Escolar Documentos

Profissional Documentos

Cultura Documentos

Mr.R.benschwartz Technology Related Issues in Manufacturing

Enviado por

lavanyachezhiyanDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Mr.R.benschwartz Technology Related Issues in Manufacturing

Enviado por

lavanyachezhiyanDireitos autorais:

Formatos disponíveis

R.

BENSCHWARTZ

Teaching Faculty

CEG Anna University

MOS FABRICATION TECHNOLOGY

RELATED ISSUES IN VLSI

Introduction

FDP_VLSI_ANNA UNIV

2

Integrated circuits: many transistors on one chip.

Very Large Scale Integration (VLSI): bucketloads!

Complementary Metal Oxide Semiconductor

Fast, cheap, low power transistors

Today: How to build your own simple CMOS chip

CMOS transistors

Building logic gates from transistors

Transistor layout and fabrication

Rest of the course: How to build a good CMOS chip

VLSI Design Flow

FDP_VLSI_ANNA UNIV

3

ENTITY test is

port a: in bit;

end ENTITY test;

DRC

LVS

ERC

Circuit Design

Functional Design

and Logic Design

Physical Design

Physical Verification

and Signoff

Fabrication

System Specification

Architectural Design

Chip

Packaging and Testing

Chip Planning

Placement

Signal Routing

Partitioning

Timing Closure

Clock Tree Synthesis

2

0

1

1

S

p

r

i

n

g

e

r

V

e

r

l

a

g

Description of an IC

FDP_VLSI_ANNA UNIV

4

Why do I care how transistors are

made?"

FDP_VLSI_ANNA UNIV

5

If designers understand the physical process, they will comprehend the reason

for the underlying design rules and in turn use this knowledge to create a better

design.

Understanding the manufacturing steps is also important when debugging some

difficult chip failures and improving yield

FDP_VLSI_ANNA UNIV

6

Silicon is a group IV element (4 valence electrons)

Forms covalent bonds with four neighbor atoms (3D cubic

crystal lattice)

Si is a poor conductor, but conduction characteristics may be

altered

Add impurities/dopants (replaces silicon atom in lattice):

Makes a better conductor

Group V element (phosphorus/arsenic) => 5 valence electrons

Leaves an electron free => n-type semiconductor (electrons, negative

carriers)

Group III element (boron) => 3 valence electrons

Borrows an electron from neighbor => p-type semiconductor (holes, positive

carriers)

Dopants

FDP_VLSI_ANNA UNIV

7

Silicon is a semiconductor

Pure silicon has no free carriers and conducts poorly

Adding dopants increases the conductivity

Group V: extra electron (n-type)

Group III: missing electron, called hole (p-type)

As Si Si

Si Si Si

Si Si Si

B Si Si

Si Si Si

Si Si Si

-

+

+

-

Moores Law: Then

FDP_VLSI_ANNA UNIV

8

1965: Gordon Moore plotted transistor on each chip

Fit straight line on semi log scale

Transistor counts have doubled every 24 months

Integration Levels

SSI: 10 gates

MSI: 1000 gates

LSI: 10,000 gates

VLSI: > 10k gates

[Moore65]

Electronics Magazine

Feature Size

FDP_VLSI_ANNA UNIV

9

Minimum feature size shrinking 30% every 2-3 years

Corollaries

FDP_VLSI_ANNA UNIV

10

Many other factors grow exponentially

Ex: clock frequency, processor performance

Levels of inter connection

FDP_VLSI_ANNA UNIV

11

FAB- Outline

FDP_VLSI_ANNA UNIV

12

Silicon Wafer Creation

FDP_VLSI_ANNA UNIV

13

The Silicon valence of 4 means that it can form a crystalline structure

This crystalline structure can be grown

We start with a Seed, which is a small piece of pure, crystalline Silicon

We then melt raw, impure Silicon into a crucible(aka, Silica)

We dip the Seed into the molten Silicon and pull it out slowly while turning-

As the molten Silicon cools, it forms covalent bonds with the Seed-these bonds track the crystal

structure of the Seed, forming more Silicon crystal

As the Silicon is pulled out, it forms a long cylinder-this cylinder is called an Ingot-

The ingot is a long cylinder of pure, crystal, Silicon

Silicon Wafers-

FDP_VLSI_ANNA UNIV

14

The seed withdrawal and rotation rates determine the diameter of the ingot.

Growth rates vary from 30 to 180 mm/hour.

The wafers are generally available in diameters of 150 mm, 200 mm, or 300

mm, and are mirror-polished and rinsed before shipment from the wafer

manufacturer.

