Escolar Documentos

Profissional Documentos

Cultura Documentos

Piping Design Engineer resume highlighting 6+ years experience

Enviado por

Daniel Premraj Danda0 notas0% acharam este documento útil (0 voto)

181 visualizações3 páginasLooking for a challenging and demanding career in Process Piping Design and Detailed Engineering in a growth oriented Mechanical Consulting, Contracting, Construction Organization to render professional skills and add value to organizational growth and objectives.

Descrição original:

Título original

CV - Daniel Danda - Piping Engineer _6+ Years_

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoLooking for a challenging and demanding career in Process Piping Design and Detailed Engineering in a growth oriented Mechanical Consulting, Contracting, Construction Organization to render professional skills and add value to organizational growth and objectives.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

181 visualizações3 páginasPiping Design Engineer resume highlighting 6+ years experience

Enviado por

Daniel Premraj DandaLooking for a challenging and demanding career in Process Piping Design and Detailed Engineering in a growth oriented Mechanical Consulting, Contracting, Construction Organization to render professional skills and add value to organizational growth and objectives.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 3

Daniel Premraj Danda

Email: daniel.premraj@gmail.com Cellular +91-9492420694 Abu-Dhabi Cell +971-563432512

H.No 24-573, Plot No 59, Road No 4, Maruthi Nagar, Lothukunta, Alwal, Secunderabad, 500015

Piping Design Engineer (Exp: 6+ Years)

Summary

Looking for a challenging and demanding career in Process Piping Design & Detailed Engineering in a growth

oriented Mechanical Consulting, Contracting, Construction Organization to render professional skills and add

value to organizational growth and objectives.

Experience Summary

Anewa Engineering (P) Ltd: (Full-Time), Hyderabad 2014 to Present

Job Role: Sr, Piping Engineer (Oil & Gas, Offshore)

Project 1: IRPC Thailand (Mercury Recovery Unit),

Client: DIALOG Group, Malaysia

Location: Thailand

Responsibilities:

Preparation of As-Built 3D Model of Entire Plant using AutoCAD Plant 3D from CADWORX Plant.

Prepared all Piping and Valve Specs in AutoCAD Plant 3D

Prepared Structural Skids of Mercury Recovery Filters.

Extracted MTO and Clash Checked the entire 3D Model.

Project 2: Main Gas Turbine Pumps (SCOP - State Company for Oil Projects) Deputation Job

Client: Penspen International, Abu Dhabi

Location: FAO Pumping Station Al Faw - Basrah, Iraq

Responsibilities:

Prepared Preliminary Piping Layouts

Piping Routing Study

Marking of P&ID's with respect to Piping Study

Allocating space for 60", 48" and 32" Main Headers

Coordinating with Client Queries during different stages of review meetings

Coordinating with SP3D Modellers to meet all Design Requirements

Preparing Material Requisitions for Piping Bulks and other items.

Preparing the Preliminary and final MTOs for the project.

Plant review and clash checking for system by using Navisworks Software.

Preparation of Pipe Loading data for civil inputs

Piping Isometric Checking in AUTOCAD

Project 3: Chemical Injection Skid (HIDAYATH)

Client: OXY, Occidental of Oman

Location: Wadi Aswad, Oman

Responsibilities:

Preparation of Piping Routing Study and Piping GA from P&ID

Preparation of Piping Material Specification, Valve Material Specification and Piping Hydraulic

Calculation based on Inputs from Client.

Preparation of 3D Model in CADWORX 2013 along with all Specs and Catalogs

Preparation of Skid Space Analysis for convenience in accessing valves and other instruments

Preparation of Piping Isometrics and final MTO for fabrication.

Project 4: Pengarang Independent Deep-water Petroleum Terminal-1

Client: DIALOG Group, Malaysia

M/s Dialog intends to develop and operate the deep-water petroleum storage and handling terminal for crude oil

at Pengarang, Malaysia.

Daniel Premraj Danda

Email: daniel.premraj@gmail.com Cellular +91-9492420694 Abu-Dhabi Cell +971-563432512

H.No 24-573, Plot No 59, Road No 4, Maruthi Nagar, Lothukunta, Alwal, Secunderabad, 500015

Location: Malaysia

Responsibilities:

Preparation of piping Layouts.

