Escolar Documentos

Profissional Documentos

Cultura Documentos

Leno Positivo Groz

Enviado por

Miguel Morales ChDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Leno Positivo Groz

Enviado por

Miguel Morales ChDireitos autorais:

Formatos disponíveis

i nfo WEAVI NG 5

T E C HNI C AL I NF OR MAT I ON

Posi Leno

AND MORE

PRODUCTS FOR LENO WEAVING

Leno fabrics are used increasingly in technical applications, resulting in attractive

market potential. PosiLeno

the new simplified and flexible leno system makes

performance increases of more than 100 percent possible. Moreover, Groz-Beckert

offers further efficient products for everything related to leno weaving.

| i nfo | WE AV I NG 5

PAGE 2

Posi Leno

THE POSI TI VELY CONTROLLED LENO SYSTEM

I T MAKES LENO WEAVI NG DOUBLY WORTHWHI LE

PosiLeno

from Groz-Beckert

PosiLeno

is the innovative, flexible and

heald-based leno weaving system. Opti-

mized shed formation movements for

doup frame, heald frame and warp yarn

have successfully doubled output in

relation to conventional leno systems

and that's not all.

The positively controlled leno system is

applicable to all fabric constructions with

leno binding technical fabrics, domestic

textiles or clothing. The system is applicable

to both the upper/lower shed leno technique

and the upper shed leno technique with

fixed auxiliary frame.

The new leno assembly consists of two

lifting frames and one positively controlled

doup frame equipped with leno healds that

have been optimized in their design. Move-

ment of the lifting frames controlled by

either a dobby or a cam shedding motion

drives the positively controlled driving

element of the doup frame. By means of

pairs of specially designed driving levers

and articulated connections, lifting frame

movement generates an optimized move-

ment of the doup frame and leno healds.

Previous requirements for hardware for the

upper or lower connection of leno springs

and leno yokes are eliminated.

The patent for the positively controlled

leno system is pending.

Outstanding characteristics include:

100 % higher production speeds on

existing systems

Unlimited patterning possibilities

Full article-change flexibility retained

Standard fabrics can be produced on the

same weaving machine just as before

Simple way to start leno weaving

Can be used on modern machines

Reduced stress on heald frames and doup

frames despite higher rpm, due to opti-

mized shed formation movements.

Upper shed leno lifting frame

PosiLeno

controls are fixed

to the lower frame rod

Doup frame moves upward

| i nfo | WE AV I NG 5

PAGE 3

doup frame PosiLeno

doup frame, traditional system

COMPARISON OF ACCELERATIONS WITH

TRADITIONAL SYSTEM AND WITH POSILENO

.

Lower shed leno lifting frame

PosiLeno

controls are fixed

to the upper frame rod

Doup frame moves downward

-1.5

0.0

1.5

3.0

4.5

6.0

7.5

9.0

10.5

12.0

13.5

15.0

16.5

18.0

19.5

Time

F

o

r

c

e

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

| i nfo | WE AV I NG 5

PAGE 4

LENO WEAVI NG

Groz-Beckert Specialist and Partner for

Leno Weaving

With a unique wealth of experience, broad

specialist knowledge with regard to material

combinations, and designs and solutions

for virtually all conventional weaving ma-

chines, Groz-Beckert makes the difference.

Leno weaving harnesses from Groz-Beckert

offer the highest quality and a high level

of exibility that is unparalleled. This applies

to the diversity of bindings, the patterning

and, not least of all, to the selection of the

most varied warp yarns.

There are therefore no limits on creativity

in leno fabric production. Short changeover

times on existing weaving machines, at

relatively low and calculable prices, go

without saying.

Tried and tested assortment

The extensive portfolio of leno healds,

based on steel or on FER+SYN

plastic,

is still available for processing the most

diverse warp yarns. The same applies to

the corresponding heald frames.

Optimal design of the leno healds is guar-

anteed by sufficient distance between the

heads of the doup healds while the heald

frames remain the same.

The leno end is raised into the cross shed,

the standard end is lowered into the cross

shed.

Change from leno weave to plain weave:

the leno end is in the lower shed, the

standard end in the upper shed.

| i nfo | WE AV I NG 5

PAGE 5

NEGATI VELY CONTROLLED LENO WEAVI NG SYSTEM

THE I NTELLI GENT ALTERNATI VE FOR LENO WEAVI NG

Perfect components, complete solution

A complete leno heald consists of two lifting

frames and a doup frame. Suitable lifting

frames are the tried and tested GROBTEX

and GROBTRA

ALrefix

heald frames with

frame staves of light metal that are 84 mm,

96 mm or 120 mm in height according to

the heald frame length. Depending on the

type of weaving machine, the heald frames

are equipped with lateral supports made

from pressed wood or light metal, as well

as suitable driving connections. The design

with free-standing doup heald carrying rods

facili-tates visibility and accessibility during

set-up of the leno weaving harness.

The leno doup frame consists of two doup

heald carrrying rods measuring 9 mm x 1.5 mm.

