Escolar Documentos

Profissional Documentos

Cultura Documentos

HM Technical File en

Enviado por

José MacedoDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

HM Technical File en

Enviado por

José MacedoDireitos autorais:

Formatos disponíveis

HEATMASTER

TECHNICAL

excellence in hot water

H

E

A

T

M

A

S

T

E

R

T

E

C

H

N

I

C

A

L

HeatMaster

...the solution to all

Hot Water needs

Large houses

Blocks of appartments

Hotels

Camp sites

Restaurants

Spas

Canteens

Schools and colleges

Sport centres

Swimming pools

Beauty parlours

& fitness centres

Hospitals &

senior residences

Car wash

Slaughterhouses

Breweries

Distilleries

Industrial & agricultural

applications

...Besides, every HeatMaster

has a primary circuit and

can be used as a heating

boiler as well

C

O

N

T

E

N

T

S

CONTENTS

INTRODUCTION

HEATMASTER RANGE

DESIGN FEATURES

DESCRIPTION OF OPERATION

SAFETY FEATURES AND CONTROL PANEL

Description

02

03

04

05

06

HOT WATER PERFORMANCE

TECHNICAL DATA

DIMENSIONS

Technical characteristics

08

12

14

HEATING CONNECTION

HOT WATER CONNECTION

ELECTRICAL CONNECTION

FLUE GAS CIRCUIT

FLUE CONNECTIONS

Connections

16

17

18

22

22

BURNERS OFFERED

APPROVED GAS CATEGORIES

BG 2000 PREMIX GAS BURNERS - DESCRIPTION OF OPERATION

BG 2000 PREMIX GAS BURNERS - TECHNICAL DATA

ATMOSPHERIC GAS BURNERS - TECHNICAL DATA

OIL BURNERS - TECHNICAL DATA

ACV/MCBA ELECTRONIC CONTROLLER

Burners and controller

24

24

24

26

27

27

28

PROJECT DESIGN

LAYOUTS: HOT WATER FUNCTION

LAYOUTS: HOT WATER & HEATING FUNCTION

Examples of systems

30

31

32

HOT WATER & HEATING ACCESSORIES

Accessories

35

DESCRIPTION FOR SPECIFICATION

Specification

37

H

E

A

T

M

A

S

T

E

R

T

E

C

H

N

I

C

A

L

02

DESCRIPTION

A single product

catering for the

most demanding

hot water and

heating needs

INTRODUCTION

HeatMaster

71-101

HeatMaster

70-100

HeatMaster

Jumbo

120-150

HeatMaster

30-60

HeatMaster

29 G - 30 G

30 GP

The HEATMASTER is a high performance hot water producer:

its annular Tank in Tank holds a limited volume of hot water

for peak demand, and becomes an indirect heat exchanger

in continuous production mode. It therefore combines

the advantages of a hot water producer with integrated

storage and of an instantaneous water heater, while avoiding

the disadvantages of space, cost and efficiency of the first

and the scaling problems of the second.

Like all ACV stainless steel Tank in Tank products, it can

operate at high temperature (over 90C) with very corrosive

water such as sea water.

Finally, the HEATMASTER has a primary circuit and can

therefore also be used as a central heating boiler.

D

E

S

C

R

I

P

T

I

O

N

03

HEATMASTER RANGE

MODEL PERFORMANCE [1] BURNER

[1] Performance figures obtained with the following parameters: Hot water setting 90C Cold water temperature 10C Hot water temperature 45C

HeatMaster

30 N

60 N

Multi-fuel: version N is compatible

with BG 2000 S/35 and S/60 burners

(on/off - gas), or BM 101 or 102 N

burners (oil). Also, HM 30 and 60

operate with any type of approved

burner available on the market.

Fuel

Natural Gas Propane Butane Oil Kerosene

Input kW

Flow rate 10 L/10

Flow rate 60 L/60

Continuous flow L/h

30 N 60 N

34.9 69.9

320 378

963 1656

772 1573

HeatMaster

29 G

30 G

30 GP

The HM 29, 30 G and 30 GP are

fitted with atmospheric gas

burners with electric ignition.

Fuel

Natural Gas Propane Butane Oil Kerosene

Input kW

Flow rate 10 L/10

Flow rate 60 L/60

Continuous flow L/h

29 G 30 G 30 GP

33.0 39.2 40.0

326 326 326

918 1016 1030

710 828 845

HeatMaster

70 N

100 N

Multi-fuel: version N is compatible

with BG 2000 S/70 and S/100

burners (on/off - gas), or BM

burners (oil). Also, HM 70 and 100

operate with any type of approved

burner available on the market.

Fuel

Natural Gas Propane Butane Oil Kerosene

Input kW

Flow rate 10 L/10

Flow rate 60 L/60

Continuous flow L/h

70 N 100 N

69.9 107

543 777

1794 2680

1573 2379

HeatMaster

71

101

HM 71 and 101 are fitted with BG

2000 M premix modulating burners.

They are extraordinarily simple to

start, and are very quiet and

environment friendly. The burner

head is NIT coated with a double

ignition-ionisation electrode.

Fuel

Natural Gas Propane Butane Oil Kerosene

Input kW

Flow rate 10 L/10

Flow rate 60 L/60

Continuous flow L/h

71 101

20.0/69.9 25.0/107.0

543 777

1794 2680

1573 2379

HeatMaster

120 Jumbo

150 Jumbo

Multi-fuel: the HM JUMBO is

compatible with BM 151 or 152 N

burners (oil) and any type of

approved burner available on the

market.

Fuel

Natural Gas Propane Butane Oil Kerosene

Input kW

Flow rate 10 L/10

Flow rate 60 L/60

Continuous flow L/h

Jumbo 120 Jumbo 150

115.0 154.0

1289 1289

3450 4138

2593 3419

H

E

A

T

M

A

S

T

E

R

T

E

C

H

N

I

C

A

L

04

DESCRIPTION

DESIGN FEATURES

OUTER BODY

containing the heating circuit

The outer body containing the

primary fluid is made of thick

carbon steel.

EXCHANGER/STORAGE

Tank-in-Tank type

The hot water tank is annular

with a large heat exchange

surface. It is made of stainless

steel and entirely TIG (Tungsten

Inert Gas) welded. The tank is

corrugated over its full height

(by an exclusive manufacturing

process) giving it high

mechanical strength and an

extremely effective anti-scaling

function.

FILLING VALVE

with removable hose and

non-return valve

COLD WATER INLET

(secondary)

EXPANSION TANK

The expansion capacity is

sufficient for operation in hot

water mode only.

LOADING PUMP

PRIMARY CIRCUIT

for heating the tank indirectly

This circuit distributes the heat

over the tank walls and prevents

scale forming inside.

JACKET

All models have a steel outer

jacket that has undergone

degreasing and phosphating

before being stove enamelled

at 220C.

AUTOMATIC AIR VENT

FLUE REDUCTION COLLAR

HEATING FLOW PIPE

(primary)

HOT WATER OUTLET

(secondary)

With dip tube for NTC

temperature sensor.

FLUE PIPES AND BAFFLES

HeatMaster models contain a

varying number of steel flue

pipes, depending on output, with

an internal diameter of 64 mm.

Each pipe is fitted with a special

steel baffle designed to improve

heat exchange and reduce flue

gas temperature.

INSULATION

The boiler body is fully insulated

in rigid polyurethane foam with

a high thermal insulation

coefficient.

HEATING RETURN

COMBUSTION CHAMBER

The combustion chamber on

HeatMaster models is entirely

water cooled by the primary

circuit (except HM 29, 30 G and

GP).

BURNER

All HeatMaster models can be

fitted with a gas burner

(atmospheric, premix on/off or

premix modulating), an ACV oil

burner and most approved

burners available on the market.

D

E

S

C

R

I

P

T

I

O

N

05

DESCRIPTION OF OPERATION

Figure A

Traditional water heater

Advantages of the

HeatMaster

Figure B

HeatMaster

TANK IN TANK

The HeatMaster series differs from traditional hot water

producers because of its ring-shaped tank immersed in the

primary fluid contained in the outer body. The inner tank is

itself a stainless steel heat exchanger with a large surface

area that enables the water to be reheated very quickly.

SELF-DESCALING

HeatMaster technology (figure B) provides an effective

solution to the problem of scaling affecting traditional water

heaters (figure A). In these, the burner flame and flue gases

are in direct contact with the walls containing the hot water.

This direct contact produces a transfer of heat at high

temperature which favours scale formation.

As scale is a poor heat conductor, its formation can cause:

- overheating of the burner chamber plates which can

eventually lead to failure of the appliance;

- a significant drop in performance and combustion efficiency.

In the HeatMaster, a neutral fluid (the primary circuit) is

placed between the combustion chamber and the flue pipes

and the hot water tank. Heat is therefore transferred at a

moderate temperature with no significant scaling taking

place.

