Escolar Documentos

Profissional Documentos

Cultura Documentos

2014 Apex Operations Plan-Web Site-3

Enviado por

snhd_swprDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

2014 Apex Operations Plan-Web Site-3

Enviado por

snhd_swprDireitos autorais:

Formatos disponíveis

10.

12

LITTER CONTROL PLAN

10.13

SULFUR ANALYTICAL DATA

10.14

OPERATIONS AND MAINTENANCE MANUAL FOR THE APEX BIOREMEDIATION FACILITY AND

LIQUID SOLIDIFICATION AREA

************************************************************************

REPUBLIC ENVIRONMENTAL TECHNOLOGIES, INC.

OPERATIONS AND MAINTENANCE MANUAL

APEX BIOREMEDIATION FACILITY

AND

LIQUID SOLIDIFICATION AREA

Apex Regional Waste Management Center

Apex, Nevada

************************************************************************

Prepared

August 1995

Revised March 17, 2000

Revised December 15, 2005

Revised July 29, 2011

Revised May 25, 2012

Revised July 25, 2012

By

Republic Environmental Technologies, Inc. (E.T.)

770 E. Sahara Avenue, Suite 100, Las Vegas, Nevada 89104

Republic Environmental Technologies, Inc.

Table of Contents

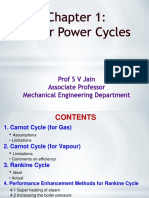

Facility Construction and Operating Plan

I.

II.

III.

IV.

INTRODUCTION

TREATMENT DESCRIPTION

2.1 Petroleum Contaminated Liquids

2.2 Non-Hazardous Liquids

2.3 Petroleum Contaminated Soils

2.4 Initiating Bioremediation Activities

2.5 Maintaining Bioremediation

2.6 Completion ofTreatment Cycle

2.7 Disposition of Treated Soils

FACILITY DESCRIPTION, OPERATIONS AND MAINTENANCE

3.1 Construction Specifications

3.2 Liner and Sump Inspections

3.3 Water Supply

TREATMENT OPERATIONS

4.1

4.2

4.3

4.4

4.5

Waste Pre-Acceptance

Waste Acceptance at the Facility

Testing and Screen Procedures

In-State Soils and Out-of-State other than California

California Out-of-State Soils Acceptance Procedures

Liquid Petroleum Contaminated Waste

770 E. Sahara Avenue, Suite 100, Las Vegas, Nevada 89104

2

Page

4

4

4

4

4

5

11

12

12

14

14

15

15

15

15

16

18

18

20

Republic Em:ironmental Technologies, inc.

Page

V. LIQUID SOLIDIFICATION AREA 21

VI. MAINTENANCE 22

VII. MONITORING 22

VIII. SAFETY 27

IX. EMERGENCY CONTACTS 27

FIGURES: Page

1. General Area Site Map 6

2. Bioremediation (ABF) Site Map 7

3. Block Diagram of the Bioremediation Facility 8

4. ABF Cell Sampling Locations 10

5. Certificate of Material for Recycling 13

6. Monitoring Probe Design 26

ATTACHMENTS:

1. NDEP Testing and Screening Procedures for all Soil Treatment Facilities in

Nevada

2. As-Built Drawing and Designs for the Geomembrane Liner System

3. Leachate Collection and Leak Detection Monitoring Procedures

4. In-State Application for Treatment of Petroleum Contaminated Soils

5. Out-of-State Application for Treatment of Petroleum Contaminated Soils

6. Liquid Waste Handling Procedures and Profile Application

7. Water Pollution Control Discharge Permit

770 E. Sahara Avenue, Suite 100, Las Vegas, Nevada 89104

3

Republic Environmentai Technoiogies, Inc.

I. INTRODUCTION

The purpose of this manual is to provide a description of the facilities, operating guidelines, and

acceptance criteria for Republic Environmental Technologies, Inc. (ET) bioremediation facilities

at the Apex Waste Management Center in Apex, Nevada (see Figures 1, 2 and 3- Site Maps).

This manual will cover ET's liquid solidification and bioremediation of soils contaminated with

petroleum hydrocarbons (such as gasoline, diesel, motor oil, etc.) through evaporation,

solidification or landfarming techniques. This 0 & M manual covers the management of

Petroleum Contaminated Soils and Non-Hazardous Liquid Waste (liquids for evaporation or

solidification), soils and liquids must be nonhazardous as defined by state and federal regulations

for acceptance into the facility.

This manual also contains application forms required for acceptance of the customer's waste.

The biological treatment employed is capable of reducing the hydrocarbon contaminates to levels

less than 100 ppm TPH. The treated soils are then primarily utilized as landfill cover material.

Soils treated to less than 50 ppm may be used for alternative purposes, such as fill material, a

component of road base materials, or as a component of sand and gravel processing materials,

where dirt is a component.

II. TREATMENT DESCRIPTION

Non Hazardous liquids, petroleum contaminated liquids and petroleum contaminated soils will

be considered for evaporation or treatment in the bioremediation facility. Both liquid petroleum

contaminated waste and petroleum contaminated soils are capable of biological treatment at the

ET's Bioremediation Facility. The Facility is designed to bioremediate 160,000 tons I yr. of soil.

2.1 Petroleum Contaminated Liquids are solidified within the double synthetically lined

Treatment cells using clean soils. The liquids are evaporated or tilled into the soils to

concentrate the petroleum sufficiently for economical biological treatment. Once sufficiently

concentrated, the solidified petroleum contaminated liquids may be disposed of by direct

landfilling into the Class I landfill sections, or used for cover as needed by landfill operations. If

the soils are to be bioremediated they are then profiled into the Soil Treatment Facility's

following Nevada Division of Environmental Protection (NDEP) guidelines (see Attachment 1)

established for all soil treatment facilities operating within Nevada.

2.2 Non-Hazardous liquids will be placed into separate cells from the petroleum contaminated

liquids, where they will be allowed to evaporate. Once the liquid has evaporated the soils may be

disposed of directly into in the Class I landfill.

2.3. Petroleum Contaminated Soils, which may include the solidification ofliquids described

above, are biologically treated using landfarming teclmiques.

770 E. Sahara Avenue, Suite I 00, Las Vegas, Nevada 89104

4

Republic Environmentol Technologies, li1.c.

2.4. Initiating Bioremediation Soil Activities

2.4.1 Upon accumulating approximately 3000 tons (approx. 2300 cu. yd.) of

Hydrocarbon contaminated soil in a treatment cell; the soil is spread with a front

loader (or equivalent). During cell accumulation, the soils are placed into small

piles in the cell to prevent settling. The soils will be tilled thoroughly to increase

soil uniformity and consistency within the treatment cell.

770 E. Sahara Avenue, Suite 100, Las Vegas, Nevada 89104

5

Republic Environmental Inc.

Figure 1

770 E. Sahara Avenue, Suite 100, Las Vegas, Nevada 89104

6

+

+

"'

~

DATE FEB. 2000

OWN KLT

APP DEH

REV 0

PROJECT NO.

800082

. i

+

+

- -t

_.,,__

~

FIGURE 1

REPUBLIC-DUMPCO

APEX MUNICIPAL WASTE DISPOSAL FACIU1Y

LAS VEGAS, NEVADA

BIOREMEDIATION FACILITY

LOCATION PLAN

Figure 2

770 E. Sahara Avenue .. Suite 100, Las Vegas, Nevada 89104

7

!

I

s

i

l

l I

2

"'

l

Republic Environmental Technologies. Inc.

Figure 3

770 E. Sahara Avenue, Suite 100, Las Vegas, Nevada 89104

8

I 390' I

CEIL#lO

50'

----

ll'l.ll!illii .

[

......................................................................................... : .............................................. \.

