Escolar Documentos

Profissional Documentos

Cultura Documentos

Seiko ColorPainter 64s High Volume User Maintenance

Enviado por

Miriam Guadalupe Sánchez Gramillo100%(1)100% acharam este documento útil (1 voto)

941 visualizações4 páginasDaily maintenance procedures should be performed in the order listed. They should be performed twice daily, once at beginning of the production day and then at 10 hour mark.

Descrição original:

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDaily maintenance procedures should be performed in the order listed. They should be performed twice daily, once at beginning of the production day and then at 10 hour mark.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

100%(1)100% acharam este documento útil (1 voto)

941 visualizações4 páginasSeiko ColorPainter 64s High Volume User Maintenance

Enviado por

Miriam Guadalupe Sánchez GramilloDaily maintenance procedures should be performed in the order listed. They should be performed twice daily, once at beginning of the production day and then at 10 hour mark.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 4

Technical Services

Ver. 2.0 - 07/22/10

Seiko ColorPainter 64s/100s

High Volume User Maintenance

WF

High Production Maintenance

Note: For print shops with 10-24 production

schedules. All cleaning to be done using the fush

that corresponds to the Triangle ink set being used,

either HPS or SCP.

Daily Maintenance

These maintenance procedures should be

performed in the order listed. They should be

performed twice daily, once at beginning of the

production day and then at 10 hour mark.

Step 1: Wiper Blade Cleaning

Take printer ofine, press Shift key once, press

the key to enter into the Service Menu, scroll

to wiper cleaning and press ENTER, confrm the

wiper cleaning procedure by pressing the ENTER

key.

Wiper blade will come up for cleaning and then

open the rear cover and the wiper door.

Using a foam tip swab dipped in Flush make

sure there is no dried ink on the wiper blades by

rubbing the front and back of the wiper blade

and make sure the wiper blades are in good

condition. Replace if necessary.

Step 2: Moistening Wiper Sponge

The wiper sponge has to always be moist with

fush so that the wiper blades can correctly clean

the print head. If sponge is dry apply 10-12 drops of

fush to the sponge. Make sure to apply fush only

on sponge and not on other areas of the printer

such as the belts.

Once the cleaning and moistening are complete

close the rear cover and wiper door.

Step 3: Capping Unit Cleaning

Take printer ofine, press Shift key once, press

the key to enter into the Service Menu, scroll

to cap cleaning and press ENTER, confrm the cap

cleaning procedure by pressing the ENTER key.

Print head carriage will move to other side of

printer giving access to capping station. Using

a foam tip swab dipped in Flush and make sure

there is no dried ink on the caps by cleaning the

edges and upper surfaces of all six caps.

Using a lint free cloth moistened with Flush clean

the metal plate surrounding the caps as well.

Once both cleanings are complete close the rear

cover and cap door.

Step 4: Waste Ink Disposal

The ink waste bottle should be checked once daily

and disposed of as industrial waste in compliance

with local and state law.

Step 5: Print Head Recovery

Once the wiper and capping cleaning are

completed, and the waste tank is emptied, perform

NORMAL cleaning

Take printer ofine, press Shift key once, press

the key to enter into CLEANING option. Press

ENTER one time to perform NORMAL cleaning.

This will take several minutes.

Step 6: Test Print

This test print can be used to check the fring

quality of the print heads, to identify any problems

such as banding, and to isolate the root cause and

color of the problem.

Technical Services

Ver. 2.0 - 07/22/10

Seiko ColorPainter 64s/100s High Volume User Maintenance

Technical Services

Take printer ofine, press Shift key twice, press

the key to enter into the Adjust Menu. The

frst option is ADJUST PATTERN. Press ENTER,

Select TEST PRINT, press ENTER to confrm. The

Test Print can be canceled at any time by pressing

the Cancel key.

Step 7: If a problem is detected in one or several

colors

Perform a cleaning on STRONG.

To perform a cleaning, take the printer ofine,

press the Shift key once, press the key to

enter the CLEANING Menu, press the ENTER

key. Depending on the print heads that are not

functioning properly, select either STRONG ALL,

STRONG L (K, lm, lc), or STRONG R (Y, M, C) then

press the ENTER key to begin the cleaning.