Photolithography-

FDP_VLSI_ANNA UNIV

15

The patterning is achieved by a process called photolithography, from the Greek

photo (light), lithos (stone), and graphe (picture), which literally means

"carving pictures in stone using light."

This is the process of creating patterns on a smooth surface, in our case a Silicon

wafer-

This is accomplished by selectively exposing parts of the wafer while other

parts are protected-

The exposed sections are susceptible to doping, removal, or metallization

Specific patterns can be created to form regions of conductors, insulators, or

doping

Putting these patterns onto a wafer is called Photolithography-

Photoresist

FDP_VLSI_ANNA UNIV

16

A material that is acid resistant under normal conditions-

To begin with, it is insoluble to acids

When exposed to UV light, the material becomes soluble to acids

We can put photoresist on a wafer and then selectively expose regions to UV

Then we can soak the entire thing in acid and only the parts of the photoresist

that were exposed to UV light will be removed

This allows us to form a protective barrier on certain parts of the wafer while

exposing others parts

Types of Photoresists (PR):

FDP_VLSI_ANNA UNIV

17

Positive:

PR pattern is same as mask. On exposure to light, light degrades the polymers (described

in more detail later) resulting in the photoresist being more soluble in developers. The PR

can be removed in inexpensive solvents such as acetone.

Negative:

PR pattern is the inverse of the mask. On exposure to light, light polymerizes the rubbers

in the photoresist to strengthen its resistance to dissolution in the developer. The resist

has to be removed in special stripping chemicals. These resists tend to be extremely

moisture sensitive.

Combination:

Same photoresist can be used for both negative and positive pattern transfer. Can be

removed in inexpensivesolvents.

Mask

FDP_VLSI_ANNA UNIV

18

Masks-a mask in an opaque plate (i.e., not transparent) with holes/shapes that

allow UV light to pass-this is kind of like an overhead transparency

The mask contains the pattern that we wish to form on the target wafer

We pass UV light through the Mask and create soluble patterns in the

photoresist

Each pattern we wish to create requires unique mask-the physical glass plate

that is used during fabrication is called a Reticle

Photolithography Systems

FDP_VLSI_ANNA UNIV

19

Contact:

Resist is in contact with the mask: 1:1 magnification

Advantages:

Inexpensive equipment ($~50,000-150,000), moderately high resolution (~0.5 um or

better but limited by resist thickness- 0.1 um demonstrated)

Disadvantages:

Contact with the mask degrades the mask (pinholes and scratches are created on the metal-

oxide layers of the mask, particles or dirt are directly imaged in the wafer, Wafer bowing or

local loss of planarization results in non uniform resolution due to mask-wafer gap

variations., and no magnification

Proximity: Resist is almost, but not in contact with the mask: 1:1 magnification

Advantages:

Inexpensive equipment, low resolution (~1-2 um or slightly better)

Disadvantages:

Diffraction effects limit accuracy of pattern transfer. Less repeatable than contact methods,

no magnification

Photolithography Systems

FDP_VLSI_ANNA UNIV

20

Projection: Mask image is projected a distance from the mask and de-magnified to a

smaller image: 1:4 -1:10 magnification

Advantages:

Can be very high resolution (~0.065 um or slightly better), No mask contact

results in almost no mask wear (high production compatible), mask defects or

particles on mask are reduced in size on the wafer.

Disadvantages:

Extremely expensive and complicated equipment, diffraction effects limit

accuracy of pattern transfer.

Issues with Photolithography

FDP_VLSI_ANNA UNIV

21

Resolution:

How small of features can you make.

Registration:

Can you repeatability align one layer to another.

Throughput:

Can these be done in a cost effective time. (50-100 wafers an hour, down to

1 chip perhour).

Etching

FDP_VLSI_ANNA UNIV

22

When talking about etching, we typically talk about the etch patterns that can be formed

Isotropic-

Etches equally in all direction-wet etch is isotropic-this etch leads to

undercutting

Anisotropic

The etch rate is dependant on the direction of the etch-dry etch is anisotropic

Wet or dry etching

Used to remove unwanted metal. Pirhana solution is a 3:1 to 5:1 mix of sulphuric

acid and hydrogen peroxide that is used to clean wafers of organic and metal

contaminants or photoresist after metal patterning.

Plasma etching

Dry etch process with fluorine or chlorine gas used for metallization steps. The

plasma charges the etch gas ions, which are attracted to the appropriately charged

silicon surface. Very sharp etch profiles can be achieved using plasma etching.