. STAGINGAREA

ouuO o "" 0 0 ""''"'''' '''' ,.,,, > 0 , 0 00 ,. , 000 0 0 "'"'"''"'" 0 0 000 t 0 " 0 '"" 0 """ " 0 0 0

SOILS

MOTOR OIL

:tviDITURES

SOILS

DIESEL

SOILS

GAS

ENTRANCE

CELL#9

1/

CELL#6 CELL#3

J I

1

CELLilffl

CEI.L#r!

20'

CEU#5

CELL#4

ROAD

BLOCK DIAGRAM

SOIL 11REATMENT FACILITY

APEX, NEVADA

F1 R11rf' J

CELL#2

CELL#l

ROAD

ENTRANCE

::

I

' I

ll

I

1

1 I

!

I!

j:\

ii

!;

i"!

,,

I .

r

0

li

\:

\i

i:

li

1:

l!

I\

i!

,:

I!

1:

li

i!

I

I!

1\

II

.I

Republic Environmental Technologies, Inc.

2.4.2 A representative "baseline" sample will be obtained from the soil within a cell when the

cell is ready to be biologically treated.

2.4.2.1 Sampling Protocol

( 1) The sampling procedure is to collect sixteen ( 16) discrete soil samples per

celL Representative composite samples for each cell will be obtained by dividing

the cell into sixteen (16) sections (see Figure 4) using sprinklers as common

reference points.

(2) A hand shovel will be used to collect a sample from the center of each section

at a depth from between 10 to 18 inches.

(3) The 16 discrete samples will be collected into a clean polypropylene bucket

and gently mixed with the hand shovel to form a homogenous composite sample.

( 4) Each treatment cell composite sample will then be tightly packed into a glass

jar and labeled with the date and cell number.

(5) The sample containers will then be placed in an ice chest for transport to the

laboratory for analysis.

2.4.3 The samples will be delivered to the laboratory with the appropriate "chain of

custody" documentation and analyzed for Total Petroleum Hydrocarbons

(modified EPA Method 8015). The analytical results will provide the baseline

soil concentration prior to implementing biological treatment activities.

2.4.4 Off-site laboratory testing is preferred for detennining the nitrogen (N) and

phosphorous (P) levels of the cell soiL On-site evaluation is possible using

common fanning testing methods. The testing will be conducted on samples from

numerous locations (approximately 8) within the celL The locations of these

samples are rotated among one-half of the 16 discrete sampling locations used to

determine the TPH of a cell shown in Figure 4. IfN or P are absent or less than

optimum concentrations in the soil, the desired concentrations can be achieved by

applying fertilizers. The desirable Nor P values are confidential to company

operations. The amount of nutrients applied will vary depending upon the

concentration levels and can be easily calculated on a case-by-case basis. The

nutrients can be applied to the soil via a water truck or more accurately with

common farm fertilizer application instruments. The concentrations of fertilizer

nutrients maintained in the soils are significantly less than 0.1 %. As such, no

potential ignitability or flammability hazard exists when working with fertilizers

and petroleum contaminated soils.

2.4.5 After application, the soil is thoroughly tilled and re-tested for nutrient

concentrations. The nutrient application/test procedure is repeated, as necessary,

throughout the treatment cycle to maintain the desired nutrient concentrations.

Upon soil tilling, and confirming the proper nutrient levels, the soils are ready for

inoculation.

770 E. Sahara Avenue, Suite 100, Las Vegas. Nevada 89104

9

n

!l

u

[!

~

~

(j

ll

Environmental Technologies of Nevada, Inc.

Bio-remediation Facility

Apex, Nevada

Cell Sampling Locations

-100'

!

l

i

i

!

, , '! i

i i I

~ k x J f x

1 !

! !

-------l!!liH---}--*--*---4--

~ ----f-, -*-t---*-------

i

i

--------lllli!l--l----------i----t-----:t----t----

X = SAMPLING LOCATIONS

II= SPRINKLER LOCATIONS

F1GURE 4

-400'

Republic Environmental Technologies, Inc.

2.4.6 The bacteria can be applied to the soil with landfarming equipment or by water

truck. Caution should be exercised not to over-water the treatment cell. After

inoculation is completed, the soil is thoroughly tilled with a tractor/disc.

Maintaining Bioremediation

2.5.1 The bioremediation cycle consists of several days of biological treatment activity.

Time is required to load a treatment cell, perform biological treatment activities,

and unload the treated soil from the cell when treatment is complete. After which

time, the treatment cell is ready for new loads of contaminated soil and start of a

new treatment cycle.

2.5.2. The following maintenance activities must be performed to ensure optimal

environment for the bacteria, and hence, successful treatment of the hydrocarbon

coi1taminated soil:

(1) Water the soil treatment area daily as required to maintain moisture

content. Moisture content will be measured primarily using an off-site

laboratory testing soil moisture levels. Water can be applied with the

water truck or with a tank/sprinkler system. The depth of the soils is

maintained at between 15 to 18 inches, so tilling of soils easily

facilitates aeration of the biological media.

(2) The contaminated soils will be tilled thoroughly on a regular basis.

During the summer, tilling occurs daily.

(3) A representative sample of the soil being treated must be obtained

through completion of the treatment cycle, and analyzed for Total

Petroleum Hydrocarbons. Reference the sampling and handling

procedures identified in Section II-3.1.2.1 of this plan. The analytical

results will be evaluated to assess the progress and efficiency of the

treatment activities.

( 4) After approximately 14 days, a representative sample is collected and a

biological plate count of the bacteria population will be performed. If

the bacteria population is significantly low, then a second inoculation of

microorganisms should be applied to the treatment area. The method

used to collect bacteria samples is described in Section IL3.1.2.1. The

method of measurement of the bacteria content is confidential to the ET

process and lab.

(5) The biological plate counting is repeated after approximately 14 days

and a third inoculation is performed, if necessary.

770 E. Sahara Avenue, Suite 100, Las Vegas, Nevada 89104

11

Republic Environmental Technologies, inc.

2.6 Completion of the Treatment Cycle

2. 6 .1. After time, the contaminated soil shall be successfully treated to hydrocarbon

concentrations less than 1 00 ppm. A representative sample must be collected and

analyzed, as previously discusses, to confirm the success and subsequent

termination of the treatment cycle.

2.6.2 A copy of the final laboratory result is included in ET's reports to NDEP to

document the successful treatment of the materiaL Customers will be provided a

copy of the successful treatment results upon their request. Ordinarily, the

customer is mailed a Certificate of Materials for Recycling (Figure 5)

documenting the acceptance of the soils into the facility.

2. 7 Disposition of Treated Soils

2. 7.1 After the soils have been treated to less than 100 ppm total petroleum

hydrocarbon content, the soils may be placed into either a municipal or industrial

section ofthe solid waste landfill for use as cover material. Additional uses may

include fill material, a component of sand and gravel processing materials, where

di1i is a component. Concentrations of petroleum contamination must be below

50 ppm TPH, if the material is to be used for alternative purposes off-site.

2.7.2 Once the soils have been removed from the cell, a small layer of clean base soils

is also removed and immediately replaced before treatment begins on a new batch

of contaminated soils. The bottom of each cell is surveyed annually and restored

as needed to ensure approximately 5 feet of clean soil exists between the liner and

soils to be treated.

770 E. Sahara Avenue, Suite J 00, Las Vegas, Nevada 89104

12

Republic Environmental Technologies, Inc.

Figure 5

770 E. Sahara Avenue, Suite 100, Las Vegas, Nevada 89104

13

7

7

0

E

.

S

a

h

a

r

a

A

v

e

n

u

e

S

u

i

t

e

1

0

0

L

a

s

V

e

g

w

;

,

N

e

v

a

d

a

8

9

1

0

4

,

\

'

.

r

-

-

n

o

f

N

<

r

r

w

o

;

,

I

n

c

._

.

.

,

,

(

.

;

,,

.. ;.

C

E

R

T

I

F

I

C

A

T

E

O

F

A

t

.

A

T

E

R

I

A

L

S

F

O

R

.

