Escolar Documentos

Profissional Documentos

Cultura Documentos

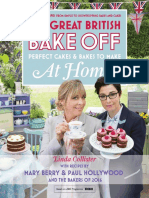

Effect of Sugars On The Biscuit

Enviado por

lpunty0 notas0% acharam este documento útil (0 voto)

267 visualizações8 páginasEffect of sugars on the biscuit

Título original

Effect of Sugars on the Biscuit

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoEffect of sugars on the biscuit

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

267 visualizações8 páginasEffect of Sugars On The Biscuit

Enviado por

lpuntyEffect of sugars on the biscuit

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 8

J Sci Food Agric 1997, 75, 383390

Effect of Sugars on the Rheological Characteristics

of Biscuit Dough and Quality of Biscuits

R Sai Manohar and P Haridas Rao*

Flour Milling, Baking and Confectionery Technology Department, Central Food Technological Research

Institute, Mysore-570 013, India

(Received 16 August 1996; revised version received 16 January 1997; accepted 18 April 1997)

Abstract : Sugars, depending on the level and type, inuenced the various rheolo-

gical characteristics of biscuit dough. Increasing the sugar content from 250 to

350 g kg~1 reduced the extrusion time from 70 to 23 s, consistency from 866 to

616 N s, hardness from 814 to 512 N and apparent biaxial extensional viscosity

from 254 ]105 to 141 ]105 Pa s. The development of gluten was also

reduced, as indicated by a decrease in the elastic recovery from 0515 to

038 mm. Spread as well as thickness of the biscuits increased with sugar level.

Density as well as compression strength were reduced signicantly (from 6326 to

5135 kg m~3 and from 1184 to 892 kg, respectively) reecting improvement in

the texture. Incorporation of an additional 20 g kg~1 reducing sugars like dex-

trose, invert syrup, liquid glucose and high fructose corn syrup, which are nor-

mally added to improve the colour of biscuits further changed the rheological

characteristics in a similar way. Among the reducing sugars, liquid glucose and

invert syrup produced greater changes in rheological characteristics particularly

in adhesiveness and stickiness, while high fructose corn syrup had a greater eect

on the colour of biscuits.

J Sci Food Agric 75, 383390 (1997)

No. of Figures: 3. No. of Tables: 7. No. of References: 25

Key words: rheological characteristics, biscuit dough, texture, reducing sugars

INTRODUCTION

Sugar is an important ingredient of short-dough

biscuits. It contributes to texture, avour, sweetness and

colour in biscuits. The quantity, granulation and type of

sugar used inuence the quality of biscuits (Smith 1972).

The amount of sugar that goes into solution depends on

the particle size of the sugar, and inuences the spread

of biscuits and machining properties of dough to a great

extent (Matz and Matz 1978). Sugar is reported to

restrict the development of gluten by competing for

water which otherwise would have been absorbed by

the gluten (Yamazaki 1971). The limited amount of

water used in biscuit formulation, and also its non-

availability to protein and starch, partially contributes

to the crispness of biscuits.

Considerable information is available on the inu-

ence of type and quantity of sugar on the quality of

* To whom correspondence should be addressed.

biscuits and cookies. Increasing sugar generally

increases the spread and reduces the thickness of

biscuits (Finney et al 1950; Kissel et al 1973; Vetter et

al 1984). Slade and Levine (1994) have reported

improved dough rmness with increasing sugar level.

Aboud et al (1985) observed a negligible eect on cookie

spread when a creaming method was followed; but an

increase in cookie spread was observed when a non-

creaming method was employed. Vetter et al (1984),

however, observed an increase in spread when cookies

were made either by a creaming or all-in-one mixing

method but the spread was greater at all sugar levels

with the all-in-one method of mixing. Olewnik and

Kulp (1984) reported that the changes in dough consis-

tency due to sugar content were dependent on the type

of cookie dough evaluated. The consistency of wire-cut

doughs remained constant between 300 and 450 g kg~1

sugar level while a sharp increase in dough consistency

was observed in deposit cookie doughs. The above

information applies to cookie dough. In the case of

383

1997 SCI. J Sci Food Agric 0022-5142/97/$17.50. Printed in Great Britain (

384 R Sai Manohar, P Haridas Rao

rotary-moulded biscuit dough, Miller (1985) has report-

ed a marginal increase in dough rmness with increase

in sugar content.

Normally, 2030 g kg~1 corn syrup are used in the

preparation of rotary-moulded biscuits, in order to

obtain a desirable golden brown colour, which is pro-

duced by a Maillard reaction (Feather 1994). In some of

the small-scale biscuit industries, invert syrup

prepared by hydrolysing sucrose with citric acidis

used, instead of corn syrup, in biscuit preparation. The

use of either of these syrups may aect the rheological

properties and also the quality of biscuits. There is no

published report on the above aspect except that of

Miller (1985). However, some reports are available on

the quality of cookies, when sucrose was replaced, par-

tially or totally, with other types of sugars like dextrose,

fructose, maltose or high fructose corn syrup (Curley

and Hoseney 1984; Doescher and Hoseney 1985).

The eects of dierent types and levels of sugar on

the rheological characteristics of biscuit dough and on

the quality of biscuits are presented in this paper.

MATERIALS AND METHODS

Materials

Flour

Two commercial wheat our samples (A and B), pro-

cured from the local market, were used in this study.

Methods

Flour analysis

Moisture, ash, gluten, colour grade value, Hagbergs

falling number, SDS sedimentation value, Farinograph

and extensograph characteristics were determined using

AACC methods (1983). Alkaline water retention capac-

ity (AWRC) was determined according to the method of

Yamazaki (1953).