They serve to guide the carrying rods that

control the doup healds. The rod ends are

kept together with wear-resistant endpieces.

Two or more leno yokes and leno springs

depending on the length of the leno heald

frame enable the doup frame to be pulled

down in upper shed leno. In lower shed leno

the doup frame is pulled up.

Heald frame lengths of more than 2,800mm

and three control positions per heald frame

guarantee the stability of the lifting frames,

with the aid of special intermediate supports.

These are fitted with an additional sliding

component, and their special shape pre-

vents any excessive friction between the

support and the doup frame. If required,

the intermediate supports can be easily

repositioned between the doup rods.

The advantages over rail guidance leno

systems:

Unlimited patterning possibilities

Full flexibility for article changes as well

as production of standard frame fabrics

on the same machine

| i nfo | WE AV I NG 5

F

B

E

A

C

D

2 1 3 4 2 1 3 4 2 1 GROB 1371 GROB 1372

mm mm mm mm mm mm Tt Nm Td NeB NeK

331 80 95 3 5 125 8 1100 5 7

GROBTEX

331 80 95 2 3 170 6 1500 4 5

GROBTRA

382 105 120 3 5 125 8 1100 5 7

382 105 120 2 3 170 6 1500 4 5

331 88 88 3 5 125 8 1100 5 7

GROBTRA

331 88 88 2 3 170 6 1500 4 5

PosiLeno

382 110 110 3 5 125 8 1100 5 7

382 110 110 2 3 170 6 1500 4 5

E

N

|

0

7

.

2

0

1

3

The depictions provided of our products are not to scale and are

intended for illustrative purposes only. Consequently they make

no claim to be an accurate representation of the original.

= Registered trademark of the Groz-Beckert company group.

= This publication is copyrighted. All rights reserved, in parti-

cular the right of duplication, distribution and translation. This

publication or any parts thereof may not be reproduced or stored,

processed, duplicated or distributed using electronic systems

in any form or by any means whatsoever without the express

written consent of Groz-Beckert.

GROZ - BE CKE RT KG

PO Box 10 02 49

72423 Albstadt, Germany

Phone +49 7431 10-0

Fax +49 7431 10-2777

contact-weaving@groz-beckert.com

www.groz-beckert.com

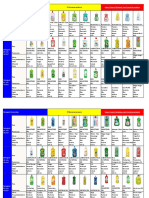

SPECI FI CATI ON TABLE FOR LENO HEALDS

A BINDING

B THREADER

C STEP SEQUENCE

D PEGPLAN

E FEED SLOT

F WARP BEAM

1 AND 3 LENO

2 AND 4 LENO

1.1 Upper shed leno heald for right hand thread 1 and 3

1.2 Lower shed leno heald for standing end thread 2 and 4

1.2

1.1

3.50 x 1.50 2.45 x 0.27 126 x 9 x 0.3

3.50 x 2.00 2.50 x 0.60 126 x 11 x 0.5

3.50 x 1.50 2.45 x 0.27 152 x 9 x 0.3

3.50 x 2.00 2.50 x 0.60 152 x 11 x 0.5

3.50 x 1.50 2.20 x 0.30 111 x 9 x 0.3

3.50 x 2.00 2.50 x 0.60 111 x 9 x 0.5

3.50 x 1.50 2.20 x 0.30 136 x 9 x 0.3

3.50 x 2.00 2.50 x 0.60 136 x 9 x 0.5

Trade mark Leno healds

Distance

insede end

loops

Max. shed

opening

Max.

density

Suitable for warp yarns

P

l

a

s

t

i

c

R

u

s

t

p

r

o

o

f

s

t

e

e

l

P

l

a

s

t

i

c

R

o

s

t

p

r

o

o

f

s

t

e

e

l

T

e

x

s

y

s

t

e

m

M

e

t

r

i

c

n

o

.

S

i

l

k

t

i

t

r

e

C

o

t

t

o

n

W

o

r

s

t

e

d

y

a

r

n

per

cm

per

cm

Lifting healds Doup healds Engl. no.

Plastic

Rustproof

steel

Strip steel

nickel-plated

Você também pode gostar

- GM 288 SeriesDocumento16 páginasGM 288 SeriesMiguel Morales ChAinda não há avaliações

- SQN7 Actuators For Oil or Gas BurnersDocumento21 páginasSQN7 Actuators For Oil or Gas BurnersMiguel Morales ChAinda não há avaliações

- Guia de Compradores de AlgodonDocumento27 páginasGuia de Compradores de AlgodonMiguel Morales ChAinda não há avaliações

- LRT HandbookDocumento41 páginasLRT HandbookAshok Kumar60% (5)

- MS Green Economy ReportDocumento16 páginasMS Green Economy ReportMiguel Morales ChAinda não há avaliações

- Man 75-100udg T1 05-15-08Documento59 páginasMan 75-100udg T1 05-15-08Miguel Morales Ch100% (1)

- Harmonic Drive Draw Transmissions SpecsDocumento12 páginasHarmonic Drive Draw Transmissions SpecsMiguel Morales ChAinda não há avaliações