R

E

C

Y

C

L

I

N

G

A

s

a

u

t

h

o

r

i

z

e

d

a

n

d

p

e

r

m

i

t

t

e

d

b

y

t

h

e

N

e

v

a

d

a

D

i

v

i

s

i

o

n

,

o

f

E

n

v

i

r

o

n

m

e

n

t

a

l

P

r

o

t

e

c

t

i

o

n

,

E

n

v

i

r

o

n

m

e

n

t

a

l

,

o

f

_

'

-

N

e

v

a

d

a

,

1

I

n

c

.

(

E

T

)

h

e

r

e

i

n

i

s

s

u

e

s

t

h

i

s

c

e

r

t

i

f

i

c

a

t

e

o

f

R

e

c

y

c

l

i

n

g

'

>

1

-

.

i

,

T

e

c

h

h

o

l

'

?

g

i

e

s

o

f

7

7

o

E

.

S

a

h

a

r

a

A

v

e

.

t

e

1

.

0

o

,

.

.

:

l

.

.

r

J

)

\

)

)

,

.,

\

.

(

2

1

Y

o

u

r

S

t

r

e

e

t

L

a

s

V

e

g

a

s

,

N

e

v

a

d

a

8

9

1

0

4

1

\

l

(

l

"

i

'

'

J

\

1

-

'

\

1

'

.

Y

o

u

r

T

o

w

n

,

U

S

A

11

'

'i

!

J

T

h

e

s

u

b

j

e

c

t

s

o

i

l

s

h

a

v

e

b

e

e

n

r

e

c

e

i

v

e

d

s

S

o

i

l

'

T

r

e

a

t

m

e

n

t

F

a

c

i

l

i

t

y

a

t

t

h

e

A

p

e

x

W

a

s

t

e

M

a

n

a

g

e

m

e

n

t

C

e

n

t

e

r

a

n

d

a

r

e

b

e

i

n

g

t

r

e

a

t

e

d

f

o

r

r

e

c

y

c

l

i

n

g

b

y

b

i

o

r

e

m

e

d

i

a

t

i

o

n

t

o

b

e

l

o

w

r

e

g

u

l

a

t

e

d

l

e

v

e

l

s

i

n

t

h

e

S

t

a

t

e

o

f

N

e

v

a

d

a

.

A

s

s

u

c

h

,

E

T

a

s

s

u

m

e

s

f

u

l

l

p

o

s

s

e

s

s

i

o

n

o

f

a

n

d

t

i

t

l

e

t

o

t

h

e

m

a

t

e

r

i

a

l

a

n

d

c

o

m

p

l

e

t

e

r

e

s

p

o

n

s

i

b

i

l

i

t

y

f

o

r

i

t

s

p

r

o

p

e

r

a

n

d

p

e

r

m

i

t

t

e

d

t

r

e

a

t

m

e

n

t

.

E

T

f

u

l

l

y

i

n

d

e

m

n

i

f

i

e

s

t

h

e

a

b

o

v

e

f

a

c

i

l

i

t

y

f

o

r

a

n

y

e

n

v

i

r

o

n

m

e

n

t

a

l

r

e

l

e

a

s

e

s

o

r

:

d

a

m

a

g

e

s

a

s

s

o

c

i

a

t

e

d

w

i

t

h

E

'

l

"

'

s

m

a

n

a

g

e

m

e

n

t

o

f

t

h

e

w

a

s

t

e

r

e

c

e

i

v

e

d

o

n

:

.

.

.

.

.

T

r

a

c

k

i

n

g

N

u

m

b

e

r

:

O

O

O

O

O

O

D

a

t

e

:

:

x

:

x

:

x

:

x

x

x

x

x

Q

u

a

n

t

i

t

y

:

:

x

x

x

x

x

.

'

:

{

!

;

I

'

.. r

.

:

;

;

!

i

'

G

e

n

e

r

a

l

M

a

n

a

g

e

r

F

i

g

u

r

e

5

j:

:

I i

i

:

:!

l r

:

.,

.,

t:;

r

'

:: :

,

,

H

\'.1

i

i

l

i

;II

i

l

l

i

'

'

I

I

r.::

I

'

!

[

;

I

I

.

t

:

I

1

:.

1

:

I

I

j

l

I

I

r

'

I';

I .1

:

I

.,

]:

\[

li

,.

(1

,,

I

r.

'

'

ii

III.

Environmental Technologies, Inc.

FACILITY DESCRIPTION, OPERATIONS, J\1ANITENANCE

3.1 Construction Specifications

3 .1.1 The Soil Treatment Facility is designated as an approximately 20-acre area at

the Apex Waste Management Center located about 30 miles north of Las

Vegas. The Facility is designed to Bioremediate solidified liquids and soils

contaminated with petroleum hydrocarbons (gasoline, diesel, motor oil, etc.)

through the process ofbiological treatment and landfarming. The access road

will be capable of facilitating vehicle transport during inclement weather

conditions.

3.1.2 Current construction involves approximately eight (8) acres of active treatment

area designed to contain any free liquids that may be generated during soil

storage or bioremediation activities. This treatment area is designed to prevent

ground water contamination. After site grading/compaction, installation was

completed with 2 layers, one 60-mil and one 30-mil, of impem1eable high-

density polyethylene (HDPE). The design and construction of the treatment

facility was directed and certified by a qualified registered engineer.

3 .1.3 Selected excerpts form the engineer's report describing the as-built layout and

construction specifications of the bioremediation facility are presented in

Attachment 2. The entire engineer's report is too voluminous for inclusion in

this manual. It is mainly comp1ised of quality control/quality assurance

documentation.

3 .1.4 The containment area is designed for soil storage and bioremediation in any of

10 separate treatment cells (approximately 100' x 400'). Treatment cells

require a minimum dimension of 80 feet to allow efficient movement of the

tractor/disc. Each cell has the capability to biologically treat up to 2300 c.y.

(3000 tons) of contaminated soil. Cells not in use for treatment of petroleum

contaminated soils will be used for solidification of petroleum contaminated

liquids and non-hazardous liquids. The pe1imeter of the containment area is

"humped" soil berm, designed to facilitate vehicle access in/out of the

treatment cells. The treatment cells are segregated by a 14-foot wide zone to

permit vehicle accessibility and the establishment of a sprinkler system.

3 .1.5 Surrounding the containment area is approximately 285,550-sq. ft. of area

designated for vehicle access, equipment storage, sprinkler system, etc.

3 .1.6 Sprinklers are strategically situated around each cell to ensure complete water

coverage.

770 E. Saham Avenue, Suite 100, Las Vegas, Nevada 89104

14

Republic Environmental Technologies, Inc.

Liner and Sump Inspections

3 .2.1 The liner system under the Facility cells was constructed to direct any liquids that may

percolate through the soils, toward a central leachate collection monitoring point (refer to

As-Built- Attachment 2) above the upper most liner. The leak detection and containment

areas will be inspected weekly. A summary ofthe weekly inspections shall be reported.

3.3. Water Supply

3.3. 1 The Treatment Facility is adjacent to a 7 million gallon synthetically lined reservoir of

1-vater supplied by three (3) on site groundwater wells. The water is distributed to each

cell by industrial sized sprinklers to ensure adequate moisture content within each cell.

IV. TREATMENT OPERATIONS

4.1 Waste Pre-Acceptance

4.1.1 The Soil Treatment Facility is a commercial facility designed for the management

and bioremediation of petroleum hydrocarbon contaminated liquids and soils, and

the disposal of non hazardous liquids. The facility manages only nonhazardous

waste capable of evaporation or complete biodegradation with especially designed

and commercially available microorganisms. Therefore, ET has established a

mandatory wastestream "pre-acceptance" procedure to ensure that all

contaminated material received at the facility is both nonhazardous and

biodegradable.

