Escolar Documentos

Profissional Documentos

Cultura Documentos

Learning The Lessons of Deepwater Asset Integrity - Offshore

Enviado por

doctor_arvind2003Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Learning The Lessons of Deepwater Asset Integrity - Offshore

Enviado por

doctor_arvind2003Direitos autorais:

Formatos disponíveis

7/30/2014 Learning the lessons of deepwater asset integrity - Offshore

http://www.offshore-mag.com/articles/print/volume-70/issue-11/engineering_-construction/learning-the-lessons-of-deepwater-asset-integrity.html 1/6

Stay Connected

Subscribe: Magazine l Newsletters

Home > Learning the lessons of deepwater asset integrity

Learning the lessons of deepwater asset

integrity

11/01/2010

Past and recent events point to need for careful assessment of materials performance and corrosion protection

Dr. Binder Singh

Wood Group Integrity Management

Dr. Paul Jukes

MCS Kenny

Bob Wittkower

JP Kenny Inc.

Ben Poblete

Cameron

On the July 6, 1988, the worlds worst offshore oil industry disaster occurred on the Piper Alpha platform in the UK sector

of the North Sea. The loss of life was staggering: 167 dead, with 62 survivors, and dozens badly injured. Much has been

written and debated on the incident. The goal here is to examine a new angle on the subject matter, in the context of

Inherently Safe Design, and the allied second tier items of interest. These are the corrosion-related items that have

been accepted as pertinent over the years, but often erroneously perceived with less priority.

This is largely because the subject matter is considered too specialistic, or complex and often requiring costly subject

matter expertise. As a result, corrosion integrity is sometimes dangerously taken off the agenda by non-subject-

appreciative project or even industry leaders. As part of this process, it is necessary to examine the role of corrosion

mechanisms in the root cause analyses of most significant failures, and virtually all loss-of-performance issues.

Offshore

Digital Magazine

Look Inside

Open +

Home Regional Reports Drilling & Completion Field Development Subsea Geosciences Pipelines Production Rigs/Vessels

Deepwater Business Briefs

7/30/2014 Learning the lessons of deepwater asset integrity - Offshore

http://www.offshore-mag.com/articles/print/volume-70/issue-11/engineering_-construction/learning-the-lessons-of-deepwater-asset-integrity.html 2/6

Piper Alpha before Accident. (Courtesy Wood Group)

The Piper Alpha accident was a monumental event. It is, perhaps, in terms of impact a top-five engineering disaster on

the global scale, considered to be in the same league as Chernobyl, Challenger, Three Mile Island, Flixborough, etc. In

terms of cost, it was also very expensive (estimated at more than $3.4 billion). And in many ways it is historically

comparable to other

high-impact human events, in that people (certainly in the British Isles and the North Sea community) often remember

where they were on the day. In that way, Piper Alpha seems to have uniqueness about it, which may be due to the fact

that it was offshore and involved a heavily manned producing platform. With the benefit of hindsight, we can conclude

that the disaster was de facto man made, in that the original platform had many major design changes made to convert

it into a gathering and distribution hub.

Though not a deliberate act in any way, many human and engineering errors were seen to hideously come into play.

Many studies have looked at that aspect, including the Cullen Report which was published in 1990. This was the

culmination of a thorough two-year inquiry involving many interviews with survivors, families, and subject-matter experts

of the day. The Cullen report has tended to be the mainstay reference source for all new offshore design and

operational guidelines the world over. Some regions have used the findings rigorously whereas others have used them

less in depth. Overall, the report led to the effective dissolution of the prescriptive regulations sanctioned up to that point,

and replaced them with the evolution of the goal-setting integrity regulations in the UK and with derivatives thereof.

On the plus side, the major outcome of the disaster has been far better, safer, and more efficient engineering practices

for the oil industry. And this, in turn, has reinforced the need for Inherently Safe Designs and procedures. These have

been realized by better, more focused research, better applied knowledge management, and a greater sense of public

and industry responsibility by the new generation of engineers and scientists.

Many more offshore, subsea and integrity-related projects and courses have evolved worldwide, largely at contract

research or post-graduate level, much to the advantage and betterment of the industry. This has been promulgated by

the recognition that the design of the asset structure, pipeline, and pressure plant can no longer be based on

projected revenues alone. Yes, the ultimate decision maker or breaker can and often is the commercial sensibility, but a

greater sense of responsibility to the public, and the environment, has fallen into place. This is largely Regulatory-driven,

but one can still discern a good dose of professionalism, merit and worthiness in the arena.

