Escolar Documentos

Profissional Documentos

Cultura Documentos

Astam Super Check

Enviado por

musaismail8863Descrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Astam Super Check

Enviado por

musaismail8863Direitos autorais:

Formatos disponíveis

ASTAM SUPER CHECK

Design

The super check valve consists of two plates hinged on a

single pin. The load is carried by two plates supported at

the center by a single beam the the cylindrical valve body.

The curved portion of the plates are supported by a flat

shoulder in the valve body. The torsion spring actuates

the plates for positive closure before the reverse flow can

occure in most applications. The stop pin serves as a

positive stop to limit the plates from traveling more than

85 degrees. The design is as per API 594.

Features

The valve is short Face-to-Face, easy to install in a narrow space. Compact figure and

light weight compared with the conventional Swing Check Valve, and simple design is

in the true sense of easy to maintain due to small number of component part in

Astams valve.

The cylindrical shape body gives full scope to its ability for high pressure-temperature

piping in case of considering thermal contraction and expansion.

Astam Super Check Valve does not only protect the casing of the high-priced pump

and compressor against their piping load, but also reducing its piping work expense

compared with the other traditional valves.

Astam Super Check Valve prevents

from Water Hammer. Reaction of

torsion spring installed inner valve

makes plate rapidly close prior to

the start of revere flow of fluid due

to the stop of power, thus prevents

line, pump and other piping facilities

from the damage and trouble due to

the Water Hammer.

Metal-to-Metal seat is applied to the body of Ductile Iron, Cast steel,etc. And SS316

overlay, SS410 overlay, Monel overlay, Stellite #6 overlay are available and can be

specified to meet the fluid applications.

Call for more detail +886-3-3675805

or email to: sales@astam-valve.com

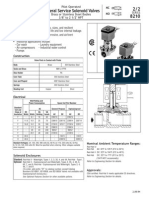

DesignAPI 594, API 6D

Dual-Plate Wafer Check Valve

TypeC1

Dual-Plate Wafer Check Valve for by-pass

TypeC2

Dual-Plate Double-Flanged Check Valve

TypeC3

Dual-Plate Full-Flange Check Valve

TypeC4

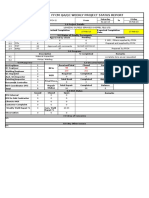

DESCRIPTION OF PART NUMBER

PLATE

BODY SEAT TORQUE

- / -

SIZE TYPE CONNECTION SPRING

RATING

Example: Dual-Plate Wafer Check Valve, ANSI 12"-150#, R.F End,

WCB BODY, CF8 PLATE, EPDM SEAT

S.S 316 SPRING LOW TORQUSE.

TYPE

SYMBOL DESIGNATION

C1 Dual-Plate Wafer Check Valve

C2 Dual-Plate Wafer Check Valve for by-pass

C3 Dual-Plate Double-Flanged Wafer Check Valve

C4 Dual-Plate Full-Flange Wafer Check Valve

RATING

ANSI A 125* 250* 150 300 400 600 900 1500 2500

J IS J 5 10* 16 10 20 30 40 63 100

ISO,BS S 10 16* 25 16 40 64 100 160 250 320

NOTE:""means only for CAST IRON Valve.

9 0 1 2 3 4 5 6 Standard 8 7 SYMBOL

12 C1 A3 R W S3 E S L

MATERIALS

BODY, PLATE End Connection

Flat Face

C A126 Class B G5501 FC250 F.F

D A536 65-45-12 G5502 FCD450 Raised Face

D1 A395 B8270 FCD-S R.F

Ring J oint

R.J

A216 Gr.WCB G5151 SCPH2

A352 Gr.LCB G5152 SCPL1

SEAT

S1 A217 Gr.CA15 G5121 SCS1

S3 A351 Gr.CF8 G5121 SCS13 N NBR(Buna-N) 0~80

S4 A351 Gr.CF8M G5121 SCS 14 C CR(Neoprene) -10~80

A351 Gr.CF3M G5121 SCS16 E EPDM(EPT) -10~100

F FPE(VITON-A) -30~150

O Matel to Matel

B B584 C83600 H5120 CAC406 S6 S.S. 316 Overlay -268~538

A B148 C95800 H5120 CAC703 S1 13%Cr. Overlay

6 Stellite 6# Overlay

Other materials are available upon request.

