Escolar Documentos

Profissional Documentos

Cultura Documentos

Vibration Isolation

Enviado por

miniongsky0 notas0% acharam este documento útil (0 voto)

52 visualizações1 páginanoise

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentonoise

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

52 visualizações1 páginaVibration Isolation

Enviado por

miniongskynoise

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 1

Wagner Power Systems

For more information: 877-933-8700

4000 Osuna Rd NE

Albuquerque NM 87109

Vibration isolation protects gen set surroundings

No isolation is required to protect a generator set from self-induced vibrations. Caterpillar gen sets are designed to absorb all normal vibrations created internally as well

as most external shock loads.

This is not true of the gen set environment. Idle gen sets, auxiliary equipment such as relays and switches, and building structures can be adversely affected by vibration

from an operating gen set.

Vibration types

There are two types of generator set vibration: torsional and linear. Torsional vibration results from combustion forces imposed on the engine crankshaft that is transmit-

ted to the total rotating mass. Except in unusual installations, proper matching of engine and generator set at the factory completely avoids this type of vibration.

Linear vibration has many causes and can usually be linked to shaking and noisy machinery. Its exact nature is often difficult to define without instruments, because total

vibration measured is approximately a sum of vibration sources. (See chart 1).

Vibration effects

There will always be some vibration in rotating machinery like an operating gen set, so it is good practice to specify isolation of the unit. The unit should not rest directly

on rock, soil, steel or concrete. These materials can transmit vibrations long distances.

Resonance of certain gen set frequencies with the natural frequencies of building structural members can cause damage to some types of construction.

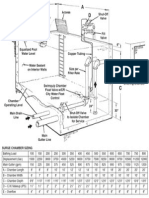

Figure 1: Vibration measured is approximately a sum of all vibration sources. Testing can determine sources

Separating the gen set from the surroundings can be done with a bulk isolator such as an inertia block or with commercial isolators.

The bulk isolators is the more expensive and elaborate of the two systems. It consists of a massive block on which the gen set is mounted. The block is surrounded by

cork or fiberglass, separating it from the surrounding structure.

Rubber pads are sometimes used to dampen high frequencies which cause noise, but the most often-used device is the spring-type isolator. It offers about 95 percent

isolation of all vibration and eliminates the need for an inertia block.

Spring isolators are placed under the gen set rails but are not bolted to the floor unless the unit is paralleled with other generator sets or is in an earthquake-prone area.

Spring isolators are most effective when located directly under the engine and generator mounting feet.

Care must be taken to make sure the spring can accommodate the gen set's weight. If the spring is compressed completely, all vibration will be directly transmitted to the

structure it rests on.

Consider idle units

Units that are not operating can be damaged by vibrations set up by nearby operating units. Because the idled units have no oil pressure to keep internal components

lubricated, the vibration can cause severe damage. Here, spring isolators can minimize vibration effects.

Fuel lines, exhaust piping and electrical connections all transmit vibrations. It is a waste of effort to provide mounting protection unless these connections are specified to

have vibration- limiting connections. Each connection must be isolated with flexible connections to provide maximum vibration reduction.

Resonance of pipe systems can also be reduced by hanging supports at unequal distances. (See figure 2). To attenuate low-frequency vibrations, specify spring-type

isolator pipe hangers. High-frequency vibrations can be minimized with rubber or cork cushioned hangers.

Figure 2: Specify hangers to be installed at uneven intervals to minimize pipe vibration problems

It is possible to test complete systems to ensure vibrations are not excessive. If a structure is sensitive to vibration from gen set operation, such test should be consid-

ered before the unit is commissioned. Wagner Power Systems can advise you how such tests can be carried out.

Vibration problems can cause considerable damage, and it is best solved when the specifications is written. The addition of spring isolators or an inertia block as well as

flexible connections on piping and electric lines can prevent many difficulties later on.

Consultants Corner: Vibration Isolation

Você também pode gostar

- Vibration Isolation TheoryDocumento4 páginasVibration Isolation TheoryRa BalamuruganAinda não há avaliações

- MEBS6008 Environmental Services II Acoustic Treatment and Vibration ControlDocumento26 páginasMEBS6008 Environmental Services II Acoustic Treatment and Vibration ControlSandeep BhatiaAinda não há avaliações

- Isolator Selection GuideDocumento30 páginasIsolator Selection GuideRaasik Jain100% (1)

- Machine Design Project ReportDocumento11 páginasMachine Design Project ReportMuhammad Abdullah100% (1)

- Mounting Bases and Vibration IsolationDocumento8 páginasMounting Bases and Vibration Isolationosto72Ainda não há avaliações

