Escolar Documentos

Profissional Documentos

Cultura Documentos

Reconfigurable Machine Tool Programming - A New Approach

Enviado por

John_AdaTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Reconfigurable Machine Tool Programming - A New Approach

Enviado por

John_AdaDireitos autorais:

Formatos disponíveis

WSEAS TRANSACTIONS on SYSTEMS and CONTROL A. Epureanu, F.B. Marin, V.

Marinescu,

M. Banu and I. Constantin

Reconfigurable machine tool programming– a new approach

A.EPUREANU, F.B.MARIN, V.MARINESCU, M.BANU, I.CONSTANTIN

Manufacturing Science and Engineering Department

Dunarea de Jos University

47, Domneasca St., Galati

ROMANIA

alexandru.epureanu@ugal.ro

Abstract: - This paper presents a new programming approach based on a proposed hardware and control

architecture for the reconfigurable manufacturing tool machine. A new CAM is described based on virtual

machining algorithm that optimizes feedrate scheduling based on geometric simulation and aims to improve

the efficiency of cutting process developed using a reconfigurable machine, configured as lathe with a specific

architecture. A searching procedure is proposed to find the parameter values corresponding to cutter locations

along tool path during generation of the final surface.

Key-Words: - RMT programming, feedrate scheduling, reconfigurable machining system, numerical control,

optimal control, virtual machining

1 Introduction tools are stored in the machine database; for

Nowadays, companies building manufacturing instance, the shape of the tools and the modules

machines must face fast changes happening on geometry.

technical, commercial and economical fields. These The reconfigurable “plug-and-play” machine

emerging evolutions are the following: kinematics and dynamic modeling algorithms need

- economy globalization, with the consequence the to be developed. These algorithms are the basis for

emphasis of competition; the control and simulation of reconfigurable

- individualization of needs, what means products manufacturing system. The concept of machine

customization; configuration optimization is introduced for the

- capital dynamization, generating high requirements effective use of the rapidly reconfigurable machine.

concerning investment efficiency; The issues involved in the reconfiguration process

- high versatility of small companies, for fast are represented by

adaptation to market. At the time, the companies - hardware modules reconfiguration

responses to these changes are based on the idea of - software reconfigurability (both programming

extending some of the attributes of classic and control)

manufacturing system to define reconfigurability. Examples of physical configurations (hardware

Whereas Dedicated Manufacturing Systems (DMSs) reconfiguration) include building a new machine

have been designed to produce a specific part and using the hardware modules. So far that concerns

Flexible Manufacturing Systems (FMSs) are software reconfigurability is a must have to develop

designed to accommodate a large variety of parts architectures and techniques to provide short ramp-

even though the parts are not specified at the system up time. Control design determines appropriate

design stage, the Reconfigurable Manufacturing process variables (modules displacements and

Systems (RMSs) combines the advantages of DMS velocities etc.), so that a configuration can be

and FMS providing an suitable solution[1][2]. It is operated to fulfill the task. The concepts of the

defined the new peculiar manufacturing system, control paradigms, such as holonic manufacturing,

reconfigurable manufacturing system, using six key bionic manufacturing, fractal companies, are

characteristics: i) universatility, ii) convertibility; iii) proposed for the next-generation manufacturing

integrability; iv) scalability; v) diagnosability; vi) systems. So far that concern the control concept, it

customisation.These systems are designed to adapt was proposed [15] a software architecture based on

manufacturing to mixed products and volumes. The a combination of object-oriented models and

reconfigurable machine is conceived with standard executable formal specifications. In this architecture,

and inter-operable components including actuated the machine control software is viewed as an

modules, fixtures and tools to be assembled into the integration of a set of reusable software components,

machine with arbitrary architecture and degrees of each modeled with a set of event-based external

freedom. The informations describing modules and interfaces for functional definitions, a control logic

ISSN: 1991-8763 463 Issue 5, Volume 3, May 2008

WSEAS TRANSACTIONS on SYSTEMS and CONTROL A. Epureanu, F.B. Marin, V. Marinescu,

M. Banu and I. Constantin

driver for execution of behavioral specifications, and approximate the part surface. These straight lines are

a set of service protocols for platform adaptation. subsequently translated into linear G codes by the

The behaviors of the entire software can be viewed computed-aided machining (CAM) software, and

as an integration of behaviors of components and then sent to the computer numerical control (CNC)

their integration. system. For a general free-form surface or

The needs for interoperation of modules from parametric surface machining, this method is

different vendors and for flexible configuration of inefficient and error-prone. The conversion of

various functions are challenges to NC systems. In surfaces into linear segments produces a large

response to such challenges, various efforts have amount of data, which usually cause a lot of

been made, such as Open Modular Architecture problems, such as lower feedrate, and longer data

Controllers (OMAC) [11], Open System storage requirements [14].