Biscuit formula and ingredients

Biscuit dough was prepared according to the following

formula: our, 300 g; powdered sugar (passing through

220 km mesh), 90 g; shortening (Marvo brand, Brooke

Bond Lipton India Ltd, Calcutta, India) 60 g; sodium

chloride, 3 g; sodium bicarbonate, 15 g; ammonium

bicarbonate, (Ranbaxy Laboratories, Punjab, India),

30 g; baking powder, 09 g and water, 48 and 57 ml for

our A and our B, respectively.

Preparation of the dough

Sugar (ie sucrose) and fat were creamed in a Hobart

mixer (N-50) with a at beater, for 2 min at 61 rpm.

Dough water containing sodium bicarbonate, ammon-

ium bicarbonate and sodium chloride was added to the

above cream, and mixed for 5 min at 125 rpm to obtain

a homogeneous cream. Finally, our sieved twice with

baking powder, was added, and mixed for 3 min at

61 rpm. Dierent doughs were prepared by varying the

sugar level, namely 250, 300 and 350 g kg~1 of our, in

the above formula. Doughs were also prepared by addi-

tionally incorporating 20 g kg~1 of dierent reducing

sugars, namely dextrose, liquid glucose (LG), invert

syrup (IS) and high fructose corn syrup (HFCS). When-

ever syrups were used the formula water was adjusted

so as to obtain the same water content in the dough.

Measurement of rheological characteristics of dough

To obtain samples for the measurement of rheological

characteristics, the dough was sheeted using a rolling

pin over a rectangular platform of height 10 cm to get

a sheet of 10 cm thickness (Haridas Rao et al 1986).

The sheeted dough was cut into a circular discs, using

cutters of varying diameter (22 and 40 cm). The

sheeted and cut cylindrical discs of 40 cm diameter and

10 cm height were used to assess the consistency, hard-

ness, cohesiveness, adhesiveness, stickiness using an

Instron Universal Testing Instrument (Model 4301) by

the two-bite texture prole analysis (TPA) method of

Peleg (1976) and Bourne (1978) under the following

conditions: plunger diameter, 85 cm; clearance,

15 cm; load cell, 500 kg; cross-head speed,

100 cm min~1. Eighty percent compression was

applied to each sample. The real time plots (Fig 1) were

analysed for the following: (i) dough consistency (N s) ;

combined area of the two resistance peaks; (ii) dough

hardness (N) : maximum resistance to the rst compres-

sion peak (height of peak 1) ; (iii) dough cohesiveness:

ratio of the areas of the two resistance peaks (A

2

/A

1

) ;

(iv) dough adhesion (N s) : area of the rst adhesion

peak (v) dough stickiness: as the complementary (A

3

) ;

angle ( \(90 [h)) made by rst adhesion peak and x

axis.

Apparent biaxial extensional viscosity (ABEV) of the

dough was measured with an Instron Universal Testing

Instrument, employing the lubricant uniaxial compres-

sion method of Bagley and Christianson (1986) under

the following conditions: plunger diameter, 85 cm;

load cell, 100 kg; cross-head speed, 50 cm min~1; com-

pression, 50%; and relaxation time, 200 s. A cylindrical

dough sample (40 cm diameter and 10 cm height) was

used in the studies. Apparent biaxial extensional vis-

cosity (ABEV) of the dough was computed by the

formula

ABEV\Fh/nR

0

2 h

0

e

r

(Pa s)

where F is the peak force (Newton) ; h is the nal height

(m) ; is the initial radius (m) ; is the initial height R

0

h

0

(m) ; (s~1) ; and dh/dt is the cross- e

r

\[dh/dt][1/2h]

head speed (m s~1).

Rheological characteristics of biscuit dough 385

Fig 1. A texture prole analysis curve for a biscuit dough showing the parameters. consistency (N s) ; cohesive- A

1

]A

2

, A

2

/A

1

,

ness; adhesiveness (N s) ; (90 [h), stickiness. A

3

,

Compliance and elastic recovery of the dough were

measured using a penetrometer, adopting the pro-

cedure described by Sai Manohar and Haridas Rao

(1992) for dough samples of 1 cm thickness and 22 cm

diameter.

Dough consistency was measured as extrusion time,

using a Research Water Absorption Meter (RWAM),

as per the procedure of Gaines (1982) using 2 kg addi-

tional weight.

Farinograph characteristics

A Brabender Farinograph, equipped with a 300 g bowl

was used to determine dough consistency (peak height)

and cohesion (band width). Olewnik and Kulp (1984)

used some additional water (100 g kg~1) while mixing

the biscuit dough in the Farinograph, so as to get the

curve within the scale. Consequently, their method does

not indicate the inherent characteristics of cookie

dough. Hence, the method was modied for the present

studies and a 50 g bowl was used. The Farinograph

characteristics of biscuit dough prepared as described

earlier were determined using 40 g of the dough. The

curve was evaluated for various parameters as given

below.

Consistency (BU) is represented by the initial height

of the curve, after the dough has been mixed in Fari-

nograph for 1 min; elasticity (BU) by the band width of

the curve at 1 min; mixing tolerance index (MTI) (BU)

by the dierence between initial and nal consistencies.

Increase in consistency is represented as negative MTI

and decrease in consistency as positive MTI.

Preparation of biscuits

Dough was sheeted to a thickness of 35 mm with the

help of an aluminium platform and a frame, by rolling

with a rolling pin. Biscuits were shaped by cutting with

a cutter of 51 mm diameter, and baked on an alu-

minium tray at 205C for 10 min. The biscuits were

cooled for 30 min and stored in air-tight tins for 24 h,

for further analysis. Biscuits were prepared from doughs

containing sucrose at dierent levels, and also from

doughs containing an additional 20 g kg~1 reducing

sugar.

Evaluation of biscuits

Physical characteristics. The diameter (D) and thickness

(T ) of six biscuits were measured by placing them edge

to edge and by stacking one above the other respec-

tively. To obtain the average, measurements were made

by rearranging and restacking. Average weight (W ) of

six biscuits was noted. The density of biscuits was calcu-

lated and expressed as kg m~3.

