Escolar Documentos

Profissional Documentos

Cultura Documentos

Pump Control Model FPC 30010

Enviado por

vstojnicDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Pump Control Model FPC 30010

Enviado por

vstojnicDireitos autorais:

Formatos disponíveis

AT A GLANCE

Aquick reference to the controller's

Keypad and Indicator functions and

meanings.

POWER

ON

LEVEL

ALARM

PUMP ON

POWER Or

Power is turnedon.

LEVEL ALARM ON

A highlevel alarmhas been

present for thepreset time.

FLASHING

Alowlevel alarmis present.

ON STEAL.

Pumpswitchedontorun.

.0AB

II.15

O V AL PUNI. CO NTIO D LIe n

DUAL

PUMP CONTROLLER

KEYPAD

INDICATORS

1 1 1 EMD ON ST.

Apump fault/overloadhas

occured.

Aprimeloss fault has occured.

DIS I RIBUTEDBY:

MUTE/

RESET

Silences the sirenandif held

downfor 3 seconds, clears all

faults

If selected(theLED indicator

will confirmif on) theparticular

pump is set to Automatic

Pumping Mode

Turns all pumps off

If selected(theLED indicator

will confirmif on) thepumpis

set toManual Pumping Mode

OFF

GI

PUSH BUTTONS

INSTALLATION DATE:

SERIAL NUMBER:

MANUFACTURED BY MATelecAUSTRALIAEMAIL: infomatelecaustralia.com.au

MATelec reserves the right toalter technical specifications without notice

PUMPCO NTRO L

O WNER'S

O PERATIO N

MANUAL

D ual PumpCon trolle rIn stallation an d

O pe ratin gIn struction s

MODEL: FPC-30010

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

REV ISED : 011112

2 CIRCUIT DIAGRAM 7 SAFETY

8 INSTALLATION3 AT A GLANCE

Mounting

Indicators

Connection

Push Buttons

GETTING STARTED

Operations

Features

4

PUMP I PUMP 2

KEYPAD CONNECTION

PUMP 1 PUMP 2

PIN I

FAULT FAULT

240V 1 0A MAX

IATelec*

DUAL PUMP

CONTROLLER

COM-30089

500550

SIREN

INPUT

BMS/

REMOO

INPUT2

POWER

1 20,25

INPUT

4 OmA

I PUT4

ODE

SELECT

STROBE

ee ee ee 0

I1 2Vdc 1 2Vdc

WELCOME TO DUAL PUMP CONTROL

Your Dual Pump Controller reflects the superior quality and attention to detail in

design, engineering and manufacturing that has distinguished MATelec Products for

decades. The controller incorporates the very latest in micro-processor technology,

ensuring you, the owner/operator, of many years of functional, reliable and 'user

friendly' operation.

Please read this manual prior to installation and operation of the controller.

CO NTENTS

WARNING: All e le ctrical con n e ction smust be carrie dout byasuitably

qualifie dan dre giste re de le ctrician .

SAFETY!

Prior to Installation, ensure power supply is isolated.

Power supply must be Circuit Breaker Protected. (Qualified Electrician to determine appropriate amp

rating.)

Electrical connection to the panel must be carried out in accordance with 'Connection Instructions',

see page 3.

Additions or modifications to the control panel are not permitted and will void warranty.

The controller is not intended for use by children or infirmpersons without supervision.

Repairs to the Controller must only be carried out by a suitably qualified Electrician.

2

1 2Wc 240V c

CIRCUIT D IAGRAM

CONTACTOR

COILS

AI A2 Al A2

eeee Mr!

IMPORTANT READINSTALLATION ANDOPERATION MANUAL BEFORE USE

2anspISOLATOR

CONTROL SWITCH

CIRCUIT

BREAKER TRANSFORMER

N

I

I PUT I I PUT 2 INPUT 3 I PUT 4 DATA STROBE BUZZER

SWITCH SWITCH SWITCH SWITCH OUTPUT

Hi Hi

7

wwc4 ill di:

. 1 3 1 3

* e l 13

Km.c,.