Development of piping spec, support spec in CADWORX.

Development of 3D model using CADWORX.

Preparation of Pipe Loading data for Civil inputs.

Extraction of Isometrics from 3D model and checking.

Preparation of Final MTO's.

Srishti Udhyog (P) Ltd: (Full-Time), Visakhapatnam 2013 to 2014

Job Role: Sr. Piping Engineer (US Projects)

Client Name:

Petrleos de Venezuela, South America, (PDVSA)

Rashtriya Ispat Nigam Ltd, (RINL)

National Thermal Power Corporation Limited, (NTPC)

Having Good Working Knowledge on ASME, ANSI, AWWA, ASTM and API Codes & Standards in Designing and

Preparing Equipment Layouts, GA, Plan, Sections, Isometrics, MTOs, Pipe Stress Analysis

Job Responsibilities:

Preparation of Piping GA Drawing from P&ID Equipment & specification

Preparation of Equipment layout from P&ID, Vendor data

Preparation of piping isometric spool drawing & MTO

P-T Ratings of fittings, Flanges & Valves

Wall thickness Calculation of Piping & Pipelines per ASME codes

Pressure Design of Miter bend, Blanks, Blind flanges Branch Reinforcement pad calculation

Preparation of Piping specification class & Valve Datasheets & piping material selection

Piping span calculations and selection of supports

Expansion loop & expansion joint design

Piping flexibility of analysis using code equations, guided cantilever method, Graphs Nomographs, M.W

Kellogg charts & CAESER II

Layout solutions for weight, thermal and Wind loadings

Calculation of sustain, expansion and occasional loads

Knowledge of PFD & P&ID and plot plan

Plan layout and process equipments

Hydraulic Design of liquid piping system (pipe sizing, pressure drop calculation & pump head selection)

CAESER II

Process Piping using ASME B 31.3 Codes and Standards

Ascent Consultancy Technologies: 2011 to 2013

FTC Employee with Larsen and Toubro HED, Visakhapatnam

Job Role: Piping Design Engineer (Oil & Gas/Offshore/Marine)

Client Name: Indian Navy

Having Good Knowledge in ASME Codes and Standards, Pipe Fitting, Pipe Flanges, Valves, Piping Special

Elements, Process Mechanical Equipments, Flow Diagrams, Piping Specifications, Plot Plan, Equipment Layout,

Piping GA Drawings, Piping Isometrics, Piping System Design, Hydraulic Design of Liquid Piping Systems and

Pipe Stress Analysis

Job Responsibilities:

Preparation of Piping GA Drawing from P&ID Equipment & specification

Preparation of Equipment layout from P&ID, Vendor data

Preparation of piping isometric spool drawing & MTO

Wall thickness Calculation of Piping & Pipelines per ASME codes

Pressure Design of Miter bend, Blanks, Blind flanges Branch Reinforcement pad calculation

Preparation of Piping specification class & Valve Datasheets & piping material selection

Piping span calculations and selection of supports

Expansion loop & expansion joint design

Daniel Premraj Danda

Email: daniel.premraj@gmail.com Cellular +91-9492420694 Abu-Dhabi Cell +971-563432512

H.No 24-573, Plot No 59, Road No 4, Maruthi Nagar, Lothukunta, Alwal, Secunderabad, 500015

Layout solutions for weight, thermal and Wind loadings

Knowledge of PFD, P&IDs and Plot Plan

Ahlada Group of Companies: Hyderabad, Andhra Pradesh 2008 to 2011

Job Role: Design Engineer - Static Equipments

CAD/CAE Engineer (Level 1):

Created Assembly drawings including bill of materials and detail drawings, for the Design of Boilers, Stainless

Steel Equipments for Pharmaceutical purposes, Power Plant Equipments, Bulk Handling Equipments, Sugar

Plant Equipments, Cement Plant Equipments according to ANSI, ISO, BIS and JIS Standards.

Conduct component tolerance studies and assembly stack evaluations

Perform engineering calculations for mass, strength and performance

Prepared engineering documents and coordinated with customer, suppliers and assembly plants.