Also, as the tank is only fixed at the top, its walls oscillate

with the changes in pressure and this prevents scale forming

on the walls.

Finally, the cold water injected in the stainless steel tank

strikes against the bottom of the tank and carries all

suspended particles into the system, helping to prevent

deposits forming in the tank.

This unique self-descaling feature ensures that the boiler

always operates with maximum efficiency.

Operating

cycle

When there is a demand for hot water or heating, the

HeatMaster temperature falls until the thermostat or controller

sensor, positioned for rapid detection of an energy drawoff,

starts the burner. The combustion gases quickly heat up the

primary fluid, and at the same time accelerate circulation

around the hot water tank.

This circulation facilitates heat exchange between the primary

fluid and the water to be heated, which occurs all over the

tank surface.

The corrugations on the inner and outer shells of the ring-

shaped tank further increase the area of heat exchange and

speed up the process of heating the tank.

Reheat Drawoff Standby (no drawoff)

ANTI-LEGIONELLAE

Thanks to the large heat exchange surface of the inner tank,

which is completely immersed, the hot water can be

maintained at a uniform minimum temperature of 60C,

which prevents the formation of legionellae.

ANTI-BACTERIA

The temperature of the tank can always be kept high (typically

between 85 and 90C).

At this temperature, most bacteria presenting a threat to

vulnerable people (hospital patients, the elderly, ...) are

eliminated thus doing away with the need for costly process

of disinfecting the domestic hot water system.

Cut-off thermostat

Preset to 95C

Primary safety valve

3 bar

Safety thermostat

Preset to 103C

Low water

pressure switch

Minimum setting

0.5 bar

Control thermostat

Adjustable between

60 and 90C

Safety thermostat

Preset to 103C

Cut-off thermostat

Preset to 95C

Low water

pressure switch

Minimum setting

0.5 bar

Primary safety valve

3 bar

Control thermostat

Adjustable between

60 and 90C

H

E

A

T

M

A

S

T

E

R

T

E

C

H

N

I

C

A

L

06

DESCRIPTION

SAFETY FEATURES AND CONTROL PANEL

HEATMASTER

29-30 G

30 GP

30-60

HEATMASTER

120-150 Jumbo

Safety

thermostat

Optimiser

Cut-off

thermostat

Fuse

On/off

switch

Socket (230V 50Hz)

Control

thermostat

Heating circuit

low water pressure

indicator

Combined

temp/pressure

gauge

Power outlet

Heating circuit

low water pressure

indicator

On/off switch

Safety thermostat

Cut-off thermostat

Combined

temp/pressure gauge

Hot water

priority relay

Optimiser

Fuse

Control thermostat

Socket (230V 50Hz)

Primary temp. sensors

NTC 1 and 2

Hot water temp.

sensor NTC 3

Low water

pressure switch

Minimum setting

0.5 bar

Primary safety valve

3 bar

Safety thermostat

Preset to 103C

Cut-off thermostat

Preset to 95C

Low water

pressure switch

Minimum setting

0.5 bar

Primary safety valve

3 bar

Control thermostat

Adjustable between

60 and 90C

D

E

S

C

R

I

P

T

I

O

N

07

HEATMASTER

70-100

HEATMASTER

71-101

The 71/101 series is fitted with an electronic controller which

controls the temperatures of the safety devices, burner

operation (ignition, safety and modulation), and provides

facilities for adapting the controller to the desired application.

The controller uses 3 temperature sensors located in the

primary circuit (NTC 1-2) and the secondary circuit (NTC 3).

Combined

temp/pressure

gauge MCBA

controller

display

On/off switch

Summer/winter

selector

Combined

temp/pressure

gauge

Burner safety

shutdown

warning light

Safety

thermostat

indicator

Control

thermostat

Optimiser

Safety

thermostat

Heating circuit

low water

pressure

indicator

On/off switch

Summer/winter

selector

H

E

A

T

M

A

S

T

E

R

T

E

C

H

N

I

C

A

L

08

TECHNICAL CHARACTERISTICS

HOT WATER PERFORMANCE [1]

[1] Test conditions: Hot water setting 90C Cold water temperature 10 +/- 1C Accuracy +/- 2%

HM 29 G Drawoff duration (min) Continuous output Recovery time to set temperature (min)

T

Hot Water 10 20 30 40 50 60 L/h kW From 10C to 90 After 10 min drawoff

40 382 520 658 796 934 1072 829 28.9 33

45 326 444 563 681 799 918 710 28.9 33

50 277 380 484 587 691 795 622 28.9 32

60 203 286 368 451 534 617 497 28.9 29

38

HM 30 G

40 382 543 704 865 1026 1187 966 33.7 28

45 326 464 602 740 878 1016 828 33.7 28

50 277 397 518 639 760 881 725 33.7 27

60 203 299 396 493 589 686 580 33.7 25

Drawoff duration (min) Continuous output Recovery time to set temperature (min)

T

Hot Water 10 20 30 40 50 60 L/h kW From 10C to 90 After 10 min drawoff

32

HM 30 GP

40 382 546 711 875 1040 1204 986 34.4 28

45 326 467 608 749 890 1030 845 34.4 28

50 277 400 523 647 770 893 740 34.4 27

60 203 301 400 499 597 696 592 34.4 25

Drawoff duration (min) Continuous output Recovery time to set temperature (min)

T

Hot Water 10 20 30 40 50 60 L/h kW From 10C to 90 After 10 min drawoff

32

HM 30 N

40 380 530 680 830.2 980.2 1130 900 31.4 30

45 320 449 577 706 834 963 772 31.4 30

50 275 388 500 613 725 838 675 31.4 29

60 201 291 381 471 561 651 540 31.4 27

Drawoff duration (min) Continuous output Recovery time to set temperature (min)

T

Hot Water 10 20 30 40 50 60 L/h kW From 10C to 90 After 10 min drawoff

35

T

E

C

H

N

I

C

A

L

C

H

A

R

A

C

T

E

R

I

S

T

I

C

S

09

HM 60 N

40 474 694 1001 1313 1629 1942 1835 64.0 19

45 378 600 862 1127 1392 1656 1573 64.0 17

50 322 510 742 974 1206 1437 1376 64.0 17

60 245 396 563 743 925 1106 1101 64.0 16

70 193 264 380 462 571 681 791 55.2 15

80 135 164 249 333 417 499 455 37.0 12

Drawoff duration (min) Continuous output Recovery time to set temperature (min)

T

Hot Water 10 20 30 40 50 60 L/h kW From 10C to 90 After 10 min drawoff

17

HM 70 N

40 646 930 1233 1530 1831 2133 1835 64.0 25

45 543 785 1028 1276 1532 1794 1573 64.0 25

50 457 664 885 1113 1339 1567 1378 64.0 24

60 346 507 683 859 1038 1219 1067 64.0 23

70 268 390 528 673 821 971 918 64.0 21

80 207 246 332 432 530 636 580 47.2 19

Drawoff duration (min) Continuous output Recovery time to set temperature (min)

T

Hot Water 10 20 30 40 50 60 L/h kW From 10C to 90 After 10 min drawoff

25

HM 100 N

40 905 1358 1817 2273 2719 3172 2776 96.8 23

45 777 1153 1528 1901 2282 2680 2379 96.8 23

50 666 979 1302 1637 1973 2309 2082 96.8 23

60 514 746 1010 1275 1544 1813 1665 96.8 22

70 343 500 670 855 1040 1226 1104 77 18

80 258 382 505 631 761 893 804 65 16

Drawoff duration (min) Continuous output Recovery time to set temperature (min)

T

Hot Water 10 20 30 40 50 60 L/h kW From 10C to 90 After 10 min drawoff

23

HM 71

40 646 930 1233 1530 1831 2133 1835 64.0 25

45 543 785 1028 1276 1532 1794 1573 64.0 25

50 457 664 885 1113 1339 1567 1378 64.1 24

60 346 507 683 859 1038 1219 1067 64.0 23

70 268 390 528 673 821 971 715 64.0 21

80 203 277 377 486 598 710 675 54.9 19

Drawoff duration (min) Continuous output Recovery time to set temperature (min)

T

Hot Water 10 20 30 40 50 60 L/h kW From 10C to 90 After 10 min drawoff

25

[1] Test conditions: Hot water setting 90C Cold water temperature 10 +/- 1C Accuracy +/- 2%

HM 150

JUMBO

40 1504 2169 2833 3498 4163 4828 3989 139.1 27

45 1289 1859 2429 2998 3568 4138 3419 139.1 27

50 1115 1614 2112 2611 3109 3608 2991 139.1 27

60 870 1269 1668 2067 2465 2864 2393 139.1 26

70 700 986 1272 1559 1845 2131 1718 119.8 25

80 540 704 869 1033 1198 1362 987 80.3 23

Drawoff duration (min) Continuous output Recovery time to set temperature (min)

