Escolar Documentos

Profissional Documentos

Cultura Documentos

Performance of Nano Crystalline H-zsm-5 As Additive in FCC Catalyst A Review

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Performance of Nano Crystalline H-zsm-5 As Additive in FCC Catalyst A Review

Direitos autorais:

Formatos disponíveis

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 03 Special Issue: 03 | May-2014 | NCRIET-2014, Available @ http://www.ijret.org 481

PERFORMANCE OF NANO CRYSTALLINE H-ZSM-5 AS ADDITIVE IN

FCC CATALYST: A REVIEW

Jitendra Kumar

1

, Chanchal Mewar

2

, Lekhraj Malviya

3

, Bharat Modhera

4

1

Chemical Engineering Department, Maulana Azad National Institute of Technology, Bhopal, India

2

Chemical Engineering Department, Maulana Azad National Institute of Technology, Bhopal, India

3

Chemical Engineering Department, Maulana Azad National Institute of Technology, Bhopal, India

4

Chemical Engineering Department, Maulana Azad National Institute of Technology, Bhopal, India

Abstract

SiO

2

/Al

2

O

3

ratios are different with ZSM-5 zeolites. The Changes to the compositions, poresizes, and morphology of the zeolite.

Alkali-treatment compare are before and after the SiO

2

/Al

2

O

3

ratios are influence with which the zeolites are synthesized. Alkali-

treated ZSM-5 zeolites are produce higher yields of light olefins compared to untreated zeolites or alkali-treatment introduces

mesopore. The zeolites are improves their catalytic cracking catalyst ability. The ZSM-5particle size has a strong effect on the

changes in product yields. And also effect gas and gasoline compositions. And the performance of HZSM-5 zeolites of varying acidity

and porosity were prepared under various synthesis conditions. In this paper discuss the effect of catalyst properties on the conversion

of ethanol to gasoline reaction were investigated. Nano crystalline ZSM-5 catalyst has high acidity. The micro crystalline ZSM-5 also

exhibited comparable acidity with nano zeolites, but gasoline yields is not higher due to the absence of mesopores in the catalyst.

Keywords: Fluid catalytic cracking, ZSM-5, Nano crystalline, and Mesoporous.

-----------------------------------------------------------------------***-----------------------------------------------------------------------

1. INTRODUCTION

Y-zeolite is the main constituent of FCC catalyst. ZSM-5 is

used as additive with Y-zeolite in FCC process. ZSM-5

belongs to is pentasile zeolite family, primarily used for

octane boosting or LPG maximization. It is a stable zeolite

with alumina content below 10% and pores in the range of

5.5 diameter. ZSM-5 is responsible for higher olefins yield.

There are two types of ZSM-5 additives are used. First type

has higher cracking activity and produces higher yields of

light olefins with reduced gasoline yield. Second type has less

cracking activity; it tends to isomerizes straight chain

molecules to branched hydrocarbons [1, 3]. The pore structure

of an FCC catalyst determines the accessibility of feed

molecules to active sites. Reaction takes place on catalytically

active sites. There are two types of acid sites. Bronsted acid

site donates protons and the Lewis acid site accepts electrons.

Both zeolite and matrix in FCC catalyst contain acid sites. The

site where most of the reaction takes place is Bronsted acid

site. Lewis acid sites are ore in matrix materials. Extra frame

work aluminum also result in Lewis acid site.

Cracking reaction is composite of many reactions. ZSM-5

zeolites have been used as catalysts that can increase the

selectivity of olefins due to their large surface areas, as well as

-defined micropores, and multi-dimensional of pores with

molecular dimensions [1, 2]. Rownaghi et al. report that

indicate the HZSM-5 catalyst with large pore volumes but

small pore sizes and pore mouths, external active centers of

surface areas and high populations, gives good stability but

high selectivity to aromatics [3]. FCC process used and ZSM-

5 and HZSM-5 catalyst due to its high surface area, porous

structure defined as well an acidic nature of pores [4].

However, the HZSM-5 catalyst sustains from low selectivity

near about C

5

-C

10

alkanes, further regeneration is requiring

carbon deposition and high yields of aromatics. Ethanol to

ethylene are process by Catalytic dehydration, and ethanol to

propylene by disproportionate and some of the studies

reported ethanol to aromatics in this direction, where the

properties of ZSM-5 zeolite in particularly its structure Si/Al.