Breaking and compression strengths. An Instron Univer-

sal Testing Instrument was used to measure the break-

ing strength of biscuits, employing the triple beam snap

(also called three-point break) technique of Gaines

(1991). The compression strength of biscuit was mea-

sured at 20% compression, at a cross-head speed of

50 cm min~1. Peak force (kg) was recorded.

Colour. The surface colour values of the biscuitin

terms of colour dierence (*E) and per cent whiteness

386 R Sai Manohar, P Haridas Rao

(w)were measured using a UVvisible recording Spec-

trophotometer (Model UV-2100 Shimadzu Corpora-

tion, Japan) (Anon 1990).

Sensory analysis

The sensory analysis of biscuits was carried out by a

panel of six experienced judges by assigning a score for

each quality attribute, such as surface colour, surface

characteristics and texture.

Statistical analysis of data

The experiment was planned according a randomised

design, and the treatments were tested using Duncans

new multiple range test (Steel and Torrie 1980).

RESULTS AND DISCUSSION

Chemical and rheological characteristics of our samples

The data of various quality characteristics of com-

mercial wheat our samples are given in Table 1. Flour

A and B selected for the studies diered considerably in

their quality characteristics, particularly in respect of

gluten content, water absorption capacity and SDS

sedimentation value. Flours A and B showed weak and

medium strong characteristics, respectively. These char-

acteristics are typical of the our types intended to be

chosen for the studies.

Eect of sugars

Rheological characteristics

Extrusion time declined signicantly with increasing

sugar levels. Reducing the sugar level to 250 g kg~1 (as

against the 300 g kg~1 used in controls) increased the

extrusion time of dough made from both the ours A

TABLE 1

Chemical and rheological characteristicsa of our samples

Characteristics Flour samples

A B

Chemical

Moisture (g kg~1) 125 125

Gluten (g kg~1) 88 108

KentJones Colour grade value 24 26

Ash (g kg~1) 38 46

Alkaline water retention

capacity (g kg~1) 56 64

SDS sedimentation value (ml) 29 38

Falling number 460 510

Rheological

Farinograph water absorption (g kg~1) 564 638

Dough development time (min) 15 25

Dough stability (min) 25 40

Mixing tolerance index (BU) 70 40

Resistance to extension (BU) 380 520

Extensibility (mm) 165 170

Area (cm2) 92 126

a Values are expressed on 14% moisture basis.

and B. The eect was more pronounced (Table 2) in the

case of our B which has a higher gluten content.

Addition of reducing sugars at 20 g kg~1 level over

and above the 300 g kg~1 sugar used when making the

dough, reduced the extrusion time further as expected;

the reduction obtained with dextrose was lower than

that obtained with any of the other reducing sugars

(Table 3). Thus, the addition of reducing sugars at just

20 g kg~1 brought about a reduction in extrusion time

equal to that which would have been produced by an

additional 50 g kg~1 of sucrose.

TABLE 2

Eect of sugar on the rheological characteristicsa of biscuit dough

Sugar Extrusion Compliance Elastic ABEV b Consistency Hardness Cohesiveness Adhesiveness Stickiness

( g kg~1) time (s) (%) recovery ]10~5 (N s) (N) (N s) ()

]10 (mm) (Pa s)

Flour A

250 70a 359c 515a 254a 866a 814a 0138c 358c 448c

300 45b 406b 460b 191b 786b 662b 0194b 543b 503b

350 23c 498a 380c 141c 616c 512c 0223a 576a 695a

SEMc (^) 24 037 0034 0022 86 79 0004 076 084

Flour B

250 105c 318c 690c 277d 964d 872d 0176c 358d 288d

300 45d 395b 555e 191e 848e 664e 0194b 482b 486b

350 20e 491a 425f 149f 564f 482f 0208a 523a 606a

SEMc (^) 33 034 0033 0023 129 101 0002 099 087

a Values for a particular column and for a particular our followed by dierent letters dier signicantly (P\005).

b ABEV: Apparent biaxial extensional viscosity.

c Standard error of the mean at 9 degrees of freedom.

Rheological characteristics of biscuit dough 387

TABLE 3

Eect of dierent reducing sugars on the rheological characteristicsa of biscuit dough

Sugar Extrusion Compliance Elastic ABEV c Consistency Hardness Cohesiveness Adhesiveness Stickiness

typeb time (s) (%) recovery ]10~5 (N s) (N) (N s) ()

]10 (mm) (Pa s)

Flour A

Control 45a 406c 460a 191a 786a 662a 0194d 543c 503c

Dextrose 36b 442b 410b 164b 654b 586b 0202cd 558bc 548b

LG 26c 488a 380d 142c 524c 492c 0220ab 578b 705a

IS 24c 486a 395c 141c 538c 476c 0210bc 625a 698a

HFCS 22c 498a 380d 136d 530c 474c 0230a 643a 715a

SEMd (^) 19 058 0038 0026 108 99 0003 087 090

Flour B

Control 45a 395d 555a 191a 848a 664a 0194c 482c 486d

Dextrose 37b 425c 495b 187a 627b 519b 0210b 502b 573c

LG 34bc 473b 495b 147b 629b 530b 0224a 563a 635b

IS 30cd 487ab 505b 148b 582c 479c 0228a 525b 687a

HFCS 28d 498a 500b 147b 564c 472c 0220ab 580a 705a

SEMd (^) 15 054 0034 0022 93 124 0003 089 098

a Values for a particular column and for a particular our followed by dierent letters dier signicantly (P\005).

b Dierent type of reducing sugars added at 20 g kg~1 level.

c ABEV, Apparent biaxial extensional viscosity; LG, liquid glucose; IS, invert syrup; HFCS, high fructose corn syrup.

d Standard error of the mean at 15 degrees of freedom.