Spring Torqsue

SPRING

S S.S. 316 121

X INCONEL X-750 538

Dual-Plate Wafer Check Valves of FLOW COEFFICIENT:(CV Value)

40A 50A 65A 80A 100A 125A 150A 200A 250A 300A 350A

1-1/2" 2" 2-1/2" 3" 4" 5" 6" 8" 10" 12" 14"

CV 46 72 132 180 380 635 864 1650 3017 4280 5790

400A 450A 500A 550A 600A 650A 700A 750A 800A 850A 900A

16" 18" 20" 22" 24" 26" 28" 12" 14" 16" 18"

CV 7922 10642 13400 19500 23500 25000 30000 37200 45000 51000 59000

950A 1000A 1050A 1100A 1150A 1200A 1250A 1300A 1350A

20" 22" 24" 26" 28" 24" 26" 28" 24"

CV 70000 81000 90000 100000 116500 136100 139200 143500 154000

J IS

SYMBOL DESIGNATION TEMPERATURE

TYPE SYMBOL FINISH

63AARH

125~250 AARH

63AARH

DN

(NPS)

Liquid: Max. 90mAq,

Gas: Max.1kg/cm

2

Gas: Max. 1kgs/cm

2

Standard SYMBOL DESIGNATION TEMP. (MAX.)

L LOW

No Mark

F

DN

(NPS)

DN

(NPS)

Torque Type SYMBOL REMARKS

L

W

S6

R

J

SYMBOL ANSI

Você também pode gostar

- Final Upcat Mock ExamDocumento24 páginasFinal Upcat Mock Examjbgonzales8Ainda não há avaliações

- Control Choke Valve 9000Documento8 páginasControl Choke Valve 9000sabi_shi100% (2)

- 2500 Valve BrochureDocumento12 páginas2500 Valve BrochureJurie_sk3608Ainda não há avaliações

- 'C' Series Control ValvesDocumento12 páginas'C' Series Control Valvesابزار دقیق100% (1)

- GWC Valve International - Dual Plate Check ValvesDocumento20 páginasGWC Valve International - Dual Plate Check ValvesGWC Valve InternationalAinda não há avaliações

- Econ Gate ValvesDocumento22 páginasEcon Gate ValvesRiyas Udheen100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsAinda não há avaliações

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsNo EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsNota: 4.5 de 5 estrelas4.5/5 (10)

- 02 MechanicalDocumento44 páginas02 Mechanicalmusaismail8863Ainda não há avaliações

- AS 1100 Part 301 Architectural DrawingDocumento24 páginasAS 1100 Part 301 Architectural DrawingHao Much100% (2)

- SEVPL BrochureDocumento20 páginasSEVPL BrochureNaveen AnandAinda não há avaliações

- Session PlanDocumento11 páginasSession PlanMat Domdom Sansano100% (1)

- Is 15707 2006Documento23 páginasIs 15707 2006anupam789Ainda não há avaliações

- Comeval Cast Steel Gate Valve ANSI 150 PDFDocumento5 páginasComeval Cast Steel Gate Valve ANSI 150 PDFblizanacAinda não há avaliações

- Risks in Facility Build Quality and Project Handover: What Happened?Documento3 páginasRisks in Facility Build Quality and Project Handover: What Happened?musaismail8863Ainda não há avaliações

- Butterfly ValveDocumento20 páginasButterfly Valvenazar750Ainda não há avaliações

- TRIPLE OFFSET BUTTERFLY VALVE TX Literature PDFDocumento8 páginasTRIPLE OFFSET BUTTERFLY VALVE TX Literature PDFjdietz4Ainda não há avaliações

- Three Way ValvesDocumento8 páginasThree Way ValvesWalter JosephAinda não há avaliações

- AV-C Butterfly ValveDocumento20 páginasAV-C Butterfly ValveSopon SrirattanapiboonAinda não há avaliações

- Mitsubishi Electric Product OverviewDocumento116 páginasMitsubishi Electric Product OverviewPepes HiuuAinda não há avaliações

- Crane - Series.rs Center LineDocumento23 páginasCrane - Series.rs Center LinenedwestAinda não há avaliações

- Block & Bleed Valve: High Technology Valve & Fitting SeriesDocumento20 páginasBlock & Bleed Valve: High Technology Valve & Fitting SeriesMayur PatelAinda não há avaliações

- HSCDocumento12 páginasHSCSuhas Natu100% (1)

- Forged Steel Valves PDFDocumento12 páginasForged Steel Valves PDFDiwakar NigamAinda não há avaliações

- Valves & ControlsDocumento16 páginasValves & ControlseborresonAinda não há avaliações

- Valves Reference PDFDocumento35 páginasValves Reference PDFJulio RodriguezAinda não há avaliações

- ASV 10 20 BrochureDocumento8 páginasASV 10 20 BrochureThomas Duane DavidsonAinda não há avaliações

- Check Valves With Tilting DiscDocumento2 páginasCheck Valves With Tilting DiscSamir RawalAinda não há avaliações

- Sewage Air ValveDocumento10 páginasSewage Air ValveAhmed TalaatAinda não há avaliações

- Technical Bulletin: Valtek Mark One Control ValvesDocumento20 páginasTechnical Bulletin: Valtek Mark One Control ValvesOscar CruzAinda não há avaliações