Ion Implantation:-

FDP_VLSI_ANNA UNIV

23

The process of adding impurities to a silicon wafer

Wafer is put in a chamber with an Ion source (i.e., B, P, As)

Ions are accelerated toward the wafer using an E-field

Ions collide with the wafer, tunneling into the crystal structure

Photolithography allows us to selectively implant the regions we want (i.e., N-

wells, Sources, Drains)

As the impurities crash into the crystal, they damage or break the covalent

bonds-

We can repair these bonds using a process called annealing, which heats the

material up and then slowly cools it down allowing the new bonds to form

Deposition

FDP_VLSI_ANNA UNIV

24

Process of adding material to the wafer (as opposed to growing, which

consumes part of the target)-

This is how we put down the polysilicon layer for the gate contact (in

addition to insulators and metal)

Polysilicon is a polycrystalline material (SiH4) which is a conductor

Polysilicon originally starts with a high resistivity, but when doped its

resistively comes down

The most common type of deposition is Chemical Vapor Deposition

(CVD)Chemical Vapor Deposition

Wafer is put into a chamber with a gas (i.e., Si and H2)

The gas then forms a chemical reaction with the Silicon dioxide (SiO2)

and Silicon to form a bond, the polysilicon is then added via chemical

reactions.-

nMOS Transistor

FDP_VLSI_ANNA UNIV

25

Four terminals: gate, source, drain, body

Gate oxide body stack looks like a capacitor

Gate and body are conductors

SiO

2

(oxide) is a very good insulator

Called metal oxide semiconductor (MOS) capacitor

Even though gate is

no longer made of metal

n+

p

Gate Source Drain

bulk Si

SiO

2

Polysilicon

n+

Body

nMOS Operation

FDP_VLSI_ANNA UNIV

26

Body is usually tied to ground (0 V)

When the gate is at a low voltage:

P-type body is at low voltage

Source-body and drain-body diodes are OFF

No current flows, transistor is OFF

n+

p

Gate Source Drain

bulk Si

SiO

2

Polysilicon

n+

D

0

S

nMOS Operation Cont.

FDP_VLSI_ANNA UNIV

27

When the gate is at a high voltage:

Positive charge on gate of MOS capacitor

Negative charge attracted to body

Inverts a channel under gate to n-type

Now current can flow through n-type silicon from source

through channel to drain, transistor is ON

n+

p

Gate Source Drain

bulk Si

SiO

2

Polysilicon

n+

D

1

S

pMOS Transistor

FDP_VLSI_ANNA UNIV

28

Similar, but doping and voltages reversed

Body tied to high voltage (V

DD

)

Gate low: transistor ON

Gate high: transistor OFF

Bubble indicates inverted behavior

SiO

2

n

Gate Source Drain

bulk Si

Polysilicon

p+ p+

Inverter Cross-section

FDP_VLSI_ANNA UNIV

29

Typically use p-type substrate for nMOS transistors

Requires n-well for body of pMOS transistors

n+

p substrate

p+

n well

A

Y

GND

V

DD

n+ p+

SiO

2

n+ diffusion

p+ diffusion

polysilicon

metal1

nMOS transistor pMOS transistor

Well and Substrate Taps

FDP_VLSI_ANNA UNIV

30

Substrate must be tied to GND and n-well to V

DD

Metal to lightly-doped semiconductor forms poor connection called Shottky

Diode

Use heavily doped well and substrate contacts / taps

n+

p substrate

p+

n well

A

Y

GND

V

DD

n+ p+

substrate tap

well

tap

n+ p+

Inverter Mask Set

FDP_VLSI_ANNA UNIV

31

Transistors and wires are defined by masks

Cross-section taken along dashed line

GND V

DD

Y

A

substrate tap

well tap

nMOS transistor pMOS transistor

Detailed Mask Views

FDP_VLSI_ANNA UNIV

32

Six masks

n-well

Polysilicon

n+ diffusion

p+ diffusion

Contact

Metal

Metal

Polysilicon

Contact

n+ Diffusion

p+ Diffusion

n well

CMOS technologies

FDP_VLSI_ANNA UNIV

33

Four dominant CMOS technologies

N-well process

P-well process

Twin-tub process

Silicon on insulator (SOI)

Fabrication

FDP_VLSI_ANNA UNIV

34

Chips are built in huge factories called fabs

Contain clean rooms as large as football fields

The RCA clean is a standard set of wafer cleaning steps which need to be

performed before high-temperature processing steps (oxidation, diffusion, CVD)

of silicon wafers in semiconductor manufacturing.