4.1.2 ET's wastestream "pre-acceptance" profiles are reviewed by Republic Services

Special Waste Approval Department before approval. Upon receiving a complete

Application for Waste Acceptance (Attachment 4- In-State Soil Treatment

Application Form; Attachment 5 -Out-of-State Soil Treatment Application

Fom1) representative samples of the stockpiled contaminated soil are fonvarded

under fmmal chain-of-custody to analytical laboratories for organic/inorganic

analysis and treatability testing. Iflaboratory analyses indicate that the

contaminated soil is a hazardous waste or incapable of complete biodegradation,

then ET notifies the customer that the wastestream is rejected for management at

the STF Facility. If, upon Republic's Special Waste Approval Dept. review of the

laboratory analyses and determines the waste soil is both nonhazardous and

treatable, the customer is notified of acceptability of the soils.

4.1.3 All "pre-approved" vehicle loads of contaminated soil must be scheduled into the

Facility and comply with the conditions of waste acceptance noted on the

Authorization of Waste Acceptance. ET inspects all contaminated soil transport

vehicles leaving the Facility for evidence of contamination and performs

decontamination, as necessary.

770 E. Sahara Avenue, Suite 100, Las Vegas, Nevada 89104

15

Environmental Technologies, Inc.

4.1.3 .1 Vehicle Decon Procedures

(1) Vehicles requiring decontamination will be directed to a Petroleum

Contaminated Liquids designated cell, or other approved areas.

(2) A facility water pressure washer will be used to remove

contaminated soils remaining within the vehicle.

. .

(3) The liquids generated from the decon of a truck will be a1lowed to drain

directly into the appropriate approved area for treatment.

( 4) The petroleum contaminated decon liquids will be presumed approved based

upon acceptance of the soils previously within the truck.

4.1.4 Liquid petroleum contaminated wastes will be profiled before acceptance into the

facility (see Attachment 6- Liquid Waste Profile Application Form). Each

profile will be evaluated and approved based upon either analytical results or a

self-classification of the generators waste. Generators may be contacted to

confirm proper self-classification of the waste.

4.2 \Vaste Acceptance at the Facility

4.2.1 Once waste has had profile or application submitted and approved, waste

transport vehicles will enter the Bioremediation facility after passing through

inspection points at the main entrance of the Apex Waste Management Center.

4.2.2 All waste contaminated shipments (liquids and solids) must have prior approval

through ET' s preacceptance procedures - Section 4.1 - Wastestream Pre-

acceptance.

4.2.3 Notification of the approved waste stream is communicated to the Apex

Inspection Station by either direct access to computer profiles, direct printer

printout, facsimile, or accompanying paperwork delivered with the load. An ET

manifest document or a bill oflading, and wastestream approval with the job

number must accompany each vehicle load of contaminated material. The

document will be reviewed for its accuracy and completeness with any

discrepancies resolved prior to accepting the waste load.

4.2.4 During inspection at the main gate, each load of contaminated waste will be

inspected for evidence of hazardous waste. The inspection will look for the

presence of unexpected colors, odors, or the presence of chlorinated compounds

using copper wire test on the waste, would cause the waste to be suspect. If

hazardous waste is detected in a vehicle waste load, the load will be rejected.

Solid wastes, or undesirable solid materials will be taken to an isolation area

pending evaluation of test results on the waste for proper disposal. Suspect liquid

waste will be directed to the liquid waste solidification area, where a holding tank

is positioned to contain waste, pending analytical results.

4.2.5 A representative sample will be collected from each suspect vehicle load (with a

hand auger or other appropriate sampling implement) received at the facility. The

770 E. Sahara Avenue, Suite 100, Las Vegas, Nevada 89104

16

Republic Environmental Technologies, Inc.

sample will be placed into a container and labeled with the following infonnation:

generator name, document nwnber, waste approval number, load number, vehicle

license number and date, as well as a copy of the manifest

4.2.6 Samples must be stored in a refrigerated environment until received at the

laboratory. Samples will be anal_yzed, as necessary, to verify the receipt of

approved wastestreams and to confinn receipt of nonhazardous waste material.

Sample retention in most cases is 30 days after acceptance into the laboratory.

1. Rejected Loads

Testing will be performed of either liquid or solid waste for the eight RCRA

heavy metals, volatile organic components or PCB 's. Ifthe waste is rejected, the

Nevada Division ofEnviromnental Protection and the Southern Nevada Health

District will be notified.

2. Acceptable Loads

(a) Non Hazardous liquids, Petroleum contaminated liquids or solid waste

successfully profiled and approved, and not considered suspect, will be accepted

into the appropriate liquid or solid cell by direct transfer from the transport

container. Soils are directed to the staging area where the waste is emptied from

the end dump trailers or bins into piles in preparation for screening and loading

into the treatment cells by front end loader.

(b) Liquid waste will be placed directly into treatment cells by opening the

back valve of the transport vehicles and dumping the waste. Once a treatment cell

has reached approximately 10% contamination, depending on the absorbent used,

the cell contents will stockpiled and sampled for the same pre-acceptance criteria

as other soils to be bio-treated (as described below). If no treatment cells are

available, and the solidified petroleum contaminated liquids require treatment as a

production priority, the soils will be profiled and treated in place. Absorbent

materials that have been found amenable to biotreatment include dirt,

diatomaceous earth and solid-a-sorb.

If, for operational reasons, the solidified soils of petroleum contaminated liquids

are found not amenable to bio-treatment (for example, due to the presence of

bactericides commonly used in maintaining sanitary systems), the material will be

profiled for acceptance into the Landfill. The analytical data required for

profiling the waste into biological treatment cells will then be used for

characterization of the soils into the Industrial Waste section ofthe Landfill. The

soils would be transferred by scraper or common loader equipment to the

Landfill.

3. Non-amenable Loads

If the soil waste is non-hazardous, but found not amenable for bio-treatment due

to pH, matrix or porosity effects, the analytical used in the pre-acceptance testing

770 E. Sahara Avenue, Suite 100, Las Vegas, Nevada 89104

17

Republic Environmenlal Technologies, Inc.

(TPH, volatile organics, heavy metals, or bioinhibition testing) will be used to

develop a profile of the waste for disposal into the Landfill.

4.2.7 Upon inspection clearance, necessary instructions for unloading the contaminated

soil will be provided to the transporter. Soils are unloaded within the lined area

and are stockpiled within the staging area ofthe STF. Liquid wastes are directed

to the Bioremediation facility into lined treatment cells. The treatment cells that

are accepting liquid waste will be clearly labeled.

4.3 Testing and Screening Procedures-

In-State Soils and Out-of-State Soils Other California

4.3.1 Prior to approval for treatment of soils, all generators shall complete a waste

profile form and submit it to Enviromnental Teclmologies for review and

approval by Republic's Special Waste Department. As stated above, it is the

responsibility of the generator to determine if the waste is hazardous. The role of

ET is to verify the generator has followed the proper steps in classifying the

NON-HAZARDOUS waste status and to determine compatibility of the waste

with the treatment system. All customers shall at a minimum provide the

following infonnation:

(1) Representative sampling and analysis for Total Petroleum Hydrocarbons

(TPH) via EPA method 8015 Modified

(2a) Representative sampling and analysis for total halogenated organic via

EPA Method 8260C for volatile organics; or

(2b) Documentation by the generator; that based upon knowledge of the waste,

no listed waste is present which would classify the material as hazardous

waste.

4.3.2 Based upon the findings of the TPH, additional information may be required to

confirm that the waste is NON-HAZARDOUS. This additional analysis may

include the following:

(1) Representative sampling and analysis for Toxicity Characte1istic via EPA

Method 1311;

(2) Representative sampling and analysis to determine for presence of free

liquids via EPA Method 9095.

(3) Representative sampling and analysis to determine for presence of

regulated heavy metals via EPA Method 1311 and/or Method 6010.

4.3.3 Environmental Technologies may waive certain tests if it can be conclusively

detennined what the source of the waste is, the lack of potential for waste mixing

or contamination with other regulated material, or documentation that the waste is

not hazardous under 40 CFR Part 261 or regulations in the State of Origin.

4.4 California Out-of-State Soils Acceptance Procedures

770 E. Sahara Avenue, Suite 100. Las Vegas. Nevada 89104

18

Republic Environmenwl Technologies, inc.

