Escolar Documentos

Profissional Documentos

Cultura Documentos

Chapter 3

Enviado por

Fadhiran YahyaDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Chapter 3

Enviado por

Fadhiran YahyaDireitos autorais:

Formatos disponíveis

M

.

H

a

m

d

i

B

i

n

K

h

o

s

r

a

n

2

0

1

4

C

h

a

p

t

e

r

3

:

D

e

s

i

g

n

o

f

M

e

c

h

a

n

i

c

a

l

J

o

i

n

t

This topic explains the design of key,

pin joint and bolt and nut joint. It

involves analysis on bolt and nut joint

carrying a direct load or eccentric

load. It also explains the design joints

of welding.

Mechanical engineering

department

Politeknik Merlimau

hamdi@pmm.edu.my

JJ513 Engineering Design Design of Mechanical Joint

2

THE BIG PICTURE

OBJECTIVES OF THIS CHAPTER

After completing this chapter, you will be able to:

1. Explain the purpose of the key

2. Sketch and name various types of key such as parallel keys, taper keys, gib-head keys, pin

keys, woodruff keys, etc.

3. Apply mathematical analysis for rectangle and parallel key based on sheer stress and

compressed stress.

4. List the advantages and disadvantages using pin and bolt and nut as the method of

joining.

5. Analyze the factors of bolt and nut joint failures.

6. Analyze bolt and nut joints by shearing load.

7. Analyze bolt and nut joints shearing caused by eccentric load.

8. Calculate the bolt size and maximum load.

9. State the advantages and disadvantages of welded joints.

10. Sketch the basic symbol for welded joint.

11. Apply the mathematical analysis for welded joint

12. Determine the weld throat and safe load.

13. Determine the welded joint size caused by eccentric load.

3 - 1

KEY DESIGN

3 - 2

DESIGN OF PIN JOINT, BOLT, AND

NUT JOINT

3 - 3

WELDED JOINTS DESIGN

JJ513 Engineering Design Design of Mechanical Joint

3

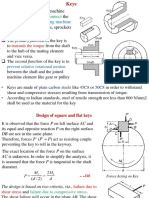

3-1 THE KEY DESIGN

A key is a machinery component placed at the interface between a shaft and the hub of a

power-transmitting element for the purpose of transmitting torque [figure 3-1]. Key is placed so

that part of it lies in a groove cut on the shaft, called key seat, and part of it fits into a groove cut

in hub, called key way. Therefore, after the assembly locked together by the key, the shaft and

hub will rotate together.

Figure 3-1 key position applied to a shaft

Square and Rectangular Parallel Keys

The most common type of key for shafts up to 6 inches in diameter is the square key, as

illustrated in figure 3-2. The rectangular key is recommended for larger shafts and is used for

smaller shafts where the shorter height can be tolerated.

Figure 3-2 Square key

JJ513 Engineering Design Design of Mechanical Joint

4

Figure 3-3 Illustration of keys. (a) dimensions of shaft with keyway in shaft and hub; (b) square

parallel key; (c) rectangular parallel key

Taper Keys and Gib Head Keys

Taper keys are designed to be inserted from the end of the shaft after the hub is in position

rather than installing the key first and then sliding the hub over the key as with parallel keys.

The gib head key has a tapered geometry inside the hub that is the same as that of the plain

taper key. But the extended head provides the means of extracting the key from same end at

which it was installed. This is very desirable if the opposite end is not accessible to drive the key

out.

(a) (b)

Figure 3-4 (a) Tapered key; (b) Gib Head key

JJ513 Engineering Design Design of Mechanical Joint

5

Pin Keys

The pin keys are a cylindrical pin placed in cylindrical groove in the shaft and hub. Lower stress

concentration factors results from this design as compared with parallel or tapered keys. A close

fit between the pin and the groove is required to ensure that the pin does not move and that the

bearing is uniform along the length of the pin.

