ProcessDhruv SutharAinda não há avaliações

- Basic Techniques For Polishing MoldsDocumento32 páginasBasic Techniques For Polishing Moldskailashparmar150% (6)

- EAM MetersDocumento20 páginasEAM MetersVictor MillanAinda não há avaliações

- 9 07sek PDFDocumento1 página9 07sek PDFMargaret DaughertyAinda não há avaliações

- Piping and Instrumentation Diagram - Legend Sheet 2 of 9 - E PDFDocumento1 páginaPiping and Instrumentation Diagram - Legend Sheet 2 of 9 - E PDFMargaret DaughertyAinda não há avaliações

- Piping and Instrumentation Diagram - Legend Sheet 3 of 9 - EDocumento1 páginaPiping and Instrumentation Diagram - Legend Sheet 3 of 9 - EMargaret DaughertyAinda não há avaliações

- Piping and Instrumentation Diagram - Legend Sheet 2 of 9 - E PDFDocumento1 páginaPiping and Instrumentation Diagram - Legend Sheet 2 of 9 - E PDFMargaret DaughertyAinda não há avaliações

- Yhl/ Ar Ali/ Subardi 11/6/2012 Scale Units MM No Scale CoolerDocumento1 páginaYhl/ Ar Ali/ Subardi 11/6/2012 Scale Units MM No Scale CoolerMargaret DaughertyAinda não há avaliações

- BoilerDocumento90 páginasBoilerMargaret DaughertyAinda não há avaliações

- Piping and Instrumentation Diagram - Legend Sheet 1 of 9 - Id PDFDocumento1 páginaPiping and Instrumentation Diagram - Legend Sheet 1 of 9 - Id PDFMargaret DaughertyAinda não há avaliações

- Big Joe Type 630SEK PDFDocumento12 páginasBig Joe Type 630SEK PDFMargaret DaughertyAinda não há avaliações

- Crankcase Ventilation (LEBW4958)Documento20 páginasCrankcase Ventilation (LEBW4958)József Nagy100% (2)

- astroSEK PDFDocumento9 páginasastroSEK PDFMargaret DaughertyAinda não há avaliações

- Agco Type81sek PDFDocumento15 páginasAgco Type81sek PDFMargaret DaughertyAinda não há avaliações

- 9 08sek PDFDocumento1 página9 08sek PDFMargaret DaughertyAinda não há avaliações

- VibrationDocumento24 páginasVibrationDaniel Codina100% (1)

- Drum Gauges PDFDocumento2 páginasDrum Gauges PDFMargaret DaughertyAinda não há avaliações

- Caterpillar G3500 Top End Overhaulesek PDFDocumento18 páginasCaterpillar G3500 Top End Overhaulesek PDFMargaret Daugherty75% (4)

- Cat D-3600sek PDFDocumento2 páginasCat D-3600sek PDFMargaret DaughertyAinda não há avaliações

- CATERPILLAR KRA Gas Lift DrawwingSEK PDFDocumento3 páginasCATERPILLAR KRA Gas Lift DrawwingSEK PDFMargaret DaughertyAinda não há avaliações

- DB GB PDFDocumento8 páginasDB GB PDFMargaret DaughertyAinda não há avaliações

- CATERPILLAR KRA Gas Lift DrawwingSEK PDFDocumento3 páginasCATERPILLAR KRA Gas Lift DrawwingSEK PDFMargaret DaughertyAinda não há avaliações

- Cat & DdsekDocumento1 páginaCat & DdsekMargaret DaughertyAinda não há avaliações

- Proposal Budgetary LevelGauges - KLINGER - 200110 PDFDocumento2 páginasProposal Budgetary LevelGauges - KLINGER - 200110 PDFMargaret DaughertyAinda não há avaliações

- Air Comp INGERSOLL-RAND SEK PDFDocumento16 páginasAir Comp INGERSOLL-RAND SEK PDFMargaret Daugherty100% (1)

- Klinger Product CatalogueDocumento248 páginasKlinger Product Cataloguemar_marcusAinda não há avaliações

- CATERPILLAR Manual For Altronic Digital Monitor CAS-2140SEK PDFDocumento16 páginasCATERPILLAR Manual For Altronic Digital Monitor CAS-2140SEK PDFMargaret DaughertyAinda não há avaliações

- 03 Tablas Catsek PDFDocumento10 páginas03 Tablas Catsek PDFMargaret DaughertyAinda não há avaliações