Architecture for Controls within Automation Also, feedrate optimization problems are the

Systems (OSACA) in Europe [12], Open System subject to several possible constraints, building the

Environment for Controllers (OSEC), Hierarchical framework for generating model. Firstly, the

Open Architecture Multi-processor for CNC common restriction used in feedrate scheduling is

(HOAM-CNC), Open Architecture Controller constant material removal rate (MRR), [3]. In the

(UMOAC) by University of Michigan, Ann Arbor, MRR based approach, feedrate is dependent to

USA etc. The common approach employed in these either average or instantaneous volumetric removal

efforts is the adoption of an open, modular rate. Secondly, the restriction is based on the process

architecture to promote interoperation [13]. mechanics [4]. In this case the force-based models,

The nowadays CNC control system is feedrate is set to values which keep either average or

inappropriate to consider as basis for the control of instantaneous machining forces to prescribed values.

RMTs. Existing CNC systems support only CNC These models computes either MRR or force values

builder-specific NC program input and this limits as a minimum allowable values, and are maintained

the potential application of many NC programs that at a constant level during processing.

have the same functions with different formats The disadvantages of keeping at allowable level are

varying one machine to another[6][7][8]. In the case in the first place, the efficiency is lowered and

of the RMT, where there is a wide range of secondly, the optimization is incomplete performed,

configurations, using nowadays programming as it does not take into account several variables in

standards will be time consuming. Because of the the process such as chip width (determining risk of

issues of software reconfiguration the ramp-up time chatter), roughness or thickness (determining force

is considerable, as overloading).

However, so far that concerns programming of RMS Commonly used CAM programs and NC code

there is no reference. generators are based on geometric and volumetric

In nowadays CNC systems, the NC program analysis, but they do not concern the current blank

processor is a very important component that surface shape to be processed. CAM software

determines the accurate resolving of machining considers only the nominal dimensions inputted

intention generated from a CAM system [1]. The from CAD model [5] [6] [7].

major functions of CNC processor include checking Also planning the isoparametric tool path it is

the syntax and decoding them into specific outputs addressed to considerable long paths (due to the G-

such as motion command, PLC command, code limitation and the nowadays machine control

parameter setting, or error messages. system architecture) and not for adjacent cutter

There have been three basic standards: RS274D location resolution.

(USA), ISO6983 (ISO) and DIN66025 (Europe) for It is critical, but often difficult, to select optimal

NC program since CNC was invented. However, cutting conditions to achieve high productivity while

new RMT machine tool and control technology have maintaining high quality of parts.

undergone great development since then. Even for Generating the optimal cutting conditions

today’s CNC there are a lot of new functions needed scheduling, described by NC programs, to produce

and controller-specific features not supported by the required geometry involves determination of the

these NC standards. optimal cutter paths and machining parameters. The

Also there is the issue of coding free-form common practice is to set machining parameters

surfaces using nowadays CNC programming such as feedrate, to constant value for the number of

languages, as these surfaces are used in a variety of cutter paths, using machinability handbooks and

applications. The conventional approach for surface experience of skilled machinist. The selected

machining is to use a series of straight lines to

ISSN: 1991-8763 464 Issue 5, Volume 3, May 2008

WSEAS TRANSACTIONS on SYSTEMS and CONTROL A. Epureanu, F.B. Marin, V. Marinescu,

M. Banu and I. Constantin

parameters are often so excessive limited that points and we referring to a current remarkable point

efficiency is very low for the machining process. on the workpiece profile as i point.

In this paper it is proposed a new programming Current cutter location is described by (i,j) pair;

approach based on a proposed hardware and control while i, is defining the current cutter location, j is

architecture for the reconfigurable manufacturing current cutter profile. Another variable in our

tool machine. A new CAM is described based on optimization program is the variable k, which is the

virtual machining algorithm that optimizes feedrate indexing variable for (i,j) pair.

scheduling based on geometric simulation and aims As described below, the reconfigurable machine is

to improve the efficiency of cutting process configured as lathe with an additional degree of

developed using a reconfigurable machine, freedom represented by rotation of the tool

configured as lathe with a specific architecture. assembly, with an ϕ angle, variable that determines j

Also, a searching algorithm is proposed to find the cutter profile.

parameter incremental values of all cutter locations Our search algorithm is using as reference

along tool path for the generation of final surface. calculation the previous cutter location (k-1), as in

The proposed algorithm includes the following two Fig.2, representing the last selected cutter location.

main steps: evaluating blank real surface shape and Consequently, every k position is associated with the

searching for adjacent non-isoparametric cutter ϕ(k), Z(k) and X(k) variable values.

locations, in the conditions to meet the the In the proposed search optimization algorithm we

restrictions. use current L variable value defining the length

The algorithm shall be embedded in a virtual {P,Q} which is the length of active cutting edge, as

machining system that optimizes machining process, seen in Fig.2.

based on geometric simulation, to improve the

process efficiency, under the assumption of

reconfigurable machines architecture.