Werner Kern developed the basic procedure in 1965 while working for RCA,

the Radio Corporation of America. It involves the following :

Removal of the organic contaminants (Organic Clean)

Removal of thin oxide layer (Oxide Strip)

Removal of ionic contamination (Ionic Clean)

Fabrication Steps

FDP_VLSI_ANNA UNIV

35

Start with blank wafer

Build inverter from the bottom up

First step will be to form the n-well

Cover wafer with protective layer of SiO

2

(oxide)

Remove layer where n-well should be built

Implant or diffuse n dopants into exposed wafer

Strip off SiO

2

p substrate

Oxidation

FDP_VLSI_ANNA UNIV

36

Grow Forming silicon dioxide (SiO2) on top of Si wafer

900 1200 C with H

2

O or O

2

in oxidation furnace

Two common approaches to oxidation of silicon:

Wet oxidation: when the oxidizing atmosphere contains wafer vapor. The temperature is usually

between 900 oC and 1000 oC. This is a rapid process.

Dry oxidation: when the oxidizing atmosphere is pure oxygen. Temperatures are in the region of

1200 oC to achieve an acceptable growth rate.

Atomic layer deposition (ALD)a process in which a thin chemical layer (material A) is

attached to a surface and then a chemical (material B) is introduced to produce a thin layer of the

required layer The process is then repeated and the required layer is built up layer by layer.

p substrate

SiO

2

Photoresist

FDP_VLSI_ANNA UNIV

37

Spin on photoresist

Photoresist is a light-sensitive organic polymer

Softens where exposed to light

p substrate

SiO

2

Photoresist

Lithography

FDP_VLSI_ANNA UNIV

38

One of the most critical problems in CMOS fabrication is the technique used to create a

pattern

The photolithographic process starts with the desired pattern definition for the layer.

Expose photoresist through n-well mask

Strip off exposed photoresist

The process for transferring the mask pattern to the surface of a silicon region

Coat photoresist

Exposure step

Etching

p substrate

SiO

2

Photoresist

Etch

FDP_VLSI_ANNA UNIV

39

Etch oxide with hydrofluoric acid (HF)

Seeps through skin and eats bone; nasty stuff!!!

Only attacks oxide where resist has been exposed

p substrate

SiO

2

Photoresist

Strip Photoresist

FDP_VLSI_ANNA UNIV

40

Strip off remaining photoresist

Use mixture of acids called piranah etch

Necessary so resist doesnt melt in next step

p substrate

SiO

2

n-well

FDP_VLSI_ANNA UNIV

41

n-well is formed with diffusion or ion implantation

Diffusion

Place wafer in furnace with arsenic gas

Heat until As atoms diffuse into exposed Si

Ion Implanatation

Blast wafer with beam of As ions

Ions blocked by SiO

2

, only enter exposed Si

n well

SiO

2

Strip Oxide

FDP_VLSI_ANNA UNIV

42

Strip off the remaining oxide using HF

Back to bare wafer with n-well

Subsequent steps involve similar series of steps

p substrate

n well

Polysilicon

FDP_VLSI_ANNA UNIV

43

Deposit very thin layer of gate oxide

< 20 (6-7 atomic layers)

Chemical Vapor Deposition (CVD) of silicon layer

Place wafer in furnace with Silane gas (SiH

4

)

Forms many small crystals called polysilicon

Heavily doped to be good conductor

Thin gate oxide

Polysilicon

p substrate

n well

Polysilicon Patterning

FDP_VLSI_ANNA UNIV

44

Use same lithography process to pattern polysilicon

Polysilicon

p substrate

Thin gate oxide

Polysilicon

n well

Self-Aligned Process

FDP_VLSI_ANNA UNIV

45

Use oxide and masking to expose where n+ dopants should

be diffused or implanted

N-diffusion forms nMOS source, drain, and n-well contact

p substrate

n well

N-diffusion

FDP_VLSI_ANNA UNIV

46

Pattern oxide and form n+ regions

Self-aligned process where gate blocks diffusion

Polysilicon is better than metal for self-aligned gates because it doesnt melt

during later processing

p substrate

n well

n+ Diffusion

N-diffusion cont.

FDP_VLSI_ANNA UNIV

47

Historically dopants were diffused

Usually ion implantation today

But regions are still called diffusion

n well

p substrate

n+ n+ n+

N-diffusion cont.