Increasing the amount of added sugar (from 250 to

350 g kg~1) made the dough softer as indicated by the

increase in the compliance value from 359 to 498% for

a dough made from our A. Incorporation of dierent

types of reducing sugarsin much smaller amounts

increased the compliance values to a similar extent.

Elastic recovery diminished with increase in sugar

levelevidently because of its inuence on the develop-

ment of gluten. However, at comparable sugar levels,

the elastic recovery was greater for our B than for

our A. Addition of any type of reducing sugar

decreased the elastic recovery to a similar extent.

Apparent biaxial extensional viscosity (ABEV) varied

with the amount of sugar used; it declined from

254 ]105 to 141 ]105 Pa s when sugar level was

increased from 250 to 350 g kg~1 (Table 2). This is

because of the tenderising eect of sugar on dough.

Among the dierent types of reducing sugars, liquid

glucose, invert syrup and high fructose corn syrup

decreased the ABEV to a greater extent than dextrose.

This may be due to the higher concentration of sugar in

the solution, and the consequent increase in the volume

of the liquid phase, when syrups were used.

When sugar content was increased from 250 to

350 g kg~1 the consistency was brought down from 866

to 616 N s, and hardness from 814 to 512 N (Table 2).

This is analogous to the observations we have made

with regard to other rheological measurements. Though

dierent reducing sugars decreased the consistency and

hardness to a similar extent, the absolute values were

lower than those of control dough (Table 3).

Cohesiveness of the dough as measured by the

Instron increased with increase in sugar level, and also

on incorporation of the reducing sugars, due to greater

amount of sugar going into solution. This was true for

both ours. It is interesting to note that the ABEV of

biscuit dough decreased, while the cohesiveness

increased. In the case of biscuit dough, the cohesiveness

results from smearing fat through the our and sugar

and wetting the mixture (Olwenik and Kulp 1984).

Adhesiveness as well as stickiness of the dough as

measured by the Instron increased with increase in

sugar level ; and they increased still further when

reducing sugar was incorporated. This was evidently

because of the sticky nature of the syrup, and also

because of more sugar going into solution. A similar

observation had been made earlier by Curley and

Hoseney (1984), when part of the sucrose was replaced

with high fructose corn syrup in cookie dough.

An increase in the sugar level, or addition of dierent

types of reducing sugars, resulted in a reduction of the

Farinograph consistency of the doughs (Fig 2). Elas-

ticity decreased with increase in sugar level, and on also

when dierent reducing sugars were added; there was

no appreciable dierence among the reducing sugars in

this respect (Fig 3). However, no dierence was

observed between the ours A and B. MTI depended on

level of sugar and decreased with increase in sugar level.

Quality of biscuits

Spread of biscuits increased from 52 to 557 mm with

increase in the sugar level, which is in agreement with

388 R Sai Manohar, P Haridas Rao

Fig 2. Eect of sugar level on the Farinograph characteristics

of biscuit dough. our Aconsistency; ], our K,

Aelasticity; 0, our AMTI; our B >,

consistency; o, our Belasticity; and , our

BMTI.

earlier reports (Smith 1972; Chandra Shekara et al

1986). Additional incorporation of any type of reducing

sugar increased the spread as compared to the control ;

the increase in spread was hardly aected by the type of

reducing sugar added. This trend was similar in the case

of both ours A and B; however, the absolute values

were lower for our B at every sugar level, and for every

type of reducing sugar added (Tables 4 and 5). This was

due to higher protein content in our B. Thickness also

Fig 3. Eect of reducing sugars (used at 20 g kg~1 our) on

the Farinograph characteristics of biscuit dough. our K,

Aconsistency; ], our Aelasticity; 0, our

AMTI; our Bconsistency; o, our B >,

elasticity; and , our BMTI.

increased with increasing sugar level ; but addition of

dierent types of reducing sugars made very little dier-

ence in this respect. Spread ratio was found to be

minimum, when additional invert syrup was added in

the formulation; however, it decreased with increase in

the level of sugar. The density and compression strength

of biscuits decreased with increase in sugar content.

TABLE 4

Eect of sugar on the physical characteristicsa of biscuits

Sugar Diameter T hickness Spread Density Breaking Compression W hiteness Colour dierence

( g kg~1) (mm) (mm) ratio (kg m~3) strength strength (%) (*E)

( g) (kg)

Flour A

250 520c 540c 9630a 6326a 1580c 1184a 318a 338c

300 540b 570ab 9474c 5420b 1985b 994b 306b 347b

350 557a 585a 9521b 5135c 2012a 892c 289c 359a

SEMb (^) 009 004 0029 21 107 14 027 025

Flour B

250 506c 525c 9638a 6372a 2284a 1786a 312a 342c

300 524b 565ab 9274c 5825b 2247b 1432b 300b 352b

350 544a 570a 9549b 5140c 2304a 1126c 284c 363a

SEMb (^) 009 003 0033 22 124 136 029 029

a Values for a particular column and for a particular our followed by dierent letters dier signicantly (P\005).

b Standard error of the mean at 9 degrees of freedom.

Rheological characteristics of biscuit dough 389

TABLE 5

Eect of dierent reducing sugars on the physical characteristicsa of biscuits

Sugar Diameter T hickness Spread Density Breaking Compression W hiteness Colour dierence

typeb (mm) (mm) ratio (kg m~3) strength strength (%) (*E)

( g) (kg)

Flour A

Control 540b 570b 9474a 5420a 1985b 994a 306a 347e

Dextrose 543b 575ab 9443ab 5348b 1988b 868bc 199cd 435bc

LG 545a 580a 9397c 5313b 2028a 846c 205bc 430cd

IS 543b 580a 9362d 5335b 2042a 884b 210b 424d

HFCS 547a 580a 9431b 5203c 1942c 813d 193d 440ab

SEMc (^) 008 003 0028 23 128 078 031 032

Flour B

Control 524c 565b 9274e 5825a 2247ab 1432a 300a 352d

Dextrose 536b 565b 9487a 5624b 2196c 1361b 195c 437ab

LG 539a 570ab 9456ab 5535c 2184c 1319cd 209b 424c

IS 538ab 575a 9357d 5597b 2224bc 1346bc 196c 435bc

HFCS 540a 575a 9391c 5430d 2092d 1286d 185e 445a

SEMc (^) 009 003 0027 21 112 11 030 028

a Values for a particular column and for a particular our followed by dierent letters dier signicantly (P\005).

b Dierent reducing sugars added at 20 g kg~1 level. LG, liquid glucose; IS, invert syrup; HFCS, high fructose corn syrup.

c Standard error of the mean at 15 degrees of freedom.