Once STRONG cleaning is completed, perform

another Test Print. Take printer ofine, press

Shift key twice, press the key to enter into

the Adjust Menu, scroll to test prints and press

ENTER, scroll to Test Print and press the ENTER

key. Confrm Test Print by pressing the ENTER key.

Step 8: If a problem is still detected in one or

several colors perform a FIll Cap

The Users Guide recommends running this

procedure for one to two hours.

To perform a FILL CAP take printer ofine, press

Shift key once, press the key to enter into the

Service Menu, scroll to FILL CAP and press ENTER

to confrm

The process prepares for a fll cap with the

principle behind this procedure being to soak

the print heads in ink. Once the print heads are

resting in the caps in ink, the printer does not

actively engage in any function until you give it

its next instruction.

Begin timing (one to two hours) at this time.

When the time is up, perform a NORMAL

CLEANING (Step 5)

When that is completed, perform another Test

Print (Step 6)

NOTE: If a problem is detected across all colors

in the same area on each color, perform a Media

Advance adjustment. Prease refer to the Users

Guide for the check F. ADJ procedure.

If a problem is still detected in one or several

colors, contact your Triangle dealer for

technical support.

Technical Services

Technical Services

Ver. 2.0 - 07/22/10

Seiko ColorPainter 64s/100s High Volume User Maintenance

WF

Weekly Maintenance

Print Head-Cap Nozzle Wash

Perform this procedure weekly at end of

production week for 30 minutes.

Begin by removing the lower side right cover by

removing the (2) screws.

Open the capping door cover and then remove

the (4) screws that secure the lower Capping

Cover to the printer.

Access the belt stem to manually lower and raise

the capping station.

Once capping station has been lowered, manually

move the print head carriage to the side to gain

access to the capping station.

Fill each cap with Flush, then position print head

carriage correctly over the caps ensuring that

each print head is in the center of the caps.

Let sit for 30 minutes.

For overnight nozzle washes, press and hold the

cancel and power button at the same time. This

will ensure that the printer will not engage the

pumps emptying the Flush.

Technical Services

Ver. 2.0 - 07/22/10

Seiko ColorPainter 64s/100s High Volume User Maintenance

WF

Quarterly Maintenance (every 3

months)

Replace the wiper station assembly. Please refer

to Users Guide for detailed instructions.

Você também pode gostar

- Custody Wash - MimakiDocumento12 páginasCustody Wash - MimakimehoAinda não há avaliações

- Mimaki JV3 Tips & TricksDocumento4 páginasMimaki JV3 Tips & TricksjjAinda não há avaliações

- Toshiba Tec Recovery Quick Guide S PDFDocumento2 páginasToshiba Tec Recovery Quick Guide S PDFAhmedAinda não há avaliações

- Requests For Care and Maintenance: Inkjet Printer CJV300-130/160, CJV300-130/160 PlusDocumento20 páginasRequests For Care and Maintenance: Inkjet Printer CJV300-130/160, CJV300-130/160 Plusjhonnatan lizarazoAinda não há avaliações

- MBISIII Maintenance ManualDocumento32 páginasMBISIII Maintenance ManualSerginho Santos100% (1)

- SB006 - Procedures For New Epson PrintheadsDocumento4 páginasSB006 - Procedures For New Epson PrintheadsЗрада ПидарештовAinda não há avaliações

- Epson Dx4 Recovery Quick Guide 3Documento2 páginasEpson Dx4 Recovery Quick Guide 3Adnan WasimAinda não há avaliações

- JV 33160 Service ManualDocumento154 páginasJV 33160 Service ManualМихаил РуббаAinda não há avaliações

- Maintenence Manual BlizzardDocumento244 páginasMaintenence Manual Blizzardjosé_muñoz_53100% (1)

- Visual Communication BrochuresDocumento69 páginasVisual Communication Brochuresdavut KelesAinda não há avaliações

- Delcam PC RequirementsDocumento1 páginaDelcam PC RequirementsMico StanojevicAinda não há avaliações

- AXYZ Vision SystemDocumento27 páginasAXYZ Vision SystemPP100% (1)