Its related to the catalyst acidity, performance of a vital role

in representative the nature of the product [5- 7]. The greatly

commercial additives usually pre-deactivated. High-

temperature (750-850 C) steam pretreatment is usually

applied to the deactivated of ZSM-5 eventful in the

commercial unit Octane increase. As ZSM-5 Catalyst is

added, the yield will be effected of the gasoline yield is less

and C

3

C

4

unsaturated. So far as typical acid function zeolitic

catalyst of HZSM-5, the changes of ZSM-5 acidity caused by

different ratio of Si/Al , the observed changes in octane

number and product yields by chemical dealumination, or

steam deactivation.

2. PHYSICO CHEMICAL CHARACT ERISTICS

OF ZSM-5 ADDITIVE

A literature survey and in this paper are that the physic

chemical characteristics of all of the ZSM-5 samples are given

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 03 Special Issue: 03 | May-2014 | NCRIET-2014, Available @ http://www.ijret.org 482

in below Table-1. The ratio of Si/Al, nominal from chemical

analysis, represents the structure ratio of Si/Al for the fresh

samples ZM-1 to ZM-6. The ratio Si/Al, particle size, acid site

number, surface area are shown for steamed samples at

various temperatures such as ZM-7 to ZM-12, in Table-1[3-

10]

Table-1: Chemical characteristics of all ZSM-5 samples

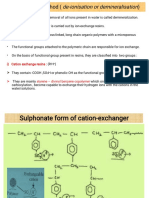

Fig. -1: SEM images of samples Zeolites (1) (a) and nano-

Zeolites (2) (b)

[3-6]

.

Fig.-2: Absorption spectra of sample Zeolites (1) in Ultra

Violate region before (a) and after (b) calcinations in air at

Tmax = 250

0

C. The dd transitions of Fe in the parent sample

Z (1) are depicted in the top

[5-15]

.

ZSM-5are takes two samples Zeolite and ZA greatly of the

surface and volume conform to zeolitic micropore but in nano

sample a large share of surface, namely the super micropore as

well as mesopore. This is also evident from the surface area

and pore volume of samples given in Table 1, where sample

Nano Zeolite exhibits higher values of external surface area,

total surface area, micropore area as well as total pore volume

compared to the corresponding micro crystalline Zeolite and

ZA samples. The volume in pores of various diameters given

in the table further indicates the perking order of porosity in

Nano Zeolite. The phenomenon of decrease in crystal size of

ZSM-5 should not influence the acidic nature of the sample, as

acidity is the inherent property of zeolite that is governed by

the framework Si/Al composition of the zeolite [13]. But, our

earlier studies on zeolite synthesis could not result in the

production of same acidity having nano zeolite and Z samples.

A special attention is given in the present study to synthesize

the samples having the similar Si/Al and acidity patterns. The

TPD patterns of the nano zeolites and Z samples shown that

indeed reveal the comparable acidity patterns of these two

samples which are differ in crystal size but having same value

of Si/Al ratios. Thus, in the present study, the crystal size of

ZSM-5 is successfully brought down from micro level to the

nano level, without affecting its acidity. These samples

allowed us to elucidate the role of additional porosity of nano

zeolite on the ethanol to gasoline reaction.

3. SYNTHESIS OF NANO ZSM-5 SAMPLE

In this synthesis Tetra ethylorthosilicate was used as silica

source. Al was added slowly to pre cooled TPAOH solution

Sample

Pretreatment

Si/Al ratio

(C.A.)

a

Surface area

(m

2

/g. SP BET)

b

No. of acid site

(mmol of NH

3

/g of Zeolite, TPD)

Particle size

(m, SEM)

Total Weak Strong

ZM-1 Fresh 12.5 431 1.15 0.55 0.60 10-15

ZM-2 Fresh 25 476 1.05 0.51 0.54 0.5-2

ZM-3 Fresh 35 448 0.70 0.34 0.36 10-30

ZM-4 Fresh >1000 430 0.07 0.07 0 10-15

ZM-5 Fresh 28 437 0.89 0.42 0.47 0.5-2

ZM-6 Fresh 41 439 0.68 0.34 0.34 0.5-2

ZM-7 Steamed, 660

0

C 26 393 0.21 0.14 0.07 0.5-2

ZM-8 Steamed, 730

0

C 27 395 0.11 0.07 0.04 0.5-2

ZM-9 Steamed, 790

0

C 27 396 0.09 0.07 0.2 0.5-2

ZM-10 Steamed, 790

0

C 42 420 0.08 0.06 0.02 0.5-2

ZM-11 Steamed, 790

0

C 36 425 0.08 0.08 0 10-30

ZM-12 Steamed, 790

0

C >1000 432 0.02 0.02 0 10-15

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 03 Special Issue: 03 | May-2014 | NCRIET-2014, Available @ http://www.ijret.org 483