4.4.1 Out-of-state hydrocarbon contaminated soil from the State of California will be

accepted at the Facility only if the following information is provided to

Environmental Technologies by the generator, reviewed and approved by

Republic's Special Waste Dept. and send a copy of the approved profile to

SNHD:

(1) A letter from the regulatory entity governing hazardous waste

management within the state of origin attesting to the non-hazardous

nature of that waste,

or;

(2) Self-classification of the waste via procedures outlined in Article 11, Title

22 of the California Administrative Code. This self classification will be

recognized only upon a review of the information pertaining to the waste

acceptance application which must include a brief report containing the

following:

a. Site Description

(1) Location: description with site plan, including location of soil

samples, excavation, and stockpile.

(2) Site usage: both past and present (brief)

(3) Source of contaminate(s) (Surface spill or UST)

( 4) Description of contaminate product type

b. Laboratory Analysis

(1) Based on generator knowledge of site and contaminates, the

appropriate analyses should be selected.

(2) Generators will elect to do the following if sufficient information

or site history exists:

(a) Acute Aquatic 96 Hr. LC50: Aquatic Toxicity Assay is

required when generator knowledge is not sufficient to

waive this test. This test is required to be perfonned either

by the customer, prior to acceptance, or by ET as part of the

evaluation process.

(b) TTLC Metals Test

(c) TCLP Benzene (Needed if spill in not associated with a

regulated UST)

(d) Volatile Organics - 8240

(e) Total Petroleum Hydrocarbons (TPH) (note: TPH analyses

are not required by Title 22 CCR; however, it is needed to

establish petroleum contamination type and concentration).

(3) Analyses may include: (optional)

(a) Pesticides and Polychlorinated Bipenyls, EPA 8080

770 E. Sahara Avenue, Suite 100, Las Vegas, Nevada 89104

19

(b) Bases/Neutrals/Acid Extractables EPA 8270

(c) Ignitability

(d) Corrosivity

(e) Reactivity

c. Sample Protocol

(1) Description of sampling method

(2) All chain-of-custody records and analyses reports

(3) California Health Services Certification number for all laboratories

used

( 4) All information must be signed and stamped by a California

Professional Geologist or Professional Engineer

4.5 Liquid Petroleum Contaminated Waste

Petroleum contaminated liquids most often are the result of pollution control devices leading to

Publicly Owned Treatment Works (POTW) such as oil/water separators, and water I sand

separators. Additional sources of petroleum contaminated liquids come from triple rinsing of

UST's, well development water, petroleum grease traps and petroleum contaminated septic

tanks. Under the ET profile system, the generator must describe the system, the source of the

contamination and provide either analytical test results, MSDS data, or demonstrate sufficient

knowledge and control over their process as justification of a proper non-hazardous waste

determination, and sign a declaration the waste is non-hazardous waste. The Transporter then

signs all related documents indicating the material is properly described and contains no

hazardous waste.

Liquid petroleum contaminated wastes will be profiled before acceptance into the

Bioremediation Facility (see Attachment 6). Each profile will be evaluated and approved based

upon either analytical results or a self-classification of the generator's waste as allowed under

guidelines found in 40 CFR 261.1 0. Generators may be contacted in order to confirm proper

self-classification of the waste, and will be required to provide appropriate test documents or

Material Safety Data Sheets.

770 E. Sahara Avenue, Suite 100, Las Vegas, Nevada 89104

20

Republic Environmental Technologies, Inc.

LIQUID SOLIDIFCATION AREA

Non-Hazardous liquids that found to be acceptable maybe solidified in the Liquid Solidification

area. These liquids are typically grease trap, porta potties type liquids, but may include other

liquid waste that is non-hazardous. Liquids with presence of petroleum will not be accepted at

the Liquid Solidification Area, but will be sent to the Bioremediation Facility

The waste acceptance procedure will follow the same profiling procedure as any waste going to

the Bioremediation Facility. The generator will fill out and complete a Republic Waste Profile

Form. Any analyst that is required wiJJ accompany the profile fmm. Once the profile has been

review and approved, it will receive a unique profile number. Any waste going into the Liquid

Solidification Area must have an approved profile number.

The liquid waste will be placed in a cleared slightly inclined borrow area. The borrow area will

be used for the solidification purpose of non-hazardous liquids. The soils in the borrow areas will

be prepared by allowing the liquids to be absorbed and blended into the surface soils. Additional

soils will be added as needed to solidify all liquids. Additional, materials such as saw dust, wood

chips, auto fluff maybe used to aid in the solidification process.

This waste category is identified as mainly, Grease Trap Wastes from food establishments, septic

waste from residential and porta potties businesses and other light industrial facilities.

No petroleum based liquid will be accepted for solidification. Liquids with incidental TPH

concentrations will be sent to the bioremediation facility solidification.

Liquid waste is discharged in a designated solidification area. There are typically two receiving

areas constructed in the borrow area for solidification purposes of grease trap, septic tank

pumping's wastes and industrial liquids that do not contain TPH constituents. The soils in the

borrow area are prepared by ripping the surface and stockpiling soils, allowing the liquids to be

absorbed and blended into the surface soils. Blending activities are conducted until free liquids

are no longer present in the resulting mixture.

A Paint test (Method 9095B) may be administered to verify that the soils have been blended with

the liquids and are solid and do not contain free liquids. All waste material will remain in the

designated area until the conditioned soils being analyzed meet the required solidification. The

solidified material is used as cover material over the landfill area as needed, or comingled for

disposal

770 E. Sahara Avenue, Suite I 00, Las Vegas, Nevada 89104

21

Republic Environmental Technologies, Inc.

VL MAINTENANCE

The Apex Bioremediation Facility is designed with little or no maintenance requirements. The

Facility is equipped with an industrial sized automatic sprinkler system, which is supplied by a 7

million-gallon fresh water reservoir. Simple water trucks, as back up to the sprinklers, are

capable of adequately watering the facility treatment cells, if needed.

VII. MONITORING

The facility is required to monitor and report certain activities. A copy of the Water Pollution

Control Permit and reporting form is included as Attachment 7.

7.1 Biological Treatment within Cells

Biological treatment of petroleum contaminated soils is monitored following the procedures

found in Section 3 .1-Initiating Bioremediation Activities

7.2 Rain Fall at the Facility

The facility also monitors rainfall events by utilizing a US Weather Service Standard Rain

Gauge. As more sophisticated technologies become available, this manual task is expected to be

replaced by computerized monitoring devices. The facility has been designed to contain the 25

year, 24 hour, rainfall event; and withstand, with no discharge, the run-off from the 24 hour,

once-in-1 00 year storm event. Monitoring of the rain gauge is perfonned daily simply by

observing and documenting the level ofliquid within a calibrated, graduated-type cylinder.

Once the liquid level is recorded, the water is discarded, and the gauge is placed back into its

holder.

7.3 Leak Detection and Leachate Systems

The entire Bioremediation Facility, cells and staging area, is lined with two layers of synthetic

liner. Monitoring the performance of the liner system of the double synthetically lined facility is

accomplished by checks for accumulations of liquids at specific monitoring locations. The

facility has a sloped and contoured design so any liquids present will migrate to one location.

The monitoring location is designed to inspect the interstitial space just above the upper most

liner (Leachate Collection Monitoring) and between the two liners (Leak Detection Monitoring).

Procedures and fonns for documenting the monitoring are included as Attachment 3. In the

event a leak should develop below any one individual cell, all soils would be required to be

removed to facilitate repairs. If the general location of a leak were not known, the leak could not

easily be located. Soils would be removed and liner inspections be made systematically, from

one end of the facility toward the other, in order to locate and repair the liner.

770 E. Sahara Avenue, Suite 100, Las Vegas, Nevada 89104

22

----------------------------

Republic Environmental Technologies, Inc.