- VersaUV White Gloss Guide PDFDocumento76 páginasVersaUV White Gloss Guide PDFJosé Alarcón PalomarAinda não há avaliações

- 721-06LT Operating Instructions/ManualDocumento48 páginas721-06LT Operating Instructions/ManualWhitaker Brothers100% (2)

- D202748-33 CJV300, CJV300Plus CareMainte eDocumento16 páginasD202748-33 CJV300, CJV300Plus CareMainte eMaulik ShahAinda não há avaliações

- USLED SignageProductsDocumento12 páginasUSLED SignageProductsmarkanmAinda não há avaliações

- Canon PricingDocumento14 páginasCanon PricingMark ReinhardtAinda não há avaliações

- En-6090 Detailed InstructionsDocumento36 páginasEn-6090 Detailed InstructionsmarcuAinda não há avaliações

- Seiko IP 6600 Plotter Service ManualDocumento361 páginasSeiko IP 6600 Plotter Service Manualwcualumni0% (1)

- Technical Service BulletinDocumento5 páginasTechnical Service BulletinRister ZinnAinda não há avaliações

- AP74700 Troubleshooting GuideDocumento94 páginasAP74700 Troubleshooting Guidegass2100% (2)

- AP-74260 SM Blizzard Rev1.0Documento244 páginasAP-74260 SM Blizzard Rev1.0Depapel Suministros de RotulaciónAinda não há avaliações

- Valuejet 1604 ServiceManualDocumento422 páginasValuejet 1604 ServiceManualIonel VanguAinda não há avaliações

- SM SX 52 Manual 2Documento20 páginasSM SX 52 Manual 2Ali HussnainAinda não há avaliações

- HD 42Documento11 páginasHD 42Resimasc GonzálezAinda não há avaliações

- Manual Mantenimiento VJ1604 MutohDocumento448 páginasManual Mantenimiento VJ1604 MutohjavierAinda não há avaliações

- Galaxy Series Machine Install Elevating Capping System InstructionDocumento10 páginasGalaxy Series Machine Install Elevating Capping System InstructiondarkenelAinda não há avaliações

- Digifold Operators Manual Issue 11Documento42 páginasDigifold Operators Manual Issue 11SARyan0% (1)

- Epson Stylus Pro 7890/9890: User'S GuideDocumento224 páginasEpson Stylus Pro 7890/9890: User'S GuideTayyab GillaniAinda não há avaliações

- WIT-Color Ultra 9000 High Definition Printer Operations ManualDocumento95 páginasWIT-Color Ultra 9000 High Definition Printer Operations ManualHerbert M. ZaycoAinda não há avaliações

- Error 171 New Head Connect For Jv300Documento2 páginasError 171 New Head Connect For Jv300MAinda não há avaliações

- SP 162 Cer Leaflet enDocumento4 páginasSP 162 Cer Leaflet enDelibash WholucyAinda não há avaliações

- PHD16 User's ManualDocumento25 páginasPHD16 User's ManualJhonatan J FloresAinda não há avaliações

- imagePRESS C700, C800, C750, C850 Series Preventative Maintenance GuideDocumento29 páginasimagePRESS C700, C800, C750, C850 Series Preventative Maintenance GuideAndres CotrinoAinda não há avaliações

- cq9303f SM PDFDocumento1.902 páginascq9303f SM PDFcesar salasAinda não há avaliações

- SG Series Printer/Cutters: Sales GuideDocumento24 páginasSG Series Printer/Cutters: Sales GuidelobarriospAinda não há avaliações

- Brochure-SinoColor SJ-1260E Eco Solvent PrinteDocumento2 páginasBrochure-SinoColor SJ-1260E Eco Solvent PrinteClaudio OliveroAinda não há avaliações

- Service Guide BookDocumento152 páginasService Guide BookSupport Biomed100% (1)

- Installing A Profile Into A ColorGate RIPDocumento2 páginasInstalling A Profile Into A ColorGate RIPmuktahansAinda não há avaliações