and TEOS was added drop wise. And adding after all the

constituent the solution was left to hydrolyze at room

temperature for 41 h. The gel obtained was heated at 80

0

C to

evaporate water and ethanol formed during the hydrolysis to

obtain a concentrated gel. The gel concentration charged with

Teflon lines autoclave for hydro thermal synthesis of zeolites

and nano zeolite. This process performed was taken at

duration of 48 h and 170

0

C. Hydrothermal treatment, in this

paper case for steamed samples. summery, the NH

3

TPD

curves of the fresh H-ZSM-5 samples consist are two peaks

with temperature between 170

o

C and 210 C for the first peak

and temperature between 430C and 440 C for the second

peak. These correspond to weak and strong acid sites,

respectively. For the fresh samples, the strong acid sites are

ore in matrix materials and certain to - OH groups of skeletal

aluminum. Extra frame work aluminum also result in Lewis

acid site. The relatively strong Bronsted acidity of H-ZSM-5

in this figure-3 shown:

Fig.-3: X- ray diffraction patterns of zeolites

[5]

.

Fig-4: SEM of zeolite samples for morphology and crystal

size A = Nano Zeolite catalyst, B = Zeolite catalyst, C = ZA

catalyst

[3]

.

Recent literature survey that According Liang Zhao, Jinsen

Gao to gives report that the ZSM-5 zeolites are typical twin

hexahedrons with perfect crystalline surfaces and highly

ordered structures. However, the morphologies of the zeolites

were changed after alkali-treatment. In this paper Literature

survey that these changes were SiO

2

/Al

2

O

3

ratio of 38

observed using SEM techniques for the zeolite sample, several

large pores appeared on the zeolite's surface. A portion of the

structure had also crash down, ZSM-5 sample with a

SiO

2

/Al

2

O

3

ratio of 50 several uniformly sized small pores

prepared, and relatively complete crystal

Table-2:- Surface area and pore volume

Sample Si/Al

Ratio

BET surface

area

(m

2

/g)

Micropore (20)

Area

(m

2

)

External surface

area

(m

2

)

Total pore volume

(cm

3

/g)

Micro pore

volume (cm

3

/g)

Z 30 346 256 90 0.176 0.102

NZ 30 461 323 138 0.385 0.132

ZA 100 330 245 92 0.172 0.100

Volume (cm

3

/g) in pores of various diameters ()

<10A 10-20

20-100

100-200

200-

500

>500

Z 0.126 0.013 0.0143 0.0039 0.0079 0.0105

NZ 0.163 0.026 0.0176 0.0097 0.0220 0.1464

ZA 0.125 0.013 0.0135 0.0036 0.0072 0.0096

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 03 Special Issue: 03 | May-2014 | NCRIET-2014, Available @ http://www.ijret.org 484

structure of the zeolite was potted. The silicon species had

been removed properly. As for the zeolite samples with

SiO

2

/Al

2

O

3

ratios of 150 and 360, their morphologies were

minimally changed after alkali-treatment, indicating that only

a small quantity of silicon species had been removed from the

zeolite structure[3-10]. Morphological changes to the zeolites

for use the amount of silicon species lost was too minimal.

The dispersion of zeolite particles was also greatly improved

after alkali-treatment [16]. Research on the alkali-treatment of

zeolites with different SiO

2

/Al

2

O

3

ratios under the same

treatment conditions has shown that SiO

2

/Al

2

O

3

ratios exert

great influences on the structural properties of zeolites. The

surface area and total pore volume of mesopores increased

with decreasing SiO

2

/Al

2

O

3

ratios. However, that lower

SiO

2

/Al

2

O

3

ratios produce better results. The SiO

2

/Al

2

O

3

ratio

also has an effect on the catalytic performance of zeolites.

Fig.-5: Tends in gasoline distribution A = at 450

0

C, B = at

500

0

C

[1-16]

.

All the three samples are observed in a very low background

signal and sharp reflections indicating good crystalline.

Fig.-6: Effect of reaction temperature on HT reaction over

various catalysts A = NZ catalyst,B = Z catalyst

[3-10]

.