T

Hot Water 10 20 30 40 50 60 L/h kW From 10C to 90 After 10 min drawoff

31

HM 120

JUMBO

40 1504 2008 2512 3016 3521 4025 3025 105.5 36

45 1289 1721 2153 2585 3018 3450 2593 105.5 36

50 1115 1493 1871 2249 2627 3006 2269 105.5 35

60 870 1173 1475 1777 2080 2382 1815 105.5 35

70 700 952 1204 1456 1708 1960 1513 105.5 33

80 540 704 869 1033 1198 1362 987 80.3 30

Drawoff duration (min) Continuous output Recovery time to set temperature (min)

T

Hot Water 10 20 30 40 50 60 L/h kW From 10C to 90 After 10 min drawoff

41

HM 101

(107 kW)

40 905 1358 1817 2273 2719 3172 2776 96.8 23

45 777 1153 1528 1901 2282 2680 2379 96.8 23

50 666 979 1302 1637 1973 2309 2082 96.8 23

60 514 746 1010 1275 1544 1813 1665 96.8 22

70 385 562 753 961 1169 1378 1241 86.6 20

80 290 429 567 709 855 1003 903 73.5 18

Drawoff duration (min) Continuous output Recovery time to set temperature (min)

T

Hot Water 10 20 30 40 50 60 L/h kW From 10C to 90 After 10 min drawoff

23

H

E

A

T

M

A

S

T

E

R

T

E

C

H

N

I

C

A

L

10

TECHNICAL CHARACTERISTICS

HOT WATER PERFORMANCE [1]

T

E

C

H

N

I

C

A

L

C

H

A

R

A

C

T

E

R

I

S

T

I

C

S

11

HIGH FLOW RATES

Thanks to their high heat output and large heat exchange surface, HeatMaster producers offer both high flow rates and

short recovery times to the set temperature.

HIGHLY CORROSIVE WATER

ACV offers tanks made of DIN 1.4462 stainless steel for applications using

highly corrosive water such as:

- thalassotherapy - heating sea water in HeatMasters and ACV indirect water

heaters;

- water with a high chloride content (such as well water in regions near a

coastline or in areas rich in phosphates) or chlorine content (when the

HeatMaster fresh water supply point is very close to a disinfection and

chlorination plant in the mains system);

- industrial applications using water with an acid pH and rich in free negative

ions.

DIN 1.4462 stainless steel is an austenitic-ferritic alloy with a high Chromium

and Molybdenum content: this grade is commonly known as Duplex 4462 or

Uranus, and should not be confused with the ordinary Duplex 2304 grade.

This grade of stainless steel is the only one that can withstand extreme

concentrations of chlorides (up to 2.000 mg/L). This grade also gives double

the mechanical strength of ordinary austenitic steels (series 3xx).

The full HeatMaster range up to model 100 and 101 is available optionally in

SS DIN 1.4462 steel.

min

F

l

o

w

a

t

t

3

0

C

(

l

i

t

r

e

s

)

HeatMaster 150 Jumbo

HeatMaster 120 Jumbo

HeatMaster 100/101

HeatMaster 70/71

HeatMaster 60 N

HeatMaster 29 G, 30 G, 30 GP, 30 N

H

E

A

T

M

A

S

T

E

R

T

E

C

H

N

I

C

A

L

12

TECHNICAL CHARACTERISTICS

[1]: T setting at 90C

[2]: per standards EN 656 - EN 297 - EN 483

[3]: electric power consumption figures given for N boilers (combined Oil/Gas) do not take account of burner consumption

[4]: the maximum operating pressure of the primary circuit is for an open (atmospheric pressure) secondary circuit (tank)

TECHNICAL DATA

Fuel

Input kW

Rated output kW

Efficiency at 100% %

30% %

Flue losses [1] on %

off %

Other operating losses [1] %

CO2 at rated output %

MaximumNOx [2] mg/kWh

Maximum CO mg/kWh

Water circuits

Heating connection

Hot water connection

Primary fluid temperature maximum C

minimum C

Maximum pressure loss primary circuit mbar

tank mbar

Total capacity (primary circuit and tank) L

Primary circuit capacity L

Tank capacity L

Tank heat exchange surface m

2

Number and capacity of expansion (vessel calibrated at 1 bar) nxL

Maximum operating pressure primary circuit [4] bar

tank bar

Test pressure of primary circuit bar

tank bar

Electrical parameters

Power supply V/Hz

Maximum power consumption W

Electrical protection IP

HM HM HM HM HM 30 N

29 G 30 G 30 GP 30 N BG2000/S35

GAS GAS PROPANE GAS/OIL GAS

33.0 39.2 40.0 34.9 34.9

28.9 34.2 34.9 31.4 31.4

87.5 87.2 87.2 90.0 90.0

85.5 85.5 85.5 89.2 95.0

10.3 10.5 10.5 8.5 8.0

1.20 1.02 1.00 0.69 0.69

2.20 2.30 2.30 1.50 2.00

4.8 4.9 5.6 9.5 9.0

174 174 209 - 60

8 21 - - 0

1

1

/4'' 1

1

/4'' 1

1

/4'' 1

1

/2'' 1

1

/2''

3/4'' 3/4'' 3/4'' 3/4'' 3/4''

90 90 90 90 90

60 60 60 60 60

25 29 29 27 27

20 20 20 20 20

163.5 163.5 163.5 162.0 162.0

87.5 87.5 87.5 82.0 82.0

76.0 76.0 76 80.0 80.0

2.46 2.46 2.46 2.46 2.46

1 x 8 1 x 8 1 x 8 1 x 8 1 x 8

3 3 3 3 3

10 10 10 10 10

4.5 4.5 4.5 4.5 4.5

13 13 13 13 13

230 / 50 230 / 50 230 / 50 230 / 50 230 / 50

82 82 82 82 [3] 160

30 30 30 30 30

T

E

C

H

N

I

C

A

L

C

H

A

R

A

C

T

E

R

I

S

T

I

C

S

13

HM HM 60 N HM HM 70 N HM HM HM 100 N HM HM HM

60 N BG2000/S60 70 N BG2000/S70 71 100 N BG2000/S100 101 120 JUMBO 150 JUMBO

GAS/OIL GAS GAS/OIL GAS GAS GAS/OIL GAS GAS GAS/OIL GAS/OIL

69.9 69.9 69.9 69.9 20.0 / 69.9 107.0 85.0 25.0 / 107.0 115.0 154.0

62.5 63.0 63.0 63.0 63.0 96.8 77.4 96.8 105.5 139.1

89.4 90.1 90.2 90.2 90.2 90.5 91.0 90.5 91.7 90.3

88.5 96.0 90.0 96.7 96.7 89.8 9.3 96.4 91.5 90.1

8.8 8.8 8.0 8.5 8.5 8.0 7.1 7.6 7.8 8.5

0.57 0.57 0.60 0.60 0.60 0.65 0.65 0.65 0.65 0.52

1.80 1.10 1.80 1.30 1.30 1.50 1.90 1.90 0.50 1.20

9.5 9.5 9.5 9.0 9.0 9.5 9.0 9.0 9.5 9.5

- 78 - 75 75 - 50 50 - -

- 29 - 3 3 - 24 24 - -

1

1

/2'' 1

1

/2'' 1

1

/2'' 1

1

/2'' 1

1

/2'' 1

1

/2'' 1

1

/2'' 1

1

/2'' DN 50 DN 50

3/4'' 3/4'' 1'' 1'' 1'' 1'' 1'' 1'' 2'' 2''

90 90 90 90 90 90 90 90 90 90

60 60 60 60 60 60 60 60 60 60

54 54 46 46 46 83 67 83 78 120

45 45 45 45 45 180 180 180 190 190

162.0 162.0 239.0 239.0 239.0 330.0 330.0 330.0 645.0 645.0

82.0 82.0 108.0 108.0 108.0 130.0 130.0 130.0 245.0 245.0

80.0 80.0 131.0 131.0 131.0 200.0 200.0 200.0 400.0 400.0

2.46 2.46 3.14 3.14 3.14 3.95 3.95 3.95 5.30 5.30

1 x 8 1 x 8 2 x 10 2 x 10 2 x 10 2 x 10 2 x 10 2 x 10 4 x 8 4 x 8

3 3 3 3 3 3 3 3 3 3

10 10 10 10 10 10 10 10 10 10

4.5 4.5 4.5 4.5 4.5 4.5 4.5 4.5 4.5 4.5

13 13 13 13 13 13 13 13 13 13

230 / 50 230 / 50 230 / 50 230 / 50 230 / 50 230 / 50 230 / 50 230 / 50 230 / 50 230 / 50

82 [3] 160 93 [3] 160 180 93 [3] 180 200 300 [3] 300 [3]