Root causes

Regarding the accident there was, perhaps, no single root cause event that was to blame. Rather, it was a confluence of

many critical factors that were almost the perfect storm. This is often described as the jigsaw or Swiss cheese effect,

whereupon critical events occurring at a certain juncture in time; and as a consequence the failure sequence fell into

place, with tragic results. In reality, integrity management (IM) is far more complex than basic maintenance (a common

misnomer). The parameters affecting IM are non-linear, and have their greatest impact during IM pre-planning, post-

planning, action and reaction, etc. They usually involve the alignment of bad sequences, events or circumstances. They

are invariably all time-dependent and thus multi-dimensional in nature. This has traditionally made IM a difficult subject

to grasp, especially since it transcends both CAPEX and OPEX cost centers.

The Piper Alpha explosion.

The Piper Alpha platform was commissioned in 1976, but was modified to act as a major gas processing and gathering

station. This meant it was handling large amounts of high-pressure gas, with a dispersed plant layout, making

inspection, maintenance and repair difficult. The rapid technology advances of the day, coupled with powerful

commercial pressures, clearly had a lot to do with the event. Regarding the best way forward, it is important to identify all

integrity-related threats, some of which may be discerned as at a secondary level, albeit with the potential to give similar

disastrous results if not taken fully into account. The majority of these are materials performance and corrosion related.

Basin Modeler - Unconventional

Saudi Aramco

Country: Saudi Arabia

A world leader in the production of hydrocarbon

based energy is building a leading "Unconventional

Gas Team" and seeks a basin modeler to contribute

to the teams advancement in unconventional

gas/liquid plays. Applicants with 10-15 years

industry experience and a strong geological and 3D

basin mode...

Geophysical Consultant (Unconventional)

Saudi Aramco

Country: Saudi Arabia

Geophysicists who have experience in identifying

and characterizing shale and tight gas reservoirs

using seismic data. Saudi Aramcos position as a

world leading hydrocarbon finder and producer

offers unique opportunities for Development

Geologists to realize their full technical potential.

Soon, Sa...

Transmission Line Design Engineer

Great River Energy

Country: United States

General SummaryWe are currently looking for a

Transmission Line Design Engineer who will be

responsible for performing engineering, project

management and technical support for transmission

line design projects.Main responsibilities

include:Provide cost-efficient design and project

management fo...

Engineer (Hydro Plant Support Engineer)

Southern Company

Country: United States

JOB SUMMARYThis position serves as a resource for

hydro management by providing technical field

support and troubleshooting. Provides specialized

hydro consultation services and multidisciplinary

technical support for developing and managing

hydro technical requirements and performing

analytical st...

Civil Engineer III- Geotechnical and Dam

Safety #2014-4703

Dominion

Country: United States

Seeking experienced Civil Engineer III to support our

Power Generation fleet to include 20 classified dams

and containment structures. Outstanding

compensation and benefits. Full relocation

package.Keywords: Geotechnical, Dam, Hydro, Civil

Engineer, Dam Safety, Hydraulics, Hydrology, Dam

Current Issue

Oil & Gas Jobs

View more Job Listings >>

7/30/2014 Learning the lessons of deepwater asset integrity - Offshore

http://www.offshore-mag.com/articles/print/volume-70/issue-11/engineering_-construction/learning-the-lessons-of-deepwater-asset-integrity.html 3/6

The latter is an important point, and necessitates the examination of second tier issues, which usually arise within

lower profile design parameters. Examples include pressure (leak) containment, corrosion analysis, erosion, wear and

tear, inspection, monitoring, pigging, and maintenance. Thus, it is not hard to see that once the Piper Alpha was

converted to its hub status, it became more important to continue producing. As a result, the inspection, maintenance

and corrosion control aspects became less important.

After the disaster it became apparent that the Piper suffered serious corrosion problems, particularly regarding the

condensate pumping systems, which were in fact later determined to be at the heart of the problem on that fateful day.

