Escolar Documentos

Profissional Documentos

Cultura Documentos

Delrin 150

Enviado por

Sardar. Vikramjit Singh RandhawaDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Delrin 150

Enviado por

Sardar. Vikramjit Singh RandhawaDireitos autorais:

Formatos disponíveis

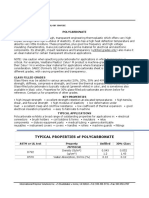

Delrin

(Acetal Homopolymer)

Delrin is a crystalline plastic that offers an excellent balance of properties that bridge the gap between metals and plastics. Delrin

possesses high tensile strength, creep resistance and toughness. It also exhibits low moisture absorption. It is chemically resistant to

hydrocarbons, solvents and neutral chemicals. These properties along with its fatigue endurance make Delrin ideal for many industrial

applications.

Delrins overall combination of physical, tribological and environmental properties make it ideal for many industrial wear and mechanical

applications. Parts exposed to a moist or wet environment, such as pump and valve components, are especially appropriate. Other common

uses for Delrin include gears, bearings, bushings, rollers, fittings and electrical insulator parts.

Good dimensional stability Excellent machinability Superior impact and creep resistance

High fatigue endurance High strength and stiffness properties Chemical resistance to fuels and solvents

Low moisture absorption - Delrin can operate in wet environments with little effect on performance or dimensions.

Good wear and abrasion properties - with its low coefficient of friction and hard and resilient surface, Delrin is the material of choice in

many wear applications. Natural grade is FDA, NSF and USDA compliant

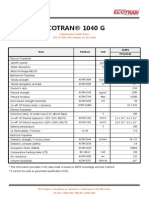

Primary Specification (Resin) (Typical) Shapes Specification (Typical)

ASTM-D-4181 POM110B34330 ASTM-D-6100 S-POM0111

Property ASTM Test Method Units Delrin 150

Physical

Density D792 lbs/in

3

0.0513

Specific Gravity D792 g/cc 1.42

Water Absorption, @ 24 hours D570 % 0.25

Water Absorption, @ Saturation D570 % 0.9

Mechanical

Tensile Strength @ Yield D638 psi 11,100

Tensile Modulus D639 psi 450,000

Elongation @ Break D638 % 25

Flexural Strength D790 psi 11,500

Flexural Modulus D790 psi 420,000

Compressive Strength D695 psi 5,200

Izod Impact Strength D256 ft-lbs/in 1.5

Rockwell Hardness D785 M (R) Scale M 94 (120)

Wear Factor Against Steel, 40 psi, 50 fpm D3702 in

3

/hr x 1/PV 55 x 10

-10

Static Coefficient of Friction D3702

Dynamic Coefficient of Friction, 40 psi, 50 fpm D3702 0.2

Thermal

Heat Deflection Temperature @ 66 psi D648 F 336

Heat Deflection Temperature @ 264 psi D648 F 257

Coefficient of Linear Thermal Expansion D696 in/in/F 6.8 x 10

-5

Maximum Servicing Temperature, Intermittent F 300

Maximum Servicing Temperature, Long Term UL746B F 185

Specific Heat BTU/lb-F 0.35

Thermal Conductivity

Melting Point D2133 F 347

Flammability UL94 HB (1.47)

Electrical

Volume Resistivity D257 ohm-cm 10

15

Dielectric Strength D149 V/mil 500

Dielectric Constant, @ 60 Hz, 50% RH D150 3.7

Dielectric Constant, @ 1 MHz D150 3.7

Dissipation Factor, @ 60 HZ D150 0.005

NOTE: The information contained herein are typical values intended for reference and comparison purposes only. They should NOT be

used as a basis for design specifications or quality control. All values at 73F (23C) unless otherwise noted.

Você também pode gostar

- Trirex 3020HF: Polycarbonate ResinDocumento5 páginasTrirex 3020HF: Polycarbonate ResinAlbert FortunatoAinda não há avaliações

- Compd Data Sheet 1040G ASTM Ver 150106Documento1 páginaCompd Data Sheet 1040G ASTM Ver 150106nimonhAinda não há avaliações

- PhysicsBowl 2002Documento14 páginasPhysicsBowl 2002satishirish3938Ainda não há avaliações

- Response Problems Crystal DefectsDocumento1 páginaResponse Problems Crystal DefectsYustinus LazuardiAinda não há avaliações

- Technical Data Sheet Teflon (Ptfe) : (Polytetrafluoroethylene Resin)Documento1 páginaTechnical Data Sheet Teflon (Ptfe) : (Polytetrafluoroethylene Resin)Dharmendra DubeyAinda não há avaliações