The SEM of the samples are the presence of about 30 nm

range crystallites in Nano zeolite, against micro meter range

crystals in Zeolite and ZA samples. The Nano Zeolite sample

shows mesoporosity and this is evident in the

adsorption/desorption isotherm. The hysteresis loop of Nano

Zeolite appeared at high relative pressure and reflects inter-

crystalline voids in the packing of the smaller crystals [12-15].

Normal ZSM-5 samples are most of the surface and volume

corresponding to zeolitic micropore. But nano zeolite sample

is a large share of surface compared to the corresponding

micro crystalline Zeolite and ZA samples. The volume in

pores for various diameters is given in Table-2. The volume in

pores indicates the order of porosity in nanozeolite [14].

4. CONCLUSIONS

The total numbers of ZSM-5 acid sides with nano zeolite in

fluid catalytic cracking process increase production in increase

porosity, as measured by TPD of ammonia. The performance

of ZSM-5 as the FCC catalyst with a additives in gas oil

cracking that a direct and smooth correlates between the

product yield and the total acidity of the ZSM-5 and the

aluminum content. The temperature of hydrothermal

deactivation of fresh sample is straight forward in FCC

process. And this paper result that nano zeolite and HZSM-5

zeolites with varying acidity with FCC catalyst. Zeolites are

high acid density and mesoporosity in HZSM-5 based

catalysts for the effective production of high octane gasoline

and diffusion reactions as exhibited by nano zeolite.

REFERENCES

[1] X.F. Li, B.J. Shen, Q.X. Guo, J.S. Gao, Effects of large

pore zeolite additions in the catalytic pyrolysis catalyst

on the light olefins production. Catal. Today. 125

(2007) 270.

[2] A. Corma, F. Melo, L. Sauvanaud, F. J. Ortega,

Different process schemes for converting light straight

run and fluid catalytic cracking naphthas in a FCC unit

for maximum propylene production. Appl. Catal. A.

265 (2004) 195.

[3] V. Nagabhatla, K. S. Sandeepp, Enhanced performance

of nano crystalline ZSM-5 in acetone to gasoline

(ATG) reaction. Fuel. 105 (2013) 195.

[4] A. A. Rownaghi, F. Rezaei, J. Hedlund, yield of

gasoline-range hydrocarbons as a function of uniform

ZSM-5 crystal. J. Catal. Commun. 14 (2011) 37.

[5] JCW. Kuo, C. Hill, US Patent (1976) 3931349.

[6] N. Youming, P. Weiye, L. Guangxing. High selective

and stable performance of catalytic aromatization of

alcohols and ethers over La/Zn/HZSM-5 catalysts. J.

Ind. Eng. Chem. 16 (2010) 503.

[7] Z. Song, A. Takahashi, N. Mimura, T. Fujitani.

Production of propylene from ethanol over ZSM-5

zeolites. React. Kinect. Catal. Lett. 131( 2009) 364.

[8] K. Murata, M. Inaba, I. Takahara. Effects of surface

modification of H-ZSM-5 catalysts on direct

transformation of ethanol into lower olefins. J. Jap.

Petrol. Inst., 51 (2008) 234.

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 03 Special Issue: 03 | May-2014 | NCRIET-2014, Available @ http://www.ijret.org 485

[9] S. Bordiga, R. Buzzoni, F. Geobaldo, C. Lamberti, E.

Giamello, A. Zecchina, G. Leofanti, G. Petrini, G.

Tozzola, Recent advances in basic and applied aspects

of industrial catalysis. J. Catal. 158 (1996) 486.

[10] K. Rajagopalan, G. W. Young, Hydrocarbon cracking

selectivities with a dual zeolite fluid cracking catalyst

containing REY and ZSM-5. Prepr. Am. Chem. Soc.

Div. Pet. Chem. 32 (1987) 627

[11] J. Biswas, I. E. Maxwell, Octane Enhancement in fluid

catalytic cracking. I. Role of ZSM-5 addition and

reactor temperature. Appl. Catal. 1990, 58.

[12] C. D. Anderson, F. G. Dwyer, G. Koch, P. Niiranen.

Proceedings of the 9

th

Ibero-American Symposium on

Catalysis, Lisbon, 1984 Institute Superior Technico:

Lisbon, Portugal, (1984) 247.

[13] R. J. Madon. Role of ZSM-5 and ultrastable Y zeolites

for increasing gasoline octane number. J. Catal. (1991)

129.