Essentially, the condensate pumps were under much delayed repair and maintenance schedules. On the fateful day,

the work was underway but incomplete. Thus, the supervisor prepared a permit to work (ptw) for the work to be

continued by the next shift. The pump was temporarily blanked off, and the paperwork was submitted. Unfortunately, the

ptw got mislaid and the next shift erroneously switched on the pump. Since the backup was offline, the blind flange

failed and a massive leak of gas under high pressure was released. A detonation was inevitable. When it happened,

the fire fighting systems failed, other platforms continued to feed into the hub, and the disaster as we know it unfolded.

After the accident, due to the media frenzy of the day, the causes were variously reported over the first year as: metal

fatigue, poor maintenance, inadequate operating procedures, bad work practices, human error, etc. The full report is a

public document, and much educational material, videos/DVDs etc. are readily available for the interested reader. The

Cullen report and other studies have highlighted many reasons for the disaster, the most damning of which were:

Poor plant design (including rapid modifications and changes)

Breakdown of the permit to work system (probably not fully tested under all scenarios)

Bad maintenance management

Inadequate safety auditing, and training procedures

Poor communications (all levels)

Poor emergency management (including with regard to action of surrounding platforms).

The Cullen report made over 106 recommendations, which included in summary:

The transfer of government responsibility for offshore health and safety to the Health and Safety Executive (HSE)

was generally well received.

The establishment of a Safety Case regime (entailing independent verification).

Overall review of legislation, definition of best practices, and better use of loss prevention studies.

Better work force involvement (crucial but sensitive).

Verification and intervention when necessary.

Permit-to-work systems (ideally fail safe and tamper proof).

Systematic approach to safety, responsibility of everyone (senior management and down the line).

Emergency response and incident reporting (effectively by training and changes in attitude and culture).

It has to be said that most of the activities listed above still fall in the grey area of judgment, and in that case best

practices must therefore be interpreted and applied through the identification of safety critical systems and components,

proactive risk analysis, risk reduction, and therefore risk management. There are many other important derivations from

the Cullen report, but without unnecessarily going outside the scope of this article, it is quite clear that management of

change (MOC) is and will continue to be the best tool available in the ever-improving area of knowledge management.

Industry changes

The many ensuing industry changes identified since the disaster have, in fact, taken many years to come to fruition.

Overall, most offshore regions in particular the North Sea, GoM, and Australia have embraced the new culture of

safety. To be sure, there is sometimes a dangerous disconnect between theory and the actual practice of

implementation. The rest of the world

has responded in a slower manner, but with positive results, especially the SE Asia regions and offshore India.

The very heartening implementation of best practices (by choice, not necessarily regulation) has given greater

confidence for the new, challenging deepwater explorations and subsea tie backs in the GoM and the new frontier Arctic

regions. The most notable changes are interpreted as follows:

Changes to offshore asset design, requirements for design review, more latitude for concept creativity, better

rationale for engineering conservatism and pragmatic safety.

New goal-setting legislation; i.e. the Safety Case, and better use of subject matter experts (SMEs).

The goal setting idea replaces the prescriptive method. This has proved to be a step change in offshore safety

and engineering performance.

For the GoM, it has been stated that the regulations conferred by the governing (now former) MMS are fit for purpose.

This suggests the designs are suitable at construction, but the gradual drift of this meaning has evolved to life-cycle

fitness for purpose and this appears to be adopted and embraced by the more recent generation of engineers (typically

5-10 years

experience) as they enter the fray. The subtle debate now ongoing is at the material selection stage. There are two

schools of thought, namely the distinction being made of whether to select carbon steel and then carefully manage the

operational corrosion; or to select the corrosion resistant alloy option with minimal corrosion management. The contrary

arguments are usually cost-center based, with strong opinions tested for CAPEX and OPEX scenarios. In other words,

do we pick materials for immediate fitness for service at fabrication (just build it) or fitness for materials life cycle

performance? The answer is now emerging as a requirement for both, and to that effect the materials engineering

specialist is having an ever-more assertive role to play within the large multidiscipline teams usually engaged on high

capital projects.