D UAL

PUMP CONTROLLER

6

I

1 2vdc

TOL TOL

PUMP 1 PUMP 2

1 1 1 .1 1 .1 1 .1 1 1 I

666

STOP/START/STANDBY/

LOWMEDIUMNIGH

LEVEL LEVEL LEVEL

240Vec

MAINSPOWER

SUPPLY

SET THERMAL OVERLOADS TO SUIT PUMP

INSTALLATIO N

MOUNTING

1 . Controller enclosure must be

mounted in a vertical position.

2. Ensure mounting method

does not compromise enclosure

weather proof rating.

3. Ensure access to main isolator

is not restricted.

4. Ensure cables/conduits

entering the panel have

mechanical protection and that

the penetrations are

sealed and do not compromise

the weather proof rating of the

enclosure.

CONNECTION

NOTE: Controller must be earthed and all electrical connections must be carried out by a suitably qualified

Electrician. For Single Working Level Float Switch Applications, connect to "Start (Input 3)" terminals

only, and NO bridge wire is required in "Stop (Input 2)" terminals.

3

Maximum Run and Alternation Mode

With DIPSwitch 3 set to "Off" the unit will alternate as usual each time a pump start condition occurs. Additionally, the

controller will automatically alternate pump duty if a pump has been running continuously for 30 minutes (maximumrun

timer)

Setting this DIP Switch to "On" will cause the controller to operate in "Circulation Mode" where duty will only alternate

once the pump has run for 6hours of accumulated time.

Anti-Seize Timer

With DIPSwitch 4 set to "On", the Anti-seize timer will automatically run the pumps for 6seconds, every 7 days. This

pump operation will completely override all inputs including the low level (if enabled). This feature will only run pumps

that are set in Auto. This "Pump Run", will altemate between Pump 1 and Pump 2. A pump that has been locked out due

to a fault will not run.

Manual Mode Timeout

With DIPSwitch 5 set to "On" the pump will only remain in Manual Mode for 5 minutes, after which time, it automati-

cally reverts to Auto.

High Level Alarm Reset

With DIPSwitch 6 set to "Off", the High Level Alarmwill automatically reset once the High Level input opens circuit. The

controller will also use the alternate High Level AlarmDelay. Typically used for StormWater applications. High Level Alarm

delay in this mode is 1 5 minutes.

Setting this DIP Switch to "On", will cause the High level Alarmto remain active until the controller is reset. The High

Level Alarmwill use the standard High Level Alarmactivation delay. Typically used for Sewerage applications. High Level

Alarmdelay in this mode is 5 minutes.

Audible and Visual Alarm Test

By pressing the Mute/Reset button on the Keypad continuously for a period of 5 seconds, the Strobe, Siren and indica-

tor Lights will be powered up for inspection.

Fault Reset

To reset all faults on the controller, press and old the Mute/Reset button on the Keypad continuously for a period of 3

seconds until an acknowledgement beep is heard.

Pump Fault

A Pump Fault is indicated for two types of faults. A Thermal Overload will be indicated by way of a steady Fault Indicator

Light. Both types of faults can be reset by way of the Fault Reset button.

Level Alarms

A High Level Alarmis indicated by way of a steady Level AlarmIndicator Light.

A Low Level/Low pressure Alarmis indicated by way of a Flashing Level AlarmLight.

Auto Silencing Alarm Feature

The audible Alarmis programmed to sound for 5 minutes continuously, unless muted and will thereafter automatically

silence and enter "Chirp" mode. In "Chirp" mode, the Audible Alarmwill sound briefly (2 seconds) every 5 minutes.