TABLE 6

Eect of sugar on the sensory characteristicsa of biscuits

Sugar ( g kg~1) Flour A Flour B

Surface Colour T exture Surface Colour T exture

250 85b 55c 140c 85b 54c 134c

300 92a 65b 165b 89ab 63b 152b

350 94a 85a 185a 93a 83a 180a

SEMb ( ^) 025 021 032 019 021 026

a Values for a particular column followed by dierent letters dier signicantly (P\005).

b Standard error of the mean at 15 degrees of freedom.

TABLE 7

Eect of dierent reducing sugars on the sensory characteristicsa of biscuits

Sugar typeb Flour A Flour B

Surface Colour T exture Surface Colour T exture

Control 92b 65c 165b 89a 63c 152c

Dextrose 94a 92b 185a 93a 92b 175ab

LG 94a 94a 188a 92a 95a 175ab

IS 95a 94a 186a 93a 95a 170b

HFCS 94a 95a 189a 94a 96a 180a

SEMc (^) 021 021 022 022 021 031

a Values for a particular column followed by dierent letters dier signicantly (P\005).

b Dierent type of reducing sugar added at 20 g kg~1 level. LG, liquid glucose; IS, invert syrup;

HFCS, high fructose corn syrup.

c Standard error of the mean at 25 degrees of freedom.

390 R Sai Manohar, P Haridas Rao

Addition of reducing sugars also brought about

decrease in these values; but the eects produced by the

dierent reducing sugars were similar (Tables 4 and 5).

Colour improved as indicated by the whiteness (%)

values which diminished with increasing sugar level.

Addition of reducing sugar at 20 g kg~1 level itself con-

siderably reduced the whiteness (%) values from 306 to

193210. Among the biscuits made with dierent

reducing sugars, high fructose corn syrup had the

maximum colour dierence value and minimum percent

whiteness value. This was true in case of both our A

and B.

Surface characteristics improved with increase in

sugar level or addition of reducing sugars (Tables 6 and

7). Even the biscuits made with 350 g kg~1 sugar had a

pale brown colour. However, incorporation of

20 g kg~1 reducing sugars imparted desired golden

brown colour and hence scored higher (Table 7).

Biscuits containing higher levels of sugar were crisper as

shown by higher textural scores.

CONCLUSION

The results indicate that sugar content in biscuit dough

inuences the various rheological characteristics such as

consistency, hardness and ABEV of the dough. Gluten

development was also aected by sugar levels, due to

sugar competing for water along with our. Sugars

made the dough more cohesive, adhesive and sticky, as

measured by an Instron, depending on the level of

incorporation. However, reducing sugars imparted a

desirable golden brown colour to the biscuits. The inu-

ence of the reducing sugars on the above rheological

characteristics depended on the physical state of the

reducing sugar; the syrups had a greater inuence on

the rheological characteristics of the dough as well as

on the colour of biscuits. The doughs made from the

above sugars were more cohesive, adhesive, sticky as

measured by an Instron and less viscous. They did not

aect the other rheological parameters. Among the dif-

ferent reducing sugars, high fructose corn syrup impart-

ed the best colour to biscuits.

REFERENCES

AACC 1983 Approved Methods (8th edn). American Associ-

ation of Cereal Chemists, St Paul, MN, USA.

Aboud A M, Rubenthaler G L, Hoseney R C 1985 Eect of

fat and sugar in sugar-snap cookies and evaluation of tests

to measure cookie our quality. Cereal Chem 62 124129.

Anon 1990 Instruction Manual of Colour Measurement and

Software Package for UV visible Spectrophotometer Model

UV -2100. Shimadzu Corporation, Kyoto, Japan.

Bagley E B, Christianson D D 1986 Response of commercial

chemically leavened doughs to uniaxial compression. In:

Fundamentals of Dough Rheology, eds Faridi H & Faubion

J M. American Association of Cereal Chemists, St Paul,

MN, USA, pp 19.

Bourne M C 1978 Texture prole analysis. Food T echnol 32

6266, 72.

Chandra Shekara S, Haridas Rao P, Shurpalekar S R 1986

Studies on the consistency of biscuit doughs using

Research water absorption meter. J Food Sci T echnol 23

208212.

Curley L P, Hoseney R C 1984 Eects of corn sweeteners on

cookie quality. Cereal Chem 61 274278.

Doescher L C, Hoseney R C 1985 Eect of sugar type and

our moisture on surface cracking of sugar-snap cookies.

Cereal Chem 62 263266.

Feather M S 1994 The mechanism of nonenzymatic browning

reactions occurring during cookie and cracker making. In:

T he Science of Cookie and Cracker Production, ed Faridi H.

Chapman and Hall, New York, USA, pp 439453.

Finney K F, Yamazaki W T, Morris V H 1950 Eects of

varying quantities of sugar, shortening and ammonium

bicarbonate on the spreading and top grain of sugar-snap

cookies. Cereal Chem 27 3041.

Gaines C S 1982 Inuence of dough absorption level and time

on stickiness and consistency in sugar-snap cookie doughs.

Cereal Chem 59 404407.

Gaines C S 1991 Instrumental measurement of the hardness of

cookies and crackers. Cereal Foods W orld 36 989, 991994,

996.