- PTFE Technical Data Sheet Highlights Chemical Resistance and Wide Temperature RangeDocumento1 páginaPTFE Technical Data Sheet Highlights Chemical Resistance and Wide Temperature RangeMarisa Yuni Nur AzizaAinda não há avaliações

- Polye PDocumento2 páginasPolye PFranco Gabriel MercadoAinda não há avaliações

- Technical Data Sheet Uhmw Polyethelyne (Uhmw Pe) : (Ultra High Molecular Weight Polyethylene)Documento1 páginaTechnical Data Sheet Uhmw Polyethelyne (Uhmw Pe) : (Ultra High Molecular Weight Polyethylene)HARSHA PAinda não há avaliações

- Acrylic Not Recc For ChlorinatedDocumento2 páginasAcrylic Not Recc For ChlorinatedoktavAinda não há avaliações

- Delrin SpecsDocumento1 páginaDelrin SpecsabhijitAinda não há avaliações

- Delrin SpecsDocumento1 páginaDelrin SpecsGrimmo1979Ainda não há avaliações

- Delrin - Mechanical PropertyDocumento1 páginaDelrin - Mechanical PropertyGovarthanan GovaAinda não há avaliações

- LdpeDocumento1 páginaLdpeArdy WiyogoAinda não há avaliações

- Technical Data Sheet Polycarbonate: Benefits ApplicationsDocumento2 páginasTechnical Data Sheet Polycarbonate: Benefits ApplicationsjackAinda não há avaliações

- Technical Data Sheet High Density Polyethylene: Typical Properties of PolyethyleneDocumento1 páginaTechnical Data Sheet High Density Polyethylene: Typical Properties of PolyethyleneQuality teamAinda não há avaliações

- PP Technical Data Sheet Provides Key Properties and BenefitsDocumento2 páginasPP Technical Data Sheet Provides Key Properties and BenefitsSabuj SaikiaAinda não há avaliações

- PolycarbonateDocumento2 páginasPolycarbonatepuvitta sudeshilaAinda não há avaliações

- PolycarbonateDocumento2 páginasPolycarbonateROHIT SHARMAAinda não há avaliações

- PolycarbonateDocumento2 páginasPolycarbonateAdnan KhanAinda não há avaliações

- Technical Data Sheet Polyimide: Benefits ApplicationsDocumento3 páginasTechnical Data Sheet Polyimide: Benefits Applicationssanthosha rkAinda não há avaliações

- Fluteck P7500 CA v01.19Documento2 páginasFluteck P7500 CA v01.19fprovitaliAinda não há avaliações

- PTFEDocumento1 páginaPTFEIkhsan LyAinda não há avaliações

- Ldpe (Low Density Polyethylene) : ApplicationsDocumento1 páginaLdpe (Low Density Polyethylene) : Applicationsarnella_hAinda não há avaliações

- PVC and CPVC properties referenceDocumento2 páginasPVC and CPVC properties referenceAdnan KhanAinda não há avaliações

- Cellulose Acetate ButyrateDocumento2 páginasCellulose Acetate Butyratenagbocca100% (1)

- Hopelen PP Homopolymer General Information: DescriptionDocumento2 páginasHopelen PP Homopolymer General Information: DescriptionKormanyos JoppeAinda não há avaliações

- NorylDocumento1 páginaNorylAnonymous P8Bt46mk5IAinda não há avaliações

- Static Dissipative Polyetherimide (Pei) / Static Dissipative UltemDocumento1 páginaStatic Dissipative Polyetherimide (Pei) / Static Dissipative UltemVC KannanAinda não há avaliações

- Delrin Mat PDFDocumento2 páginasDelrin Mat PDFyajneshwaradixitAinda não há avaliações

- Delrin MaterialDocumento2 páginasDelrin MaterialyajneshwaradixitAinda não há avaliações

- Delrin PDFDocumento2 páginasDelrin PDFA. Kumar RaiAinda não há avaliações

- Properties of High Density Polyethylene (HDPE) : Astm or UL Test Property HdpeDocumento1 páginaProperties of High Density Polyethylene (HDPE) : Astm or UL Test Property HdpedangdinhthyAinda não há avaliações

- PolystyreneDocumento1 páginaPolystyrenejoshkajasmineAinda não há avaliações

- Technical Data Sheet Abs: (Acrylonitrile-Butadiene-Styrene)Documento1 páginaTechnical Data Sheet Abs: (Acrylonitrile-Butadiene-Styrene)Paulo RicardoAinda não há avaliações