[14] M. M. Yangchang, Conversion of ethanol broth to LPG

and Gasoline. US patent (2010) 174127.

[15] G.A Gayubo, A.M. Tarrio, A.T. Aguayo. Kinetic

modeling of the transformation of aqueous ethanol into

hydrocarbons on a HZSM-5 zeolite. Ind. Eng. Chem.

Res. 40 (2001) 3467.

Você também pode gostar

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Fracture Toughness Testing - TwiDocumento5 páginasFracture Toughness Testing - TwiSergio MunhosAinda não há avaliações

- BOQ - Civil, Structural and ArchitecturalDocumento46 páginasBOQ - Civil, Structural and ArchitecturalVincent SaysonAinda não há avaliações

- GasketDocumento1.120 páginasGasketEntratainmentAinda não há avaliações

- Production of 1,5-Pentanediol From Biomass Via Furfural andDocumento20 páginasProduction of 1,5-Pentanediol From Biomass Via Furfural andMihaela PatrascuAinda não há avaliações

- Hohne DSCDocumento304 páginasHohne DSCHari Shankar100% (1)

- Enhancing Post Disaster Recovery by Optimal Infrastructure Capacity BuildingDocumento8 páginasEnhancing Post Disaster Recovery by Optimal Infrastructure Capacity BuildingInternational Journal of Research in Engineering and TechnologyAinda não há avaliações

- Wind Damage To Trees in The Gitam University Campus at Visakhapatnam by Cyclone HudhudDocumento11 páginasWind Damage To Trees in The Gitam University Campus at Visakhapatnam by Cyclone HudhudInternational Journal of Research in Engineering and TechnologyAinda não há avaliações

- Impact of Flood Disaster in A Drought Prone Area - Case Study of Alampur Village of Mahabub Nagar DistrictDocumento5 páginasImpact of Flood Disaster in A Drought Prone Area - Case Study of Alampur Village of Mahabub Nagar DistrictInternational Journal of Research in Engineering and TechnologyAinda não há avaliações

- Flood Related Disasters Concerned To Urban Flooding in Bangalore, IndiaDocumento8 páginasFlood Related Disasters Concerned To Urban Flooding in Bangalore, IndiaInternational Journal of Research in Engineering and TechnologyAinda não há avaliações

- Groundwater Investigation Using Geophysical Methods - A Case Study of Pydibhimavaram Industrial AreaDocumento5 páginasGroundwater Investigation Using Geophysical Methods - A Case Study of Pydibhimavaram Industrial AreaInternational Journal of Research in Engineering and TechnologyAinda não há avaliações

- Likely Impacts of Hudhud On The Environment of VisakhapatnamDocumento3 páginasLikely Impacts of Hudhud On The Environment of VisakhapatnamInternational Journal of Research in Engineering and TechnologyAinda não há avaliações

- Wind Damage To Buildings, Infrastrucuture and Landscape Elements Along The Beach Road at VisakhapatnamDocumento10 páginasWind Damage To Buildings, Infrastrucuture and Landscape Elements Along The Beach Road at VisakhapatnamInternational Journal of Research in Engineering and TechnologyAinda não há avaliações

- Shear Strength of RC Deep Beam Panels - A ReviewDocumento15 páginasShear Strength of RC Deep Beam Panels - A ReviewInternational Journal of Research in Engineering and TechnologyAinda não há avaliações

- Monitoring and Assessment of Air Quality With Reference To Dust Particles (Pm10 and Pm2.5) in Urban EnvironmentDocumento3 páginasMonitoring and Assessment of Air Quality With Reference To Dust Particles (Pm10 and Pm2.5) in Urban EnvironmentInternational Journal of Research in Engineering and TechnologyAinda não há avaliações

- Effect of Lintel and Lintel Band On The Global Performance of Reinforced Concrete Masonry In-Filled FramesDocumento9 páginasEffect of Lintel and Lintel Band On The Global Performance of Reinforced Concrete Masonry In-Filled FramesInternational Journal of Research in Engineering and TechnologyAinda não há avaliações

- Low Cost Wireless Sensor Networks and Smartphone Applications For Disaster Management and Improving Quality of LifeDocumento5 páginasLow Cost Wireless Sensor Networks and Smartphone Applications For Disaster Management and Improving Quality of LifeInternational Journal of Research in Engineering and TechnologyAinda não há avaliações