Figure 3-5 Pin keys

Woodruff Keys

Where light loading and relatively easy assembly and disassembly are desired, the woodruff key

should be considered. The circular groove in the shaft holds the key in position while the mating

part is slid over the key.

Figure 3-6 Woodruff keys

JJ513 Engineering Design Design of Mechanical Joint

6

Stress Analysis

There are two basic modes of potential failure for keys transmitting power:

(1) shear across the shaft/hub interface

(2) Compression failure due to the bearing action between the sides of the key and the shaft

or hub material.

Figure 3-7 shows the idealized case in which the torque on the shaft creates a force on the left

side of the key.

Figure 3-7 Forces on a key

Key design is successful if failure from shear or compression is prevented, both of which are

considered here:

1. Failure due to shear:

(3.1)

The design shear stress is

(3.2)

Above equation (3.2) is independent of the height h. to avoid failure due to shear

(3.3)

JJ513 Engineering Design Design of Mechanical Joint

7

2. Failure due to compressive or bearing stress. The compression or bearing area of the key

is

(3.4)

The compressive or bearing design stress is

(3.5)

Above equation (3.5) is independent of the width w. Failure due to compressive or

bearing stress can be avoided if

(3.6)

Noted:

The allowable normal stress

all

and the allowable shear stress

for ferrous and nonferrous

metals for various types of loading may be represented by,

Shear:

(3.7)

Compressive:

(3.8)

*S

y

is a Yield Strength

Example problem 3-1

Given: A 4-in-diameter shaft with a hub is made of high-carbon steel. A square key made of low-

carbon steel has a width and height of 1 in. assume a torque value at 2-in radius.

Find: The critical length of the key while assuming a safety factor of 2 and considering both

compression and shear.

Solution: from table A.1 (appendix) the yield strength for the shaft and hub is S

y

= 55 ksi. From

equation (3.7) and (3.8)

Thus, the design stresses are

JJ513 Engineering Design Design of Mechanical Joint

8

For a shaft with circular cross section

The maximum torque acting on the shaft at a radius of 2 in is

The maximum force is

From table A.1 (Appendix) the yield strength for the key is S

y

= 43 ksi. From equation (3.7) and

(3.8)

The design stresses are

For equation (3.2)

Thus, to avoid key shear failure, the key should be at least 8.035 in long. From equation (3.5)

To avoid key compressive or bearing failure, the key should be at least 7.144 in long. Therefore,

failure will first occur from key shearing, and the key must be at least 8.036 in long.

JJ513 Engineering Design Design of Mechanical Joint

9

3-2 THE DESIGN OF BOLT AND NUT JOINT

Figure 3-8 Bolt and Nut

The bolt and nut shown in figure 3-8 can be thought of as a spring system, as shown in figure 3-

9. The bolt is viewed as a spring in tension with stiffness k

b

. The joint, with a number of

members being joined, is viewed as a compressive spring with stiffness k

j

.

Figure 3-9 bolt-and-nut assembly modeled as bolt-and-joint spring

Bolt stiffness

A bolt with tread is considered as a stepped shaft. The root diameter is used for the threaded

section of the bolt, and the crest diameter is used for the unthreaded section, called the shank.

JJ513 Engineering Design Design of Mechanical Joint

10

Figure 3-10 Bolt and nut. (a) Assembled; (b) stepped-shaft representation of shank and

treaded section.

Figure 3-10(a) shows a bolt-and-nut assembly and figure 3-10(b), the stepped-shaft

representation of the shank and the threaded section. In figure 3-10(b) the effective length of

the shaft and the threaded section includes additional lengths extending into the bolt head and

nut. Making use of equation:

)

Where d

c

= crest diameter, m

d

r

= root diameter,m

Joint stiffness

Determining joint stiffness is much more complicated than determining bolt stiffness. Thus, an

approximation is that the stress included in the joint is uniform throughout a region surrounding

the bolt hole with zero stress outside this region. Figure 3-11 shows the conical frustum stress

representation of the joint in a bolt-and-nut assembly.

a) b)

JJ513 Engineering Design Design of Mechanical Joint

11

Figure 3-11 Bolt-and-nut assembly with conical frustum stress representation of joint

In calculating stiffness, always use the smallest of frustum cone diameters. For the member

closet to the bolt head or to the nut, d

i

= d

w

= 1.5d

c

.