HVAC Layout Design Engineer (Level 2):

Created HVAC Layouts for Pharmaceutical Companies and other Industries including classification of AHU and

Supply Systems

Worked with Projects related to Sheet Metal for the Construction of Clean Room Equipment, Clean rooms, De

mountable Panels, Ceiling Panels, Heat Exchangers, Blenders and other Equipments used by Pharmaceutical

Companies for mass production of bulk drugs

Worked with projects on site, which includes drawing of projects, layouts and HVAC on site premises for a

detailed technical client

Worked with Major Pharma based clients in and around India, like Hetero Biotech, Dr. Reddy Labs, Virco

Biotech, Supra Biotech and many more

Senior Design Engineer (Level 3):

Validating the Calculations and the Design Aspects regarding Structural Engineering, Strength Analysis and

Fabrication Drawings of Industrial EOT Cranes

Updating the Design Calculations as per change in Bureau of Indian Standards

Skills used since 2008-Present

AutoCAD

Smart Plant Review

CADWORX Plant Administrator

Navisworks

MS Project

Education

P.G Diploma in Process Piping Design as per ASME B31.3

B.Tech in Mechanical Engineering from JNTUC (2008)

Intermediate from Board of Intermediate Education (2004)

SSC from State Board of Secondary Education (2001)

Training Seminars (Overseas)

Effective Leadership Training You Lead the Ship" A Leadership Course, Institute of Training and Development,

Penang, Malaysia, 2011

Personal Details

Date of Birth: 22

nd

June 1986

Marital Status: Single

Passport Number: L5582773

Passport Valid Upto Year: 2023

Você também pode gostar

- Sahaya David Raja T: Profile SummaryDocumento5 páginasSahaya David Raja T: Profile SummarysahaAinda não há avaliações

- Denny Thomas - Experienced Piping Engineer Seeking New OpportunitiesDocumento4 páginasDenny Thomas - Experienced Piping Engineer Seeking New OpportunitiesdennykvgAinda não há avaliações

- C2C BrochureDocumento8 páginasC2C BrochureDarla ChavezAinda não há avaliações

- Piping Engineer: Resume CV: Sponsored LinksDocumento7 páginasPiping Engineer: Resume CV: Sponsored Linksravi gurungAinda não há avaliações

- Main Pipe Rack - An Overview - ScienceDirect TopicsDocumento79 páginasMain Pipe Rack - An Overview - ScienceDirect TopicsSandip SurAinda não há avaliações

- Piping Components Classification GuideDocumento45 páginasPiping Components Classification Guideindika sunarkoAinda não há avaliações

- Diploma Course CatalogueDocumento337 páginasDiploma Course CatalogueSwapnil YenpureAinda não há avaliações

- Ganesh Bharadwaj H S-Resume-2023Documento6 páginasGanesh Bharadwaj H S-Resume-2023Bharadwaj's ArohanaAinda não há avaliações

- L&T Walk in DriveDocumento1 páginaL&T Walk in Drivenaveen kumar pathiAinda não há avaliações

- Maxpro Company Presentation - New - 11.11.13Documento49 páginasMaxpro Company Presentation - New - 11.11.13Soumitra GuptaAinda não há avaliações

- Mechanical Engineer Resume SEODocumento4 páginasMechanical Engineer Resume SEOShahbaz100% (1)

- Certificate Course On Piping EnggDocumento453 páginasCertificate Course On Piping EnggVignesh DheenakumarAinda não há avaliações

- CADtech BrochureDocumento2 páginasCADtech BrochureTemporaryAinda não há avaliações

- AutoPIPE v9.4 SS3Documento96 páginasAutoPIPE v9.4 SS3Jack LeeAinda não há avaliações

- Engineering deliverables listDocumento2 páginasEngineering deliverables listAngling DharmaAinda não há avaliações

- Piping Presentation MasterDocumento61 páginasPiping Presentation MasterQC NGUYEN100% (2)

- MOHD AZWAN BIN MUHAMAD - Piping DesignerDocumento3 páginasMOHD AZWAN BIN MUHAMAD - Piping DesignerAzwanAinda não há avaliações

- Cadworx Customising Backing SheetDocumento27 páginasCadworx Customising Backing Sheetalan172081100% (1)

- Engineering Design Outsourcing - Pharmaceutical PlantDocumento1 páginaEngineering Design Outsourcing - Pharmaceutical PlantchemionixAinda não há avaliações