30 30 30 30 30 30 30 30 30 30

Certification given by TECHNIGAZ (BE) number 0461

A

K

H

J

E

C

D

F

G

562

C/2

D

A

C

D

A

C

G

F

E

J

H B K

H

E

A

T

M

A

S

T

E

R

T

E

C

H

N

I

C

A

L

14

TECHNICAL CHARACTERISTICS

DIMENSIONS

A mm

B mm

C mm

D mm

E mm

F mm

G mm

H mm

J mm

K mm

Weight empty kg

HM HM HM HM HM 30 N

29 G 30 G 30 GP 30 N BG2000/S35

1691 1691 1691 1698 1698

1513 1513 1513 1583 1583

538 538 538 538 538

801 801 801 625 801

540 540 540 540 540

390 390 390 390 390

150 150 150 150 150

898 898 898 898 898

281 281 281 281 281

1560 1560 1560 1560 1560

190 190 191 220 230

[1]: the widths and depths given are for the HeatMaster fully assembled and fitted with a BM burner

HEATMASTER

29 G

30 G

30 GP

30 N

60 N

HEATMASTER

120 JUMBO

150 JUMBO

Version N coupled to BG 2000 S

D

G

F

E

J

H B

K

A

C

C/2

G

F

E

J

H B

K

C/2

D

A

C

D

A

C

T

E

C

H

N

I

C

A

L

C

H

A

R

A

C

T

E

R

I

S

T

I

C

S

15

HM HM 60 N HM HM 70 N HM HM HM 100 N HM HM HM

60 N BG2000/S60 70 N BG2000/S70 71 100 N BG2000/S100 101 120 JUMBO 150 JUMBO

1698 1698 1743 1743 1743 2093 2093 2093 2124 2124

1583 1583 1630 1630 1630 2030 2030 2030 2117 2117

538 538 680 680 680 680 680 680 1020 [1] 1020 [1]

625 801 797 937 937 797 937 937 1440 [1] 1440 [1]

540 540 680 680 680 680 680 680 1020 [1] 1020 [1]

390 390 390 390 390 390 390 390 600 600

150 150 150 150 150 150 150 150 250 250

1098 1098 1289 1289 1289 1693 1693 1693 1383 1383

281 281 285 285 285 285 285 285 590 590

1665 1665 1720 1720 1720 2120 2120 2120 2226 2250

220 232 270 282 282 320 333 335 530 530

HEATMASTER

70 N

100 N

HEATMASTER

71

101

Version N coupled to BG 2000 S

1

2

3

4

5

6 4

8

4

10

11

7

9

H

E

A

T

M

A

S

T

E

R

T

E

C

H

N

I

C

A

L

16

CONNECTIONS

HEATING CONNECTION

The HeatMaster has two couplings at the rear that can be used to connect a central heating circuit. If the heating flow

temperature needs to be less than the hot water temperature setting then a mixing valve should be fitted to the heating

circuit.

EXPANSION TANK

The HM 29/30/60 range is fitted with an 8L expansion tank. HM 70/100 models are delivered with two 10L expansion

tanks, and HM Jumbos with four 8L expansion tanks. The expansion tanks are dimensioned for hot water operation

only. If the primary circuit is connected to a heating circuit then the expansion capacity needed should be added to the

configuration.

Example of a basic circuit configuration

1. Outside temperature sensor

2. ACV independent controller

3. Three-way mixing valve

4. Isolating valve

5. Heating circulator

6. Non-return valve

7. Flow temperature sensor

8. Heating circuit

9. Room temperature sensor

10. Heating expansion tank

11. Heating circuit drain

1

2

3

3

4

5

1 1

7

8

1 1

11

1

6

10

9

C

O

N

N

E

C

T

I

O

N

S

17

HOT WATER CONNECTION

PRESSURE REDUCER

If the mains water pressure is greater than 6 bar, a pressure reducer calibrated to 4.5 bar must be fitted.

SAFETY VALVE

The safety valve is set to 7 bar and must be ACV approved. The valve discharge must be connected to the main drain.

HOT WATER EXPANSION TANK

The hot water expansion tank stops water being discharged through the safety valve when the system is warming up.

It also protects the system against ordinary water hammer.

HOT WATER CIRCULATION LOOP

If the drawoff point is situated at a distance, then installing a circulation loop ensures a contstant supply of instant hot

water.

THERMOSTATIC MIXER

As a safety measure against burns, we strongly recommend installing a thermostatic mixing valve. It also provides

optimum comfort and reduces energy consumption (recommended distribution temperature: 60C).

To limit line losses in applications with a recirculation loop, we recommend choosing a thermostatic mixing valve fitted

with a temperature control of the recirculation loop.

IMPORTANT

The HeatMasters hot water tank must always be filled and pressurised before the primary circuit.

For the operating procedure, the installing engineer should refer to the installation and commissioning instructions.

1. Isolating valve

2. Pressure reducer

3. Non-return valve

4. Expansion tank

5. Safety valve

6. Drain

7. Air vent

8. Thermostatic mixing valve

9. Recirculation temperature

thermostatic control valve

10. Circulation pump

11. Drawoff point

5

9

2

7

8

3

11

6

4

1

10

103C

95C

60 to 90C

6.3 A

H

E

A

T

M

A

S

T

E

R

T

E

C

H

N

I

C

A

L

18

CONNECTIONS

ELECTRICAL CONNECTION

POWER SUPPLY

The boiler operates with a 230 V - 50 Hz single phase supply. An on-off switch box with 6 A fuses must be fitted outside

the boiler to allow power to be shut off during servicing and before any repairs are carried out on the boiler.

CONFORMITY

Boiler installation must comply with the prevailing local standards and legislation.

SAFETY

The stainless steel tank must be earthed separately.

HEATMASTER

29 G

30 G

30 GP

1. 230 V Plug

2. On/off switch

3. Manual reset safety thermostat

4. Low water pressure switch

indicator lamp

5. Low water pressure switch

6. Optimiser

7. Loading pump

8. Cut-off thermostat 95C

9. Control thermostat

10. 230 V socket for measuring

instruments

11. Spill switch

1

3

10

11

2

13

6

5

4

7 8

9

12

14 15

103C

95C

10 - 100C

6.3 A

C

O

N

N

E

C

T

I

O

N

S

19

ELECTRICAL CONNECTION

HEATMASTER

120 JUMBO

150 JUMBO

1. 230 V Plug

2. On/off switch

3. Manual reset safety thermostat

4. Low water pressure switch

indicator lamp

5. Low water pressure switch

6. Optimiser

7. Loading pump

8. Heating circulator (option)

9. Burner plug connector

10. Cut-off thermostat 95C

11. Control thermostat

12. 230 V socket for measuring

instruments

13. Hot water priority relay

14. Room thermostat (option)

15. Flow pressure switch (option)

11 9

1

2

3 4

5

6

7

8

10

12 13

14

15

16

17

103C

95C

60 to 90C

H

E

A

T

M

A

S

T

E

R

T

E

C

H

N

I

C

A

L

20

CONNECTIONS

ELECTRICAL CONNECTION

HEATMASTER

30 N

60 N

70 N

100 N

1. 230 V Plug

2. On/off switch

3. Reset safety thermostat

indicator lamp (70 - 100 N)

4. Manual reset safety

thermostat

5. Low water pressure switch

indicator lamp

6. Low water pressure switch

7. Optimiser

8. Summer/winter selector

9. Hot water priority thermostat

10. Burner safety shutdown

warning lamp (70 - 100 N)

11. Room thermostat

12. Heating circulator

13. Loading pump

14. Burner plug connector

15. Flow pressure switch

16. Cut-off thermostat 95C

17. Control thermostat

13 14 15 17

16

7 8 9 10 11 12

3

4

5 6

2 1

C

O

N

N

E

C

T

I

O

N

S

21

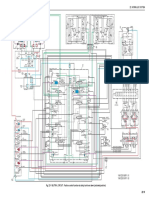

ELECTRICAL CONNECTION

HEATMASTER

71

101

1. 7-pin burner plug connector

(230 V)

2. 4-pin burner plug connector

(24 V)

3. On/off switch

4. Power and pump connection

5. Heating circulator

6. Loading pump

7. Room thermostat

8. Low water pressure switch

9. Primary temperature sensor

NTC 1

10. Primary temperature sensor

NTC 2

11. Hot water temperature sensor

NTC 3

12. Summer/winter selector

13. Fan 230 V power supply

14. Fan PWM

15. Gas valve rectifier

16. Second gas valve rectifier

(HM 101)

17. Gas pressure switch (option)

B

A

B

F

E

> 1000 mm

> 200 mm

D

D

C

> 400 mm

H

E

A

T

M

A

S

T

E

R

T

E

C

H

N

I

C

A

L

22

CONNECTIONS

CHIMNEY CONNECTION

[1]: the data for N boilers (combined Oil/Gas) correspond to the CO2 reference values given on pages 12-13

In the absence of single European standards for B23 and B11BS connections, each system must comply with the technical regulations

applicable in the country of installation. The following diagrams show the regulations applicable in Belgium.