- VERTEC 1009: VERTEC 1009™ Is A Polymer Filled PTFE (Polytetrafluorethylene) Material. It Exhibits Good SealabilityDocumento1 páginaVERTEC 1009: VERTEC 1009™ Is A Polymer Filled PTFE (Polytetrafluorethylene) Material. It Exhibits Good Sealabilityseeralan_1986Ainda não há avaliações

- TecamidDocumento2 páginasTecamidTejas HuddarAinda não há avaliações

- Technical Data Sheet Nylon: (Polyamide)Documento3 páginasTechnical Data Sheet Nylon: (Polyamide)Dharmendra DubeyAinda não há avaliações

- ABS (Acrylonitrile Butadiene Styrene) :: S.R. No. Propery ASTM Test Method Units ABS FR Physical MechanicalDocumento1 páginaABS (Acrylonitrile Butadiene Styrene) :: S.R. No. Propery ASTM Test Method Units ABS FR Physical Mechanicalshailesh284Ainda não há avaliações

- ETFE Vs ECTFE PDFDocumento2 páginasETFE Vs ECTFE PDFpinkAinda não há avaliações

- Sanalite Hdpe Hoja TecnicaDocumento1 páginaSanalite Hdpe Hoja TecnicaFreddy VeraAinda não há avaliações

- Technical Data Sheet G-10: General DescriptionDocumento1 páginaTechnical Data Sheet G-10: General Descriptionbahtiar affandyAinda não há avaliações

- PEEK (Polyetheretherketone) : PossibilitiesDocumento2 páginasPEEK (Polyetheretherketone) : PossibilitiesMilan BojovicAinda não há avaliações

- 400 00030953en Engage 8180 TdsDocumento3 páginas400 00030953en Engage 8180 TdsSIDDHARTH BHASNEYAinda não há avaliações

- Epofine 556 FR/ FInehard 951Documento3 páginasEpofine 556 FR/ FInehard 951Karishma Prabhu100% (1)

- Virgin PTFE Datasheet: Property Method Units ValuesDocumento2 páginasVirgin PTFE Datasheet: Property Method Units ValuesMuhammad Ejaz QureshiAinda não há avaliações

- Technical Data Sheet Peek: Typical Properties of Virgin (Unfilled) PeekDocumento2 páginasTechnical Data Sheet Peek: Typical Properties of Virgin (Unfilled) PeekSyed MoinAinda não há avaliações

- Daelim M-LLD Roto Lh3750mDocumento1 páginaDaelim M-LLD Roto Lh3750mGabs GabrielaAinda não há avaliações

- Daelim Industrial HDPE Product Technical Data SheetDocumento2 páginasDaelim Industrial HDPE Product Technical Data SheetAkoyoAinda não há avaliações

- TDS Infinam ST 6100 LDocumento5 páginasTDS Infinam ST 6100 LKacperAinda não há avaliações

- Topilene HJ541CPDocumento1 páginaTopilene HJ541CPEmmylouCasanovaAinda não há avaliações

- 3 Property H7900 EngDocumento1 página3 Property H7900 EngMohit MohataAinda não há avaliações

- Pellethane 5863-82AE TPU: Technical Data SheetDocumento2 páginasPellethane 5863-82AE TPU: Technical Data SheetaAinda não há avaliações

- Filament Specifications Unit ValueDocumento4 páginasFilament Specifications Unit ValueRoberto Gonzalo PelazAinda não há avaliações

- Kocetal K700 Property DataDocumento1 páginaKocetal K700 Property DataRanjan GnanaoliAinda não há avaliações

- HJ541CP: Polypropylene Block CopolymerDocumento1 páginaHJ541CP: Polypropylene Block CopolymerEmmylouCasanovaAinda não há avaliações

- BT 8602Documento2 páginasBT 8602Shagun SharmaAinda não há avaliações

- Plastic Steel Putty A v3Documento2 páginasPlastic Steel Putty A v3feri.ferdianto02Ainda não há avaliações

- Tritan TX1001Documento2 páginasTritan TX1001qiongyao cuiAinda não há avaliações

- Hdpe Me8000 (En)Documento1 páginaHdpe Me8000 (En)Judith Casstañeda AgurtoAinda não há avaliações

- Halene - H : Technical Data SheetDocumento1 páginaHalene - H : Technical Data SheetIshah KaziAinda não há avaliações

- High Stiffness, Fluidity PP HomopolymerDocumento1 páginaHigh Stiffness, Fluidity PP HomopolymerMohit MohataAinda não há avaliações

- Is 802 Part-III Code of Practice Use of Structural Steel I.183132521Documento10 páginasIs 802 Part-III Code of Practice Use of Structural Steel I.183132521Kapil VatsAinda não há avaliações