- Yarn ConditioningDocumento2 páginasYarn ConditioningMiguel Morales ChAinda não há avaliações

- Reduction and Analysis Methods of IndigoDocumento72 páginasReduction and Analysis Methods of IndigoBilal MasoodAinda não há avaliações

- Engomado Teñido PDFDocumento4 páginasEngomado Teñido PDFMiguel Morales ChAinda não há avaliações

- Manual PROGRAMDOR Caldero AceiteDocumento18 páginasManual PROGRAMDOR Caldero AceiteMiguel Morales ChAinda não há avaliações

- Viscosity Conversion ChartDocumento1 páginaViscosity Conversion ChartOmar Teny Cigueñas OlanoAinda não há avaliações

- Sizing M ClariantDocumento1 páginaSizing M ClariantMiguel Morales ChAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Venky 2Documento48 páginasVenky 2Uday GowdaAinda não há avaliações

- COPQ, CEPQ and CRPQ Measurements To TYSGDocumento38 páginasCOPQ, CEPQ and CRPQ Measurements To TYSGNguyễn Tiến DũngAinda não há avaliações

- List of In-Principle ApprovalsDocumento9 páginasList of In-Principle ApprovalsManasvi MehtaAinda não há avaliações

- Textile Engineering Department: A Lecture Note ON Introduction To Wet ProcessingDocumento21 páginasTextile Engineering Department: A Lecture Note ON Introduction To Wet ProcessingAbel TayeAinda não há avaliações

- Alok Report of RichaDocumento6 páginasAlok Report of Richazaya sarwarAinda não há avaliações

- Group 5 AsosDocumento3 páginasGroup 5 AsosMai67% (3)

- Textile ImportYeti CompanyDocumento104 páginasTextile ImportYeti CompanySay KhaAinda não há avaliações

- Ecocell PresentationDocumento13 páginasEcocell Presentationaliveli1Ainda não há avaliações

- Accountancy ProjectDocumento10 páginasAccountancy ProjectAham GamingAinda não há avaliações

- Luxottica Rise To Power Through Extreme Vertical Diversification PDFDocumento28 páginasLuxottica Rise To Power Through Extreme Vertical Diversification PDFdiegob_250% (2)

- Crafting A Livelihood - DasraDocumento37 páginasCrafting A Livelihood - Dasraswatijoshi_niam08Ainda não há avaliações

- Jess 106Documento16 páginasJess 106Tej Krishan SinghAinda não há avaliações

- Produs in Romania - Detergenti de Vase Comercializati in Romania - FMGCDocumento3 páginasProdus in Romania - Detergenti de Vase Comercializati in Romania - FMGCanda lupAinda não há avaliações

- A Study On Training and Development: Master of Business AdministrationDocumento83 páginasA Study On Training and Development: Master of Business Administrationsaimounika maramAinda não há avaliações

- Handicraft Production LMDocumento82 páginasHandicraft Production LMJohathan Turner100% (4)

- 1.7.1 CBLMDocumento64 páginas1.7.1 CBLMNovi Ember75% (4)

- Review of Literature On Khadi IndustriesDocumento5 páginasReview of Literature On Khadi Industriesafdtktocw100% (1)

- Prevention of BarreDocumento5 páginasPrevention of BarreKavi DhingraAinda não há avaliações

- Departmental Accounts - Gr. IIDocumento7 páginasDepartmental Accounts - Gr. IINitesh JainAinda não há avaliações

- Request For Proposals (RFP) : (SCBTS)Documento15 páginasRequest For Proposals (RFP) : (SCBTS)zeeshan_220Ainda não há avaliações

- Untold Legends Brotherhood of The BladeDocumento225 páginasUntold Legends Brotherhood of The BladepspzombieAinda não há avaliações

- Ariana Grande v. Forever 21Documento21 páginasAriana Grande v. Forever 21GMG EditorialAinda não há avaliações

- AMIGURUMI Unicorn PatternDocumento6 páginasAMIGURUMI Unicorn PatternClaudia Deus100% (2)

- Studies On Elastane-Cotton Core-Spun Stretch Yarns and Fabrics: Part I Yarn CharacteristicsDocumento7 páginasStudies On Elastane-Cotton Core-Spun Stretch Yarns and Fabrics: Part I Yarn CharacteristicsMitu ChowdhuryAinda não há avaliações

- Jai Narayan Vyas University: JodhpurDocumento32 páginasJai Narayan Vyas University: JodhpurDilip JaniAinda não há avaliações

- Database Client BandungDocumento44 páginasDatabase Client BandungPhitra SouvantanaAinda não há avaliações

- Teen Talk 1 Issue 1Documento10 páginasTeen Talk 1 Issue 1ivy_11_23Ainda não há avaliações

- Textiles - History, Properties and Performance and Applications (Gnv64)Documento597 páginasTextiles - History, Properties and Performance and Applications (Gnv64)dusanAinda não há avaliações

- Final Draft Business Envirnment Assignment Iman HaseebDocumento23 páginasFinal Draft Business Envirnment Assignment Iman HaseebimanAinda não há avaliações