Besides the efficient cutting condition scheduling

goal, there is the advantage by using such virtual

machining system, represented by the optimized

choosing of the tool for a specific operation and a

specific blank. The example given is taking into

account a reconfigurable machine configured as a

lathe. However, the algorithm may be extended to

all cutting processing.

Paper has the following structure: section 2

present the problem formulation, section 3 contains

the problem solution and section 4 summarizes the

main conclusions achieved.

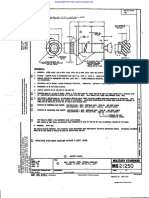

Fig.1 Insert

According to our approach there are several data

2 Problem Formulation to be used as input data:

Firstly, workpiece profile and cutting edge

2.1 Variables and terms definition

profile is inputted from CAD model, as we assume

that all tool modules are described in the database

We formulate the problem of optimizing the

stored in the reconfigurable machine information

values of cutting processing to improve its

system.

efficiency. We consider to be addressed to a RMT

Secondly, the blank profile is determined by on-

configured as lathe with a specific architecture.

machine measurement. Thirdly, it is inputted the

In order to define the problem, the issues

restricted variables: allowable force -Fa, allowable L

involved and determine a solution, we need to define

–La (the length of cutting active edge as shown in

several variables according to our approach.

Fig.2 represented by PQ length), allowable chip

As shown in Fig.1, the insert cutting edge profile

thickness - aa ( chip thickness), allowable roughness

is divided defining remarkable (m) points; when we

–Ra.

addressing to a current remarkable point on the

cutting edge as j point. Similarly as depicted in Fig.2

the workpiece profile is divided in remarkable n

ISSN: 1991-8763 465 Issue 5, Volume 3, May 2008

WSEAS TRANSACTIONS on SYSTEMS and CONTROL A. Epureanu, F.B. Marin, V. Marinescu,

M. Banu and I. Constantin

Fig.3 The reconfigurable lathe

position of controlled variables X(k), Z(k), θ(k) and

ϕ(k) computed from (i,j) pair.

Part surface generation it is performed by moving

tool profile along helicoidally generating path,

Fig.2 Current and previous cutter locations obtained by combining revolution of the part and the

translation of the tool. The trajectory of the

helicoidally path it is divided, as described above,

2.2 Reconfigurable lathe description by coordinates computing of a many successive (i,j)

For a better understanding, the reconfigurable pair points to control motors that performs

lathe hardware configuration and the control system movement actions of the machine.

is described bellow.

Our proposed architecture for the reconfigurable

lathe is composed of virtual processing planning 2.3 Problem statement

system, machining database, and “plug-and-play” Our objective is to determine (i,j) pair under the

hardware modules. criteria objective of maximizing locally chip area.

The reconfigurable lathe considered is build out While the search criteria in the MRR and force

of four independent modules, numerical controlled, model are the MRR and the force respectively, in

with independent sensor and motors. These modules our approach the search criterion is the locally

are main spindle, carriage, and the rotary tool maximized chip area.

assembly. The reconfigurable lathe, configured for In the above two approaches the variable for

cutting of longitudinal profiles, as shown in the controlling the process is the feedrate, whereas we

picture, is made of the following parts: bed 1, main are using two distinct variables, cutter location CL

spindle 2, workpiece 3, cutting tool 4, tool holder 5, (or federate) and cutter profile (CP). The cutter

carriage 6, rotary tool assembly 7, cross-slide 8, profile variable is the additional freedom degree

slideway 9. Having a supplementary degree of determined by rotary tool assembly.

freedom represented by rotation of cutting tool it is Concerning the restrictions, in the case of MRR

an advantage for tool to positioning, and using model, is the chip area which is set to a minimum

interpolation for x and z axis and the rotation of the allowable (A<Aa), and in the case of force model,

tool it can be achieved peculiar surface processing. the restriction is the force (F<Fa). Our approach

Using a configuration with rotary assembly tool defines four restrictions: (Aa>A(i,j), Ra>R(i,j),

parallel with the axel of the spindle, it can be aa>a(i,j), La>L(i,j).