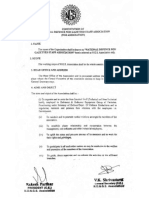

- CIC Appeal Procedure RulesDocumento4 páginasCIC Appeal Procedure RulesSardar. Vikramjit Singh RandhawaAinda não há avaliações

- Is 3177:1999Documento67 páginasIs 3177:1999Sardar. Vikramjit Singh RandhawaAinda não há avaliações

- 2266-Steel Wire-Ropes PDFDocumento21 páginas2266-Steel Wire-Ropes PDFAshish PattanaikAinda não há avaliações

- CCS (Conduct) Rules 1964 20.1.2006Documento218 páginasCCS (Conduct) Rules 1964 20.1.2006Alokdev Mishra0% (1)

- NPSDocumento21 páginasNPSSardar. Vikramjit Singh RandhawaAinda não há avaliações

- 802 1 1Documento22 páginas802 1 1vijaystructuralAinda não há avaliações

- IS 802 Part-2:1978Documento13 páginasIS 802 Part-2:1978Sardar. Vikramjit Singh RandhawaAinda não há avaliações

- IS 802 Part-1 (2) :1992Documento16 páginasIS 802 Part-1 (2) :1992Sardar. Vikramjit Singh RandhawaAinda não há avaliações

- The Central Administrative Tribunal (Procedure) Rules, 1987Documento18 páginasThe Central Administrative Tribunal (Procedure) Rules, 1987Sardar. Vikramjit Singh RandhawaAinda não há avaliações

- NPSDocumento21 páginasNPSSardar. Vikramjit Singh RandhawaAinda não há avaliações

- CCS (CCA) Rules 1965 20.1Documento127 páginasCCS (CCA) Rules 1965 20.1mbanlj33% (3)

- NPSDocumento21 páginasNPSSardar. Vikramjit Singh RandhawaAinda não há avaliações

- NPSDocumento21 páginasNPSSardar. Vikramjit Singh RandhawaAinda não há avaliações

- Administrattve Tribunals Act 1985Documento28 páginasAdministrattve Tribunals Act 1985api-243542776Ainda não há avaliações

- The Prevention of Corruption Act, 1988Documento17 páginasThe Prevention of Corruption Act, 1988vivek kumar singhAinda não há avaliações

- Written SubmissionDocumento3 páginasWritten SubmissionSardar. Vikramjit Singh RandhawaAinda não há avaliações

- UntitledDocumento120 páginasUntitledSardar. Vikramjit Singh RandhawaAinda não há avaliações

- Written Submission SwapnilDocumento6 páginasWritten Submission SwapnilSardar. Vikramjit Singh RandhawaAinda não há avaliações

- M L SharmaDocumento2 páginasM L SharmaSardar. Vikramjit Singh RandhawaAinda não há avaliações

- CCS (Leave) RulesDocumento53 páginasCCS (Leave) Rulespoojasikka196380% (5)

- Central Civil Services: GeneralDocumento83 páginasCentral Civil Services: GeneralSardar. Vikramjit Singh RandhawaAinda não há avaliações

- Applicants Wait in DespairDocumento1 páginaApplicants Wait in DespairSardar. Vikramjit Singh RandhawaAinda não há avaliações

- Byelaws NdgbgoaDocumento14 páginasByelaws NdgbgoaSardar. Vikramjit Singh Randhawa100% (1)

- NDNGS ByelawsDocumento13 páginasNDNGS ByelawsSardar. Vikramjit Singh Randhawa50% (2)

- Discplinary Action FAADocumento4 páginasDiscplinary Action FAASardar. Vikramjit Singh RandhawaAinda não há avaliações

- Madras High Court Assets OfficersDocumento10 páginasMadras High Court Assets OfficersSardar. Vikramjit Singh RandhawaAinda não há avaliações

- Commission Duty Bound To Levy Penalty For No Reasonable Cause For DelayDocumento4 páginasCommission Duty Bound To Levy Penalty For No Reasonable Cause For DelaySardar. Vikramjit Singh RandhawaAinda não há avaliações

- Discplinary Action FAADocumento4 páginasDiscplinary Action FAASardar. Vikramjit Singh RandhawaAinda não há avaliações

- OVERVIEW (4 Points) : CH116 General and Organic Principles LabDocumento4 páginasOVERVIEW (4 Points) : CH116 General and Organic Principles Labapi-557329548Ainda não há avaliações

- Sika Solutions For Concrete BridgesDocumento17 páginasSika Solutions For Concrete BridgescaapromoAinda não há avaliações