A Top vent

B Bottom vent

CD Height and diameter

according to regulations

E Draught regulator

F Servicing hatch

FLUE GAS CIRCUIT

Combustion chamber volume m

3

Mass rate of combustion products [1] g/sec

Flue circuit pressure loss mbar

Maximum allowable draught mbar

Chimney outlet diameter mm

Maximum net flue temperature C

Air intake and flue connections [2] B11BS

B23

C13

C33

C53

HM HM HM HM HM 30 N

29 G 30 G 30 GP 30 N BG2000/S35

- - - 0.051 0.051

20.8 24.5 25.9 15.2 16.0

0.00 0.00 0.00 0.01 0.01

-0.10 -0.10 -0.10 -0.15 -0.15

153 153 153 150 150

106 117 125 180 163

Yes Yes Yes - -

- - - Yes Yes

- - - - -

- - - - -

- - - - -

C13

C33

C53

C53

2

m

m

i

n

.

1

5

0

m

i

n

.

120

C

O

N

N

E

C

T

I

O

N

S

23

[2]: the connection configurations indicated are applicable provided they are permitted by the prevailing regulations in the country concerned

HM HM 60 N HM HM 70 N HM HM HM 100 N HM HM HM

60 N BG2000/S60 70 N BG2000/S70 71 100 N BG2000/S100 101 120 JUMBO 150 JUMBO

0.051 0.051 0.075 0.075 0.075 0.075 0.075 0.075 0.15 0.15

30.6 32.1 30.6 32.1 32.1 46.9 40.8 51.4 51.0 68.0

0.6 0.6 0.6 0.6 0.6 1.4 0.9 1.4 0.3 0.6

-0.20 -0.20 -0.20 -0.20 -0.20 -0.30 -0.30 -0.30 -0.30 -0.35

150 150 150 150 150 150 150 150 250 250

195 186 170 172 172 170 145 154 165 181

- - - - - - - - - -

Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

- Yes - Yes Yes - Yes Yes - -

- Yes - Yes Yes - Yes Yes - -

- Yes - Yes Yes - Yes Yes - -

C13: air intake and flue at the same

pressure in a horizontal concentric

connection

C33: air intake and flue at the same

pressure in a vertical or parallel

concentric connection

C53: air intake and flue in different

pressure zones

CONNECTION FOR SEALED COMBUSTION

A

B C

D

E

F

G

H

E

A

T

M

A

S

T

E

R

T

E

C

H

N

I

C

A

L

24

BURNERS AND CONTROLLER

Atmospheric

BG 2000 S/35

BG 2000 S/60

BG 2000 S/70

BG 2000 S/100

BG 2000 M/70

BG 2000 M/100

OTHERS

BMR 31

BM 101

BM 151

OTHERS

BURNERS OFFERED

G

A

S

O

I

L

HM29G

HM30GP

HM30G

HM30N

SERIES

OPTION

[1]: N boilers (combined Oil/Gas) must be approved with the corresponding gas burner

I2E+

I2E(S)B

I2Er

I2ELL

I2H

I2L

I3P

BE - FR

LU - DE

AT - DK - ES - GB - IT - PT - IE - SE

NL

BE - FR - ES - GB - IE - PT

APPROVED GAS CATEGORIES [1]

HM HM HM HM HM 30 N

29 G 30 G 30 GP 30 N BG2000/S35

- Yes - - -

- - - - Yes

- - - - Yes

- - - - Yes

Yes Yes - - Yes

- Yes - - Yes

- - Yes - Yes

BG 2000 PREMIX GAS BURNERS - Description of operation

ACV BG 2000 S burners belong to the air/gas premix family of gas burners.

ACV burners are fitted with a Honeywell gas valve, a venturi and an electrically operated relay. The gas valve has been

specially developed for low NOx burners with automatic ignition and ionisation flame detection.

A. Air

B. Venturi

C. Fan

D. Air-gas mixture

E. Gas flow adjustment screw

F. Offset regulating screw

G. Gas

The fan sucks air through the venturi producing a pressure differential, dependent on the flow rate, in the neck of the

venturi. In addition, the gas pressure at the valve outlet is equal to the air pressure in the neck of the venturi, less the

offset. Gas is sucked through the venturi and is mixed thoroughly with the air in the fan. The optimised air-gas mixture

is then forced into the burner and combustion spreads evenly around the burner head.

B

U

R

N

E

R

S

A

N

D

C

O

N

T

R

O

L

L

E

R

25

HM150 JUMBO

HM120 JUMBO

HM101

HM71

HM100N

HM70N

HM60N

HM HM 60 N HM HM 70 N HM HM HM 100 N HM HM HM

60 N BG2000/S60 70 N BG2000/S70 71 100 N BG2000/S100 101 120 JUMBO 150 JUMBO

- - - - - - - - - -

- Yes - Yes Yes - Yes Yes - -

- Yes - Yes Yes - Yes Yes - -

- Yes - Yes Yes - Yes Yes - -

- Yes - Yes Yes - Yes Yes - -

- Yes - Yes Yes - Yes Yes - -

- Yes - Yes Yes - Yes Yes - -

ADVANTAGES

EASY INSTALLATION AND ADJUSTMENT

Easy adjustment: the gas flow (and therefore the rate of CO2) is adjusted by a regulating screw situated on the venturi;

the fan rotation speed is adjusted by a potentiometer. All BG 2000-S burners are preset at the factory.

THE COMFORT OF SILENCE

Lighting and operation are much quieter than with forced draught burners.

EASY MAINTENANCE

No maintenance required. Faults are easily diagnosed. Components are standard.

MAXIMUM SAFETY

The venturi technology combined with the Honeywell gas valve ensures completely safe operation:

if there is an air blockage, the pressure differential in the venturi neck falls, the gas flow diminishes, and the burner

performs a safety shutdown due to flame failure

if there is a blockage in the flue outlet, the air flow diminishes, as does the pressure differential in the venturi neck,

causing the gas to be shut off and the burner to shut down in safety mode due to flame failure.

NIT BURNER

HEAD

The burner head on ACV BG 2000 burners of 60 kW and over is coated with a

metal fibre (NIT) that sharply reduces NOx emissions (typically less than 60

mg/KWh), and also extends the life of the burner significantly.

Finally, the quantity of energy transmitted by radiation is significantly higher than

with an ordinary burner head, which helps to improve thermal efficiency in the

combustion chamber, especially at low loads.

H

E

A

T

M

A

S

T

E

R

T

E

C

H

N

I

C

A

L

26

BURNERS AND CONTROLLER

BG 2000 PREMIX GAS BURNERS - Technical Data

BG 2000 S

BG 2000 M

The BG 2000 M burner continually adjusts output to demand, significantly improving efficiency in heating mode. The

BG 2000 M burner fitted to the HeatMaster 71 and 101 is regulated by an ACV/MCBA (Honeywell) controller which

controls both the operating safety and modulation of the burner.

[1]: Propane

Input kW

Rated output kW

Combustion efficiency - natural gas %

CO2 %

Gas G20 - 20 mbar - I 2E(S)B - I 2Er - I 2H - I 2ELL

Flow rate m

3

/h

Gas G25 - 25 mbar - I 2L

Flow rate m

3

/h

Gas G31 - 37/50 mbar - I 3P

Flow rate m

3

/h

Net flue gas temperature C

Mass rate of combustion products g/sec

HM 71 HM 101

22.0/69.9 25.0/107.0 - 22.0/110 [1]

18.4/63.0 23.0/96.3 - 20.2/99 [1]

92.0 92.1

9.0 9.5

2.12/7.40 2.64/11.32

2.46/8.60 3.08/13.17

0.82/2.86 0.94/4.50

172 165

9.2/32.1 11.5/49.2

Input kW

Rated output kW

Combustion efficiency %

CO2 %

Gas G20 - 20 mbar - I 2E(S)B - I 2Er - I 2H - I 2ELL

Flow rate m

3

/h

Gas G25 - 25 mbar - I 2L

Flow rate m

3

/h

Gas G31 - 37/50 mbar - I 3P

Flow rate m

3

/h

Net flue gas temperature C

Mass rate of combustion products g/sec

HM 30 N HM 60 N HM 70 N HM 100 N

(BG 2000 S/35) (BG 2000 S/60) (BG 2000 S/70) (BG 2000 S/100)

34.9 69.9 69.9 85.0

31.4 63.0 63.0 77.4

92.0 91.2 91.5 92.9

9.0 9.5 9.0 9.0

3.7 7.40 7.40 8.99

- 8.60 8.60 10.46

1.43 2.86 2.86 3.47

173 186 172 145

16 32.1 32.1 39.1

B

U

R

N

E

R

S

A

N

D

C

O

N

T

R

O

L

L

E

R

27

ATMOSPHERIC GAS BURNERS - Technical Data

These atmospheric burners are fitted with a SIT gas valve and an electrically operated relay. This gas valve has been

specially developed for atmospheric burners with automatic ignition and ionisation flame detection.