processed surfaces such as poliexcentric revolution The search technique used in our approach is

surfaces, complex surfaces or cams. The hardware exhaustive search by virtual machining.

modules (main spindle, tool holder, etc) are design Online control such as used in force model, need

as “plug and play” and are controlled directly using monitoring hardware; the proposed optimizing

optimal control variable, by-passing the post method needs a measurement system, which is

processing phase of G-code generation. The control performing every blank exploring.

of the modules it is performed by sending

simultaneously successive

ISSN: 1991-8763 466 Issue 5, Volume 3, May 2008

WSEAS TRANSACTIONS on SYSTEMS and CONTROL A. Epureanu, F.B. Marin, V. Marinescu,

M. Banu and I. Constantin

3 Problem Solution so that the object may have these characteristics –

This means that the part-program should contain a

In order to program the RMT under the above stated list of targets and not a list of instructions. Starting

conditions we need to state several key ideas to from the targets included in the part-program, its

define our proposed RMT control: structure of the machine should allow for

-adaptive negotiation of the plan design, plan analysis and

- online plan proper execution. The part-program shall be

- optimal very simple as it will contain only the targets written

- self-programming in a high-level language. Consequently the machine

The part-program should comprise information programming time shall be much shorter, which is

regarding the characteristics imposed on the crucial in case of small batch production.

manufactured object in order to be considered

acceptable, and not information on the way in which

the functioning cycle of the machine should develop

Fig.4 CNC control hardware architecture

For instance in Fig.4 it is described nowadays CNC another kind of a computer, is chosen as the NC core

conceptual control architecture. Traditionally, CAM system platform, where human machine interaction

has been considered as an NC programming tool or interface (HMI), NC code editing and decoding

used to generate CNC code to drive numerical functions are implemented. Functions such as

controlled machine tools. Most of current numerical interpolation and control, cutter radius

control (NC) systems adopt an architecture as compensation, general I/O (or logic control), servo

described in Fig.4 A computer system, which is control, etc., are implemented in several auxiliary

usually a general-purpose personal computer (PC) or controllers (such as PLCs – Programmable Logic

ISSN: 1991-8763 467 Issue 5, Volume 3, May 2008

WSEAS TRANSACTIONS on SYSTEMS and CONTROL A. Epureanu, F.B. Marin, V. Marinescu,

M. Banu and I. Constantin

Controller). Consequently, the controllers are motors and read data from sensors.

managing commands to servo drives to control

Fig. 5 Proposed RMT control hardware architecture

Our approach considers a bus able to handle part, CAD model of the rough part, technical

communication for all modules. Compared to requirements of the finished part (such as tolerance

today’s fieldbus architecture the hardware modules range and roughness), operation description, and

have close-loops control represented by an rough part material description (such as material

integrated controller able to communicate with hardness).

industrial computer. The information send to As depicted in Fig.7 modern CNC machine

hardware module is the required position only. Also, programming architecture is considering the

if a hardware module has specific sensors besides following data flow. A CAD program is used for

position control of its movement, these are to be workpiece design. Based on the workpiece

handled by the integrated controller on the hardware specification process planning is then performed

module. Compared to nowadays CNC architecture, using a CAPP (Computer Aided Process Planning)

CAM is not providing source code to be interpreted software package. Then, using a manufacturing

and executed by machine, but an algorithm process plan as input the part program is generated

calculated with nominal values. Whereas modern by CAM software. The CNC process this program

CNC CAM software outputs source code describing and the result is the finished workpiece. No

geometric path, and none or few information correction is performed during the machine running.

concerning technological parameters(such as In our proposed architecture Online Learning

federate), our approach is providing the advantage System is providing the parameter correction

of providing the values for technological description computed during process. This is not subject to the

of the process. Therefore our CAM is adaptive and current paper. Also the stability of the process is not

consequently we name it Adaptive-CAM (A- taken in account. Only the stability of each axis is

CAM).The algorithm computed in the A-CAM it is assured during the machine setup by setting

also computed in Algorithm running unit (ARU). choosing a set of parameters.