Haridas Rao P, Leelavathi K, Shurpalekar S R 1986 Objective

measurements of the consistency of the chapati dough using

a Research Water Absorption Meter. J T exture Stud 17

401420.

Kissel L T, Marshall B D, Yamazaki W T 1973 Eect of

variability in sugar granulation on the evaluation of our

cookie quality. Cereal Chem 50 255264.

Matz S A, Matz T D 1978 Cookie and Cracker T echnology

(2nd edn). AVI Publishing Company Inc, Westport, CT,

USA, p 36.

Miller A R 1985 The use of a penetrometer to measure the

consistency of short doughs. In: Rheology of W heat Pro-

ducts, ed Faridi H. American Association of Cereal Chem-

ists, St Paul, MN, USA, pp 117132.

Olewnik M C, Kulp K 1984 The eect of mixing time and

ingredient variation on fraginograms of cookie doughs.

Cereal Chem 61 532537.

Peleg M 1976 Texture prole analysis parameters obtained by

an Instron universal testing machine. J Food Sci 41 721

722.

Sai Manohar R, Haridas Rao P 1992 Use of a penetrometer

for measuring rheological characteristics of biscuit dough.

Cereal Chem 69 619623.

Slade L, Levine H 1994 Structurefunction relationships of

cookie and cracker ingredients. In: T he Science of Cookie

and Cracker Production, ed Faridi H. Chapman and Hall,

New York, USA, pp 23141.

Smith W H 1972 Biscuits, Crackers and Cookies (Vol 1: Tech-

nology, Production and Management). Applied Science,

London, UK, pp 8081.

Steel R G D, Torrie J H 1980 Principles and Procedures of

Statistics. McGraw-Hill, New York, USA.

Vetter J L, Bright H, Utt M, Mcmaster G 1984 Cookie formu-

lating: sugar, mixing aect specic gravity, spread. Bakers

Digest 58 6, 7, 9.

Yamazaki W T 1953 An alkaline water retention capacity test

for the evaluation of cookie baking potentialities of soft

wheat ours. Cereal chem 30 242246.

Yamazaki W T 1971 Soft wheat products. In: W heat Chem-

istry and T echnology, ed Pomeranz Y. American Associ-

ation of Cereal Chemists, St Paul, MN, USA, p 749.

Você também pode gostar

- IntroductionDocumento4 páginasIntroductionSadhana GhimireAinda não há avaliações

- TS Extruder GuideDocumento11 páginasTS Extruder GuideKhaulla AwanAinda não há avaliações

- Cereal Products AssignmentsDocumento9 páginasCereal Products AssignmentsSaima100% (1)

- Et 45 2001 PDFDocumento9 páginasEt 45 2001 PDFmy09Ainda não há avaliações

- Biogas Production From Decanter Cake of Palm Oil Mill From South IndiaDocumento4 páginasBiogas Production From Decanter Cake of Palm Oil Mill From South IndiaEditor IJTSRDAinda não há avaliações

- Production Process - II (Module 3 - Notes) : Elements Mentioned in These NotesDocumento9 páginasProduction Process - II (Module 3 - Notes) : Elements Mentioned in These NotesDeepak DevasagayamAinda não há avaliações

- Sustainable Manufacturing and Cutting TechniquesDocumento30 páginasSustainable Manufacturing and Cutting TechniquesAmbati TejaswararaoAinda não há avaliações

- Chapter-I 1.1 About The Industry: Plastic Should Not Be Confused With The TechnicalDocumento37 páginasChapter-I 1.1 About The Industry: Plastic Should Not Be Confused With The Technicalsindhu90Ainda não há avaliações

- Company Catalog BookDocumento43 páginasCompany Catalog BookWaqas KhalidAinda não há avaliações

- Biogas ProductionDocumento6 páginasBiogas Productionpaul machariaAinda não há avaliações

- Thermoplastic Polymers in Product DesignDocumento11 páginasThermoplastic Polymers in Product DesignJoey Zamir Huerta MamaniAinda não há avaliações

- Coca Cola Training DevelopmentDocumento65 páginasCoca Cola Training DevelopmentMT RAAinda não há avaliações

- Environmental, Health, and Safety Guidelines For Pesticide Manufacturing, Formulation, and PackagingDocumento17 páginasEnvironmental, Health, and Safety Guidelines For Pesticide Manufacturing, Formulation, and Packagingmaddukuri jagadeesh babuAinda não há avaliações

- Metal Cutting Fluids: Meaning, Functions and Types: in Metal Cutting Process Heal Is Generated Due To Following ActionsDocumento3 páginasMetal Cutting Fluids: Meaning, Functions and Types: in Metal Cutting Process Heal Is Generated Due To Following ActionsTulsi ChouhanAinda não há avaliações

- Sealant: Sealant Is A Substance Used To Block The Passage ofDocumento52 páginasSealant: Sealant Is A Substance Used To Block The Passage ofRoland CepedaAinda não há avaliações

- 'Business Model and Project'viability' For A Technical Textile Project Based On 2 No Nonwoven Plant Lines'Documento11 páginas'Business Model and Project'viability' For A Technical Textile Project Based On 2 No Nonwoven Plant Lines'Krishna GadodiaAinda não há avaliações

- Sample of A Business Plan: Jinkyan'S Setters Hair StudioDocumento14 páginasSample of A Business Plan: Jinkyan'S Setters Hair StudioAdam Christopher TolosaAinda não há avaliações

- Recycling 2000Documento13 páginasRecycling 2000A MahmoodAinda não há avaliações

- SC Wheat-Soya Blend With Sugar 1.5Kg - 3KgDocumento10 páginasSC Wheat-Soya Blend With Sugar 1.5Kg - 3Kgfaheem ulislamAinda não há avaliações

- Polyester Fibre ManufacturingDocumento16 páginasPolyester Fibre ManufacturinghaishpithadiyaAinda não há avaliações