- 01 Piping ComponentsDocumento23 páginas01 Piping Componentshwang2100% (1)

- Bestline Mining Supplies LTD - 2010 EditionDocumento50 páginasBestline Mining Supplies LTD - 2010 EditionTalabarteria RaygozaAinda não há avaliações

- Introduction To Piping EngineeringDocumento6 páginasIntroduction To Piping EngineeringchaitraAinda não há avaliações

- Greenesol Power Systems Engineering CapabilitiesDocumento30 páginasGreenesol Power Systems Engineering CapabilitiessrinivasanAinda não há avaliações

- Okpoho Piping MTODocumento39 páginasOkpoho Piping MTOSTEPHEN ONYEFOROAinda não há avaliações

- August 2012 IssueDocumento56 páginasAugust 2012 IssueGas, Oil & Mining Contractor Magazine100% (1)

- Engineering Design Basis FOR Project: Client: Projec T: Job No.Documento11 páginasEngineering Design Basis FOR Project: Client: Projec T: Job No.Priyanka KumariAinda não há avaliações

- Saipem Triune Engineering PVT Ltd. New Delhi, IndiaDocumento18 páginasSaipem Triune Engineering PVT Ltd. New Delhi, IndiaKhurram Shadab IqbalAinda não há avaliações

- Piping ArticlesDocumento187 páginasPiping Articlesdhanu1308Ainda não há avaliações

- About UsDocumento32 páginasAbout UsSubbu Ram PAinda não há avaliações

- Prabhu - CV - Structural DesignerDocumento4 páginasPrabhu - CV - Structural DesignerprabhutmuAinda não há avaliações

- Business Plan January 2011Documento21 páginasBusiness Plan January 2011Hussein BoffuAinda não há avaliações

- Curriculum Vitae: Total Years of Experience - 12 YearsDocumento4 páginasCurriculum Vitae: Total Years of Experience - 12 YearsnandakumarAinda não há avaliações

- Sarath Ravikumar Saraswathy's ResumeDocumento3 páginasSarath Ravikumar Saraswathy's ResumeAnbarasan SubbaiyanAinda não há avaliações

- Autodesk Navisworks Installation GuideDocumento120 páginasAutodesk Navisworks Installation GuidemindwriterAinda não há avaliações

- Dots in ASME B36.10 Under Schedule TableDocumento5 páginasDots in ASME B36.10 Under Schedule TableIbrahim BashaAinda não há avaliações

- Piping Group Time Charge Codes: Piping Sub-Group Operation Number & Name ( ) 250 251 252 253 PEL PME PDG PMCDocumento39 páginasPiping Group Time Charge Codes: Piping Sub-Group Operation Number & Name ( ) 250 251 252 253 PEL PME PDG PMCTheVirus PapaAinda não há avaliações

- Resume 2021 NovDocumento6 páginasResume 2021 NovSyed KhalidAinda não há avaliações

- FOX Solutions - Project Reference List PDFDocumento16 páginasFOX Solutions - Project Reference List PDFOuseppachan AmbookenAinda não há avaliações

- P&id SeminarDocumento30 páginasP&id SeminaryasirvazhikkadavuAinda não há avaliações

- Tecnimont - Civil&InfrastructuresDocumento17 páginasTecnimont - Civil&InfrastructuresAtish RedizAinda não há avaliações

- Typical Piping Project SequenceDocumento23 páginasTypical Piping Project SequenceJackAinda não há avaliações

- Company Profile SISTECH CONSULTANTSDocumento6 páginasCompany Profile SISTECH CONSULTANTSnagarajhebbarAinda não há avaliações

- Career Opportunities in Petroleum IndustryDocumento1 páginaCareer Opportunities in Petroleum IndustryBilal KhanAinda não há avaliações

- Sudeepmishra: Career ObjectiveDocumento6 páginasSudeepmishra: Career Objectivesudeep9666Ainda não há avaliações

- Online Piping and Caesar Course SyllabusDocumento10 páginasOnline Piping and Caesar Course Syllabusm 418Ainda não há avaliações