The CAM running in process design phase is virtual The basic idea which is based our approach is

machining considering nominal values. that the programmer is inputting “the required part”,

Consequently, the ARU running on the machine is “part to be processed” and “the requirements of

running with measured values, which are finished part”. The A-CAM distinctive software

continuously updated and computed. As shown in modules, is running in the design phase (A-CAM)

Fig.5 and Fig.6 it is inputted in the A-CAM the considering nominal parameters (Fig.7). A CAE

following information: CAD models of required program is used to test current kinematical

ISSN: 1991-8763 468 Issue 5, Volume 3, May 2008

WSEAS TRANSACTIONS on SYSTEMS and CONTROL A. Epureanu, F.B. Marin, V. Marinescu,

M. Banu and I. Constantin

configuration. However this is not subject of our module. According to us CSV data list is the part-

paper. ARU, which is basically an extension of A- program which is generated online and is taking into

CAM, is outputting Continuous State Variable List account the current part to be processed.

data set representing the offset moving for each

Fig. 6 A-CAM proposed architecture

Fig.7 Proposed RMT programming

The programming and control architecture proposed The main idea of the optimization algorithm is that,

is allowing commanding to the hardware modules starting with the current i point on the profile part

optimized trajectory. generated by j point on the tool, it is searched the

ISSN: 1991-8763 469 Issue 5, Volume 3, May 2008

WSEAS TRANSACTIONS on SYSTEMS and CONTROL A. Epureanu, F.B. Marin, V. Marinescu,

M. Banu and I. Constantin

next i cutter location and the next cutter profile j dividing the propeller resulted from one revolution,

coordinate point, taking into account the restrictions in four intermediary steps, with coordinate X, Z and

defined by restricted variables (Aij<Aa, Lij<La, ∆θ. All intermediary (i,j) pair coordinates are stored

aij<aa, Rij<R, with the maximum chip area, in order with their restricted variables.

to maximize productivity. In sort, as shown in Fig.8, the proposed algorithm

For generation of certain i point on the workpiece contains the following steps:

profile, the tool must be positioned tangent to this Preparatory steps

profile in a j point. 1) workpiece and tool CAD model are inputted in

For this current cutter position, it is computed the the optimizing system;

values of controlled variables Aij, Lij, aij, Rij. 2) the blank profile is measured on the machine;

Afterwards it is tested restrictions conditions 3) the restricted variables values are inputted in the

Aij<Aa, Lij<La, aij<aa, Rij<R and also of it is virtual manufacturing program

satisfied restriction that j point is on the active Scheduling optimizing steps

cutting edge. The results of the testing are 4) the tool profile it is positioned tangent with the

consequently stored. final profile, successively in all points on the tool.

Fig.8 depictures the generation sequence for final 5) it is computed the restriction conditions for all

surface, using optimization algorithm. For instance, positions and its characteristics,

the point i=21 on the workpiece profile and point 3) when all conditions are denied, then it is selected

j=16 on the cutting profile describes the starting an intermediary position with maximum area,

point for the searching of next point for an 360 4) the algorithm it is repeated starting with 1) until

revolution (pair (21,16) is the previous cutter the tool reaches the end of the profile.

location). 5) the software output are the (i,j) pair coordinates

To achieve this, it is tested one at a time tool 6) processing cinematic configuration of the lathe by

position for i=22 and the points that verify intermediary of the (i,j) pair coordinates there is

restrictions are stored. The searching it is finalized obtained the controlled variables values - X(k), Z(k),

when it is found a point in the final surface profile, θ(k) and ϕ(k) - to be send to the modules by ARU.

with all points on the tool profile, tangent, that do

not verifies conditions. Points i=25 and j=15 is the

pair points for which chip area is maximized for the

given points. It is considered that the new i point, in

this case, i=25 is the correct cutter location and the

search algorithm is continued searching the next

point referred to the last (i,j) pair location.

Fig.8 An example for search loop

Trajectory from point i=21, j=16, to point i=25,

j=15, it is described by the points i=22,23,24, Fig.9 Algorithm basic steps

ISSN: 1991-8763 470 Issue 5, Volume 3, May 2008

WSEAS TRANSACTIONS on SYSTEMS and CONTROL A. Epureanu, F.B. Marin, V. Marinescu,

M. Banu and I. Constantin

Algorithm testing was performed using the

software developed in this research.

It is important to note that the experimental tests

shown in the Fig.10 was executed using arbitrary

scale and on few sequences, for an acceptable

picture accuracy.

The histogram is given bellow to demonstrate the

performances of the algorithm. As shown in Fig.11,

a) image is representing the successive position of c) MRR based algorithm

the cutting edge using our algorithm and lathe F only restricted

architecture, whereas in b) image it was simulated Fig.10 Graphical representation of the cutter

constant MRR based approach with classical lathe location and cutter profile during virtual machining

architecture.