(a) Joint Stiffness for same material.

The expression for joint stiffness is

Where A

i,

B

i

= numerical constants given in table 3-1 below:

Table 3-1 Constants used in joint stiffness formula

Material Modulus of

elasticity,

E(GPa)

Numerical constant

A

i

B

i

Steel 206.8 0.78715 0.62873

Aluminum 71.0 0.79670 0.63816

Copper 118.6 0.79568 0.63553

Gray cast iron 100.0 0.77871 0.61616

JJ513 Engineering Design Design of Mechanical Joint

12

(b) Joint stiffness for different materials

The equation is

]

Where;

L

i

= axial length of the frustum cone

d

i

= frustum cone diameter; d

i

= 1.5d

c

The resulting joint stiffness is

Once the joint and bolt stiffnesses are known, the dimensionless stiffness parameter can be

calculated from equation

Strength

The proof load of a bolt is the maximum load that a bolt can withstand without acquiring a

permanent set. The proof strength is the limiting value of the stress determined by using the

proof load and the tensile stress area. Although proof strength and yield strength have

something in common, the yield strength is usually higher because it is based on a 0.2%

permanent deformation.

The proof strength S

p

, as defined by the Society of Automotive Engineers (SAE), the American

Society For Testing and Materials (ASTM), and International Organization for Standardization

(ISO) specifications, defines bolt grades or classes that specify material, heat treatment, and

minimum proof strength for the bolt or screw. Table 3-1 gives the strength information for

several metric grades. Metric grade numbers from 4.6 to 12.9, with higher numbers indicating

greater strength.

JJ513 Engineering Design Design of Mechanical Joint

13

Table 3-2 strength of steel bolts for various sizes in millimeters

Table 3-2 gives the dimensions and the tensile stress areas for M coarse and fine threads.

Table 3-3 Dimensions and tensile stress areas for M coarse and fine threads.

JJ513 Engineering Design Design of Mechanical Joint

14

Bolt Preload-static loading

The bolt failure safety factor

(3.9)

Where A

t

= tensile stress area given by table 3-2

P

i

= preload, N

P

max,b

= maximum load applied to bolt, N

C

k

= dimensionless stiffness parameter

Figure 3-12 Separation

Equation 3.9 suggests that the safety factor is maximized by having zero preload on the bolt. For

statiscally loaded bolts where separation is not a concern, this certainly true. However, a preload

is often applied to bolted connections to make certain that members are tightly joined in order

to minimize tolerances and provide tight fits. Further, many applications require members to

avoid separation as shown in figure 3-12. Thus, the safety factor guarding against separation is

(3.10)

Where P

max,j

= maximum load applied to joint, N.

The amount of preload that is in practice applied to bolts under static conditions is therefore a

compromise between bolt overloading (where zero preload is most beneficial) and separation

(where a larger preload is desirable). The preload is given for reused and permanent connections

as

} (3.11)

Where P

p

= proof load, S

p

A

t

.

for reused connection

for permanent connections

JJ513 Engineering Design Design of Mechanical Joint

15

Example problem 3-2

Figure 3-13. (a) Hexagonal bolt-and-nut assembly and dimensions. (b) Dimension of frustum

cone. (All dimensions are in millimeters)

Given:

A hexagonal bolt-and-nut assembly, shown in figure 3-12 is used to join two members. The bolt

and the nut are made of steel, and the frustum cone angle is 30. The thread crest diameter is 14

mm, and the root diameter is 12 mm.

Find:

1. Find the bolt and joint stiffnesses as well as the dimensionless stiffness parameter. Use

the modulus of elasticity and Poissons ratio from table 3-1, and consider the cases

where

a. Both members are made of steel.

b. The 15 mm thick member is made of steel, and the 10 mm thick member made of

aluminum.