7.4 Tons of\Vaste Accepted

Daily per load recording of the tons of waste accepted into the facility is accomplished by

certified scales positioned at the entrance to the facility. Each vehicle entering the facility will

be weighed, and a unique transaction number will be printed documenting the vehicle license

number, customer account number, and gross weight. The customer/transporter will then be

directed to the appropriate unloading area, i.e. the soils staging area or the petroleum

contaminated treatment cells. The vehicles will then cross over the scales again in order to

generate computer calculated net weight of waste received. All the information is documented

on a Dumping Ticket provided to the driver.

7.4.1 Weigh in Procedures

(1) Vehicle and waste will be inspected and all paperwork will be reviewed

(2) Customer account number and vehicle ID will be entered into the computer along

with initial gross weight

(3) Vehicle will be directed, or escorted, to the appropriate unloading area

( 4) Vehicle will again cross over the scales for tare weight and automatic calculation

of net weight*.

(5) Copies of manifests, bills oflading or dumping receipts will be acknowledged and

provided to the vehicle drivers

* "Gallons" received of non-hazardous liquids and petroleum contaminated liquids are

calculated by conversion of net weight, in pounds, divided by a conversion factor of 8. 8

pounds per gallon.

7.5 Tons of Soils Removed from the Containment Pad

The daily per load of tons of soil removed from the containment pad are only those tons received

into the containment pad. The phrase "containment pad" used for reporting, are the treatment

cells. Each customer's soils are assigned a particular cell for treatment. The cell number is

documented and cross-referenced to a specific account number established for that customer.

The total tons of soils within any individual cell is linked via the computer system to the net

weight calculated for each customer as the waste arrived. Once a cell contains approximately

3000 tons of soils, the cell is prepared for Initiation of Biological Treatment (see Section II-2.1).

Once the treatment is completed, the tons of soils placed into a cell are removed from the cell.

That tonnage is used to report "Tons of Soil Removed fonn the Containment Pad".

7.5 .1 Procedures for Calculation of Tons Removed from the Containment Pad

(1) Net weight of customers soils are automatically calculated and cross referenced to

the customers account number when the vehicle crosses the facility scales

(2) Each customers soils are assigned a specific cell for treatment

(3) Total tonnage of soils within a cell is calculated, and treatment begins when

tonnage approached 3000 tons

( 4) After treatment is complete, all soils placed into the cell (total tons) are removed

770 E. Sahara Avenue, Suite 100, Las Vegas, Nevada 89104

23

Republic Environmenlal Technologies, Inc.

7.6 Daily Maximum of Tons of Soils being Treated on the Containment Pad

The reporting of daily tons being treated with in the treatment cells is documented as those soils

received into a specific cell as described in Section VI- 6.4, above. The net tons within any cell

can be cross-referenced to a customer account number. A computer printout can be generated,

for any particular day, indicating the tons of soils received at the facility.

7.7 TPH in Treated Soils Prior to Removal from Containment Pad

Once again, the phrase "containment pad" used for reporting, are the treatment cells. The

procedure for determining the TPH concentration for treatment cells are provided in Section II.

7.8 Daily Maximum Gallons Contaminated Liquids in BioceUs

The volume of petroleum contaminated liquid waste accepted into the Bioremediation facility is

facilitated by using the facility scales; and converting the net weight of waste received into

gallons via a conversion factor. The procedure for tracking gallons received into the facility is

described in Section IV- 4.2

7.9 Tons of Solidified Media Removed from the Liquid Cells

Once the solidified petroleum contaminated liquids are prepared for biological treatment, the

soils are profiled (tested) as any other petroleum soils being profiled into the Bioremediation

Facility (see Section IV- 4.5). The soils will be moved from dedicated solidification cells,

estimates of cubic yards will be made, and tonnage will be calculated based upon volume using

approximately 1.3 tons per cubic yard. If production priorities require the solidified petroleum

contaminated liquids to be treated within their solidification cell or moved directly to the Landfill

operations without biological treatment. "Tons of Solidified Media ... " will be calculated, based

upon volume removed when the cell is cleaned out.

7.10 Liquid in the Leachate Collection Sump

The entire facility is lined with two layers of synthetic liner. The base grade of the facility has

been sloped (see diagrams in Attachment 2- Report of Design) so any liquids, that may collect

within the Leachate Collection System, drain to a central low spot that can be monitored for

moisture. The actual sump is not a man-way type structure, but rather a 6-inch diameter pipe

leading to the liner low spot. The procedures for detecting, and forms for documenting, liquids

in the sump are found in Attachment 3. The monitoring is perfonned weekly, or as directed in

the permit.

770 E. Sahara Avenue, Suite I 00. Las Vegas, Nevada 89104

24

Environmental Technologies, Inc.

7.11 Liquid in the Leak Detection System

Liquid in the leak detection system is monitored using the leak detection pipe designed the same

as the Leachate Collection Sump. The 3-inch diameter Leak detection pipe is located adjacent to

the Leachate Collection pipe, but is positioned to measure liquids that may be present at the same

low spot, except under both liners. The procedures for detecting, and forms for documenting,

liquids in the sump are found in Attachment 3. The monitoring is perfom1ed weekly, or as

directed in the permit.

7.12 Groundwater Monitoring 'Vell #5

Well #5 is located immediately north of the Bioremediation Facility and the 7 million-gallon

reservoir (see Figures 1). This well provides water to the reservoir. A..lmual monitoring and

reporting of Well #5 for TPH, by Method 8015B, and VOC's by Method 8260B (including

MTBE), is accomplished by collection of water exiting the active pumping well. Water will be

collected at the well head sample port. A water sample will be collected into two (2) full 1-quart

glass jars, and three (3) VOA vials, with zero headspace. The samples will be immediately

placed into an ice chest and transported to an off-site laboratory certified for testing for TPH and

VOC's.

770 E. Sahara Avenue, Suite 100, Las Vegas, Nevada 89104

25

Environmental Technologies ofNevada, Inc.

Wire

Monitoring Probe Design

I

I

l I

___ L_I ----

\ I

II

\I

l I

II

I l

J !

I

Figure 6

Republic Environmenza! Technologies, Inc.

V1II. SAFETY

Standard level of personal protection required at the site is Level D. Level D Personnel

Protective Equipment includes:

o Coveralls

o Gloves

o Boots/shoes, leather or chemical-resistant

o Safety glasses as needed (Optional)

o Hard hat (Optional)

Beside the chemicals present in the contaminated soils, the only chemicals used at the facility are

water and fertilizers containing nitrogen and phosphorus based supplements.

IX. EMERGENCY CONTACTS

The following list provides names and telephone numbers for emergency contact personnel. In

the event of a medical emergency, personnel will take direction form the appropriate emergency

organization. In the event of a fire or spill, the site supervisor will notify the appropriate local,

state, and federal agencies.

Organization Contact

Ambulance MERCY

Police METRO

Fire: CLARK COUNTY FIRE DEPT.

Regional IX EPA

State Authority (NDEP)

Local Authmity (CCHD)

National Response Center

Center for Disease Control

Chemtrec

Management

Mark Clinker - Landfill GM

Tim Hipps- Landfill Operations Manager

Dave McCafferty- Landfill Operations Manager

Rob Tidwell- Regulatory Compliance

Dave Fink- Medical Waste Manager

Emergency Response Coordinator

Elaina Turner- Safety

Telephone

911

911, (702) 799-3403

911, (702) 455-8579

415-947-8000

(702) 486-2850

(702) 759-1000

800-424-8802

1-800-232-4636

1-800-262-8200

Telephone

(702) 599-5901

(702) 599-5902

(702) 599-5902

(702) 599-5907

(702) 599-5632

Cell: (702) 280-0057

(702) 599-5917

770 E. Sahara Avenue, Suite I 00, Las Vegas, Nevada 89104

27

Environmental Inc.

770 E. Sahara Avenue .. Suite 100, Las Vegas, Nevada 89104

28

1

J

l

]

l

1 r

l !

!_1 t

Jt.