- Instant NoodlesDocumento18 páginasInstant NoodlesTrần Tú LinhAinda não há avaliações

- Cutting FluidDocumento8 páginasCutting FluidDevarakonda KondayyaAinda não há avaliações

- Polyester Fully Drawn YarnDocumento2 páginasPolyester Fully Drawn YarnShoaib ChaudhryAinda não há avaliações

- Final Dinesh ProjectDocumento16 páginasFinal Dinesh ProjectAravindhan LAinda não há avaliações

- Emulsified and Special MixturesDocumento26 páginasEmulsified and Special MixturesharAinda não há avaliações

- Properties of Palm Oil MargarineDocumento7 páginasProperties of Palm Oil Margarinemcalidonio5656Ainda não há avaliações

- Mango Butter Yield Ed Casas Et AlDocumento35 páginasMango Butter Yield Ed Casas Et AlAri HalosAinda não há avaliações

- Extraction and Characterization of Nigeria Shea Butter OilDocumento7 páginasExtraction and Characterization of Nigeria Shea Butter OilJordon AlvaradoAinda não há avaliações

- Cuttinf FluidsDocumento29 páginasCuttinf Fluidsshrikanth100% (1)

- H1platinum Blonde Virgin Human Hair Wig Sixteenh1wywowDocumento3 páginasH1platinum Blonde Virgin Human Hair Wig Sixteenh1wywowclavelyre2Ainda não há avaliações

- Methods of Manufacture of PaneerDocumento13 páginasMethods of Manufacture of PaneerMustafa Samim67% (3)

- Project A03 - ICPNADocumento2 páginasProject A03 - ICPNACarlos Castañeda OkamuraAinda não há avaliações

- Light Liquid Paraffin - Ip - BP - EpDocumento1 páginaLight Liquid Paraffin - Ip - BP - Epप्रियदर्शन गोंधळेकरAinda não há avaliações

- Edible Oil PressDocumento6 páginasEdible Oil Press3bandhuAinda não há avaliações

- OM (401) - Plant Layout ADocumento9 páginasOM (401) - Plant Layout AVivek ShaAinda não há avaliações

- Project Profile On Petroleum JellyDocumento10 páginasProject Profile On Petroleum JellyG.p.AiyerAinda não há avaliações

- Different Types of Plastics and Their Classification: Recycle. Polycarbonate (PC) Is Used in Baby Bottles, Compact DiscsDocumento2 páginasDifferent Types of Plastics and Their Classification: Recycle. Polycarbonate (PC) Is Used in Baby Bottles, Compact DiscsSiddharth GhorpadeAinda não há avaliações

- Wafer BatterDocumento12 páginasWafer BatternanahidayatAinda não há avaliações

- Rebond DocumentationDocumento35 páginasRebond DocumentationHandri YantoAinda não há avaliações

- Dettol Antibacterial Sunscreen SoapDocumento17 páginasDettol Antibacterial Sunscreen SoapNayab ButtAinda não há avaliações

- Final PPT CADocumento90 páginasFinal PPT CAFatma M. BarakatAinda não há avaliações

- Hdpe Bottle Jar Traders, Wholesalers and Buyers in JamnagarDocumento46 páginasHdpe Bottle Jar Traders, Wholesalers and Buyers in Jamnagarsamir249Ainda não há avaliações

- What Is Green Manufacturing?Documento10 páginasWhat Is Green Manufacturing?ShankarAinda não há avaliações

- Cereal ProcessingDocumento23 páginasCereal ProcessingAnjar CoolAinda não há avaliações

- Formulation of Rice Flour BiscuitDocumento10 páginasFormulation of Rice Flour BiscuitLaksilu Viduraga Peiris100% (1)

- Toilet Soap Production BusinessDocumento4 páginasToilet Soap Production BusinessBalakrishna GopinathAinda não há avaliações

- Shisha Charcoal and Honeycomb Process FlowDocumento12 páginasShisha Charcoal and Honeycomb Process FlowDhiangga JauharyAinda não há avaliações

- Polyester Is A Synthetic Fiber Derived From CoalDocumento3 páginasPolyester Is A Synthetic Fiber Derived From Coalshajibur2011Ainda não há avaliações

- Technologies of Millet Value Added Products-1Documento51 páginasTechnologies of Millet Value Added Products-1KeertAinda não há avaliações

- Term Paper OF Production Technology Topic-Cutting Fluids & Lubricants BYDocumento22 páginasTerm Paper OF Production Technology Topic-Cutting Fluids & Lubricants BYLovepreet SinghAinda não há avaliações

- Environmentally Friendly Production of Pulp and PaperNo EverandEnvironmentally Friendly Production of Pulp and PaperAinda não há avaliações

- Emulsifier For Base Cutting OilsDocumento3 páginasEmulsifier For Base Cutting Oilscm_chemical810% (1)

- Catalogue Plastic Bottles 2016Documento36 páginasCatalogue Plastic Bottles 2016miha3la33Ainda não há avaliações

- Acknowledgement : To Whom It May ConcernDocumento8 páginasAcknowledgement : To Whom It May ConcernUsama MaoudAinda não há avaliações

- Project Profile On PET Bottles: Product Code (NIC Code) : 22203Documento12 páginasProject Profile On PET Bottles: Product Code (NIC Code) : 22203Mr.vijay VaddiAinda não há avaliações

- Cereals and Legume TechnologyDocumento23 páginasCereals and Legume TechnologyLê Tất TiếnAinda não há avaliações

- Chương 4 Công nghệ sản suất mì sợiDocumento45 páginasChương 4 Công nghệ sản suất mì sợiTrungAinda não há avaliações

- My Project New EditDocumento38 páginasMy Project New Editmuhammad m butuAinda não há avaliações

- Effect of Sodium Lauryl Sulphate On The Texture of Sponge CakeDocumento6 páginasEffect of Sodium Lauryl Sulphate On The Texture of Sponge CakeronaldyuncosaAinda não há avaliações