Implementation

The implementation of the Cullen report recommendations has, it is believed, shown through various studies that

reportable incidents that impact safety issues in the UK sector have been significantly reduced by some 75% a major

achievement. This clearly means the industry is on the right track, but there are still problems and issues. It is argued

that more attention should and must be made to the secondary tier items such as root cause corrosion mechanisms,

7/30/2014 Learning the lessons of deepwater asset integrity - Offshore

http://www.offshore-mag.com/articles/print/volume-70/issue-11/engineering_-construction/learning-the-lessons-of-deepwater-asset-integrity.html 4/6

advanced

monitoring and inspection techniques, etc. This aspect is best illustrated by an adaption of the Swiss cheese effect. It

is to this effect that this article is targeted, with the intent that by paying more focused attention to these parameters and

findings, the integrity management discipline will be more substantively improved.

The Cullen report also identified two areas of under-emphasis that may be appropriately reasoned, firstly the industry

tendency to avoid the acceptance of external consultants advice if the recommendations are not supported by more

experienced personnel, often even if the consultation seems logical and safety sensible. The case of the central riser

argument for the Piper Alpha is cited; here evidently the dangerous proximity of the risers to the control and radio room

areas was, in fact, identified, but no action taken (design change, relocation, blast walling, etc). Nowadays, virtually all

new designs insist on the risers being as far away as possible from the accommodations.

The Swiss cheese analogy as applied to materials engineering.

The second point of observation is the concept of addressing root cause effects. The Piper Alpha condensate pump

problems that initiated the whole tragic sequence of events were plagued with corrosion problems, the attendance to

which was seemingly consistently delayed as lower priority. Apparently some platform corrosion issues were left for

over four years. If corrosion management as a recognized discipline had been in place, rather than an ad hoc to-do

item, then again (with the benefit of hindsight), the tragedy could have been avoided. That, unfortunately, is how the

learning and knowledge management process works. And it has to be said that companies today often have very

valuable lessons-learned meetings after major projects are concluded. There is a strong case, and new initiatives,

underway for such formal lesson learning on an ongoing basis.

The use of modern-day corrosion risk assessment techniques are under development and application. It is hoped that

ultimately these will be implemented by the weight of motivation, though in reality some degree of mandatory regulation

may be ultimately required. In almost all major comparable disaster cases, the commonality has been the confluence of

many variables coming into a tragic alignment, sometimes referred as the jigsaw or Swiss cheese effect. The authors

of this article contend that in almost all cases, the loss of materials performance as stimulated by corrosion is the root

cause effect. A close examination of the modes of failure reveals the uncanny role of corrosion dissolution at either the

macro or micro level (whether it be by alloy, embrittlement, crevice corrosion, mixed metal galvanic, etc) the outcome is

the same: severe loss of material properties and/or load carrying capabilities.

The resolution of the corrosion aspect will, therefore, in virtually all cases eliminate the closure of the jigsaw effect,

thereby preventing the failure. On a positive note, the concepts of knowledge management, advanced inspection

techniques, implementation of MOC, and the more newly defined roles and responsibilities for pertinent decision

makers, etc., have all been very instrumental in making this industry safer and better equipped to tackle the challenges

faced ahead. It is strongly argued that one new recommendation that would be instrumental in helping improve this

aspect an order of magnitude would be the mandatory requirement for each asset to submit a clear annual corrosion

integrity statement on the facility, and pertinent (safety critical parts) thereof. The burden for doing this is not high, but the

results would be extremely positive.

Conclusion

The Piper Alpha review has been a work in progress, with many derived findings, conclusions and specifically KPI-

based recommendations, most of which are capable of being tailored to new and existing projects. The most valuable

observation is the need for continued life cycle vigilance, most likely through diligent but limited regulatory control, since

the North Sea experience has shown that over regulation can impose major financial burdens often to the detriment of

the project, and sometimes to the creativity of solutions.

It is important for the future deepwater offshore community to look more closely at new designs and new solutions from

both a materials fabrication and the materials performance basis, especially for safety critical elements such as SCRs,

and pressure containment plant, and potential leak sources at interfaces. Companies must continually re-educate staff

so that lessons learned (and near misses) are not forgotten, and be prepared to look at alternative approaches to

design/operational issues even if they emanate from unconventional sources.

Better cooperation between the CAPEX and OPEX cost centers is vital if full advantage of lessons learned from Piper

Alpha and other disasters are to be realized. In reality, this may take the form of an extended CAPEX commitment.