The yellow and green area depicts the cutting In the Fig.7 it is shown a histogram representing

tool successive position. the situation seen in Fig.6, c showing the roughness,

It was noticed an average efficiency chip width and cutting edge length variations for

improvement up to 20%, resulting a higher cutting each cutter location, to evaluate the necessities of

productivity. Compared with the classical case, the more than one or two restrictions.

additional freedom degree represented by rotary tool Since a and R values are greater than the

assembly is the cause for the increased productivity. allowable value for the given example, see Fig.7 a)

Secondly, the computation of all four restrictions, and b) respectively, all four variables are required

instead of one or two, assures that the process is for the establishment of feedrate scheduling. It can

correctly performed according to the specifications. be stated that is compulsory requirement for using

As seen in Fig.7, when the process is based on more than one restriction, in terms of stability

MRR approach, and there is no limitation process and control.

concerning the length of the edge, it is possible to

emerge a situation could cause instable process

because of the vibration.

Furthermore, there is the possibility to undermine

the roughness or chip width allowable values.

a) Chip width variation

a) Proposed algorithm sequences -F,L,a,R restricted

b) Cutting edge length

b) MRR based algorithm sequences c) Roughness variation

F and R restricted Fig.11 Histograms showing undermining allowable

levels

ISSN: 1991-8763 471 Issue 5, Volume 3, May 2008

WSEAS TRANSACTIONS on SYSTEMS and CONTROL A. Epureanu, F.B. Marin, V. Marinescu,

M. Banu and I. Constantin

[5]Stanislav Makhanov, Optimization and

correction of the tool path of the five-axis

4 Conclusion milling machine Part 1. Spatial optimization,

Mathematics and Computers in Simulation 75,

Compared with the classical case, the additional

2007, 210-230

degree of freedom represented by rotary tool

[6]Stanislav Makhanov, Optimization and

assembly, is determining a 20% productivity

correction of the tool path of the five-axis

increase.

milling machine Part 2: Rotations and setup,

The computation of all four restrictions instead of

Mathematics and Computers in Simulation 75,

one or two, assure that the process is correctly

2007, 231-250

performed according to the specifications, and the

[7] B.S. Soa, Y.H. Jung b,, T.R. Kurfess c, S.M.

processing parameters are in the allowable range.

Hwang, 5-Axis machining speed enhancement

The proposed control concept proofing was aimed

by step length optimization, Journal of Materials

by virtual simulation by processing cinematic

Processing Technology 187–188 75, 2007, 2-5

configuration of the lathe by intermediary of

[8] M. Gallo, G.Guizzi, V. Zoppoli, A

controlled variables values ( X(k), Z(k), θ(k) and methodological approach to develop an

ϕ(k) ) to be send to the modules during optimized integrated simulation system in manufacturing

virtual processing. We conclude the new A-CAM processes, 6th WSEAS International Conference

proposed is a viable option for RMT programming on System and Simulation and Engineering,

and it can be implemented physically. 2007

Several topics remain to be studied in the future: [9] M. Paolucci, R. Revetria, F. Tonelli, An Agent-

-firstly, methodologies to rapidly refine the control based System for Sales and Operations Planning

reconfiguration describing current machine in Manufacturing Supply Chains, 6th WSEAS

architecture in order to accurately identify hardware International Conference on System and

modules. Simulation and Engineering, 2007

-secondly, it is challenge to design controller [10] M. Yurtseven, Design and performance

embedded in hardware modules to meet RMT analysis of a linear quadratic Gaussian controller

requirements. in a manufacturing process, 6th WSEAS

International Conference on Circuit, System,

Acknowledgement Electronic, Control and Signal Processing, 2007

The authors gratefully acknowledge the financial [11] OMAC API Work Group (1999) OMAC API

support of the Romanian Ministry of Education and set, Version 0.23. Work-ing document.

Research through grant PN-II-ID_653/2007. http://www.isd.mel.nist.gov/projects/omacapi/

[12] OSACA (1996) Open system architecture

References: controls within automation systems. Final report.

[1] R. Galan, J. Racero, I. Eguia, J.M. Garcia, A http://www.osaca.org/

systematic approach for product families [13] Yi-Hong Long & Zu-De Zhou & Quan Liu

formation in Reconfigurable Manufacturing &Ben-Yuan Chen & Heng-Lin Zhou,

Systems, Robotics and Computer-Integrated Embedded-based modular NC systems, Int J Adv

Manufacturing 23, 2007, 489–502 Manuf Technol, 2008

[2] Jaspreet Dhupia, Bartosz Powalka, Reuven Katz, [14] Wei Li & Yadong Liu & Kazuo Yamazaki &

A. Galip Ulsoy, Dynamics of the arch-type Makoto Fujisima & Masahiko Mori, The design of a

reconfigurable machine tool, International NURBS pre-interpolator for five-axis machining,