2. Determine the maximum load for bolt-and-nut joint failure while assuming reused

connections and a static safety factor of 2. Assume a 5.8 grade and coarse threads.

Solution:

1. The bolt stiffness

)

JJ513 Engineering Design Design of Mechanical Joint

16

a) Steel joint.

) (

)

241 GN/m

The dimensionless stiffness parameter gives

b) Steel-aluminum joint

As shown in figure 3-12, the members have to consider as 3 frusta. The member

stiffnesses are:

For the 1

st

frusta,

We know that the material is steel; from table 3-1, we know E = 206.8 GPa and

{

[ ]

[ ]

}

d

1

1

st

frusta

10

25

12.5

2

nd

frusta

3

rd

frusta

JJ513 Engineering Design Design of Mechanical Joint

17

For the 2

nd

frusta,

We need to obtain the d

2

first as shown in figure below

Thus, d

2

= 21 + 2(5.77) = 32.54

{

[ ]

[ ]

}

For the 3

rd

frusta,

We know that the material is aluminum; E= 71 GPa and the d

3

= d

1

= 21.

{

[ ]

[ ]

}

2.620 GN/m

Thus,

The dimensionless parameter for steel-aluminum joint is

10

x

30

21

d

2

JJ513 Engineering Design Design of Mechanical Joint

18

2. From table 3-1 for 5.8 grade, S

P

= 380 MPa; and from the table 3-3 for crest diameter of

14 mm and coarse threads, A

t

= (84.3 + 157)/2 = 120.7 mm

2

. For reused connections,

The maximum load that the bolt can carry while assuming a safety factor of 2 is

The maximum load before separation occurs is

Thus, failure due to separation will occur before bolt failure.

JJ513 Engineering Design Design of Mechanical Joint

19

3-3 THE WELDED JOINTS DESIGN

The welding is a process of joining together two or more metal parts. It is done by heating the

surfaces, to be connected, to a high temperature and then adding additional molten metal,

which fuses with and combines the two surfaces. The molten or fused metal is deposited

between the parent metal parts, which are also fused metal gets cooled; the parent metal parts

are joined by this new metal.

Some advantages of welded joints over threaded fasteners are that they are inexpensive and

there is no danger of joint loosening. The welding allows the arrangement of the structure

components, in such a way, the joint provides maximum efficiency but it is possible in case of

bolted joints. Additions and alterations can be easily made in the existing structures. In welded

connections, the tension members are not weakened as in the case of bolted joint. A welded

joint has a great strength. Sometimes, the members are of such a shape that they afford

difficulty for riveting. But they can easily weld. The welding provides very rigid joints. It is

possible to weld any part of structure at any point. But bolting requires enough clearance. The

process of welding takes less time than the bolting. No need to drilling and measuring.

Some disadvantages of welded joints over threaded fasteners are that they produce residual

stresses; they distort the shape of the member, metallurgical changes occur, and disassembly is

a problem. As there is an uneven heating and cooling, during the fabrication, therefore the

members may get distorted or additional stresses may develop. It requires a highly skilled labor

and supervision. As the welded joints are rigid joints, therefore they have to be treated as such

in their design. The inspection of welding work is more difficult than bolting work.

There are many configurations of welds and manufacturing process for producing them. Figure

3-12 shows the standard symbols for welds, indicating that weld joints offer considerable design

flexibility. Although welded joints are available in a wide variety of forms, only the fillet weld is

considered here.

JJ513 Engineering Design Design of Mechanical Joint

20

Figure 3-14 Basic weld symbols

A fillet weld, shown in figure 3-13 , is made with equal legs. The thinnest section is then at the

throat of the weld, at 45 from the legs. The governing stress in fillet welds is shear on the throat

of the weld, as show in figure 3-13. Observe from this figure that in the fillet weld aligned

parallel to the load, the shear stress occurs along the throat of the fillet parallel to the load. In a

fillet weld aligned transverse to the load; the shear stress occurs at 45 to the load, acting

transverse to the axis of the fillet.