- KVC 01Documento35 páginasKVC 01hamidreza_m85Ainda não há avaliações

- Feed Water Heater - Isolation System: Features & BenefitsDocumento9 páginasFeed Water Heater - Isolation System: Features & BenefitsAkash PatilAinda não há avaliações

- Basic Type of Valves PDFDocumento2 páginasBasic Type of Valves PDFMohamed MustafaAinda não há avaliações

- Válvulas Bola SegmentadaDocumento12 páginasVálvulas Bola SegmentadarehynaldoAinda não há avaliações

- 100G - 2100G ClavalDocumento2 páginas100G - 2100G Clavale1901bAinda não há avaliações

- 11502Documento9 páginas11502balajivangaruAinda não há avaliações

- Full Lift Spring Loaded Open PDFDocumento4 páginasFull Lift Spring Loaded Open PDFVenkatespatange RaoAinda não há avaliações

- 125T Series: Cast Iron Triple Duty ValvesDocumento2 páginas125T Series: Cast Iron Triple Duty ValvesSharon LambertAinda não há avaliações

- Vctds-02233 Model 171c (Asme) - enDocumento12 páginasVctds-02233 Model 171c (Asme) - enDGWAinda não há avaliações

- Eko4000-4100 WebDocumento4 páginasEko4000-4100 WebSubramanian SaravananAinda não há avaliações

- CVC Steel Valvulas LunkenheimerDocumento28 páginasCVC Steel Valvulas LunkenheimerAlex WilmerAinda não há avaliações

- Valvula Reductora de Presion Bermad Area 675 720-ULDocumento4 páginasValvula Reductora de Presion Bermad Area 675 720-ULChristian FherAinda não há avaliações

- 61502Documento10 páginas61502balajivangaruAinda não há avaliações

- Ball Valves - Metal SeatedDocumento6 páginasBall Valves - Metal Seatedmetasoniko2014Ainda não há avaliações

- RedvalvE 90 01Documento4 páginasRedvalvE 90 01Rizal FalevyAinda não há avaliações

- Pressure Releif ValveDocumento24 páginasPressure Releif Valvemtalha_loveAinda não há avaliações

- MasterSeries 850 Specification SheetDocumento2 páginasMasterSeries 850 Specification SheetFEBCOAinda não há avaliações

- rc18011 f09Documento7 páginasrc18011 f09Trayo AyangbayiAinda não há avaliações

- 61502YDocumento9 páginas61502YbalajivangaruAinda não há avaliações

- rc33026 D12-UscDocumento7 páginasrc33026 D12-Usceww08Ainda não há avaliações

- Valve Spirax Sarco 25P Ti-3-015-UsDocumento2 páginasValve Spirax Sarco 25P Ti-3-015-Ussugesus100% (2)

- Bimetallic Steam TrapsDocumento2 páginasBimetallic Steam Trapsasad_naqviAinda não há avaliações

- MPVN BrochureDocumento32 páginasMPVN Brochurefernando_naciamentAinda não há avaliações

- Manual Spirax SarcoDocumento2 páginasManual Spirax SarcoAlex CarreraAinda não há avaliações

- GLT Ball Valve FLoatingDocumento12 páginasGLT Ball Valve FLoatingKIMAinda não há avaliações

- OIL GAS Plug ValvesDocumento6 páginasOIL GAS Plug ValvesMabeli MartinezAinda não há avaliações

- Virgo Welded Valve BrochureDocumento8 páginasVirgo Welded Valve BrochureHerrera Jorge AgustínAinda não há avaliações

- E4Documento14 páginasE4juanca_eduAinda não há avaliações

- Valve Cast Steel Gate Globe PDFDocumento58 páginasValve Cast Steel Gate Globe PDFjua666nAinda não há avaliações

- AUTOMAX Supernova BrochureDocumento12 páginasAUTOMAX Supernova BrochureEnrique Domingo RubioAinda não há avaliações

- 11422Documento10 páginas11422balajivangaruAinda não há avaliações

- SELENOIDE-Valv Solen 8210Documento6 páginasSELENOIDE-Valv Solen 8210MARACO46Ainda não há avaliações

- Ep31492 PDFDocumento11 páginasEp31492 PDFJilJilAinda não há avaliações

- Simple Plumbing Repairs for the Home and FarmsteadNo EverandSimple Plumbing Repairs for the Home and FarmsteadAinda não há avaliações

- FFCM-MSI QAQC Weekly Project Status Report (07.02. 15-13 02 15)Documento1 páginaFFCM-MSI QAQC Weekly Project Status Report (07.02. 15-13 02 15)musaismail8863100% (1)

- Material Specification Sheet Saarstahl - C40E (Ck40)Documento2 páginasMaterial Specification Sheet Saarstahl - C40E (Ck40)musaismail8863Ainda não há avaliações