- Is 14812 2005Documento12 páginasIs 14812 2005JayDeep KhajureAinda não há avaliações

- Self-Cleaning Filters Manual & Automatic GuideDocumento4 páginasSelf-Cleaning Filters Manual & Automatic Guidedevang asher100% (1)

- WeldDocumento35 páginasWeldashkansoheylAinda não há avaliações

- Heatload Calculation - Kirloskar Ferrous - UPS RoomDocumento6 páginasHeatload Calculation - Kirloskar Ferrous - UPS Roomsenthil kumarAinda não há avaliações

- RelazioneDocumento21 páginasRelazioneSandeep BhatiaAinda não há avaliações

- Design and Analysis of Muffler for Two-wheelerDocumento9 páginasDesign and Analysis of Muffler for Two-wheelerDeepak ChaurasiaAinda não há avaliações

- Terminal Report ShredderDocumento25 páginasTerminal Report ShredderEnriv YasiladAinda não há avaliações

- Young's ModulusDocumento7 páginasYoung's ModulusNgatno100% (1)

- Convolution and Signal Processing FundamentalsDocumento22 páginasConvolution and Signal Processing Fundamentals174A1 HindupriyaAinda não há avaliações

- Lecture 5 - Power SuppliesDocumento48 páginasLecture 5 - Power SuppliesNimsiri AbhayasingheAinda não há avaliações

- Bevel Gear Pair Transmission DesignDocumento12 páginasBevel Gear Pair Transmission Designrip111176Ainda não há avaliações

- Split Pin Guide: Types, Sizes & UsesDocumento4 páginasSplit Pin Guide: Types, Sizes & UsesRylai CrestfallAinda não há avaliações

- Deflection Calculation Due To Imposed Load On Corridor JoistDocumento14 páginasDeflection Calculation Due To Imposed Load On Corridor JoistranjitAinda não há avaliações

- Main Pivot Pin Diameter CalculationDocumento2 páginasMain Pivot Pin Diameter Calculationjdutia83100% (1)

- Optional straight sidebar caterpillar drive chainDocumento1 páginaOptional straight sidebar caterpillar drive chainFernando Mendoza0% (1)

- Vibration Isolation Selection GuideDocumento5 páginasVibration Isolation Selection GuidearifzakirAinda não há avaliações

- Antivibration MountsDocumento6 páginasAntivibration MountsvldxbAinda não há avaliações

- Welcome To The Bill Pentz Cyclone Design Spreadsheet.: 0 No 1 YesDocumento10 páginasWelcome To The Bill Pentz Cyclone Design Spreadsheet.: 0 No 1 YesMarcelo MoraisAinda não há avaliações

- Lug Analysis MechaniCalcDocumento29 páginasLug Analysis MechaniCalcOSCARDELTAAinda não há avaliações

- Introduc) On To Wear: Surfaces, Interfaces, and Their Applica) Ons II Nicholas D. SpencerDocumento26 páginasIntroduc) On To Wear: Surfaces, Interfaces, and Their Applica) Ons II Nicholas D. SpencerKunal PandeyAinda não há avaliações

- ESP Insulation Thickness CalculationDocumento1 páginaESP Insulation Thickness CalculationaruntpeAinda não há avaliações

- Major Project ShredderDocumento12 páginasMajor Project Shredderaman kumarAinda não há avaliações

- 35-Duct Weight Calculation SheetDocumento11 páginas35-Duct Weight Calculation SheetAnanth Ganesan100% (1)

- Shaft Stress CalculationsDocumento2 páginasShaft Stress CalculationsVivek PrajapatiAinda não há avaliações

- Modal Space - in Our Own Little World: by Pete AvitabileDocumento2 páginasModal Space - in Our Own Little World: by Pete AvitabileVignesh SelvarajAinda não há avaliações

- VFD Panels and SCCR: Short-Circuit Current Rating (SCCR) Is A Number You Need To HeedDocumento5 páginasVFD Panels and SCCR: Short-Circuit Current Rating (SCCR) Is A Number You Need To HeedelengineerAinda não há avaliações

- Pressure Vessel Inspection ReportDocumento33 páginasPressure Vessel Inspection ReportJinlong SuAinda não há avaliações

- Metal Fatigue - Understanding the ProcessDocumento69 páginasMetal Fatigue - Understanding the Processaap1Ainda não há avaliações

- Mechanical VibrationDocumento22 páginasMechanical VibrationrajeshkunuAinda não há avaliações

- Noise Pollution - Prevention and Control - Rules 2000 & Laws & Noise Limits - IndiaDocumento32 páginasNoise Pollution - Prevention and Control - Rules 2000 & Laws & Noise Limits - IndiaIastra50% (2)