_l t.;:

1 (

, I

. I

I

STATE OF NE:V!.DA

6.. H. !'ilifl ,"\!U1\

e,r;6

Cli!!ll!y

l!:rilll

F<!rn:l

DEPARTMENT OF CONSERVATION AND NATURAL RESOURCES

DIVISION OF ENV ONMENTAL PROTECTION

C.lp!to! Compb

J:!J W. Nyi! Lane

Cu-wn City, Nenda 8.9il 0

.June 20, 1994

TOt All permitted Hydrocarbon Contaminated Soil Treatment

Facilities in Nevada

SUOM: Allen Biaggi, Chief, Bureau of Corrective

StmJ5CT: Testing and Scre'ening Procedures for Waste .Acceptance and

Receipt of out of state waste.

This a to and policry of

January 25, 1991 and subsequent issued by the

Division.

Due to inconsistencies in acceptance . procedures between

_permitted soils treatment facilities in Nevada and new regulatory

requirements, the Division has determined that a need exists to

standardize waste testing and analytical procedures. Commencing

July 1, 1994 the following minimum testing requirements shall be in

place for all permitted soil treatment facilities in Nevada:

* Representative sampling and analysis for Total Petroleum.

Hydrocarbons (TPH) via EPA Method 8015 (modified}i

Representative sampling and analysis by EPA Method 8240 for

volatile organics;

Preaeceptance field screening (prior to facility acceptance)

for halogens using the copper wire test or equivalent;

Screening for other contaminants which :may be expected to be

present in the waste stream (i.e. dielectric fluids or mineral

oil-PCB's, waste oil-heavy metalsr etc.);

-:-- .. -

J

l

1

l

i

fti\fltlO

June 20, 1994

Pagl3 2

NOTE: These are mi:aim1..11n screening criteria only. The

may require additional tests as necessary.

The Division is willing to consider waiving certain tests if

it can be determined what the source of the waste is,

the lack of potential for waste mixing or contamination with other

regulated material and documentation that the waste is not a

hazardous waste under 40 CFR Part 261.

The Toxic Characteristic Leachate Procedure (TCLP) in 40 CFR

261 requires the evaluation of waste for toxicity. A major

component of this rule is the evaluation of certain organic

compounds most notable of which is benzene.

o:f TCLP require:ments is in place for UST related contaminated

debris and media, contaminated debris and media from other

sources (i.e. trucking accidents, above ground tank releases,

releases from unregulated tanks) must be evaluated for hazard via

. TCLP prior to acceptance unless other knowledge can be applied

which documents the non-hazardous nature of the waste.

caution should be taken when accepting waste material from sources

other than those related to USTs.

Out of state hydrocarbon contaminated soil may be accepted

only if the following information in 1 r 2 or 3 is provided!

revie.,led and approved by the Division:

1. A letter from the regulatory entity governing hazardous

waste management within the state of origin attesting to

the non-hazardous nature ofthat waste, or

2.

3.

Evidence that the waste is not hazardous using

the regulatory provisions of the state of origin.

Self declassification (California derived waste only) of

the waste via procedures outlined in Article llr

Title 22 of the California .Administrative code. This

self-declassification will be recognized only under the

following

A.

B.

Sample protocols must be certified as

representative by a California Registered

Professional Engineer or Geologist. .A wet

stamped letter of certification is requlred;

All tests required under Title 22 for

self-declassification must be conducted and

results be at or below the specified critical

levels unless other generator

can be applied which documents t.-he

non-hazardous nature of the waste.

l

l

l i

l

ll

I

l

-) t

_]1

., r .

. I

---j .

. r

J

i

I;

Memo

June 20, 1994

Page J

C. All sample protocols, test methods

f

cert1f1cat1ons and results must be reviewed by

a Nevada Registered Professional Engineer or

Certified Environmental Manager knowledgeable

of California and Nevada wasta regulations.

The Nevada portion of the review must include

a recommendation to the Division on whether or

not the material meets the Title 22

requirements for self declassification.

D. All data is then provided to the Division

along with the results of all tests and

associated recommendations for acceptance. A

review will then be conducted by NDEP and a

de:termination made as to the hazardous

status of the soils and applicability for

importation into Nevada;

E" All testing and screening procedures placed

upon the treatment facility still apply to the

waste materiali -

Individual facilities may post a bond or other financial

assurance instrument acceptable to NDEP, the amount of which shall

be determined by calculating the average importation project waste

load processed at the facility per calendar year. For facilities

with an average imported project waste load in excess of 500 cubic

yards,. the bond amount shall be $100 r 000. For facilities importing

an average project waste load below 500 cubic yards the bond amount

be $50, 000. After the proper posting of this bond or other

financial assurance instrument, soils may be imported without the

specific written approval of the Division prior to acceptance at

the facility. However, .. all the above referenced relevant tests by

California and Nevada environmental professionals including

recol!Uilendations for acceptance by the Nevada CEM shall be provided

to the Division for review on a monthly basis.

Each project subject to these requirements shall be tracked

and segregated in the treatment unit in case removal is required at

a later time.

The Nevada CEI-1 may include employees of the treatment

facility.

If the improper acceptance of a hazardous waste is determined

through the monthly reports or other means, the Division shall

immediately notify the facility and require actions be undertaken

for the :material r s timely removal .

from the facility and proper disposal at a permitted TSD at tne

.:; -

---------- --- --

1

l

]I

l !

c_J !.

'.1

l

J .

I.

\ ..

J'UJnQ 20

1

1994

4

---------------

facility or If the lity cannot or will not

commance removal of (i.e. contact a TSD, begin

additional amplinq or analytical etc.) in a timely manner

(within 5 days) may call for the bond and use these

funds to pay for th!!lil proper disposition of the materiaL

These procedures are the only way pt\ttroleum conta:m.inated

materials and granulated activated carbon (GAC) if the

facility permit allows) can be legally imported into Nevada for

disposal or treatmant other than as waste to a permitted

'l'SD facility. It you have any information on the improper

importation into Nivada, plca!Ol1 notify the Division.

I hop!!ii will clarify the Divisions oosition on this

If que$tions .or feel free to

contact :me.

EnvironmenirJ Technologies, Inc.

Selected excerpts from the engineer's Report of Design originally sent to NDEP

under separate cover from Vector Engineering, Inc. dated February 2, 1994

entitled; As-Built Report for the Apex Regional Waste Managenzent Center Soil

Treatment Facility Double Liner System.

770 E Sahara Avenue. Suite I 00. Las l'egas. Nevada 89104

29

AS-BUILT REPORT

for the

APEX P.EGIONAL W4SIE

l'r!ANAGEMENT CENTER

SO JL TREA_._TMENT FACILIT""r

DOUBLE liNER SYSTEM

Prepared for.

Environmental Techn-ologies of Neva.rla, Inc.

77() East Salwm Avenue

Las Vegas

1

Nevada 89104

(702) 734-5400

Prepared by:

Vector Engineering, lite.

1601 Fairview Avenue, Suite H

Carson City, Nevadil 89701

(702) 883-7065

Jab No. 935015.00

7

Phase 5S

February 2, 1994

--------------- __:__. .. ..:__:_- . __ __::___...:;

1

1

f

,

r

1

r

,

r

I

I

f

EC

OR_

-NG INEERING, INC.

February 2, 1994

Job No. 93.5015.00

Mr. James Smitherman

Errvironmental Management Specialist ill

Bureau of Water Pollution Control

Nevada Division of Environmental Protection

333 W. Nye Lane

Carson City, Nevada 89710

Re: Apex Regional Waste 11anagement Center Soil

Treatment Facility Double Liner System As-Built Report

Dear }Af. Smitherman:

This letter is intended to provide as-built docmnentation for the double llirer installed

at the Apex Regional Waite Management Center, soil treatment facility (STF). The design

of the STF was based on meetings between your department and Vector Engineering, Inc.