ADVANTAGE

- No pilot flame, therefore no gas consumption when the boiler is off.

Input kW

Rated output kW

Injector 1/100 mm

Gas G20 - 20 mbar - I 2E(S)B - I 2Er - I 2H - I 2ELL

Burner pressure mbar

Flow rate m

3

/h

Gas G25 - 25 mbar - I 2L

Burner pressure mbar

Flow rate m

3

/h

Gas G31 - 37/50 mbar - I 3P

Burner pressure mbar

Flow rate m

3

/h

HM 29G HM 30G HM 30GP

33.0 39.2 40.0

29.0 34.2 39.4

470 510 3 x 190

12.8 12.3 -

3.50 4.13 -

13.4 13.4 -

3.88 4.50 -

- - 28.5

- - 1.66

BM 101

BM 151

OIL BURNERS - Technical data

ACV medium output oil burners meet current environmental requirements. These burners are fitted with standard high

quality components including a two-stage oil pump that permits incremental lighting.

AVANTAGES

- Easy to install

- Fitted with a safety shutdown device and a new burner

mounting system

- The burner air pressure adjusts to the pressure in the

combustion chamber

- An automatic valve shuts off the air flow when the burner

is turned off, preventing the boiler from cooling

- Quiet and highly reliable

- Adjustable to the depth of the boiler combustion chamber

thanks to the deflector plate adjustable bracket

- Three air adjustment points to ensure the best air/oil

mixture

upstream air presetting

primary setting

combustion head setting.

Input kW

Nozzle flow US Gal/h

Nozzle angle

Oil flow kg/h

Pump pressure bar

HM 30 N HM 60 N HM 70 N HM 100 N HM 120 J HM 150 J

(BMR 31) (BM 101) (BM 101) (BM 101) (BM 151) (BM 151)

34.9 69.9 69.9 107.0 115.0 154.0

0.85 1.50 1.50 2.00 2.50 3.00

60 60 60 60 60 60

2.94 5.9 9.09 8.92 9.7 13.0

11 10.5 14 13.5 10.2 13.5

C

B

A

E

H

D

G

F

MODE EAU CHAUDE MODE CHAUFFAGE

Hot Water

temperature

Loading

pump

Heating

circulator

Setting + diff. OFF

Setting

Setting + diff. ON

H

E

A

T

M

A

S

T

E

R

T

E

C

H

N

I

C

A

L

28

BURNERS AND CONTROLLER

ACV/MCBA ELECTRONIC CONTROLLER

HeatMasters 71 and 101 are fitted with an ACV/MCBA (Honeywell Gasmodul) electronic controller. This controller

regulates the boiler (start-up, safety, modulation), the loading pump and the heating circulator in response to heating

and hot water demand.

This controller offers numerous advanced features:

Hot water priority is extremely accurate: even very small drawoffs are immediately detected

The hot water tank is always kept at a uniform maximum temperature

Hot water performance (temperature of water drawn off at more than 70C) is optimum

HeatMasters 71 and 101 are particularly suited to central heating thanks to their large output modulation range

Energy efficiency is optimised in both operating modes - Hot Water and Heating

Location of

NTC sensors

The temperature of HeatMasters 71 and 101 is measured constantly by 3 NTC (Negative Temperature Coefficient) sensors:

Sensor NTC 1 is placed at the highest point in the primary circuit and measures the temperature of the primary circuit.

Sensor NTC 2 is next to sensor NTC 1 and acts as a cross-check, which makes a safety thermostat unnecessary.

Sensor NTC 3 is located at the bottom of a dip tube immersed in the Hot Water tank and very quickly detects the smallest

amounts of cold water entering the tank.

The temperature mesured by sensor NTC 3 determines the operating mode of the HeatMaster:

Hot Water mode when the measured temperature is lower than the Hot Water temperature setting

Heating mode when the measured temperature is higher than the Hot Water temperature setting

The HeatMaster gives priority to the Hot Water mode. The Hot Water temperature setting and the operating temperature

(equivalent to the temperature of the heating circuit) are set by the user.

Operation

A. MCBA controller

B. Maximum T sensor NTC1 (primary)

C. Safety sensor NTC2 for checking NTC1

sensor (primary)

D. Hot Water tank T sensor NTC3

E. Hot Water loading loop

F. Heating circulator

G. Room thermostat

H. BG 2000 M burner

HOT WATER MODE HEATING MODE

Schematic section of

HeatMaster 71 and 101

When Hot Water is drawn off, cold

water enters the tank. Sensor NTC 3

very quickly detects this cold water

flow and when the measured

temperature falls below the Hot Water

temperature setting (taking into

account a differential), the MCBA

controller switches to Hot Water mode:

the loading pump is activated and the

heating circulator is stopped.

In Hot Water mode, the temperature

setting for the primary circuit is

automatically set to 3C above the Hot

Water temperature setting.

B

U

R

N

E

R

S

A

N

D

C

O

N

T

R

O

L

L

E

R

29

The BG 2000 M burner starts as soon as the temperature measured by sensor NTC 1 falls below this set value. The

controller adjusts the boiler output in accordance with the difference between the heating temperature setting and the

temperature measured by sensor NTC 1.

When the temperature measured by sensor NTC 3 again reaches the Hot Water setting of the tank, the MCBA controller

switches to heating mode: the loading pump is stopped and the heating circulator is activated. The BG 2000 M burner

is controlled by the temperature measured by sensor NTC 1. When the room thermostat reaches its set temperature,

the controller stops the heating circulator.

Burner

output

Boiler

temperature

Heating

circulator

Heating

demand

Max

Min

Setting + diff. OFF

Setting

Setting + diff. ON

The heating temperature setting is set

by the user at between 60 and 90C (it

must be higher than the Hot Water

temperature setting). The burner starts

when the temperature measured by

sensor NTC 1 falls below the set

temperature (taking into account a

differential). Burner modulation is then

controlled in accordance with the

difference between the temperature

measured by sensor NTC 1 and the set

temperature. The controller operates

in Proportional Integral (PI) mode: the

amplitude of fluctuation around the set

temperature is small but more time is

needed to reach the set temperature.

The inertia of the heating system is not

sensitive to this phenomenon and

burner operation and modulation

stability are optimised.

Heating

Mode

Burner

output

Boiler

temperature

Hot Water

temperature

Loading

pump

Hot water

drawoff

Max

Min

Setting + diff. OFF

Setting

Setting + diff. ON

Setting + diff. OFF

Setting

Setting + diff. ON

The burner starts when the

temperature measured by NTC 1 falls

below the heating temperature setting

(automatically set to the hot water

temperature setting + 3C in Hot Water

mode). Burner modulation is then

controlled by NTC 1. The controller

works in Proportional Integral

Differential (PID) operating mode: the

amplitude of fluctuation around the set

temperature of the primary circuit is

large but the set temperature is

reached quicker, which is essential for

a high performance Hot Water

producer.

Hot Water

Mode

H

E

A

T

M

A

S

T

E

R

T

E

C

H

N

I

C

A

L

30

EXAMPLES OF SYSTEMS

PROJECT DESIGN

Your ACV contact will be pleased to demonstrate these tools for you and help you determine what is best for your needs.

With ACV, project design, the installation of the hot water system and its operation are simplified immensely!

Along with this integrated tool, ACV

has developed a software program

called Specialist on line, into which

data on the hot water design

requirements of a project can be

entered. This data is then transmitted

to ACV Technical Support by e-mail,

which produces a complete design

specification within 48 hours and

sends it back to the design engineer.

Specialist on line

System diagrams

produced by

Archimedes

From among the configurations

proposed, the engineer can choose

one that meets his criteria (connection

to an existing boiler, boiler redundancy,

reserve peak capacity, reserve

continuous flow, ).

Finally Archimedes provides system

layouts, technical data on the

appliances selected and a technical

description for their specification.

All this information can then be printed

or transferred to a Word document or

AutoCAD file.

Hot water production occupies an important place in most building equipment

projects: system design includes a careful evaluation of the requirements

followed by the identification of sound, economically viable solutions that ensure

maximum comfort, high operating efficiency, faultless reliability and simple and

cheap maintenance over the long term.

Designing such a system is not simple and a number of variables must be

considered: the timing of drawoffs, the length and frequency of peak periods of

use, and various parameters related with the specific nature of the application.

Archimedes

CD ROM

As a leading designer and manufacturer of hot water production systems, ACV

has special experience in system design. This has been translated into a simple

but effective computer tool, Archimedes.

This tool allows engineers to calculate hot water requirements in a wide variety

of applications (hotels, hospitals, sports centres, campsites, health units,

industrial processing, ), and to propose several configurations that meet the

design requirements.