JJ513 Engineering Design Design of Mechanical Joint

21

Figure 3-15 Fillet weld. (a) Cross section of weld showing throat and legs; (b) shear planes.

Static Axial and Direct shear loading

Total weld throat area is

Where h

e

= weld leg length, m

= weld length, m

Welding-distortion or deformation or warping of weldments during welding is a natural outcome

of intrinsic non uniform heating and cooling of the joint. The distortion energy theory says that

failure occurs due to distortion of a part. Distortion energy theory is

JJ513 Engineering Design Design of Mechanical Joint

22

Where

= Yield Strength of the material part.

Eccentric static load, F is

Where

= safety factor

Example problem 3-2

Weld joints subjected to static axial and direct shear loading. Estimate the static strength of a

parallel loaded fillet weld. The plates in figure below are 12 mm thick and made of steel having

yield strength, S

Y

350 MPa. They are welded together by convex fillet welds along sides AB and

CD, each of which is 50 mm long. With a safety factor of 3, what static load, F can be carried

using a 6 mm weld leg?

Analysis

Total weld throat area is

A B

C

D

l =50 mm

JJ513 Engineering Design Design of Mechanical Joint

23

Distortion energy theory is

Thus, the eccentric static load is

JJ513 Engineering Design Design of Mechanical Joint

24

APPENDIX

TABLE A.1: Properties of ferrous metals

TABLE A.2: Properties of non-ferrous metals

JJ513 Engineering Design Design of Mechanical Joint

25

REFERENCES

Anon. (2010, februari 7). Parallel Keys Flat Keys Machine Keys Shaft Keys Sizes and Prices.

Retrieved may 30, 2012, from CTS Enterprises Ltd (Machine Key Manufacturer) web site:

http://www.machinekey.org/parallel-keys-machine-keys/

Bernard J.Hamrock, S. R. (2005). fundamentals of machine elements 2nd edition. kuala lumpur:

The McGraw Hill Companies.

KHURMI, R. S. (2007). Strength of Materials. new delhi: S. Chand & Co.

Krok, P. (2006, march). wikepedia foundation inc. Retrieved june 18, 2012, from wikepedia wed

site: http://eo.wikipedia.org/wiki/Dosiero:Bolt-with-nut.jpg

Mott, r. L. (2004). Machine Elements in Mechanical Design 4th Edition. New Jersey: Pearson

prentice hall.

Robert C. Juvinall, K. M. (2000). Fundamentals of Machine Component Design 3rd Edition. new

york: John Wiley & Sons, Inc.

Você também pode gostar

- Manual of Engineering Drawing: British and International StandardsNo EverandManual of Engineering Drawing: British and International StandardsNota: 3.5 de 5 estrelas3.5/5 (4)

- Nut & Bolt Connection DesignDocumento16 páginasNut & Bolt Connection DesignChandana KumaraAinda não há avaliações

- Chapter 6 ConnectionDocumento30 páginasChapter 6 ConnectionIvy SeahAinda não há avaliações

- Corri DurDocumento2 páginasCorri DurStuartAinda não há avaliações

- Anchor Bolts Design of Headed Anchor BoltsDocumento12 páginasAnchor Bolts Design of Headed Anchor BoltsDoug LambAinda não há avaliações

- JDM H4: Specification For O-Ring Materials and PropertiesDocumento30 páginasJDM H4: Specification For O-Ring Materials and PropertiesVikash SharmaAinda não há avaliações

- Bar Bending Schedule For Pile Foundation With CalculationsDocumento5 páginasBar Bending Schedule For Pile Foundation With Calculationsvenkateswara rao pothinaAinda não há avaliações

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNo EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsAinda não há avaliações

- Screw Jack DesignDocumento13 páginasScrew Jack DesignIbrahimovic Elsaied78% (9)