- HP Designjet T920 T1500 EPrinter and T2500 T3500 EMultifunction Service ManualDocumento477 páginasHP Designjet T920 T1500 EPrinter and T2500 T3500 EMultifunction Service ManualPhil Garbett100% (2)

- Cjv30 Maintenance v10Documento101 páginasCjv30 Maintenance v10Leor Santos75% (4)

- WIT-Color Ultra 9600 High Definition Printer User ManualDocumento62 páginasWIT-Color Ultra 9600 High Definition Printer User ManualHerbert M. ZaycoAinda não há avaliações

- Roland FJ52 Service ManualDocumento154 páginasRoland FJ52 Service ManualJason TiuAinda não há avaliações

- QJ 1825 Manual Ploter de ImpresionDocumento50 páginasQJ 1825 Manual Ploter de ImpresionFeRchiitoo VeNnegass0% (1)

- Processor-Grafmac-maintain - 32+45+53CDN - 20080923A-KSDocumento26 páginasProcessor-Grafmac-maintain - 32+45+53CDN - 20080923A-KSalejandro100% (1)

- pumaII PDFDocumento54 páginaspumaII PDFJuan Sanchez GutierraAinda não há avaliações

- HP LFP Signage and DisplayDocumento78 páginasHP LFP Signage and DisplayLeaf AsiaAinda não há avaliações

- Glow Sign Board ManufacturersDocumento1 páginaGlow Sign Board ManufacturersChineseMartLanguagesolutionsAinda não há avaliações

- Heidelberg Global Training For Print ProfessionalsDocumento6 páginasHeidelberg Global Training For Print ProfessionalsChenna VijayAinda não há avaliações

- Ngaranaing Saha Atuh UdinDocumento1 páginaNgaranaing Saha Atuh Udinadian herawanAinda não há avaliações

- ETINK UV DTF Printer User's ManualDocumento59 páginasETINK UV DTF Printer User's ManualVMLP OrMdo SecGenAinda não há avaliações

- Colorcalibrationtutorial 2008 v4 enDocumento21 páginasColorcalibrationtutorial 2008 v4 enpicolorjAinda não há avaliações

- KBA-Rapida 75 I Part EnglDocumento8 páginasKBA-Rapida 75 I Part EnglKBR Graphics CanadaAinda não há avaliações

- Puma II Users ManualDocumento54 páginasPuma II Users ManualDiana Arghir100% (1)

- 3-3D PrinterDocumento73 páginas3-3D PrinterNurhuda HayatiAinda não há avaliações

- Ink Absorber CanonDocumento3 páginasInk Absorber CanonNyoman At Premaswarupa100% (1)

- Z350+quick StartDocumento16 páginasZ350+quick Startxitta00Ainda não há avaliações

- 5-Instructions of Machine Maintenance A3 A3 Uv l1800Documento3 páginas5-Instructions of Machine Maintenance A3 A3 Uv l1800Madjid El ayariAinda não há avaliações

- UJF 3042 DailyMaintenance D202116 V15Documento20 páginasUJF 3042 DailyMaintenance D202116 V15Miguel DuranAinda não há avaliações

- K8+ Single Chip Keyer Manual: 3 To 5 VDCDocumento8 páginasK8+ Single Chip Keyer Manual: 3 To 5 VDCtito351Ainda não há avaliações

- PETRO TCS Engineering Manual 682Documento44 páginasPETRO TCS Engineering Manual 682paulm3565Ainda não há avaliações

- Section 12-22, Art. 3, 1987 Philippine ConstitutionDocumento3 páginasSection 12-22, Art. 3, 1987 Philippine ConstitutionKaren LabogAinda não há avaliações

- Kajian Sistematik: Strategi Pembelajaran Klinik Di Setting Rawat JalanDocumento5 páginasKajian Sistematik: Strategi Pembelajaran Klinik Di Setting Rawat JalanrhiesnaAinda não há avaliações

- Universal Marine: Welcome To Our One Stop Marine ServicesDocumento8 páginasUniversal Marine: Welcome To Our One Stop Marine Serviceshoangtruongson1111Ainda não há avaliações

- Partes Oki - MPS5501B - RSPL - Rev - HDocumento12 páginasPartes Oki - MPS5501B - RSPL - Rev - HJaiber Eduardo Gutierrez OrtizAinda não há avaliações