FDP_VLSI_ANNA UNIV

48

Strip off oxide to complete patterning step

n well

p substrate

n+ n+ n+

P-Diffusion

FDP_VLSI_ANNA UNIV

49

Similar set of steps form p+ diffusion regions for pMOS source and drain and

substrate contact

p+ Diffusion

p substrate

n well

n+ n+ n+ p+ p+ p+

Contacts

FDP_VLSI_ANNA UNIV

50

Now we need to wire together the devices

Cover chip with thick field oxide

Etch oxide where contact cuts are needed

p substrate

Thick field oxide

n well

n+ n+ n+ p+ p+ p+

Contact

Metalization

FDP_VLSI_ANNA UNIV

51

Sputter on aluminum over whole wafer

Pattern to remove excess metal, leaving wires

p substrate

Metal

Thick field oxide

n well

n+ n+ n+ p+ p+ p+

Metal

Latchup

FDP_VLSI_ANNA UNIV

52

Transient currents flowing in substrate during startup can cause VSUB to

rise, turning on Vsub. This will turn on Vwell, which turns on Vsub

harder in a positive feedback loop, causing large current to flow

between Vdd/GND (destructive current!).

Keep Rwell, Rsub low, also place numerous well taps to collect stray

charge.

Twin-Tub (Twin-Well) CMOS Process

FDP_VLSI_ANNA UNIV

53

This technology provides the basis for separate optimization of the nMOS and pMOS

transistors, thus making it possible for threshold voltage, body effect and the channel

transconductance of both types of transistors to be tuned independently.

Generally, the starting material is a n+ or p+ substrate, with a lightly doped epitaxial

layer on top.

This epitaxial layer provides the actual substrate on which the n-well and the p-well

are formed.

Since two independent doping steps are performed for the creation of the well

regions, the dopant concentrations can be carefully optimized to produce the desired

device characteristics. The Twin-Tub process is shown below.

In the conventional p & n-well CMOS process, the

doping density of the well region is typically about

one order of magnitude higher than the substrate,

which, among other effects, results in unbalanced

drain parasitics. The twin-tub process avoids this

problem.

Benefits of SOI

FDP_VLSI_ANNA UNIV

54

No parasitic bipolar devices

No Latchup

Sources

Cosmic Rays (aircraft electronics vulnerable)

Decaying uranium and thorium impurities in integrated circuit interconnect

Generates electron-hole pairs in substrate

Excess carriers collected by diffusion terminals of transistors

Can cause upset of state nodes floating nodes, DRAM cells most vulnerable

Not as much substrate to generate charge in!

Alpha Particles

Another subtle advantage:

FDP_VLSI_ANNA UNIV

55

Lower thresold voltage

In bulk-CMOS, Vt varies with channel length

variations in polysilicon etching shows up as variations in threshold voltages

Vt must be high enough in the worst case (lowest Vt) to limit subthreshold

leakage, so nominal threshold must b higher

SOI has lower Vt variations than bulk-CMOS

So nominal Vt can be lower, resulting in faster circuits, esp. for lower VDD

The immunity to latch-up, resistance to alpha-particle strikes makes SOI

attractive for space-based ICs, military applications seeking radiation hardness

Honeywell is a leader in CMOS SOI for military, space applications

Smaller diffusion capacitance makes it attractive for low-power design (lowers

dynamic power dissipation)

Wafer Inspection

FDP_VLSI_ANNA UNIV

56

Each IC on the completed wafer is electronically tested by the tester.

After this inspection, the front-end processing is complete

Dicing

FDP_VLSI_ANNA UNIV

57

In back end processing, a wafer completed in front end processing is cut into

individual IC chips and encapsulated into packages.

Power Supply Voltage

FDP_VLSI_ANNA UNIV

58

GND = 0 V

In 1980s, V

DD

= 5V

V

DD

has decreased in modern processes

High V

DD

would damage modern tiny transistors

Lower V

DD

saves power

V

DD

= 3.3, 2.5, 1.8, 1.5, 1.2, 1.0,

Layout

FDP_VLSI_ANNA UNIV

59

Chips are specified with set of masks

Minimum dimensions of masks determine transistor size (and hence speed,

cost, and power)

Feature size f = distance between source and drain

Set by minimum width of polysilicon

Feature size improves 30% every 3 years or so

Normalize for feature size when describing design rules

Express rules in terms of l = f/2

E.g. l = 0.3 mm in 0.6 mm process

LAYOUT DEIGN RULES

FDP_VLSI_ANNA UNIV

60

Prescription for preparing photo masks in fabrication of IC

Circuit designer links process engineer in manufacturing phase

OBJECTIVE

To obtain the circuit with optimum yield

As small a geometry as possible

No compromise in reliability of the circuit

More conservative more likely the circuit will function

More aggressive greater the improvements in performance

LAYOUT DEIGN RULES

FDP_VLSI_ANNA UNIV

61

Unit dimension: Minimum line width

scalable design rules: lambda parameter

absolute dimensions (micron rules)

All widths, spacings, and distances are written in the form

Value =

l m

Layout Layers and Design Rules

FDP_VLSI_ANNA UNIV

62

Size rules, such as minimum width:

The dimensions of any component (shape), e.g., length of a boundary edge or

area of the shape, cannot be smaller than given minimum values. These values

vary across different metal layers.