- Chap8 RivetsDocumento51 páginasChap8 RivetsManoj ManoharanAinda não há avaliações

- Chapter 3 - Design of Mechanical JointDocumento26 páginasChapter 3 - Design of Mechanical JointRaj KeeranAinda não há avaliações

- Testing and Inspection of Welding CourseDocumento186 páginasTesting and Inspection of Welding CourseWahyu Tirta Nugraha100% (1)

- Reinforced Concrete Design - Review Exam 1 - 2014Documento7 páginasReinforced Concrete Design - Review Exam 1 - 2014Jenesis de GuzmanAinda não há avaliações

- ME 6301 Engineering Thermodynamics NotesDocumento39 páginasME 6301 Engineering Thermodynamics NotesamdevaAinda não há avaliações

- Aluminum DesignDocumento8 páginasAluminum Designxhq08100% (1)

- Introduction to Impact Dynamics ModelingDocumento202 páginasIntroduction to Impact Dynamics ModelingFABIAN FIENGOAinda não há avaliações

- Bracing Design To Eurocode 3Documento13 páginasBracing Design To Eurocode 3Greg Rabulan100% (1)

- Guidlines For Displacement-Based Design of Buildings and BridgesDocumento231 páginasGuidlines For Displacement-Based Design of Buildings and Bridgespouyamh100% (2)

- Reinforced Concrete Buildings: Behavior and DesignNo EverandReinforced Concrete Buildings: Behavior and DesignNota: 5 de 5 estrelas5/5 (1)

- Chapter 8: Screws, Fasteners and The Design of Nonpermanent JointsDocumento27 páginasChapter 8: Screws, Fasteners and The Design of Nonpermanent JointsSandeep KumarAinda não há avaliações

- The Family Tree of Stainless SteelDocumento14 páginasThe Family Tree of Stainless Steelnike_y2kAinda não há avaliações

- Rreinforced Concrete-Beam DesignDocumento38 páginasRreinforced Concrete-Beam DesignMohamed AbdAinda não há avaliações

- Procedures For Rotational Capacity Testing of Galvanized ASTM A325 ..Documento14 páginasProcedures For Rotational Capacity Testing of Galvanized ASTM A325 ..Sayed Diab AlsayedAinda não há avaliações

- Lifting - Lug (Modification)Documento11 páginasLifting - Lug (Modification)Sam LowAinda não há avaliações

- Sutton - Electronic Structure of Materials PDFDocumento275 páginasSutton - Electronic Structure of Materials PDFHaroldMartinezAinda não há avaliações

- Design Aids For Tension Members As Per Revised Is: 800-2007Documento7 páginasDesign Aids For Tension Members As Per Revised Is: 800-2007dev_1989Ainda não há avaliações

- Keys and Keyways DesignDocumento5 páginasKeys and Keyways Designalexandre_motta_3Ainda não há avaliações

- Me331-Design of Machine Elements Unit Iii Design of Fasteners and JointsDocumento21 páginasMe331-Design of Machine Elements Unit Iii Design of Fasteners and JointsMuthuvel MAinda não há avaliações

- Cad & Component DrawingDocumento36 páginasCad & Component DrawingkousikkumaarAinda não há avaliações

- Course Activity Sample ReportDocumento10 páginasCourse Activity Sample ReporthimanshuAinda não há avaliações

- Types of Shafts Couplings Rigid CouplingsDocumento7 páginasTypes of Shafts Couplings Rigid CouplingsOkay 123Ainda não há avaliações

- Design of the connecting rod dimensions and stressesDocumento11 páginasDesign of the connecting rod dimensions and stressesDeep DaveAinda não há avaliações

- Structural Properties of Bolted JointsDocumento5 páginasStructural Properties of Bolted JointsL095244Ainda não há avaliações

- Machine Shaft Coupling TypesDocumento30 páginasMachine Shaft Coupling TypesKrishna VamsiAinda não há avaliações

- Design of CouplingsDocumento10 páginasDesign of CouplingsvrajendraupadhyayAinda não há avaliações