- OL2068LFDocumento9 páginasOL2068LFdieselroarmt875bAinda não há avaliações

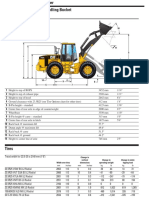

- DX225LCA DX340LCA Sales MaterialDocumento46 páginasDX225LCA DX340LCA Sales MaterialAntonio Carrion100% (9)

- Pac All CAF Subject Referral Tests 1Documento46 páginasPac All CAF Subject Referral Tests 1Shahid MahmudAinda não há avaliações

- Sinamics gm150 sm150 Catalog d12 02 2020 enDocumento238 páginasSinamics gm150 sm150 Catalog d12 02 2020 enGo andWatchAinda não há avaliações

- Mine Gases (Part 1)Documento15 páginasMine Gases (Part 1)Melford LapnawanAinda não há avaliações

- Security Enhancement in 2016 SQL ServerDocumento21 páginasSecurity Enhancement in 2016 SQL ServerAtul SharmaAinda não há avaliações

- National Action Plan Implementation Gaps and SuccessesDocumento8 páginasNational Action Plan Implementation Gaps and SuccessesHamza MinhasAinda não há avaliações

- Chapter 3: Classical Production Models: News Vendor ModelDocumento85 páginasChapter 3: Classical Production Models: News Vendor ModelmauriciovendraminAinda não há avaliações

- Shell Omala s2 GX 320 TdsDocumento2 páginasShell Omala s2 GX 320 TdsOnie Hammamz OylAinda não há avaliações

- Final Exam - Comprehensive - 10.24.16Documento5 páginasFinal Exam - Comprehensive - 10.24.16YamateAinda não há avaliações

- Pivacare Preventive-ServiceDocumento1 páginaPivacare Preventive-ServiceSadeq NeiroukhAinda não há avaliações

- 2B. Glicerina - USP-NF-FCC Glycerin Nutritional Statement USP GlycerinDocumento1 página2B. Glicerina - USP-NF-FCC Glycerin Nutritional Statement USP Glycerinchristian muñozAinda não há avaliações

- Details For Order #002 5434861 1225038: Not Yet ShippedDocumento1 páginaDetails For Order #002 5434861 1225038: Not Yet ShippedSarai NateraAinda não há avaliações

- RVT Liquid DistributorDocumento5 páginasRVT Liquid DistributorimeagorAinda não há avaliações

- Analisis Dan Perbandingan Jaringan Wifi Dengan Frekuensi 2.4 GHZ Dan 5 GHZ Dengan Metode QosDocumento19 páginasAnalisis Dan Perbandingan Jaringan Wifi Dengan Frekuensi 2.4 GHZ Dan 5 GHZ Dengan Metode QosNoltujuh Nollapan (Congyang)Ainda não há avaliações

- Cat It62hDocumento4 páginasCat It62hMarceloAinda não há avaliações

- Mysuru Royal Institute of Technology. Mandya: Question Bank-1Documento2 páginasMysuru Royal Institute of Technology. Mandya: Question Bank-1chaitragowda213_4732Ainda não há avaliações

- An Overview of The Geostatistical Analyst Toolbar and ToolboxDocumento1 páginaAn Overview of The Geostatistical Analyst Toolbar and ToolboxSumit SumanAinda não há avaliações

- LOVDocumento43 páginasLOVMei FadillahAinda não há avaliações

- Poverty Eradication Cluster HLPF Position Paper With Case StudiesDocumento4 páginasPoverty Eradication Cluster HLPF Position Paper With Case StudiesJohn Paul Demonteverde ElepAinda não há avaliações

- Allergies To Cross-Reactive Plant Proteins: Takeshi YagamiDocumento11 páginasAllergies To Cross-Reactive Plant Proteins: Takeshi YagamisoylahijadeunvampiroAinda não há avaliações

- Tesco 750 ESIDocumento2 páginasTesco 750 ESIjlmunozvAinda não há avaliações

- On Fracture MechanicsDocumento81 páginasOn Fracture MechanicsDEEPAK100% (1)