Journal of Machine Tools & Manufacture 47, Int J Adv Manuf Technol, 2008

2007, 326–334 [15] Young KW, Piggin R, Rachitrangsan P (2001)

[3] X1. Hwan Pyo Moon, Equivolumetric offsets for An object-oriented approach to an agile

2D machining with constant material removal manufacturing control system design. Int J Adv

rate, Computer Aided Geometric Design Manufact Technol,2006

nternational 2007 Elsevier B.V , Vol.X, No.X,

2007

[4]Jeong Hoon Ko, Won Soo Yun, Dong-Woo Cho,

Off-line feed rate scheduling using virtual CNC

based on an evaluation of cutting performance,

Computer-Aided Design 33, 2003, 383-393

ISSN: 1991-8763 472 Issue 5, Volume 3, May 2008

Você também pode gostar

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Side Pocket Mandral PDFDocumento27 páginasSide Pocket Mandral PDFwajihhasnainAinda não há avaliações

- Amazing Curly ScarfDocumento1 páginaAmazing Curly ScarfBea Ann100% (1)

- Machine Design An Integrated ApproachDocumento280 páginasMachine Design An Integrated ApproachJorge fernandezAinda não há avaliações

- Computational Materials ScienceDocumento32 páginasComputational Materials ScienceJohn_AdaAinda não há avaliações

- Nasm21250 (MS21250, Nas624 .. Nas644)Documento4 páginasNasm21250 (MS21250, Nas624 .. Nas644)Bogdan RusuAinda não há avaliações

- LHM 420Documento432 páginasLHM 420Mohamed El Gamal100% (1)

- Copper Nickel Alloys Properties and Applications 12007Documento28 páginasCopper Nickel Alloys Properties and Applications 12007chocohmxAinda não há avaliações

- Mse 2015Documento21 páginasMse 2015John_AdaAinda não há avaliações

- Copper Nickel Alloys Properties and Applications 12007Documento28 páginasCopper Nickel Alloys Properties and Applications 12007chocohmxAinda não há avaliações

- Mining Data From CFD Simulations Using Suport Vector Machine LearningDocumento4 páginasMining Data From CFD Simulations Using Suport Vector Machine LearningJohn_AdaAinda não há avaliações

- Material Science EngineDocumento5 páginasMaterial Science EngineJohn_AdaAinda não há avaliações

- Engineering: Chemical Engineering and Materials ScienceDocumento3 páginasEngineering: Chemical Engineering and Materials ScienceJohn_AdaAinda não há avaliações

- MseDocumento3 páginasMseJohn_AdaAinda não há avaliações

- Material Science EngineDocumento5 páginasMaterial Science EngineJohn_AdaAinda não há avaliações

- Curie Temperature in Ferromagnetic MaterialsDocumento6 páginasCurie Temperature in Ferromagnetic MaterialsJohn_AdaAinda não há avaliações

- Thermo-Cam at Topic WeekDocumento11 páginasThermo-Cam at Topic WeekJohn_AdaAinda não há avaliações

- MatscienceDocumento13 páginasMatscienceapi-73325304Ainda não há avaliações

- Experimentation With Ferromagnetic Materials UsingDocumento6 páginasExperimentation With Ferromagnetic Materials UsingJohn_AdaAinda não há avaliações

- Thermo-Cam at Topic WeekDocumento11 páginasThermo-Cam at Topic WeekJohn_AdaAinda não há avaliações

- Fe-C Phase DiagramDocumento34 páginasFe-C Phase DiagramYoung-long Choi100% (1)

- Analyses of The Fundamental Parameters of Cold DieDocumento8 páginasAnalyses of The Fundamental Parameters of Cold DieJohn_AdaAinda não há avaliações

- 104phases Notes 1314 CDocumento69 páginas104phases Notes 1314 Cnilanga123Ainda não há avaliações

- Chapter 3Documento26 páginasChapter 3Bala SubramanianAinda não há avaliações

- 1-2 Learning ABAQUSDocumento9 páginas1-2 Learning ABAQUSCuGáyLâmĐồngAinda não há avaliações

- Holonic ReconfigurableDocumento6 páginasHolonic ReconfigurableJohn_Ada100% (1)

- Beading Inspiration - How To Use Color in Jewelry DesignDocumento95 páginasBeading Inspiration - How To Use Color in Jewelry DesignJohn_Ada100% (3)

- The Art of Bead EmbroideryDocumento113 páginasThe Art of Bead Embroiderymunteanu_oana_7100% (3)