- Chapter 19: Security: Name: Alvin Irwanto NIM: 41518010055Documento8 páginasChapter 19: Security: Name: Alvin Irwanto NIM: 41518010055Alvin IrwantoAinda não há avaliações

- Common Interview QuestionsDocumento5 páginasCommon Interview QuestionsMary CorpuzAinda não há avaliações

- AVEVA PDMS and Instrumentation Training ModulesDocumento4 páginasAVEVA PDMS and Instrumentation Training ModulesPoonam AshwinAinda não há avaliações

- 1-Piping Manual-Pdms12Documento413 páginas1-Piping Manual-Pdms12MOHSEN2005IBAinda não há avaliações

- Critical Line ListDocumento20 páginasCritical Line ListCristhian Solano Bazalar100% (1)

- Piping Design Enginerring & Construction: Atul PatelDocumento19 páginasPiping Design Enginerring & Construction: Atul Patelसरदार अतुल भाई पटेलAinda não há avaliações

- 3D Model ReviewDocumento3 páginas3D Model ReviewSreejesh SundaresanAinda não há avaliações

- Piping S1Documento44 páginasPiping S1Rajkumar AAinda não há avaliações

- Checklist For Piping Isometrics - P&ID, Layout, Drafting RelatedDocumento5 páginasChecklist For Piping Isometrics - P&ID, Layout, Drafting RelatedkarunaAinda não há avaliações

- P&ID Handbook PDF - Google SearchDocumento2 páginasP&ID Handbook PDF - Google SearchAhmed Essam El-Din100% (1)

- Sahaya David: Design Engineer PipingDocumento5 páginasSahaya David: Design Engineer PipingsahaAinda não há avaliações

- Piping Engineering Study BookDocumento3 páginasPiping Engineering Study BooksahaAinda não há avaliações

- M N R V C PrakashDocumento5 páginasM N R V C Prakashvarma511Ainda não há avaliações

- Engineering Job SearchDocumento5 páginasEngineering Job SearchTaha ZakiAinda não há avaliações

- Bsr-March 2011Documento6 páginasBsr-March 2011Prasanna kumar subudhiAinda não há avaliações

- Appointment LetterDocumento2 páginasAppointment LetterDaniel Premraj DandaAinda não há avaliações

- SP 21 201209Documento1 páginaSP 21 201209Daniel Premraj DandaAinda não há avaliações

- Cover Letter - DanielDocumento1 páginaCover Letter - DanielDaniel Premraj DandaAinda não há avaliações

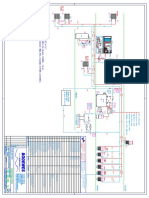

- Abu Dhab International Airport NetworkDocumento1 páginaAbu Dhab International Airport NetworkDaniel Premraj DandaAinda não há avaliações

- RESUME for Instrumentation EngineerDocumento2 páginasRESUME for Instrumentation EngineerDaniel Premraj DandaAinda não há avaliações

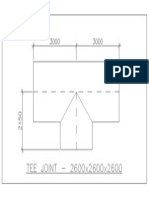

- Tee Joint Dimensions-IS 3589 PDFDocumento1 páginaTee Joint Dimensions-IS 3589 PDFDaniel Premraj DandaAinda não há avaliações

- Iso 1 PDFDocumento1 páginaIso 1 PDFDaniel Premraj DandaAinda não há avaliações

- Standard Cost CodesDocumento17 páginasStandard Cost CodesThahir HussainAinda não há avaliações

- ANSI AHRI Standard 1360 I-P 2013 With Addendum 1 PDFDocumento15 páginasANSI AHRI Standard 1360 I-P 2013 With Addendum 1 PDFdimaomarAinda não há avaliações

- 8 WATER CONSUMPTION AND WATER DEMANDDocumento9 páginas8 WATER CONSUMPTION AND WATER DEMANDjurhym doteAinda não há avaliações

- Decathlon Climate Report TCFD-2020Documento27 páginasDecathlon Climate Report TCFD-2020Shruti tiwariAinda não há avaliações

- Montgomery County Public Schools District's Contract With Highland Electric FleetsDocumento54 páginasMontgomery County Public Schools District's Contract With Highland Electric FleetsABC7News100% (1)

- Green Technology Application in Construction IndustryDocumento7 páginasGreen Technology Application in Construction Industrykamran KhanAinda não há avaliações