- 3500 Engine Oil and Filter - ChangeSEK PDFDocumento11 páginas3500 Engine Oil and Filter - ChangeSEK PDFMargaret DaughertyAinda não há avaliações

- 3500 TroubleshootingSEK PDFDocumento33 páginas3500 TroubleshootingSEK PDFMargaret Daugherty50% (2)

- Cat D-3600sek PDFDocumento2 páginasCat D-3600sek PDFMargaret DaughertyAinda não há avaliações

- ARIEL CompressorSEK PDFDocumento80 páginasARIEL CompressorSEK PDFMargaret Daugherty100% (1)

- Nortel Networks Product CatalogDocumento40 páginasNortel Networks Product Cataloghongnh-1Ainda não há avaliações

- Design Guide For MassBloc Retaining WallDocumento17 páginasDesign Guide For MassBloc Retaining WallKen LiewAinda não há avaliações

- GP Posters 36-42Documento7 páginasGP Posters 36-42Tom AlexAinda não há avaliações

- Jagat Singh PurDocumento6 páginasJagat Singh PurPrarthana MohapatraAinda não há avaliações

- The Study of Li & Fung LimitedDocumento19 páginasThe Study of Li & Fung LimitedJames James ChowAinda não há avaliações

- Lined Split ClampDocumento0 páginaLined Split ClampSundar RamasamyAinda não há avaliações

- Southwest Airlines Business AnalysisDocumento16 páginasSouthwest Airlines Business Analysisapi-184659947Ainda não há avaliações

- Cable Crane DerinerDocumento2 páginasCable Crane DerinerRicardo Jesus Mallma CubasAinda não há avaliações

- GE Lighting Systems Natural Lightstyles Pole Brochure 1-73Documento4 páginasGE Lighting Systems Natural Lightstyles Pole Brochure 1-73Alan MastersAinda não há avaliações

- CanadaDocumento25 páginasCanadaRahman Lee RahmanAinda não há avaliações

- Cause Inefficiency Bus Operation Flow at The Larkin Bus TerminalDocumento61 páginasCause Inefficiency Bus Operation Flow at The Larkin Bus TerminalohferhanisabellaAinda não há avaliações

- Mil STD 1907Documento19 páginasMil STD 1907domsonengAinda não há avaliações

- Jalandhar City Bus ServiceDocumento12 páginasJalandhar City Bus ServicesachinrstAinda não há avaliações

- 2016CompositeList Web 20Documento1 página2016CompositeList Web 20AnuranjanAinda não há avaliações

- AlShahin Metal IndustriesDocumento54 páginasAlShahin Metal IndustriesCyruzLeyteAinda não há avaliações

- Pepsi Pakistan: Drink Ingredients and Fills Up Cans and Bottles With The Drink) All Over Pakistan. TheseDocumento9 páginasPepsi Pakistan: Drink Ingredients and Fills Up Cans and Bottles With The Drink) All Over Pakistan. Thesemughni5000Ainda não há avaliações

- TCS Smart Manager Case ContestDocumento2 páginasTCS Smart Manager Case ContestMangesh JoshiAinda não há avaliações

- 150 Mandatory Tariff Codes (Hs Code 2012)Documento8 páginas150 Mandatory Tariff Codes (Hs Code 2012)mfakhrudAinda não há avaliações

- MasonryDocumento44 páginasMasonryCalin AlexandruAinda não há avaliações

- Visit For More Project Reports, Presentations, Notes Etc.: Lesson 1 An Overview of RetailingDocumento235 páginasVisit For More Project Reports, Presentations, Notes Etc.: Lesson 1 An Overview of Retailingsrishivanov30Ainda não há avaliações

- Indian Standard: Specification FOR Precast Concrete Pipes (With and Without Reinforcement)Documento45 páginasIndian Standard: Specification FOR Precast Concrete Pipes (With and Without Reinforcement)Yashvardhan Singh SisodiyaAinda não há avaliações

- Renewal, Update of Fire Control Plan:: Fire Alarm Systems Sprinkler Installation Remote OperationDocumento3 páginasRenewal, Update of Fire Control Plan:: Fire Alarm Systems Sprinkler Installation Remote Operationduckerz28Ainda não há avaliações

- Seepage and Contraction Joints in Concrete Canal LiningDocumento25 páginasSeepage and Contraction Joints in Concrete Canal LiningRohan ShivasundarAinda não há avaliações

- The Merchant Navy CareerDocumento24 páginasThe Merchant Navy CareerMannMannAinda não há avaliações