Separation rules, such as minimum separation:

Two shapes, either on the same layer or on adjacent layers, must be a

minimum (rectilinear or Euclidean diagonal) distance apart.

Overlap rules, such as minimum overlap:

Two connected shapes on adjacent layers must have a certain amount of

overlap due to inaccuracy of mask alignment to previously-made patterns on

the wafer.

Categories of design rules

Layout Layers and Design Rules

FDP_VLSI_ANNA UNIV

63

Categories of design rules

Minimum Width: a

Minimum Separation: b, c, d

Minimum Overlap: e

a

d

c

l

b

e

l: smallest meaningful technology-dependent

unit of length

2

0

1

1

S

p

r

i

n

g

e

r

V

e

r

l

a

g

Physical Design Optimizations

FDP_VLSI_ANNA UNIV

64

Technology constraints

enable fabrication for a specific technology node and are derived from

technology restrictions. Examples include minimum layout widths and spacing

values between layout shapes.

Electrical constraints

ensure the desired electrical behavior of the design. Examples include meeting

maximum timing constraints for signal delay and staying below maximum

coupling capacitances.

Geometry (design methodology) constraints

Introduced to reduce the overall complexity of the design process. Examples

include the use of preferred wiring directions during routing, and the

placement of standard cells in rows.

Types of constraints

Constraints & issues

FDP_VLSI_ANNA UNIV

65

Its important that these rules dont represent hard boundary between correct

and incorrect fabrication

Represent the maximum tolerance that ensures very high probability of correct

fabrication i.e) if the manufacturer finds a violation in design rules may still

function correctly he can proceed fabrication

But frequent departure from this may seriously prevent the success of the

design

Constraints in Design rule

Line width

Interlayer registration

Two main issues:

Geometrical reproduction of features that can be reproduced by the masking

and lithographical process

Interactions between different layers

Approaches used to describe design

rules

FDP_VLSI_ANNA UNIV

66

In general micron rules - few microns resolution

Alpha() and beta () rules

Lambda based rules

Alpha() and beta () rules

Feature size by and Grid size by

and related by a constant factor for Scaling

Lambda based rules

Popularized by Mead and Conway in 1980 based on single parameter

No valid reason that micron rules cannot be used

Transistor dimensions are in W/L ratio

NFETs are usually twice the width

PFETs are usually twice the width of NFETs

Holes move more slowly than electrons (must be wider to deliver same current)