- MDR NDT Drawing Tembikai As of 08.11.2014Documento1 páginaMDR NDT Drawing Tembikai As of 08.11.2014musaismail8863100% (1)

- Abs Guide Rules For Fpso ConversionDocumento1 páginaAbs Guide Rules For Fpso Conversionmusaismail8863Ainda não há avaliações

- 16 - Metal and SpecialtyDocumento12 páginas16 - Metal and Specialtymusaismail8863Ainda não há avaliações

- 232 50Documento2 páginas232 50musaismail8863Ainda não há avaliações

- Instruction Manual - Dial Thickness Gauge Kit How Replica Tape WorksDocumento6 páginasInstruction Manual - Dial Thickness Gauge Kit How Replica Tape Worksmusaismail8863Ainda não há avaliações

- Apartment Harga SederhanaDocumento3 páginasApartment Harga Sederhanamusaismail8863Ainda não há avaliações

- MC9S12XD128 ProcessadorDocumento1.350 páginasMC9S12XD128 ProcessadorMarcelo OemAinda não há avaliações

- DRM Transmitter PresentationDocumento22 páginasDRM Transmitter PresentationJuan Jose PerezAinda não há avaliações

- Cinegy User ManualDocumento253 páginasCinegy User ManualNizamuddin KaziAinda não há avaliações

- 9C606C.64 To 65Documento24 páginas9C606C.64 To 65SHIRISHA YADAVAinda não há avaliações

- Bombas Pentax SADocumento48 páginasBombas Pentax SAAgustin CahuanaAinda não há avaliações

- APP157 CoP For Site Supervision 2009 202109Documento92 páginasAPP157 CoP For Site Supervision 2009 202109Alex LeungAinda não há avaliações

- Metric DIN 434 Square Taper Washers: Visit Our For Product AvailabilityDocumento4 páginasMetric DIN 434 Square Taper Washers: Visit Our For Product AvailabilityRodrigoAinda não há avaliações

- PB Hydro en PDFDocumento86 páginasPB Hydro en PDFWahyu Tirta NugrahaAinda não há avaliações

- Electrical SubstationsDocumento16 páginasElectrical SubstationsEngr Syed Numan ShahAinda não há avaliações

- University of Mumbai: Syllabus For Sem V & VI Program: B.Sc. Course: PhysicsDocumento18 páginasUniversity of Mumbai: Syllabus For Sem V & VI Program: B.Sc. Course: Physicsdbhansali57Ainda não há avaliações

- Rubber FaberDocumento10 páginasRubber FabersoldatechAinda não há avaliações

- Iso 9974-2Documento4 páginasIso 9974-2willianAinda não há avaliações

- Drive ConfigDocumento136 páginasDrive ConfigGiangDoAinda não há avaliações

- Interfacing Seven Segment Display With LPC1769Documento18 páginasInterfacing Seven Segment Display With LPC1769Gurudatta Palankar0% (1)

- Analysis of Metal Matrix Composite (MMC) Applied Armor System Analysis of Metal Matrix Composite (MMC) Applied Armor SystemDocumento8 páginasAnalysis of Metal Matrix Composite (MMC) Applied Armor System Analysis of Metal Matrix Composite (MMC) Applied Armor SystemDerianSyahAinda não há avaliações

- Use Case Diagram For Employee Management SystemDocumento60 páginasUse Case Diagram For Employee Management SystemAnant JaiswalAinda não há avaliações

- SECTION 1213, 1214, 1215: Report By: Elibado T. MaureenDocumento19 páginasSECTION 1213, 1214, 1215: Report By: Elibado T. MaureenJohnFred CativoAinda não há avaliações

- Exterity g44 Serie 1.2 ManualDocumento87 páginasExterity g44 Serie 1.2 Manualruslan20851Ainda não há avaliações

- REE Copy PDFDocumento9 páginasREE Copy PDFJake ZozobradoAinda não há avaliações

- RSA Code in JavaDocumento3 páginasRSA Code in Javadeepak00707Ainda não há avaliações

- April 2016Documento68 páginasApril 2016Treatment Plant Operator MagazineAinda não há avaliações

- CTLG MINI08engDocumento48 páginasCTLG MINI08enggadacz111Ainda não há avaliações

- By George G. Meyerhof, F. Asce: J. Geotech. Engrg., 1983, 109 (6) : 797-806Documento10 páginasBy George G. Meyerhof, F. Asce: J. Geotech. Engrg., 1983, 109 (6) : 797-806PoYing HuangAinda não há avaliações

- LN3 Geng2340Documento61 páginasLN3 Geng2340Seth VineetAinda não há avaliações

- QAP For Conical StrainerDocumento2 páginasQAP For Conical StrainersatishchidrewarAinda não há avaliações

- Astm D3350-10Documento7 páginasAstm D3350-10Jorge HuarcayaAinda não há avaliações