- Maache Rezzoug Et Al.1998Documento20 páginasMaache Rezzoug Et Al.1998Mădălina ȘtefanAinda não há avaliações

- Cxs 152e CodexDocumento3 páginasCxs 152e CodexGisela Prima PaskhalienAinda não há avaliações

- Aspartame Information-What WhereDocumento5 páginasAspartame Information-What WherelpuntyAinda não há avaliações

- Erythritol-Sucralose As Replacement For SugarDocumento4 páginasErythritol-Sucralose As Replacement For SugarlpuntyAinda não há avaliações

- Research Article Utilization of Seawater As A Medium For Mass Production of Spirulina Platensis - A Novel ApproachDocumento6 páginasResearch Article Utilization of Seawater As A Medium For Mass Production of Spirulina Platensis - A Novel ApproachlpuntyAinda não há avaliações

- Spirulina Platensis EffectsDocumento7 páginasSpirulina Platensis EffectslpuntyAinda não há avaliações

- Industrial University of Ho Chi Minh City1Documento19 páginasIndustrial University of Ho Chi Minh City1lpuntyAinda não há avaliações

- (Thanh Xu JR) Ielts Preparation - A Brief On Writing Task 1Documento3 páginas(Thanh Xu JR) Ielts Preparation - A Brief On Writing Task 1Jackson PmAinda não há avaliações

- (Thanh Xu JR) Ielts Preparation - A Brief On Writing Task 1Documento3 páginas(Thanh Xu JR) Ielts Preparation - A Brief On Writing Task 1Jackson PmAinda não há avaliações

- Plant Layout of Bakery IndustryDocumento6 páginasPlant Layout of Bakery IndustryPoonam Nanda80% (5)

- Se Gong Korean Mart Market Price PDFDocumento2 páginasSe Gong Korean Mart Market Price PDFTullao Mark CarloAinda não há avaliações

- Sec A Maliban MeDocumento72 páginasSec A Maliban MeDINU67% (6)

- An Introduction To Food & Beverages SectorDocumento21 páginasAn Introduction To Food & Beverages SectorniftyronnieAinda não há avaliações

- 459 - So FG13Documento5 páginas459 - So FG13ronni gunadi sAinda não há avaliações

- Azebe TsegayeDocumento62 páginasAzebe Tsegayeberhanu seyoumAinda não há avaliações

- Market SegmentationDocumento2 páginasMarket SegmentationAravind MahendranAinda não há avaliações

- Artisan Biscuits: IngredientsDocumento2 páginasArtisan Biscuits: IngredientsE EAinda não há avaliações

- Educational Research Quantitative Qualitative and Mixed Approaches 6th Edition Johnson Solutions ManualDocumento35 páginasEducational Research Quantitative Qualitative and Mixed Approaches 6th Edition Johnson Solutions Manualstrunttriose1xjj100% (21)

- Horlicks CookbookDocumento23 páginasHorlicks CookbookConstiAinda não há avaliações

- Universiti Utara Malaysia Thesis TemplateDocumento28 páginasUniversiti Utara Malaysia Thesis Templatempnaidu13111998Ainda não há avaliações

- Work Schedule Task 2 (3063)Documento6 páginasWork Schedule Task 2 (3063)Jack JollyAinda não há avaliações

- 9781473615441 (1)Documento449 páginas9781473615441 (1)iki29280% (5)

- LO1 PretestDocumento1 páginaLO1 PretestshaigestAinda não há avaliações

- Elsa's Story - Cookie Collection CatalogDocumento18 páginasElsa's Story - Cookie Collection CatalogIsrael ExporterAinda não há avaliações

- Soul Cake Ingredients: For The GlazeDocumento2 páginasSoul Cake Ingredients: For The Glazeshaheen orangeAinda não há avaliações

- Gulfood Exhibitor List N 1Documento19 páginasGulfood Exhibitor List N 1Lupu CarmenAinda não há avaliações

- Food Composition TableDocumento11 páginasFood Composition TablenrgcoreAinda não há avaliações

- 4 класс - Сборник упражнений, часть 1 (Барашкова Е.А. - для УМК English (Верещагина И.Н.) ) PDFDocumento129 páginas4 класс - Сборник упражнений, часть 1 (Барашкова Е.А. - для УМК English (Верещагина И.Н.) ) PDFNarine HovhannisyanAinda não há avaliações

- RLB's Biscuit RouladeDocumento2 páginasRLB's Biscuit RouladeBobanMatićAinda não há avaliações

- Soft Dough Biscuits:: A) Fermented Hard Biscuits (Crackers)Documento11 páginasSoft Dough Biscuits:: A) Fermented Hard Biscuits (Crackers)Lokraj PantAinda não há avaliações

- Products CatalogDocumento16 páginasProducts CatalogBrighton Rajab Musa100% (1)

- Breakfast: Menu PriceDocumento6 páginasBreakfast: Menu PriceGcoolguyAinda não há avaliações

- Imapmilkladderrecipes 201119Documento7 páginasImapmilkladderrecipes 201119H&M SzathmáriAinda não há avaliações

- Good Nutrition in Pregnancy: A Healthy Pregnancy Is Important For You and Your BabyDocumento12 páginasGood Nutrition in Pregnancy: A Healthy Pregnancy Is Important For You and Your Babymicky mouseAinda não há avaliações

- Bake Off ChristmasDocumento341 páginasBake Off ChristmasKarina O100% (2)

- Ingredients Method: Serves 4Documento2 páginasIngredients Method: Serves 4aruldeepakAinda não há avaliações

- Trade Prices October 2019Documento907 páginasTrade Prices October 2019Starter's SuccessAinda não há avaliações

- BiscuitsDocumento28 páginasBiscuitsAlpeshAinda não há avaliações

- BritaniaDocumento21 páginasBritaniaMohit AroraAinda não há avaliações