- 10th Wseas Int. Conf. On Automatic Control, Modelling & SimulationDocumento6 páginas10th Wseas Int. Conf. On Automatic Control, Modelling & SimulationJohn_Ada100% (1)

- 10th Wseas Int. Conf. On Automatic Control, Modelling & SimulationDocumento6 páginas10th Wseas Int. Conf. On Automatic Control, Modelling & SimulationJohn_Ada100% (2)

- FLY Software Package Expert hyperMILL enDocumento3 páginasFLY Software Package Expert hyperMILL enVinicius Sabrina PedroAinda não há avaliações

- Geometric Accuracy of Machine Tools" Holub, M. (2018)Documento24 páginasGeometric Accuracy of Machine Tools" Holub, M. (2018)Edgar CaloAinda não há avaliações

- ESAFORM2008 ProceedingsDocumento82 páginasESAFORM2008 Proceedingsnyilmaz72411Ainda não há avaliações

- Optimalisasi Hasil Proses Wire-Cut Edm Dengan Metode Principal Component Analysis (Pca) (Studi Kasus Di CV - Catur Prasetya Packindo) Mulyadi, Agus Puji SuryantoDocumento6 páginasOptimalisasi Hasil Proses Wire-Cut Edm Dengan Metode Principal Component Analysis (Pca) (Studi Kasus Di CV - Catur Prasetya Packindo) Mulyadi, Agus Puji SuryantoSigit BagusAinda não há avaliações

- Catalogo Adaptadores HidraulicosDocumento97 páginasCatalogo Adaptadores HidraulicosGonzalo Villalobos SanchezAinda não há avaliações

- Spin Del BrochureDocumento14 páginasSpin Del BrochureshifaAinda não há avaliações

- Catalogue W170Documento46 páginasCatalogue W170graham4877Ainda não há avaliações

- IMECS2009 pp1803-1808Documento6 páginasIMECS2009 pp1803-1808Ratan KumarAinda não há avaliações

- Me6703 Cim Mech Viist Au Unit IIIDocumento51 páginasMe6703 Cim Mech Viist Au Unit IIISiva RamanAinda não há avaliações

- 6th Sem Milling MachineDocumento41 páginas6th Sem Milling MachineIshan VermaAinda não há avaliações

- Un NecessaryDocumento86 páginasUn NecessaryAbdul AhadAinda não há avaliações

- Heckert H Series Brochure 2022 enDocumento15 páginasHeckert H Series Brochure 2022 enKalees WaranAinda não há avaliações

- True Bore Alignment System: User GuideDocumento12 páginasTrue Bore Alignment System: User GuideDenis BenderAinda não há avaliações

- ASU Design and Manufacturing BOOKLETDocumento0 páginaASU Design and Manufacturing BOOKLETIndranil BhattacharyyaAinda não há avaliações

- Module 1. Prelims Workshop Theory and Practice 1ADocumento7 páginasModule 1. Prelims Workshop Theory and Practice 1AmanuelAinda não há avaliações

- Automan 3 AprilDocumento14 páginasAutoman 3 AprilJohn DonboscoAinda não há avaliações

- Labormil Multi-Purpose Lathe N Machine ToolDocumento14 páginasLabormil Multi-Purpose Lathe N Machine Toolgotti45Ainda não há avaliações

- Drilling-Machine Group 5Documento19 páginasDrilling-Machine Group 5Chandra Kiran HjAinda não há avaliações

- Project Report: Submitted To: Sir Anees Ur RehmanDocumento9 páginasProject Report: Submitted To: Sir Anees Ur RehmanMuneeb Ur RehmanAinda não há avaliações

- Reverse Edm Collective Electrodes in Micro EcmDocumento5 páginasReverse Edm Collective Electrodes in Micro EcmInternational Journal of Application or Innovation in Engineering & ManagementAinda não há avaliações

- Automation, Prouction Systems and CIM MP GROOVER CHAPTER 7 SolutionDocumento24 páginasAutomation, Prouction Systems and CIM MP GROOVER CHAPTER 7 SolutionMuhammad Adeel Ahsen100% (1)

- PhoenixDocumento65 páginasPhoenixdominant cncAinda não há avaliações

- Tugas Presentasi Prosman Kelas C Ganjil 2021 OkDocumento2 páginasTugas Presentasi Prosman Kelas C Ganjil 2021 OkRidwan HakimAinda não há avaliações

- Optimization of Reamming Process Using Particle Swarm OptimizationDocumento18 páginasOptimization of Reamming Process Using Particle Swarm OptimizationArivazhagan ArtAinda não há avaliações

- Risk AssessmentDocumento6 páginasRisk AssessmentEhab Yahia Khalel100% (2)