- Sensor Devices Mechanical SensorsDocumento41 páginasSensor Devices Mechanical Sensorsdesaivilas60100% (1)

- FEA Report PDFDocumento24 páginasFEA Report PDFDanish JavedAinda não há avaliações

- VibrationsDocumento2 páginasVibrationsUdayAinda não há avaliações

- PVEfea Assembly AnalysisDocumento20 páginasPVEfea Assembly AnalysisAnandh PsAinda não há avaliações

- Noise Reduction in Hvac Duct SystemsDocumento27 páginasNoise Reduction in Hvac Duct SystemsQOBITAinda não há avaliações

- Wind and Earthquake Analysis Results SummaryDocumento8 páginasWind and Earthquake Analysis Results SummaryBrahim HammamiAinda não há avaliações

- Circular Duct Attenuators: Performance Data - Open TypeDocumento3 páginasCircular Duct Attenuators: Performance Data - Open TypePaul ShermanAinda não há avaliações

- OxfordFiltration SelfCleaningFiltersDocumento2 páginasOxfordFiltration SelfCleaningFiltersgui51comlimaoAinda não há avaliações

- 2015 - Finite Element Modelling of Debonding Failures in Steel Beams Flexurally Strengthened With CFRP Laminates - Teng Fernando Yu PDFDocumento12 páginas2015 - Finite Element Modelling of Debonding Failures in Steel Beams Flexurally Strengthened With CFRP Laminates - Teng Fernando Yu PDFvlad lupasteanuAinda não há avaliações

- Engineering Standard: SAES-A-105 30 November, 2003 Noise Control Environmental Standards Committee MembersDocumento10 páginasEngineering Standard: SAES-A-105 30 November, 2003 Noise Control Environmental Standards Committee MembersLegend AnbuAinda não há avaliações

- Classification of Noise Reduction SilencersDocumento4 páginasClassification of Noise Reduction SilencersKamalakarAthalyeAinda não há avaliações

- Bevel GearDocumento17 páginasBevel Gearparesh09Ainda não há avaliações

- CohesiveZoneModels PDFDocumento31 páginasCohesiveZoneModels PDFGopal KondaguntaAinda não há avaliações

- Lining DuctworkDocumento4 páginasLining Ductworkthanh_79Ainda não há avaliações

- Calculate Exhaust Capacity for PEB AreaDocumento2 páginasCalculate Exhaust Capacity for PEB AreaAkhtar BahramAinda não há avaliações

- HPCBS Duct Fitting SavingsDocumento6 páginasHPCBS Duct Fitting SavingsSvetla NikolovaAinda não há avaliações

- Mep Hvac 3Documento133 páginasMep Hvac 3Muhammad Musa100% (1)

- Appendix A: Variable Ranges For Filter Cycle Calculations: Basic Properties of Solids, Solutes and FluidsDocumento10 páginasAppendix A: Variable Ranges For Filter Cycle Calculations: Basic Properties of Solids, Solutes and FluidsBrendaline EnopiaAinda não há avaliações

- Spray-Type Deaerating Heaters: TABLE 12.2Documento2 páginasSpray-Type Deaerating Heaters: TABLE 12.2Yanuar KrisnahadiAinda não há avaliações

- Sinusoidal and Random Vibration Testing PrimerDocumento6 páginasSinusoidal and Random Vibration Testing PrimerMohamad AsrulAinda não há avaliações

- Vibration IsolationDocumento1 páginaVibration IsolationjoAinda não há avaliações

- Generator Set RoomsDocumento7 páginasGenerator Set RoomsAnonymous TvOpvXAinda não há avaliações

- Fan Vibration Isolation ED1900 PDFDocumento4 páginasFan Vibration Isolation ED1900 PDFsivajirao70Ainda não há avaliações

- Isolators For NVMDocumento18 páginasIsolators For NVMSaad KhanAinda não há avaliações

- CIH Taco7aExpansionTankAirSepDocumento16 páginasCIH Taco7aExpansionTankAirSepminiongskyAinda não há avaliações

- Bolger Group Logistics Consultants To Management - Pdfwarehouse Fire ComplianceDocumento6 páginasBolger Group Logistics Consultants To Management - Pdfwarehouse Fire ComplianceminiongskyAinda não há avaliações

- Combining DOAS and VRF, Part 2 of 2Documento9 páginasCombining DOAS and VRF, Part 2 of 2miniongskyAinda não há avaliações