History has shown that major step change progress is usually made after major disasters and often through non-

7/30/2014 Learning the lessons of deepwater asset integrity - Offshore

http://www.offshore-mag.com/articles/print/volume-70/issue-11/engineering_-construction/learning-the-lessons-of-deepwater-asset-integrity.html 5/6

DOT 2013: Tubular Bells a fasttrack success for Hess

Nov 21, 2013 The Tubular Bells deepwater spar production platform is scheduled for start-up mid-2014, only

three years from Hess sanction in 2011, making it a successful fast-track project, said Jason Olson, pr...

Surfactant system could lead to enhanced oil recovery

Nov 21, 2013 Surface Active Solutions has teamed with Exilica to develop a chemical surfactant system named

SAS Oil-Rec.

WFS Technologies and Fugro to offer first wireless ROV integration

Jul 29, 2014 WFS Technologies, which delivers underwater wireless instrumentation and control solutions to

offshore oil and gas operations, and Fugro Subsea Technologies, which designs, builds, and delivers the FCV

range of ROVs to its Subsea Services Division, are jointly offering subsea wireless capability on all FCV Work

Class ROVs from 2015 onward.

Eco Atlantic set to acquire interest in block offshore Ghana

Jul 29, 2014 Eco (Atlantic) Oil & Gas Ltd reports that the Parliament of the Republic of Ghana has ratified a

petroleum agreement pursuant to which the company may acquire a 50.51% interest in the Deepwater Cape

Three Points West block, located in the Tano Cape Three Points basin, offshore Ghana, adjacent to Tullow Oil

plcs producing Jubilee oil field.

BOEM calls for 2017 Beaufort Sea lease sale area nominations

Jul 29, 2014 The Bureau of Ocean Energy Management has issued a call for information and nominations for a

potential lease sale offshore Alaska.

Apache hits gas at Phoenix South-1

Jul 29, 2014 Carnarvon Petroleum Ltd. reports that gas and indications of associated liquid hydrocarbons were

observed in the Phoenix South-1 well, offshore Western Australia.

CNOOC, Primeline start up Lishui offshore China

Jul 29, 2014 CNOOC has started production from the Lishui 36-1 gas field.

Offshore Topics

Drilling & Completion

Field Development

Subsea

Geosciences

Pipelines

Production

Rigs/Vessels

Deepwater

Business Briefs

Regional Reports

Africa

Asia

Australia & New Zealand

Canada

Latin America

Middle East

North Sea & Europe

Russia

US & Gulf of Mexico

conventional means. The new solution sets, and developments vis-a- vis inherently safer designs will come from a

closer liaison between industry and academia, as exemplified by the JIPs already in place. The powerful role of

academia whether through JIPs or self driven changes in university curricula will be instrumental in the paradigm

shift required and perhaps expected.

Acknowledgment

Based on a paper presented at the Deep Offshore Technology International Conference, held at the George R. Brown

Convention Center in Houston, Texas, February 2-4, 2010; and on a paper presented at the Offshore Technology

Conference, Offshore Integrity Management 20 years onOverview of Lessons Learnt Post Piper Alpha (Paper # OTC-

20051-PP).

More Offshore Issue Articles

Offshore Articles Archives

View Oil and Gas Articles on PennEnergy.com

More Offshore Issue Articles

Offshore Articles Archives

Related Articles

Trending News

7/30/2014 Learning the lessons of deepwater asset integrity - Offshore

http://www.offshore-mag.com/articles/print/volume-70/issue-11/engineering_-construction/learning-the-lessons-of-deepwater-asset-integrity.html 6/6

1455 W. Loop South, STE. 400

Houston, Texas 77027 | (713)

621-9720

Copyright 2013: PennWell

Corporation All Rights Reserved

Home

About Us

Advertise

Contact Us

Subscribe

Terms

Events

RSS

Company News

Special Reports

Resources

Privacy Policy

General

Regional Reports

Drilling & Completion

Field Development

Subsea

Geosciences

Pipelines

Production

Rigs/Vessels

Deepwater

Business Briefs

Topic Centers

Pennwell

View All Pennwell Websites

View All Pennwell Events

Sitemap

Webmaster

PennWell

Você também pode gostar

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- HSE Certificate-Zob Hazard AnalysisDocumento1 páginaHSE Certificate-Zob Hazard Analysisdoctor_arvind2003Ainda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- HSE Certificate-Zob Hazard AnalysisDocumento1 páginaHSE Certificate-Zob Hazard Analysisdoctor_arvind2003Ainda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- HSE-H2S Awareness and EscapeDocumento1 páginaHSE-H2S Awareness and Escapedoctor_arvind2003Ainda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