- Steel Structures Fasteners GuideDocumento34 páginasSteel Structures Fasteners GuideEmreAinda não há avaliações

- Pin Connections and Failure of Bolted JointsDocumento3 páginasPin Connections and Failure of Bolted JointsAvish GunnuckAinda não há avaliações

- Lecture 4Documento27 páginasLecture 4nofal AdreesAinda não há avaliações

- SYS Bolt ManualDocumento64 páginasSYS Bolt ManualNoppolNorasriAinda não há avaliações

- Unit 1Documento30 páginasUnit 1balachandran143Ainda não há avaliações

- Belt AnalysisDocumento4 páginasBelt AnalysisMaheswaran MuthaiyanAinda não há avaliações

- KeysDocumento26 páginasKeysMontu Chintu100% (1)

- RC Beam Design ACI 318m-11 ManualDocumento9 páginasRC Beam Design ACI 318m-11 ManualPitolwala ZuzarAinda não há avaliações

- Design and Fabrication of Toggle JackDocumento30 páginasDesign and Fabrication of Toggle JackJitendra Rout0% (1)

- Bolt Pressure DistributionDocumento24 páginasBolt Pressure DistributionbitconceptsAinda não há avaliações

- Equipment Design Chapter 3Documento30 páginasEquipment Design Chapter 3Miguel Magat JovesAinda não há avaliações

- Sp208-04ex 6Documento22 páginasSp208-04ex 6Žarko LazićAinda não há avaliações

- Design of Shaft Keys and CouplingsDocumento57 páginasDesign of Shaft Keys and CouplingsKelvin Kindice MapurisaAinda não há avaliações

- Welding - Group G - Welding-02Documento27 páginasWelding - Group G - Welding-02christofer kevinAinda não há avaliações

- Me-331 Design of Machine Elements Unit Iv Design of Basic ElementsDocumento25 páginasMe-331 Design of Machine Elements Unit Iv Design of Basic ElementsMuthuvel MAinda não há avaliações

- Example 6: Prestressed Beam: Adolfo Matamoros Julio RamirezDocumento19 páginasExample 6: Prestressed Beam: Adolfo Matamoros Julio RamirezTùng HìAinda não há avaliações

- Tutorial 1Documento4 páginasTutorial 1Noel NaborAinda não há avaliações

- 5 Strength AnalysisDocumento63 páginas5 Strength Analysisdan20000Ainda não há avaliações

- Key Assemblings Guide TransmissionDocumento22 páginasKey Assemblings Guide TransmissionGabriel IulianAinda não há avaliações

- Unit 3 Screw Threads, Nuts and Bolts: StructureDocumento24 páginasUnit 3 Screw Threads, Nuts and Bolts: StructuremanchiprasadAinda não há avaliações

- Akshat DmeDocumento38 páginasAkshat DmekartikeyAinda não há avaliações

- Chapter Two, Tension Members PDFDocumento10 páginasChapter Two, Tension Members PDFZeleke TaimuAinda não há avaliações

- MECH3403 Assignment 1 Report FINALDocumento16 páginasMECH3403 Assignment 1 Report FINALCong Thanh LeAinda não há avaliações

- 2 ShaftsDocumento24 páginas2 Shaftsrdksj100% (1)

- Modeling Repaired Composite StructuresDocumento14 páginasModeling Repaired Composite StructuresVicky VigneshAinda não há avaliações

- Chapter 2-Coupling and ClutchesDocumento40 páginasChapter 2-Coupling and Clutcheskibromgidey12Ainda não há avaliações

- DCDocumento24 páginasDCnandhakumarmeAinda não há avaliações

- Key and Coupling 2Documento13 páginasKey and Coupling 2Anantha BhatAinda não há avaliações

- Boundy Screw ThreadsDocumento4 páginasBoundy Screw ThreadsMohammed ImranAinda não há avaliações