E

X

A

M

P

L

E

S

O

F

S

Y

S

T

E

M

S

31

LAYOUTS: Hot Water Function

CAUTION

The hydraulic layouts proposed are merely functional layouts. For greater clarity, they exclude some of the safety (safety unit, expansion tank, ...) or operating

components (balancing valves, filling system, ...) that may be necessary. The heating and/or installing engineer should see to it that all equipment needed for

the particular applications implemented is included.

Several HeatMasters in parallel

The HeatMasters hot water circuits are

connected in parallel and the primary

circuits are interconnected: this allows

the whole storage volume of the

HeatMasters to be used, even if one of

the burners is down. The hot water

performance of the configuration is

equal to the sum of the individual

performances of each HeatMaster.

The Hot Water performance of this

configuration is:

10 peak flow = 10 peak flow of HeatMaster

+ 10 peak flow of indirect water heater

60 peak flow = 60 peak flow of HeatMaster

+ 10 peak flow of indirect water heater

Continuous flow = Continuous flow of

HeatMaster

HeatMaster with indirect water heater

The indirect water heater is placed

upstream of the HeatMaster because:

This configuration limits the number

of burner stop/start cycles when small

quantities are drawn off, and reduces

operating costs

The indirect water heater can be the

multi-energy type and use energy from

other sources (e.g. solar collectors)

HeatMaster with low or medium

temperature indirect water heater

The indirect water heater is placed

upstream of the HeatMaster and uses

the preheating energy provided by a

solar collector, or by another low

temperature source such as a heat pump

or the condensor of a cooling unit.

The HeatMaster brings the hot water

up to the set temperature during drawoff

and reduces overall energy consumption

while giving superior hot water

performance.

H

E

A

T

M

A

S

T

E

R

T

E

C

H

N

I

C

A

L

32

EXAMPLES OF SYSTEMS

LAYOUTS: Hot Water & Heating Functions

HeatMaster alone and HeatMaster with

an indirect water heater

The heating circuit is connected directly

to the HeatMaster primary circuit and

the heating circulator is controlled either

by the room thermostat connected to

the HeatMaster (depending on models),

or by a separate controller. The

HeatMaster operates at high

temperature (85 - 90C) to optimise its

hot water performance and a three-way

valve is used in the heating circuit if the

temperature has to be set lower than

that of the HeatMaster. Except in a

special application with large heating

requirements, the design computation

allows for the full output of the

HeatMaster to be available for the

heating function.

E

X

A

M

P

L

E

S

O

F

S

Y

S

T

E

M

S

33

LAYOUTS: Hot Water & Heating Functions

The primary circuits of the HeatMasters (type 71 or 101) are connected in parallel to one balanced header. An external ACV controller (1 or more

Control Units) measures the temperature in the balanced header and adjusts the temperatures of each heating circuit.

On detecting a heating demand, the controller inputs a heating demand to each HeatMaster progressively. Priority for the Hot Water function is

retained by each HeatMaster.

This configuration can also be adopted (without the modulation function) with HeatMasters N using the appropriate analogical controllers.

HeatMaster and high temperature boiler

One or more HeatMasters can be

connected to the same balanced header

as a high temperature boiler (for example,

a high power boiler). The primary circuits

of the HeatMasters are used in

conjunction with the primary circuit of

the high temperature boiler to provide

maximum output for heating; which also

allows the system to be used even when

one of the burners is down. The hot

water performance of the configuration

is equal to the sum of the individual

performances of each HeatMaster.

Several HeatMasters with indirect water

heater and HT/LT heating circuits

Pmax: 240 kW Outside temperature per the standard: tNe - 12C

HeatMaster + Prestige available output: > 240 kW

Prestige 160 kW cascade available output: 20-160 kW

Hours of operation of heating system

H

e

a

t

i

n

g

d

e

m

a

n

d

1

0

0

%

S

y

s

t

e

m

o

u

t

p

u

t

(

k

W

)

O

u

t

s

i

d

e

t

e

m

p

e

r

a

t

u

r

e

(

C

)

H

E

A

T

M

A

S

T

E

R

T

E

C

H

N

I

C

A

L

34

EXAMPLES OF SYSTEMS

LAYOUTS: Hot Water & Heating Functions

ACV offers a range of wall-mounted

medium output condensing boilers (from

40 to 80 kW) - the Prestige range - which

are easily configured in cascade.

HeatMaster and condensing boiler

One or more HeatMasters bring to a

cascade of condensing boilers the

additional heating power necessary for

the coldest days of winter. The following

diagram shows that the condensing

cascade is operated at maximum output

for 5400 hours and that the HeatMaster

contributes the additional power needed

for the 1400 hours during which the

energy requirement exceeds the power

available from the condensing cascade.

The Hot Water function of the

HeatMasters is operated with priority to

heating, as in all standard heating

cascades.

COMPACT MIX

Mixing valve for all configurations with circulation loop

Distribution temperature adjustable from 30 to 60C

Nickel plated steel body with circulation loop temperature regulation

2 regulating valves also serving as non-return valve

3 immersion thermometers

Available in 6 diameters from 1/2'' to 2'' (DN 15 to 50) and circulation loop

of 1/2'' (diameters of 1/2'' and 3/4'') and 3/4'' (diameters of 1'' to 2'')

A

C

C

E

S

S

O

R

I

E

S

35

HOT WATER & HEATING ACCESSORIES

ACCESSORIES

SIMPLE MIX

Mixing valve for all configurations without circulation loop

Distribution temperature adjustable from 30 to 60C

Nickel plated steel body with immersion thermometer

Available in 6 diameters from 1/2'' to 2'' (DN 15 to 50)

ACV offers a wide range of accessories to take maximum advantage of the HeatMasters functions, in both hot water

production and heating mode.

HOT WATER

EXPANSION

TANKS

The hot water expansion tank has become an important accessory in hot water systems: it stops water being discharged

through the safety valve when the system is warming up.

In addition, due to the growing use of quick closing mixing valves, pipes and fittings are regularly submitted to sudden

rises in pressure (water hammer), which subjects systems to high stresses. In this respect also, hot water expansion

tanks provide effective protection for hot water systems.

HYDRO 5 5 L

HYDRO 8 8 L

HYDRO 12 12 L

HYDRO 18 18 L

Proposed sizes

For indirect water heaters up to 150 L and HeatMaster 29/30

For indirect water heaters up to 250 L and HeatMaster 60 & 70/71

For indirect water heaters up to 360 L and HeatMaster 100/101

For indirect water heaters up to 500 L and HeatMaster Jumbo

Models offered

ACV offers a broad range in various countries both in and outside Europe.

The models described here are available in most countries in continental Europe.

The temperature of the water stored in the best indirect water heaters can be very high: in all cases, the entire volume

of hot water stored in the tank (including the water at the bottom of the tank) must be kept at a minimum of 60C to

prevent legionella bacteria developing, or in excess of 85C for other bacteria in a hospital environment for example.

To allow high temperature storage, distribution at a minimum 60C and to prevent burn risks in the event of a sudden

major change in flow rate, ACV recommends the use of high quality thermostatic mixing valves.

THERMOSTATIC

MIXING VALVES

1 bar

2 bar

3 bar

4 bar

Sizes

1/2'' 3/4'' 1'' 1

1

/4'' 1

1

/2'' 2''

28 43 53 82 155 212

40 63 75 118 225 300

50 76 92 145 270 370

58 90 108 167 320 430

Flow rate L/min Pressure

H

E

A

T

M

A

S

T

E

R

T

E

C

H

N

I

C

A

L

36

ACCESSORIES

HOT WATER & HEATING ACCESSORIES

Balanced headers are used to separate the flows in the primary circuit (boilers) and secondary circuits (heating circuits)

and make them independent. As a result, in multiple boiler and/or circuit systems, changes in flow rates do not affect

the operation of the control devices (boiler cascade, mixing valves of heating circuit, ...).

Sizing instructions

The output of boilers connected to a balanced header determines the flow rate

to be achieved in the balanced header. This rate must permit the primary (boilers)

and secondary (heating) circuits to be decoupled effectively. This rate also defines

the diameter of the balanced header and all related dimensions. Tables are

available in the technical literature for identifying sizes quickly and reliably.

Models offered

ACV offers a varied range in individual countries both in and outside Europe.

Balanced headers for connections of 1

1

/2'' to 4''

BALANCED

HEADER

ACV offers a variety of controllers for different heating and/or hot water applications

using heating cascades, hot water cascades, and multi-zone high and low

temperature heating systems.

These controllers can be used with all HeatMaster models. In addition, HeatMasters

71, 101, which come fitted with an ACV/MCBA controller, can be included in the

control system to improve performance both in a heating cascade (individual

output modulation) and a hot water cascade (tank temperature control).

Our specialists are ready to help you design the type of control that suits your

needs, and even to propose a complete HeatMaster solution, including control

and accessories.