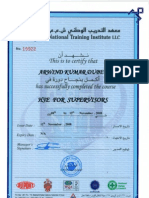

- HSE of SupervisorsDocumento1 páginaHSE of Supervisorsdoctor_arvind2003Ainda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- HSE of SupervisorsDocumento1 páginaHSE of Supervisorsdoctor_arvind2003Ainda não há avaliações

- Personal Selling and Sales Promotion: Chapter ObjectivesDocumento17 páginasPersonal Selling and Sales Promotion: Chapter ObjectivesNishu GoyalAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- HSE-Gas Testing CertificateDocumento1 páginaHSE-Gas Testing Certificatedoctor_arvind2003Ainda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Corrosion Inhibition of Mild Steel by Using Polyethylene Glycol Methyl Ether PEGMEDocumento15 páginasCorrosion Inhibition of Mild Steel by Using Polyethylene Glycol Methyl Ether PEGMEArwind Kr DubeyAinda não há avaliações

- Sample PMP Preparatory Questions and Answers: LeadershipDocumento42 páginasSample PMP Preparatory Questions and Answers: Leadershippelle_3_hard9131100% (2)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Production and Operations ManagementDocumento21 páginasProduction and Operations ManagementGaurav218100% (4)

- Design GuidelinesDocumento15 páginasDesign GuidelinesdolonbgdAinda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Pigging Pipeline Operations-2011Documento15 páginasPigging Pipeline Operations-2011doctor_arvind2003100% (2)

- NDT Manual PDFDocumento1.030 páginasNDT Manual PDFFuchsbau100% (4)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Reviewer Certification of American Chemical Science JournalDocumento1 páginaReviewer Certification of American Chemical Science Journaldoctor_arvind2003Ainda não há avaliações

- WWT Cooling WaterDocumento38 páginasWWT Cooling Waterdoctor_arvind2003Ainda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Chemical Control of CorrosionDocumento64 páginasChemical Control of Corrosiondoctor_arvind2003Ainda não há avaliações

- GWUTDocumento23 páginasGWUTdoctor_arvind2003100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- AffirmationDocumento21 páginasAffirmationdoctor_arvind2003Ainda não há avaliações

- Arabic PhrasebookDocumento40 páginasArabic Phrasebookdoctor_arvind2003Ainda não há avaliações

- Practical Considerations For Users of Guided Wave Ultrasonic Testing (51300-07164-SG)Documento6 páginasPractical Considerations For Users of Guided Wave Ultrasonic Testing (51300-07164-SG)doctor_arvind2003Ainda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Article - Corrosion Under Insulation (CUI)Documento3 páginasArticle - Corrosion Under Insulation (CUI)doctor_arvind2003Ainda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- HSE of SupervisorsDocumento1 páginaHSE of Supervisorsdoctor_arvind2003Ainda não há avaliações

- Candries Paint ReviewDocumento27 páginasCandries Paint Reviewapi-3864361Ainda não há avaliações

- Risk Based AssessmentDocumento11 páginasRisk Based Assessmentdoctor_arvind2003Ainda não há avaliações

- Glossary of Gas SystemDocumento56 páginasGlossary of Gas Systemdoctor_arvind2003Ainda não há avaliações

- Microbial Induced Corrosion MIC Article Published Netherland Magazine Jan Feb 13 Edition by DR Arwind Kumar DubeyDocumento2 páginasMicrobial Induced Corrosion MIC Article Published Netherland Magazine Jan Feb 13 Edition by DR Arwind Kumar Dubeydoctor_arvind2003Ainda não há avaliações

- Epoxy Coating GuideDocumento8 páginasEpoxy Coating GuideAzlan Othman100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Inspection Manual For PipingDocumento183 páginasInspection Manual For PipingMartin Zaballa100% (3)

- Welding CoatingDocumento69 páginasWelding CoatingspaljeniAinda não há avaliações

- Noor Hafiz Kamaruddin Resume Rev 1Documento3 páginasNoor Hafiz Kamaruddin Resume Rev 1Noor Hafiz KamaruddinAinda não há avaliações