- 16 Ways To Reduce HVAC Energy in Supermarkets and RetailDocumento4 páginas16 Ways To Reduce HVAC Energy in Supermarkets and RetailminiongskyAinda não há avaliações

- Glossary - Education - CAGI - Compressed Air and Gas InstituteDocumento6 páginasGlossary - Education - CAGI - Compressed Air and Gas InstituteminiongskyAinda não há avaliações

- Sugar - Fluid Flow VelocitiesDocumento4 páginasSugar - Fluid Flow VelocitiesminiongskyAinda não há avaliações

- Types and efficiencies of fuel-fired boilersDocumento4 páginasTypes and efficiencies of fuel-fired boilersminiongskyAinda não há avaliações

- Combining DOAS and VRF, Part 1 of 2Documento8 páginasCombining DOAS and VRF, Part 1 of 2miniongskyAinda não há avaliações

- "Solutions For The Plastics Industry": Co. IncDocumento4 páginas"Solutions For The Plastics Industry": Co. IncminiongskyAinda não há avaliações

- Cooling-Tower Design Tips - Air Conditioning Content From HPAC EngineeringDocumento3 páginasCooling-Tower Design Tips - Air Conditioning Content From HPAC EngineeringminiongskyAinda não há avaliações

- Improving Efficiency With Variable-Primary Flow - Air Conditioning Content From HPAC EngineeringDocumento7 páginasImproving Efficiency With Variable-Primary Flow - Air Conditioning Content From HPAC EngineeringminiongskyAinda não há avaliações

- Expert Cooling Tower Repair, LLC - 303.790Documento4 páginasExpert Cooling Tower Repair, LLC - 303.790eimrehAinda não há avaliações

- Selecting Chillers, Chilled Water Systems - Consulting-Specifying EngineerDocumento5 páginasSelecting Chillers, Chilled Water Systems - Consulting-Specifying EngineerminiongskyAinda não há avaliações

- Application & Design of Energy Recovery Wheels - Airxchange, Inc PDFDocumento8 páginasApplication & Design of Energy Recovery Wheels - Airxchange, Inc PDFminiongskyAinda não há avaliações

- FMDS 1-35 Green Roof SystemsDocumento27 páginasFMDS 1-35 Green Roof SystemsminiongskyAinda não há avaliações

- FM Global Property Loss Prevention Data Sheets: List of FiguresDocumento13 páginasFM Global Property Loss Prevention Data Sheets: List of FiguresminiongskyAinda não há avaliações

- Table 1MDocumento2 páginasTable 1MminiongskyAinda não há avaliações

- Back To Basics - Water Pipe SizingDocumento5 páginasBack To Basics - Water Pipe Sizingminiongsky100% (1)

- APEC Building Codes, Regulations and StandardsDocumento227 páginasAPEC Building Codes, Regulations and StandardsminiongskyAinda não há avaliações

- Air King Ventilation Ashrae 62Documento5 páginasAir King Ventilation Ashrae 62miniongskyAinda não há avaliações

- Design Considerations of Water FeaturesDocumento102 páginasDesign Considerations of Water Featuresminiongsky100% (1)

- Table - First Hour RatingDocumento1 páginaTable - First Hour RatingminiongskyAinda não há avaliações

- Table - Hot Water Temperatures NHSDocumento1 páginaTable - Hot Water Temperatures NHSminiongskyAinda não há avaliações

- ACH Recommended air changes per hourDocumento2 páginasACH Recommended air changes per hourminiongskyAinda não há avaliações

- Table 6 - Demographic2Documento1 páginaTable 6 - Demographic2miniongskyAinda não há avaliações

- Surge ChamberDocumento1 páginaSurge ChamberminiongskyAinda não há avaliações

- Back To Basics - Water HeatersDocumento5 páginasBack To Basics - Water HeatersminiongskyAinda não há avaliações

- Evaporative Pool DehumidificationDocumento9 páginasEvaporative Pool DehumidificationminiongskyAinda não há avaliações

- Table - Hot Water Temperatures22Documento2 páginasTable - Hot Water Temperatures22miniongskyAinda não há avaliações

- Characteristics, Behavior, and Properties of LPG - Petronas Energy Philippines, IncDocumento2 páginasCharacteristics, Behavior, and Properties of LPG - Petronas Energy Philippines, IncminiongskyAinda não há avaliações

- Steel Cross-Section ClassificationDocumento2 páginasSteel Cross-Section ClassificationMohan BhalmeAinda não há avaliações

- SPLM - Construction Pre-Planning PDFDocumento11 páginasSPLM - Construction Pre-Planning PDFJommarVocalTagalogAinda não há avaliações

- Boq Gisu OkDocumento61 páginasBoq Gisu OkYedid Amq100% (2)