- Role of Voluntary Teams of Professional Engineers in Dissater Management - Experiences From Gujarat EarthquakeDocumento6 páginasRole of Voluntary Teams of Professional Engineers in Dissater Management - Experiences From Gujarat EarthquakeInternational Journal of Research in Engineering and TechnologyAinda não há avaliações

- Cyclone Disaster On Housing and Coastal AreaDocumento7 páginasCyclone Disaster On Housing and Coastal AreaInternational Journal of Research in Engineering and TechnologyAinda não há avaliações

- Hudhud Cyclone - A Severe Disaster in VisakhapatnamDocumento8 páginasHudhud Cyclone - A Severe Disaster in VisakhapatnamInternational Journal of Research in Engineering and TechnologyAinda não há avaliações

- A Geophysical Insight of Earthquake Occurred On 21st May 2014 Off Paradip, Bay of BengalDocumento5 páginasA Geophysical Insight of Earthquake Occurred On 21st May 2014 Off Paradip, Bay of BengalInternational Journal of Research in Engineering and TechnologyAinda não há avaliações

- Cpw-Fed Uwb Antenna With Wimax Band-Notched CharacteristicsDocumento5 páginasCpw-Fed Uwb Antenna With Wimax Band-Notched CharacteristicsInternational Journal of Research in Engineering and TechnologyAinda não há avaliações

- Review Study On Performance of Seismically Tested Repaired Shear WallsDocumento7 páginasReview Study On Performance of Seismically Tested Repaired Shear WallsInternational Journal of Research in Engineering and TechnologyAinda não há avaliações

- Comparative Study of The Forces in G+5 and G+10 Multi Storied Buildings Subjected To Different Wind SpeedsDocumento10 páginasComparative Study of The Forces in G+5 and G+10 Multi Storied Buildings Subjected To Different Wind SpeedsInternational Journal of Research in Engineering and TechnologyAinda não há avaliações

- Assessment of Seismic Susceptibility of RC BuildingsDocumento4 páginasAssessment of Seismic Susceptibility of RC BuildingsInternational Journal of Research in Engineering and TechnologyAinda não há avaliações

- Detection of Hazard Prone Areas in The Upper Himalayan Region in Gis EnvironmentDocumento9 páginasDetection of Hazard Prone Areas in The Upper Himalayan Region in Gis EnvironmentInternational Journal of Research in Engineering and TechnologyAinda não há avaliações

- Challenges in Oil and Gas Industry For Major Fire and Gas Leaks - Risk Reduction MethodsDocumento4 páginasChallenges in Oil and Gas Industry For Major Fire and Gas Leaks - Risk Reduction MethodsInternational Journal of Research in Engineering and TechnologyAinda não há avaliações

- Developing of Decision Support System For Budget Allocation of An R&D OrganizationDocumento6 páginasDeveloping of Decision Support System For Budget Allocation of An R&D OrganizationInternational Journal of Research in Engineering and TechnologyAinda não há avaliações

- Can Fracture Mechanics Predict Damage Due Disaster of StructuresDocumento6 páginasCan Fracture Mechanics Predict Damage Due Disaster of StructuresInternational Journal of Research in Engineering and TechnologyAinda não há avaliações

- Effect of Hudhud Cyclone On The Development of Visakhapatnam As Smart and Green City - A Case StudyDocumento4 páginasEffect of Hudhud Cyclone On The Development of Visakhapatnam As Smart and Green City - A Case StudyInternational Journal of Research in Engineering and TechnologyAinda não há avaliações

- Coastal Zones - Seismic Vulnerability An Analysis From East Coast of IndiaDocumento4 páginasCoastal Zones - Seismic Vulnerability An Analysis From East Coast of IndiaInternational Journal of Research in Engineering and TechnologyAinda não há avaliações

- Disaster Recovery Sustainable HousingDocumento4 páginasDisaster Recovery Sustainable HousingInternational Journal of Research in Engineering and TechnologyAinda não há avaliações

- Brain Tumor Segmentation Using Asymmetry Based Histogram Thresholding and K-Means ClusteringDocumento4 páginasBrain Tumor Segmentation Using Asymmetry Based Histogram Thresholding and K-Means ClusteringInternational Journal of Research in Engineering and TechnologyAinda não há avaliações

- Analytical Solutions For Square Shape PressureDocumento4 páginasAnalytical Solutions For Square Shape PressureInternational Journal of Research in Engineering and TechnologyAinda não há avaliações