- Abstract - Mooring Analysis of Semisubmersible (Rifel Landong Pordiman)Documento1 páginaAbstract - Mooring Analysis of Semisubmersible (Rifel Landong Pordiman)Rifel Landong PordimanAinda não há avaliações

- Petromechanics Systems IiDocumento11 páginasPetromechanics Systems IiIsaac Junior Honny100% (1)

- Deepwater Oil Field Production Facility SelectionDocumento9 páginasDeepwater Oil Field Production Facility SelectionAnil Chanana100% (1)

- Electrical and Instrumentation (E & I) Engineering For Oil and Gas FacilitiesDocumento33 páginasElectrical and Instrumentation (E & I) Engineering For Oil and Gas FacilitiesIslam HassanAinda não há avaliações

- Report-Under Water Inspection Fuel Pipelines and Unloading FacilitiesDocumento49 páginasReport-Under Water Inspection Fuel Pipelines and Unloading FacilitiesEarl Justin EnriqueAinda não há avaliações

- Oil and Gas EngineeringDocumento50 páginasOil and Gas Engineeringjairo73scribdAinda não há avaliações

- Well Failure Model - Example: Mitigating Action Matrix - Key To Numbers Entered in Matrix AboveDocumento20 páginasWell Failure Model - Example: Mitigating Action Matrix - Key To Numbers Entered in Matrix Aboveeng7mohamed7hashimAinda não há avaliações

- TSB Gas Development ProjectDocumento24 páginasTSB Gas Development ProjectMarlon Moncada100% (2)

- Group K FinalDocumento82 páginasGroup K Finalvijay_bhargavanAinda não há avaliações

- Subs On YachtsDocumento18 páginasSubs On YachtsAna BrajkovicAinda não há avaliações

- WOM Subsea Brochure 8Documento40 páginasWOM Subsea Brochure 8arietilangAinda não há avaliações

- Scanrope - UmbilicalDocumento6 páginasScanrope - Umbilicalcuongpham301Ainda não há avaliações

- Eni Australia Scalybutt Tieback Rev 1Documento1 páginaEni Australia Scalybutt Tieback Rev 1JustinAinda não há avaliações

- Osv Class AbsDocumento40 páginasOsv Class AbsAhmad ImranAinda não há avaliações

- Cameron MOSAIC Systems For The Ceiba Field Early Production SystemDocumento8 páginasCameron MOSAIC Systems For The Ceiba Field Early Production SystemsmashfacemcgeeAinda não há avaliações

- Drilling Practices: Drill Stem TestingDocumento37 páginasDrilling Practices: Drill Stem TestingDenier Rubiano100% (2)

- ISO Standards For O&G Industry April 2022 v2Documento1 páginaISO Standards For O&G Industry April 2022 v2Emre Metin100% (1)

- H010198 DW BrochureDocumento4 páginasH010198 DW BrochurePrototypeAinda não há avaliações

- Subsea Installation PosterDocumento1 páginaSubsea Installation Postercxb07164Ainda não há avaliações

- Marine Structures: Yong Bai, Jiandong Tang, Weiping Xu, Weidong RuanDocumento18 páginasMarine Structures: Yong Bai, Jiandong Tang, Weiping Xu, Weidong RuankamalAinda não há avaliações

- Ge Subsea Manifolds Connection Systems BrochureDocumento7 páginasGe Subsea Manifolds Connection Systems BrochureRashesh ShahAinda não há avaliações

- Subsea EngineeringDocumento16 páginasSubsea EngineeringMae JoyceAinda não há avaliações

- 2 - FMC Technologies Overview Service School Singapore June 11 PDFDocumento43 páginas2 - FMC Technologies Overview Service School Singapore June 11 PDFI PUTU EKA PRASADAAinda não há avaliações

- F12 Gas DevelopmentDocumento4 páginasF12 Gas DevelopmentDidiAinda não há avaliações

- Maersk DeveloperDocumento12 páginasMaersk DeveloperNoor HadiAinda não há avaliações

- Surface Well HeadDocumento106 páginasSurface Well HeadAnonymous U5t9NYzhLW83% (6)

- SrgewDocumento37 páginasSrgewHugo DuchovnyAinda não há avaliações

- Well StreamDocumento6 páginasWell StreamErick de la CruzAinda não há avaliações

- BP Subsea Realiability StrategyDocumento25 páginasBP Subsea Realiability Strategyrize1159Ainda não há avaliações