- Cooling Tower Specs - Cti Certified Cross FlowDocumento2 páginasCooling Tower Specs - Cti Certified Cross FlowShahab Z AhmedAinda não há avaliações

- A400Documento8 páginasA400Aleksei AvilaAinda não há avaliações

- Pressure Vessels Lectures 87Documento1 páginaPressure Vessels Lectures 87Adeel NizamiAinda não há avaliações

- 01 Boq 220KV - Gis - Karanjde - Price Schedule (Consolidated)Documento4 páginas01 Boq 220KV - Gis - Karanjde - Price Schedule (Consolidated)Akd DeshmukhAinda não há avaliações

- 5geb20c2 PB 31107 016Documento6 páginas5geb20c2 PB 31107 016lei songAinda não há avaliações

- 2022 23 Secme Balsa Bridge Contest RulesDocumento4 páginas2022 23 Secme Balsa Bridge Contest RulesgernAinda não há avaliações

- Pre-Registration Form at Isabela State UniversityDocumento2 páginasPre-Registration Form at Isabela State UniversityKristelle V. TorrealbaAinda não há avaliações

- RVT Mist Eliminator en WEB 220809Documento8 páginasRVT Mist Eliminator en WEB 220809Göksel VATANAinda não há avaliações

- Misk - Method Statement Tracker (Till 21-June-21)Documento13 páginasMisk - Method Statement Tracker (Till 21-June-21)ehteshamAinda não há avaliações

- Reinforced Concrete DesignDocumento10 páginasReinforced Concrete Designmuhammed sabir v aAinda não há avaliações

- UAE TESTING BODIESDocumento67 páginasUAE TESTING BODIESMahmoud ElomdaAinda não há avaliações

- Hanlan UpdateDocumento6 páginasHanlan Updaterobert_trewarthaAinda não há avaliações

- Hafsa - Bensghir French PrimeveraDocumento3 páginasHafsa - Bensghir French Primeverahz135874Ainda não há avaliações

- Matlab Code ABBD MatrixDocumento4 páginasMatlab Code ABBD MatrixmehdiAinda não há avaliações

- 3 Way Ball ValvesDocumento17 páginas3 Way Ball ValvesSagar Bhosale100% (1)

- Rev2 - MDCC MDC Park Central North Tower 32-35F Architectural Fitout Works - High Level PDFDocumento4 páginasRev2 - MDCC MDC Park Central North Tower 32-35F Architectural Fitout Works - High Level PDFChristelle Marie Aquino BeroñaAinda não há avaliações

- Compact Solenoid Valve - General Purpose: Threaded Port 1/8"-1/4" NPT and Sub-BaseDocumento4 páginasCompact Solenoid Valve - General Purpose: Threaded Port 1/8"-1/4" NPT and Sub-BasekicsnerAinda não há avaliações

- DeliviroDocumento4 páginasDeliviroDanielAinda não há avaliações

- CON 311 V00 (Method Statement For Structural Steel and Pipe Support Fabrication)Documento22 páginasCON 311 V00 (Method Statement For Structural Steel and Pipe Support Fabrication)mnmsingam100% (1)

- Wagner2011 Glass Rail PDFDocumento26 páginasWagner2011 Glass Rail PDFthe_dehumanizerAinda não há avaliações

- Highway Materials Manual: Kingdom of Saudi Arabia Ministry of CommunicationsDocumento75 páginasHighway Materials Manual: Kingdom of Saudi Arabia Ministry of CommunicationsAyman KandeelAinda não há avaliações

- Detailed Measurement Sheet - RAB 9: SL - No Description Unit Nos Measurements L B D QtyDocumento4 páginasDetailed Measurement Sheet - RAB 9: SL - No Description Unit Nos Measurements L B D QtyTekumudi Venkata NagendraAinda não há avaliações

- BOQ For Repair Work of 40'X20' Building at A/Selesthimaduwa VidyalayaDocumento9 páginasBOQ For Repair Work of 40'X20' Building at A/Selesthimaduwa VidyalayaAnuranga SahampathAinda não há avaliações

- DME 1 Assignment 3Documento3 páginasDME 1 Assignment 3AnilAinda não há avaliações

- 211-02. Steering System Power Steering Removal and Installation (Power Steering Pump - 6.4L Dies 6Documento3 páginas211-02. Steering System Power Steering Removal and Installation (Power Steering Pump - 6.4L Dies 6KawikaAinda não há avaliações

- Catalogue Pipe Hangers SupportsDocumento111 páginasCatalogue Pipe Hangers SupportsIlija Runjajic100% (1)