- Solutions - Short Notes - Vijeta Series Class-10thDocumento3 páginasSolutions - Short Notes - Vijeta Series Class-10thAshutosh SinghAinda não há avaliações

- Kinkelder StandardDocumento24 páginasKinkelder StandardJason StephensAinda não há avaliações

- Heating Element ArticleDocumento10 páginasHeating Element ArticleFrea Kent-Dazze D'DrughiAinda não há avaliações

- Lesson 1 - Reactions Energy WorksheetDocumento4 páginasLesson 1 - Reactions Energy WorksheetAvakoalaAinda não há avaliações

- Anse Co. 2023 Catalog Pipe FittingsDocumento600 páginasAnse Co. 2023 Catalog Pipe FittingsShakeer PttrAinda não há avaliações

- Spring 2013 Lecture 2 - 4Documento15 páginasSpring 2013 Lecture 2 - 4XiuQingAinda não há avaliações

- Springwire Xinhua 2006Documento10 páginasSpringwire Xinhua 2006teban09Ainda não há avaliações

- Figure 1: Coordinate of Plant LocationDocumento11 páginasFigure 1: Coordinate of Plant LocationJonathon John100% (1)

- Efficient Synthesis of 3-Hydroxy-1,4-Benzodiazepines Oxazepam and Lorazepam by New Acetoxylation Reaction of 3-Position of 1,4-Benzodiazepine Ring - Organic Process Research & DevelopmentDocumento12 páginasEfficient Synthesis of 3-Hydroxy-1,4-Benzodiazepines Oxazepam and Lorazepam by New Acetoxylation Reaction of 3-Position of 1,4-Benzodiazepine Ring - Organic Process Research & DevelopmentSimon GeschwindAinda não há avaliações

- Merck Chemicals - Advantages For The EnvironmentDocumento4 páginasMerck Chemicals - Advantages For The EnvironmentMerck ChemicalsAinda não há avaliações

- Chemical Reaction Lab ReportDocumento14 páginasChemical Reaction Lab ReportBùi Nhật MaiAinda não há avaliações

- Formulation and Evaluation of Orally Disintegrating Tablets of SertralineDocumento7 páginasFormulation and Evaluation of Orally Disintegrating Tablets of SertralineDinesh BabuAinda não há avaliações

- BIS CreamsDocumento13 páginasBIS CreamsNAVNEET BAGGA100% (2)

- Recent Advances in Homoeopathy ResearchDocumento39 páginasRecent Advances in Homoeopathy ResearchAnubhav Vichitra100% (1)

- Astm A743 - A743m (98) (Ca15)Documento2 páginasAstm A743 - A743m (98) (Ca15)ashsurya2008Ainda não há avaliações

- ATCO Gas STOPAQ-Vinylester Procedure Rev0Documento45 páginasATCO Gas STOPAQ-Vinylester Procedure Rev0mkash028Ainda não há avaliações

- Duct BurnersDocumento23 páginasDuct BurnersMartín Diego MastandreaAinda não há avaliações

- Practical of Chemistry PDFDocumento377 páginasPractical of Chemistry PDFrajesh971Ainda não há avaliações

- Manual Screen Changer For Extrusion Processes: Your Benefi TsDocumento2 páginasManual Screen Changer For Extrusion Processes: Your Benefi Tsneuro4761Ainda não há avaliações

- Agitated Nutsche Filter & Dryer (ANF/ANFD) : EquipmentsDocumento8 páginasAgitated Nutsche Filter & Dryer (ANF/ANFD) : EquipmentsJiril JacobAinda não há avaliações

- Chemical Bonding and Molecular Structure - Lecture NotesDocumento51 páginasChemical Bonding and Molecular Structure - Lecture NotesEdith EatonAinda não há avaliações

- Reasons to Replace Expired Fire ExtinguishersDocumento3 páginasReasons to Replace Expired Fire ExtinguishersswapnilmanwtkarAinda não há avaliações

- Philippine Coconut Authority: Coconut Methyl Ester (Cme) As Petrodiesel Quality EnhancerDocumento37 páginasPhilippine Coconut Authority: Coconut Methyl Ester (Cme) As Petrodiesel Quality EnhancerAnthony MoraAinda não há avaliações

- Arkema POF Brochure 2019Documento6 páginasArkema POF Brochure 2019julioAinda não há avaliações

- BS En1096 1 1999 PDFDocumento14 páginasBS En1096 1 1999 PDFanalunlAinda não há avaliações

- SemiconDocumento9 páginasSemiconRealyn PugayAinda não há avaliações