- Rate Adaptive Resource Allocation in Ofdma Using Bees AlgorithmDocumento5 páginasRate Adaptive Resource Allocation in Ofdma Using Bees AlgorithmInternational Journal of Research in Engineering and TechnologyAinda não há avaliações

- D and F BlockDocumento15 páginasD and F Blockthinkiit100% (1)

- Ion Exchange ProcessDocumento10 páginasIon Exchange Process056 Jatin GavelAinda não há avaliações

- SUPER THERM Weather Resistive Barrier Solves Building ChallengesDocumento1 páginaSUPER THERM Weather Resistive Barrier Solves Building ChallengesbulentbulutAinda não há avaliações

- Synthetic Oils: E-Books Download Weblog: Water Engineering WeblogDocumento11 páginasSynthetic Oils: E-Books Download Weblog: Water Engineering WeblogalbertofgvAinda não há avaliações

- Synthetic ester oils for air compressorsDocumento1 páginaSynthetic ester oils for air compressorsironiteAinda não há avaliações

- Design For Production of PropyleneDocumento168 páginasDesign For Production of PropyleneEmiliano Rohwein100% (1)

- Activities Carried Out in Quality Control LaboratoryDocumento61 páginasActivities Carried Out in Quality Control LaboratorySunil SingireddyAinda não há avaliações

- A Detailed Investigation of Overhead Line Insulators: June 2006Documento76 páginasA Detailed Investigation of Overhead Line Insulators: June 2006Classic LipuAinda não há avaliações

- Zetkama Fig. 215 SpecsDocumento11 páginasZetkama Fig. 215 SpecsAntonio VelardeAinda não há avaliações

- Beam Design ReportDocumento22 páginasBeam Design Reportkwoshaba pidsonAinda não há avaliações

- Specification - Road Repairs (Ade)Documento11 páginasSpecification - Road Repairs (Ade)Sathish KumarAinda não há avaliações

- Gas CuttingDocumento8 páginasGas CuttingringboltAinda não há avaliações

- To Measure The Head Loss (HL) in A Pipe of Uniform Diameter (D)Documento6 páginasTo Measure The Head Loss (HL) in A Pipe of Uniform Diameter (D)Syed Ali Hasnain NaqviAinda não há avaliações

- Aluminum Alloys For AerospaceDocumento2 páginasAluminum Alloys For AerospaceNicholas Featherston100% (1)

- Conductor and SuperconductorDocumento12 páginasConductor and Superconductorankesh_ghoghariAinda não há avaliações

- Pozzolith 575: Chloride Accelerating AdmixtureDocumento2 páginasPozzolith 575: Chloride Accelerating AdmixtureFrancois-Ainda não há avaliações

- Surfactant Enhanced Oil Recovery by Wettability Alteration in SandstoneDocumento77 páginasSurfactant Enhanced Oil Recovery by Wettability Alteration in SandstoneSaurabhSharmaAinda não há avaliações

- What Is X-Ray Powder Diffraction (XRD) : Bragg's LawDocumento8 páginasWhat Is X-Ray Powder Diffraction (XRD) : Bragg's LawsafiAinda não há avaliações

- Construction Tech II Door TypesDocumento105 páginasConstruction Tech II Door Typessydney augustAinda não há avaliações

- Recent Patents On EngineeringDocumento67 páginasRecent Patents On EngineeringmarcomtnAinda não há avaliações

- NA3 AND NA4 - Troubleshooting Guide (IM278TS SEPT 2006)Documento32 páginasNA3 AND NA4 - Troubleshooting Guide (IM278TS SEPT 2006)Julio BacilioAinda não há avaliações

- Dektite Diverter and Retrofit Dektite Diverter: Pipe FlashingsDocumento2 páginasDektite Diverter and Retrofit Dektite Diverter: Pipe FlashingscherandinhoAinda não há avaliações

- Pipeline Testing and DisinfectionDocumento10 páginasPipeline Testing and DisinfectionWayjantha Sunethra Bandara JayawardhanaAinda não há avaliações

- Firekab Je H ST H BD Fe180 ph120Documento2 páginasFirekab Je H ST H BD Fe180 ph120Azzeddine ZerroukAinda não há avaliações

- Geot 2007 57 3 289 PDFDocumento13 páginasGeot 2007 57 3 289 PDFDaniel Felipe Ruiz RestrepoAinda não há avaliações