CONTROLLERS

a

a

a

a

a

2a

Boiler

circuit

Boiler

inflow

Boiler

return

Heating

circuit(s)

a= 3x

When the supply pressure is too high, a pressure reducer saves the valves from

premature wear, reduces the intensity of water hammer and the risk of leaks,

lowers noise pollution (vibration, hissing), improves user comfort by preventing

drawoff sputtering and facilitates blender and mixing valve settings.

Having the correct pressure in the hot water distribution circuit also limits water

consumption and prevents wastage.

PRESSURE

REDUCERS

The hot water safety unit comprises a 7 bar safety valve, a non-return valve and

an isolating valve.

HOT WATER

SAFETY UNIT

S

P

E

C

I

F

I

C

A

T

I

O

N

37

DESCRIPTION FOR SPECIFICATION

High performance hot water producer of the semi-instantaneous indirect heating type.

PRIMARY CIRCUIT

Steel heating body completely insulated in thick rigid polyurethane foam.

Steel primary circuit with combustion chamber and flue pipes entirely immersed in the primary circuit. Flue pipes fitted

with baffles of special steel.

Connections for a high temperature heating circuit.

Complete with (i) primary circuit filling device, (ii) expansion capacity dimensioned for hot water production, (iii) safety

valve, (iv) low water pressure switch and (v) loading pump for forced circulation of primary fluid.

HOT WATER TANK

Annular tank with a large surface area totally immersed in the primary circuit: contains a sufficient volume of hot water

for peak demand and is an indirect heat exchanger in continuous production mode.

Tank walls corrugated over their full length: their oscillations prevent scale forming over the whole heat exchange

surface.

Stainless steel tank for hot water at high temperature (90C).

No protective anode.

Anti-bacteria protection (legionellae).

BOILER BURNER AND CONTROL

Atmospheric gas burner, electrically lit with thermocouple safety (model 30G = Natural Gas; model 30 GP = Propane).

Flue connection B11BS.

Wired control panel with (i) on/off switch, (ii) summer/winter selector, (iii) daily programmer, (iv) control thermostat,

(v) automatic reset thermostat, (vi) manual reset safety thermostat, (vii) combined temp/pressure gauge, (viii) safety

lamps for low water pressure, burner failure and overheating.

MAIN TECHNICAL DATA

Peak flow from 10 to 45C:

HM 29 G 326 L/10 918 L/60 710 L/h

HM 30 G 326 L/10 1016 L/60 828 L/h

HM 30 GP 326 L/10 1030 L/60 845 L/h

Rated output:

28.9 kW (HM 29 G)

34.2 kW (HM 30 G)

34.9 kW (HM 30 GP)

Maximum operating pressure:

primary: 3 bar

secondary: 10 bar

Tank heat exchange surface: 2.46 m

2

Manufacturer ACV

HeatMaster models 29 G or 30 G or 30 GP

RECOMMENDED HEATING AND HOT WATER ACCESSORIES

Thermostatic mixing valve

Pressure reducer

Flow limiter

Hot water expansion tank

HEATMASTER

29 G

30 G

30 GP

SPECIFICATION

HEATMASTER

N

120 JUMBO

150 JUMBO

High performance hot water producer of the semi-instantaneous indirect heating type.

PRIMARY CIRCUIT

Steel heating body completely insulated in thick rigid polyurethane foam or 120 mm rock wool.

Steel primary circuit with combustion chamber and flue pipes entirely immersed in the primary circuit. Flue pipes fitted

with baffles of special steel.

Connections for a high temperature heating circuit.

Complete with (i) primary circuit filling device, (ii) expansion capacity dimensioned for hot water production, (iii) safety

valve, (iv) low water pressure switch and (v) loading pump for forced circulation of primary fluid.

HOT WATER TANK

Annular tank with a large surface area totally immersed in the primary circuit: contains a sufficient volume of hot water

for peak demand and is an indirect heat exchanger in continuous production mode.

Tank walls corrugated over their full length: their oscillations prevent scale forming over the whole heat exchange

surface.

Stainless steel tank for hot water at high temperature (90C).

No protective anode.

Anti-bacteria protection (legionellae).

BOILER BURNER AND CONTROL

To be fitted with an approved on/off gas burner (premix or forced draught) or oil burner.

Flue connection B23.

Wired control panel with (i) on/off switch, (ii) summer/winter selector, (iii) daily programmer, (iv) control thermostat,

(v) automatic reset thermostat, (vi) manual reset safety thermostat, (vii) combined temp/pressure gauge, (viii) safety

lamps for low water pressure, burner failure and overheating.

MAIN TECHNICAL DATA

Peak flow from 10 to 45C:

HM 30 N 320 L/10 963 L/60 772 L/h

HM 60 N 378 L/10 1656 L/60 1573 L/h

HM 70 N 543 L/10 1794 L/60 1573 L/h

HM 100 N 777 L/10 2680 L/60 2379 L/h

HM 120 Jumbo 1289 L/10 3450 L/60 2593 L/h

HM 150 Jumbo 1289 L/10 4138 L/60 3419 L/h

Rated output:

31.4 kW (HM 30 N)

62.5 kW (HM 60 N)

63.0 kW (HM 70 N)

96.8 kW (HM 100 N)

105.5 kW (HM 120 Jumbo)

139.1 kW (HM 150 Jumbo)

Maximum operating pressure:

primary: 3 bar

secondary: 10 bar

Tank heat exchange surface:

2.46 m

2

(HM 30 N and 60 N)

3.14 m

2

(HM 70 N)

3.95 m

2

(HM 100 N)

5.30 m

2

(HM 120 Jumbo and 150 Jumbo)

Manufacturer ACV

HeatMaster models 30 N or 60 N or 70 N or 100 N or 120 Jumbo or 150 Jumbo

RECOMMENDED HEATING AND HOT WATER ACCESSORIES

Thermostatic mixing valve

Pressure reducer

Flow limiter

Hot water expansion tank

H

E

A

T

M

A

S

T

E

R

T

E

C

H

N

I

C

A

L

38

DESCRIPTION FOR SPECIFICATION

SPECIFICATION

HEATMASTER

N

BG 2000-S/xx

High performance hot water producer of the semi-instantaneous indirect heating type.

PRIMARY CIRCUIT

Steel heating body completely insulated in thick rigid polyurethane foam.

Steel primary circuit with combustion chamber and flue pipes entirely immersed in the primary circuit. Flue pipes fitted

with baffles of special steel.

Connections for a high temperature heating circuit.

Complete with (i) primary circuit filling device, (ii) expansion capacity dimensioned for hot water production, (iii) safety

valve, (iv) low water pressure switch and (v) loading pump for forced circulation of primary fluid.

HOT WATER TANK

Annular tank with a large surface area totally immersed in the primary circuit: contains a sufficient volume of hot water

for peak demand and is an indirect heat exchanger in continuous production mode.

Tank walls corrugated over their full length: their oscillations prevent scale forming over the whole heat exchange

surface.

Stainless steel tank for hot water at high temperature (90C).

No protective anode.

Anti-bacteria protection (legionellae).

BOILER BURNER AND CONTROL

On/off premix natural gas or propane burner with safety ionisation electrode.

NIT coated burner head (on HM 60, 70, 100) low NOx.

Flue connections B23, C13, C33, C53.

Wired control panel with (i) on/off switch, (ii) summer/winter selector, (iii) daily programmer, (iv) control thermostat,

(v) automatic reset thermostat, (vi) manual reset safety thermostat, (vii) combined temp/pressure gauge, (viii) safety

lamps for low water pressure, burner failure and overheating.

MAIN TECHNICAL DATA

Peak flow from 10 to 45C:

HM 30 320 L/10 963 L/60 772 L/h

HM 60 378 L/10 1656 L/60 1573 L/h

HM 70 543 L/10 1794 L/60 1573 L/h

HM 100 777 L/10 2680 L/60 2379 L/h

Rated output:

31.4 kW (HM 30)

62.5 kW (HM 60)

63.0 kW (HM 70)

77.4 kW (HM 100)

Maximum operating pressure:

primary: 3 bar

secondary: 10 bar

Tank heat exchange surface:

2.46 m

2

(HM 30 and 60)

3.14 m

2

(HM 70)

3.95 m

2

(HM 100)

Manufacturer ACV

HeatMaster models 30 BG 2000-S/35 or 60 BG 2000-S/60 or 70 BG 2000-S/70 or 100 BG 2000-S/100

RECOMMENDED HEATING AND HOT WATER ACCESSORIES

Thermostatic mixing valve

Pressure reducer

Flow limiter

Hot water expansion tank

39

S

P

E

C

I

F

I

C

A

T

I

O

N

High performance hot water producer of the semi-instantaneous indirect heating type.

PRIMARY CIRCUIT

Steel heating body completely insulated in thick rigid polyurethane foam.

Steel primary circuit with combustion chamber and flue pipes entirely immersed in the primary circuit. Flue pipes fitted

with baffles of special steel.

Connections for a high temperature heating circuit.