Design rules and gate layout

FDP_VLSI_ANNA UNIV

67

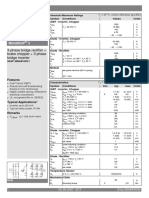

MOSIS design rules

FDP_VLSI_ANNA UNIV

68

MOSIS design rules

FDP_VLSI_ANNA UNIV

69

FDP_VLSI_ANNA UNIV

70

Vdd

GND

OUT

IN2

IN1

OUT

IN2

IN1

OUT

IN1

Vdd

GND

IN2

Contact

Diffusion layer

p-type

transistor

n-type

transistor

Metal layer

Poly layer

FDP_VLSI_ANNA UNIV

1.3 VLSI Design Styles

Power (Vdd)-Rail

Ground (GND)-Rail

Contact

Vdd

GND

OUT

IN2

IN1

OUT

IN2

IN1

OUT

IN1

Vdd

GND

IN2

Diffusion layer

p-type

transistor

n-type

transistor

Metal layer

Poly layer

FDP_VLSI_ANNA UNIV

72

Layout Layers and Design Rules

Layout layers of an inverter cell

with external connections

Contact

Metal1

polysilicon

p/n diffusion

Vdd

GND

Via

Metal2

Inverter Cell

External

Connections

2

0

1

1

S

p

r

i

n

g

e

r

V

e

r

l

a

g

LAYER REPRSENTATION

FDP_VLSI_ANNA UNIV

73

CMOS process is too complex inhibit visualization of all mask levels

Colour scheme is proposed by Jet propulsion Laboratory, California Institute of

Technology

For convenience the CIF (Caltech Intermediate Form) layer names as used by

JPL

It is noted by four alpha numeric characters

Process CIF Character

P-channel MOS P

N-Channel MOS N

Bulk CMOS C

Silicon On Insulator S

CMOS Process Enhancements

FDP_VLSI_ANNA UNIV

74

Multiple threshold voltages

Low-Vt more on current, but greater subthreshold leakage

High-Vt less current, but smaller subthreshold leakage

User low-Vt devices on critical paths and higher-Vt devices elsewhere to limit

leakage power

Multiple masks and implantation steps are used to set the various thresholds

CMOS Process Enhancements

FDP_VLSI_ANNA UNIV

75

Silicon on insulator (SOI) process

The transistors are fabricated on an insulator

Two major insulators are used, SiOs and sapphire

Two major advantages: elimination of the capacitance between the

source/drain regions and body, leading to higher-speed devices;

lower subthreshold leakage

High-k gate dielectrics

MOS needs high gate capacitance to attract charge to channelvery

thin SiO2 gate dieletrics

Scaling trends indicate the gate leakage will be unacceptably large in

such thin gates

Gates could use thicker dielectrics and hence leak less if a material

with a higher dielectric constant were available

CMOS Process Enhancements

FDP_VLSI_ANNA UNIV

76

Higher Mobility

Increasing the mobility () of the semiconductor improves drive current

and transistor speed.

This has been achieved by using silicon germanium (SiGe) for bipolar

transistors in the same process as conventional CMOS devices

SiGe transistors can be constructed on conventional CMOS processing by

adding a few extra implantation steps.

The resulting bipolar transistors have extremely good radio frequency (RF)

performance.

Strainedsilicon" silicon into which is implanted germanium atoms that

stretch the silicon lattice

This yields an increase in the mobility of the devices over conventional silicon of up to 70%

and which corresponds to roughly a 30% increase in performance.

CMOS Process Enhancements

FDP_VLSI_ANNA UNIV

77

High-voltage Transistors

High-voltage MOSFETs can also be integrated onto conventional CMOS

processes for switching and high-power applications.

Gate oxide thickness and channel length have to be larger than usual to

prevent breakdown. Specialized process steps are necessary to achieve very

high breakdown voltages.

CMOS Process Enhancements

FDP_VLSI_ANNA UNIV

78

Low Dielectrics

Low-k dielectrics between wires are attractive because they decrease

the wire capacitance . This reduces both wire delay and power

consumption.

Adding fluorine to the silicon dioxide creates fluorosilicate glass

(FSG) with a dielectric constant of 3.6, widely used in 130 nm

processes.

Adding carbon to the oxide can reduce the dielectric constant to 2.7-

3. Alternatively, porous polymer-based dielectrics can deliver even

lower dielectric constants.

Challenge

Developing low-k dielectrics that can withstand the high

temperatures during processing and the forces applied during CMP is

a major challenge.

Beyond Conventional CMOS

FDP_VLSI_ANNA UNIV

79

Nanotechnology is presently a hot research area seeking alternative structures

to

Replace CMOS when scaling finally runs out of steam.

For example, carbon nanotubes have been used to demonstrate transistor

behavior and build inverters

They are of interest as the nanotube is smaller than the predicted end- point for

CMOS gate lengths.

Presently, the speeds are quite slow and the manufacturing techniques are

limited, but they may be of interest in the future.

Manufacturing Issues

FDP_VLSI_ANNA UNIV

80

Moving to new process for new designs

Failing to account the parasitic effect of metal fills

Failing to include process calibration test structures

Stack Height Effect

Substrate Noise

Self-Heating

THANK YOU

Você também pode gostar

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- O & M of Sub StationDocumento94 páginasO & M of Sub StationAlbert Sekar100% (2)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Roland e 80 Service NotesDocumento116 páginasRoland e 80 Service NotesAdriano Camocardi50% (2)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- CommunicationsDocumento6 páginasCommunicationsRaine LopezAinda não há avaliações

- Worksheet 13 PDFDocumento4 páginasWorksheet 13 PDFVijay Bhaskar50% (2)

- WaveletsDocumento109 páginasWaveletslavanyachezhiyanAinda não há avaliações

- PranamDocumento3 páginasPranamlavanyachezhiyanAinda não há avaliações

- Linear Filtering Methods Based On The DFTDocumento50 páginasLinear Filtering Methods Based On The DFTlavanyachezhiyan67% (3)

- The Basics of Antenna ArraysDocumento8 páginasThe Basics of Antenna ArrayslavanyachezhiyanAinda não há avaliações