- Tabla de CODIGOS de ERRORDocumento14 páginasTabla de CODIGOS de ERRORAlbertoAinda não há avaliações

- Tank Installation and Operation Manual M MT1 enDocumento4 páginasTank Installation and Operation Manual M MT1 enSamuel SaskaAinda não há avaliações

- 616-100-402a - 00 - Central Heating SchemeDocumento1 página616-100-402a - 00 - Central Heating SchemeAnonymous yyjpEsydasAinda não há avaliações

- 110 007 PDFDocumento12 páginas110 007 PDFJames LoewenAinda não há avaliações

- Compact 205 40/25 HI CatalogueDocumento71 páginasCompact 205 40/25 HI CatalogueHow to channelAinda não há avaliações

- Catalog F-1 PRV Adrp SporlanDocumento16 páginasCatalog F-1 PRV Adrp Sporlancafreita0Ainda não há avaliações

- Samrya Case StudyDocumento14 páginasSamrya Case StudySporty GameAinda não há avaliações

- Incubadora Ref 3990ltDocumento2 páginasIncubadora Ref 3990ltKarynaHernandezMonarrezAinda não há avaliações

- Refrigeration & Air Conditioning Lab (Mey-303) Experiment No. 3 Aim: To Evaluate The Performance of Domestic Air ConditionerDocumento9 páginasRefrigeration & Air Conditioning Lab (Mey-303) Experiment No. 3 Aim: To Evaluate The Performance of Domestic Air ConditionerIshwarjit SinghAinda não há avaliações

- Rethinking Hospital Design: by Paul Marmion, P.Eng., Life Member ASHRAEDocumento10 páginasRethinking Hospital Design: by Paul Marmion, P.Eng., Life Member ASHRAEAlex PullaAinda não há avaliações

- Carrier CatalogDocumento1 páginaCarrier CatalogMohamad NourAinda não há avaliações

- اسعار قطع غيار هافال اتش 9 بعد التحديثDocumento20 páginasاسعار قطع غيار هافال اتش 9 بعد التحديثWolfox 68Ainda não há avaliações

- Project: 4B+G+15Typ.+Roof Owner: Mr. Abdulla Ali Hamad Area: (Commercial/Residential Building) Saeed BuhaleebaDocumento11 páginasProject: 4B+G+15Typ.+Roof Owner: Mr. Abdulla Ali Hamad Area: (Commercial/Residential Building) Saeed BuhaleebahaseebamerAinda não há avaliações

- Safety & Installation Instructions: Model 8920W Wi-Fi IAQ ThermostatDocumento11 páginasSafety & Installation Instructions: Model 8920W Wi-Fi IAQ ThermostatsturrockAinda não há avaliações

- Tempeff Catalogue 2019Documento72 páginasTempeff Catalogue 2019Pierre MackenzieAinda não há avaliações

- Abstract of Cooling Tower ProjectDocumento8 páginasAbstract of Cooling Tower ProjectAWAL ADAMAinda não há avaliações

- Remote Temperature Controllers: Quick Selection GuideDocumento8 páginasRemote Temperature Controllers: Quick Selection GuideAudasisAinda não há avaliações

- Sustainability - Research PaperDocumento18 páginasSustainability - Research PapermrigssAinda não há avaliações

- Licensed Contractors by Business Name May23Documento214 páginasLicensed Contractors by Business Name May23ALI KHALIDAinda não há avaliações

- Effects of InverterDocumento8 páginasEffects of InverterSaahiel SharrmaAinda não há avaliações

- EBksDownload-LINKS 2016dec 1Documento213 páginasEBksDownload-LINKS 2016dec 1Pinca JoshuaAinda não há avaliações

- MEP Module BrochureDocumento14 páginasMEP Module BrochureNaveed KhalidAinda não há avaliações

- Parts Location: Air Conditioning - Air Conditioning SystemDocumento13 páginasParts Location: Air Conditioning - Air Conditioning SystemAlexander FatuatiaAinda não há avaliações

- AE21-1160 - Hot Gas By-Pass Control SystemsDocumento6 páginasAE21-1160 - Hot Gas By-Pass Control SystemsTwo and a HalfAinda não há avaliações