(Veetor) in early November of last year. The purpose of the double liner system is to

provide a means of detecting leaks through the primary geomembrane liner; The design and

installation of the STF was conducted according to the Vector letter dated November 4,

1993. This letter has been included with this report in Appendix A.

L11 order for contaminated soil to be placed on the STF, the liner system must be installed

and observed to verify compliance with the project plans and specifications. As part of the

CQA inspection services at the site, Vector observed the installation of the minus 3/4 inch

subgrade soil, seconcia_ry 30 mil BDPE flexible membrane liner, one foot thick granular

drainage layer vrith collection piping, 60 mil HDPE primary geomembrane liner,

geocomposite drain layer, leachate collection pipeline, leachate collection \leak detection

sumps, and operations layer protective soil cover. During installation, Vector provided

continuous observation of ill liner phases. with a field staff of one quality assurance monitor,

a CQA project engineer who routinely visited the site throughout the construction, and

lffil fairview Ave., Suitt: H Carson Cicy, t-IV 89701

5

(702) 883-7065 Fax: (702) 883-7161

GR.AS:S VALLEY, CA UTil..ITON, CO ' SA.l:'<'Tl!-DD. CHILE

----

- ---

..........

---

sri MIL SMOOlH HDPE .PRJMARY LJNER

'

' DRAJNAGE LAYE."'R MATERlAL

30 MIL SMOQTI-1 HDPE SECONDARY UNER

3 FT.

(min.)

COMPACTED

BACICF1LL

3 FT.

(min.)

------""'! I FT. I

NOTE: EXTEND WELDS FOR UNER SEAMS

MINIMUM 1 FT. INTO ANCHOR TRENCH

TYPICAL ANCHOR TRENCH EBB

rnr......., .......,. um ;;;;;;;q:;; u:wm

- . NTS fV

----'-.

....11

I

\\

ii

I;

I'

l>l

1:

!

.i

.'\

\\

,-:

I:

\

1:

I:

r:l

:1!

I

'\:\

-':

.. :

I

::\

[

'

;')

\\

\!

11

u

\

:

.,

'

:

:;

\\

\\

\

l

1

l

J

l

1

J

M:r. June SrnithofiD.Ilr\

F::bn.mr 1, L994

P.Kgo 1

. . . ~ . .

administrative support staff. Vector's CQA monitor prep3.1-ed daily field construction reports

during the errtire liner system installation.. Appendix B coo.tains these daily reports.

Vector's CQA monitor observed subgrade (foundation) preparation prior to liner deployment.

Areas were cut and filled to render a fum foumi?-tion. The relative compaction of the

sub grade was tested and found to meet the requirements of 90% of the maximum dry density

as determined by ASTM D-1557. A summary of these tests is provided in Appendix C.

The subgrade was then rolled 1vith a smooth drum roller and insped:ed for suitability of

geomembrane placement. A record of these tests and observations is provided in

Appendix D. Following completion of the prepared sub grade, the instillation of the smooth

30 mil HDPE geomembrane begaiL Prior to deployment of any geosynthetic material, the

manufacturer's quality control documentation was reviewed by Vector's CQA monitor and

the CQA project engineer. According to that documentation, all material utilized in the

construction of the STF met the required values as stated within the speciiications.

As each geomembrane panel was placed, Vector's CQA monitor recorded the temperature,

wind conditions, panel number, roll number, and location. Prior to any seauling activities at

the beginning of each day and on.ce during the middle of the shift, a test seam (start-up trial

weld test) was prepared for each extrusion and! or double wedge welder used for that shift.

The Contractor's seaming technicians prepared a test specimen and marked the sample with

the machine number, machine temperature, date, time, and therr name. Vector performed

shear and peel te..sts in the field in accordance with ASTM D-4437. If the start-up weld

sample -failed to meet the project specifications, the welding technician and the liner

installation supervisor were notified and recommended to take corrective action or place the

machine out of service. No weldi.tl.g machine or technician began work until a start-up weld

was tested and shown to conform t ~ the requirements.

The geomembrane panels were seamed in the field using double-wedge fusion and extrusion

welding techniques by the Gundle Lining Systems crews. Vector's CQA monitor observed

the seaming activities and observed for proper panel overlap, cleanliness of the seams,

grinding where required, and the preheat and weld temp....=ratures of the equipment used.

Seam continuity was tested by Gundle using the air pressure and vacuum boX. methods.

Vector's monitor observed the seam contiuuity testing performed by Gundle's QC technicians

and maintained documerrtation. of this procedure. This documentation included recording the

seam number, QC technician, test type, number of repairs and their loca.tions, dates of

repairs and retests, and the CQA monitor observing the testing.

!eDe!:

Feb mary 2, 1994

Pogo 3

-----------------------------

In addition to nondestructive quality control, destructive samples were obtained at random

intervals of approximately one sample per 500 linear feet of seam as determined and located

by the Vector CQA monitor. Each sample was at least 12 inches wide by 40 inches 1orrg and

was cut by Gundle and provided to Vector for determination of bonded seam strength in

shear and peel according to AS'.Thi D-4437. All destructive sear:u evaluations were

accomplished on-site by Vector's CQA monitor using a field tensiometer. All finished field

seams from the STF liner system met the requirements of the specu'lcations for shear and

peel strength. The results of the destructive testing on the 30 mil HDPE secondary liner are

provided in Appendix E ..

After the 30 mil geomembrane was installed, a final w.alkdown was conducted by Vector and

Gundle. The final starus of each panel was recorded on a '

1

panel acceptance form" which are

included as Appendix F. 1ne leak detection and removal system layer was then placed.

According to our testing and observations, all material components met the requirements of

the specifications and the letter to NDEP dated November 4, 1993 (included in Appendix A).

As previously mentioned, Vector's CQA monitor carefully observe<:! the placement of the

drainage layer and collection piping to verify that the underlying 30 mil geomembrane was

not damaged.

After the leak detection layer was placed, the primary 60 mil BDPE liner was installed. The

manufacturer's certification, CQA testing, observations; and documentation conducted orr the

30 mil secondary rul.er were also conducted on the 60 wil primary liner. Documentation of

the acceptance of the completed 60 mil HDPE panels is provided in Appendix G.

Documentation on the shear and peel (destructive) testing conducteD on the 60 mil

geomembrane seams is provided in Appendix H. After primary liner placement,

geocomposite leachate collection sb:;ips and a.s.sociated collection piping were plac.ed. The

operations protective layer was then placed over the STF primary liner and the area was

opened for placement of the soil treatment cells and subsequent contarflinated soil.

As of the submittal of this letter, and based on our observations and testing, it is our opinion

that all components of the STF liner system were installed in general accordance with the

project plarts and specifications. Drawings showing the as-built configuration of the STF are

included with this letter. This letter was prepared in accordance with generally accepted

soils and geosynthetic engineering practices applicable at the time the letter was prepared.

Vector Engineering, Inc., makes no other warranties, either expressed or implied, as to the

professional advice provided under the terms of this agreement, and as described in t:his

letter.

Mr. hm<t5 S roltho..;,w

F<ob-nUtry i, 19-!4

hge4

If you require any additional infurrnation

1

please do not hesitate to call Scott Purdy or Mark

Smith at (916) 272-2448. Your timely review and approval of this letter is greatly

a._vpreciated. Environmental Technologies of Nevada, Inc. will begin operation of the STF

L'TIIDediately following your approval.

Regards,

VECTOR ENGI},('EffiliNG, illC.

Scott Purdy, CQA Project Engineer

Vice President

Mark Smith, P .E. 6546

President

cc: Johnnie Isola - Ef

Thomas DUMPCo

Doug 1:'1'l:artin - Y ector

enclosu.L--es: Appendices

As-built Drawings

N: \9350 15\WP\STFCERT .LTR

I

I ,

l'"GiliEERINLi INC.

November 4, 1993

Job No. 925010.0

MI. James Smitherman

Environmental Management Specialist III

Bureau ofWater Pollution Control

Nevada DiVision of Envirornnental Protection

Capitol Complex

333 W. Nye Lane

Carson City, Nevada g9710