- Mace 60035Documento7 páginasMace 60035eng_ayman_H_MAinda não há avaliações

- Bajet PTPTNDocumento5 páginasBajet PTPTNFadhiran YahyaAinda não há avaliações

- Bearing Types, Selection and Design LifeDocumento12 páginasBearing Types, Selection and Design LifeFadhiran Yahya0% (1)

- Chapter 1Documento12 páginasChapter 1Fadhiran YahyaAinda não há avaliações

- Chapter 2Documento9 páginasChapter 2Fadhiran YahyaAinda não há avaliações

- Bajet PTPTNDocumento5 páginasBajet PTPTNFadhiran YahyaAinda não há avaliações

- MIG Welder SOP GuideDocumento1 páginaMIG Welder SOP GuideFadhiran YahyaAinda não há avaliações

- Assalamualaikum and Good AfternoonDocumento1 páginaAssalamualaikum and Good AfternoonFadhiran YahyaAinda não há avaliações

- 6 Principle of Material HandlingDocumento1 página6 Principle of Material HandlingFadhiran YahyaAinda não há avaliações

- Projek LawatanDocumento5 páginasProjek LawatanFadhiran YahyaAinda não há avaliações

- 10 1016@j Polymertesting 2015 11 004 PDFDocumento7 páginas10 1016@j Polymertesting 2015 11 004 PDFmaryeonee12Ainda não há avaliações

- Tensile Testing of Metals Proficiency Testing Program Round 4Documento39 páginasTensile Testing of Metals Proficiency Testing Program Round 4Pinku MaitiAinda não há avaliações

- Design Seta (Latest)Documento13 páginasDesign Seta (Latest)steven bianesAinda não há avaliações

- AMTL Test Charges UPDATEDDocumento9 páginasAMTL Test Charges UPDATEDkartikAinda não há avaliações

- Advanced Structural AnalysisDocumento9 páginasAdvanced Structural AnalysisYeswanth RaghavendraAinda não há avaliações

- 4-Optical Properties of Materials-Dielectrics and MetalsDocumento36 páginas4-Optical Properties of Materials-Dielectrics and MetalsvenkateshsanthiAinda não há avaliações

- A Case Study On The Behaviour of A Deep Excavation in SandDocumento11 páginasA Case Study On The Behaviour of A Deep Excavation in SandshrikanttekadeyahoocAinda não há avaliações

- ULTRADUR B4300G6 (03p023)Documento3 páginasULTRADUR B4300G6 (03p023)ayala castroAinda não há avaliações

- Macromechanical Analysis of a Lamina Exercise SetDocumento12 páginasMacromechanical Analysis of a Lamina Exercise SetAnonymous hWj4HKIDOFAinda não há avaliações

- Ae8511 Aircraft Structures LaboratoryDocumento2 páginasAe8511 Aircraft Structures Laboratorykarthipriya100% (2)

- Shear FrictionDocumento11 páginasShear FrictionMohamed Ismail ShehabAinda não há avaliações

- Spin Electronic DevicesDocumento8 páginasSpin Electronic DevicesAmal RejiAinda não há avaliações

- Collapse Resistance of CasingDocumento50 páginasCollapse Resistance of CasingIslam FawzyAinda não há avaliações

- Monel Alloy 400 PropertiesDocumento16 páginasMonel Alloy 400 PropertiesVelibor StokicAinda não há avaliações

- Apl Iit DelhiDocumento1.215 páginasApl Iit DelhiManral SaurabhAinda não há avaliações

- Ballistic Performance of Unidirectional Glass Fiber Laminated Composite Plate Under Normal and Oblique ImpactDocumento8 páginasBallistic Performance of Unidirectional Glass Fiber Laminated Composite Plate Under Normal and Oblique ImpactVeeturiVarunAinda não há avaliações

- Makrolon 6487 Stress-Strain Data and CurveDocumento3 páginasMakrolon 6487 Stress-Strain Data and Curvekrishnakant gargAinda não há avaliações

- Metode PengujianDocumento17 páginasMetode Pengujianabraham samadAinda não há avaliações