- Sobel Edge Detection Algorithm - TutorialDocumento11 páginasSobel Edge Detection Algorithm - TutorialjoseolivapAinda não há avaliações

- Module 2,3 & 4Documento199 páginasModule 2,3 & 4lavanyachezhiyanAinda não há avaliações

- Clarion 3225kca Audio CarDocumento22 páginasClarion 3225kca Audio CarLeonardo BeltraoAinda não há avaliações

- Tan Delta CDF-6000Documento2 páginasTan Delta CDF-6000MarcoGiraldoAinda não há avaliações

- Electronic System Design PPT - Electrical Behavior of CMOS and BiCMOSDocumento6 páginasElectronic System Design PPT - Electrical Behavior of CMOS and BiCMOSAnoop MathewAinda não há avaliações

- Fuses-Medium Voltage 9.0-1: September 2011Documento12 páginasFuses-Medium Voltage 9.0-1: September 2011Fredelito Dela CruzAinda não há avaliações

- 13 Optimizing Universal Radio ICsDocumento11 páginas13 Optimizing Universal Radio ICswebdrifter100% (1)

- Obsolescence Management The Impact OnDocumento8 páginasObsolescence Management The Impact OnZia Ul BasithAinda não há avaliações

- Converter, Inverter, Brake: Skiip 35Nab126V1Documento4 páginasConverter, Inverter, Brake: Skiip 35Nab126V1JesusRiveroAinda não há avaliações

- A Bidirectional DC-DC Converter For An Energy Storage System With Galvanic IsolationDocumento8 páginasA Bidirectional DC-DC Converter For An Energy Storage System With Galvanic IsolationKrishnaChaitanyaAinda não há avaliações

- Basic Electronics Slides 1 30Documento30 páginasBasic Electronics Slides 1 30Nithish KolliAinda não há avaliações

- Electronic Devices Model Question PapersDocumento2 páginasElectronic Devices Model Question Papersk_kunarajAinda não há avaliações

- CS302 Spring2009 2010 MidTerm PDFDocumento38 páginasCS302 Spring2009 2010 MidTerm PDFattiqueAinda não há avaliações

- Service Manual: Sony@Documento20 páginasService Manual: Sony@Javier CisnerosAinda não há avaliações

- Weighing in On Photonic-Based Machine Learning For Automotive MobilityDocumento2 páginasWeighing in On Photonic-Based Machine Learning For Automotive MobilitymtkliemaAinda não há avaliações

- Three-Port Rectifier-Based AC-DC Power Converters With Sigma Architecture and Reduced Conversion StagesDocumento10 páginasThree-Port Rectifier-Based AC-DC Power Converters With Sigma Architecture and Reduced Conversion StagesifyAinda não há avaliações

- EPF10K20RC208 4 (Pin Out)Documento3 páginasEPF10K20RC208 4 (Pin Out)api-3825669Ainda não há avaliações

- CheetahPerc JKM380-400M-72H-V-A1-EN PDFDocumento2 páginasCheetahPerc JKM380-400M-72H-V-A1-EN PDFLuis PerdomoAinda não há avaliações

- 7404 DatasheetDocumento4 páginas7404 DatasheetLaura Morales DiazAinda não há avaliações

- Ultrasonic MachiningDocumento16 páginasUltrasonic Machininggovind jodhaniAinda não há avaliações

- LC Circuit - Wikipedia, The Free EncyclopediaDocumento9 páginasLC Circuit - Wikipedia, The Free EncyclopediaAdrian TanaseAinda não há avaliações

- Cineral Tc1433nuDocumento4 páginasCineral Tc1433nuMundodoRadioAinda não há avaliações

- Communication TechnologyDocumento5 páginasCommunication TechnologyHerthik PrathabanAinda não há avaliações

- Reliability: Gerard's ColumnsDocumento1 páginaReliability: Gerard's ColumnsAmanda GonzálezAinda não há avaliações

- Single Phase PWM InverterDocumento11 páginasSingle Phase PWM InverterFoom A. Alshekh100% (2)

- Data Sheet: 1 W BTL Audio Amplifier With Digital Volume ControlDocumento20 páginasData Sheet: 1 W BTL Audio Amplifier With Digital Volume ControlНаталія ЛіськевичAinda não há avaliações

- SST-2000 SeriesDocumento33 páginasSST-2000 SeriesLeyverMBAinda não há avaliações

- Ansi C37.66 1969 (R1982) PDFDocumento21 páginasAnsi C37.66 1969 (R1982) PDFIvanAinda não há avaliações