6

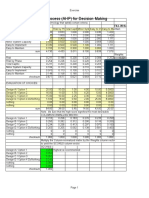

The basic logic on which a High or Low Level Alarmis determined, is set out in the Table below:

Input 1

Low Level

Input 2 Input 3 Input 4

Pump Stop Pump Start High Level

Pump

State

Closed Open/Closed Open Open Off

Closed Open/Closed Closed Open On

Closed Open/Closed Closed Closed Both On

Closed Open/Closed Open Closed Both On

Open Open/Closed Open Open Off

Open Open/Closed Closed Open Off

Open Open/Closed Open Closed Off

Open Open/Closed Closed Closed Both On

If there is a Low Level Alarm, then both Pumps will be locked out until the alarmis

over ridden upon a High Level condition where both the Pump Start and High level

Note that after a High level is triggered, the pumps will both run until the Pump Start and Stop inputs are opened.

Mode C: Standard Configuration plus Prime Loss

As per Mode A, except Input 1 is connected to a prime loss/flow switch. If at any stage, after Pump Start, or whilst a pump

is running, the Prime Loss input opens, for a continuous 1 minute period, a fault is immediately triggered for that pump

and duty alternates. Input functions are as follows:

Input

Function

Input 1

Prime Loss

Input 2

Pump Stop

Input 3

Pump Start

Input 4

High Level

Mode D: Pressure Pumping Configuration

Duty Pump: Lead Pump

Standby Pump: Lag Pump

Input functions are as follows:

Input

Function

Input 1

Not Used

Input 2

Lead Pump Pressure Switch (set at say 350kPa)

Input 3

Lag Pump Pressure Switch (set at say 350kPa)

Input 4

Low Pressure Switch (set at say 200kPa)

Typical Operation for Mode D:

Pressure drops to 400kPa: Lead (for this cycle) Pump cuts in.

Pressure increases and Pump cuts out.

Cycle continues with duty (Lead and Lag) alternating between the two pumps.

If pressure drops to 350kPa, Lead Pumps will cut in and remain running until Lead Pressure Switch opens circuit.

Then duty alternates.

No faults are logged against the Lead Pump if the Lag Pump starts.

The controller has inbuilt timers for "Delayed" Start and Stop to obviate pump chatter. Upon Input 1 contact closure,

the pump will not start (delay start) for 1 second and will not stop (minimumrun time) for 1 0 seconds (or 1 1 sec-

onds fromclose of Input contacts). This "run on" occurs even if Lead Pressure switch opens circuit during this initial

period. If however run time exceeds 1 1 seconds, the pump will stop immediately upon "Open Circuit" occurring.

If the Lead Pressure Switch input closes circuit as well as he Low Pressure Switch input, both pumps will be turned

on and the Low Pressure Timer will begin counting. If this condition exists for a period of 60 seconds, then both

pumps are shut down and the systemsignals a level alarm. This would be typical of a Loss of Prime, or Burst main

situation.

Pressure switches are normally Closed and Opened on High Pressure.

5

Alarm

O PERATIO N

This controller can performcontrol functions for most Dual Pump pumping applications. It is more than likely that the con-

trol parameters have already been set up for your particular application, however, hereunder you will find details of the set

up and configuration options.

There are 6DIP switches located on the lower side of the control module, which allows for selecting "mode" and "feature"

options, as per the following table:

DIPSwitch Position Function

1 /2 Off/Off Mode A: Standard typical float switch configuration (Start, Stop and High Level). No Low Level

Off/On Mode B: Standard configuration plus low level (Start, Stop, High Level and Low Level).

On/Off Mode C: Standard configuration plus Prime Loss enabled, on Low Level (Input 1 )

On/On Mode D: Pressure Pumping configuration (Lead, Lag and Low Pressure)

3Off Operating Pump alternates each time a pump start is triggered, or after 30 minutes continuous

running.

On Operating Pump alternates after 6hours continuous running.

4 Off Anti-seize Timer disabled

On Anti-seize Timer 6seconds every 7 days enabled

5 Off When placed in Manual Mode, pump remains in Manual Mode

On When placed in Manual Mode after 5 minutes the pump will revert to Auto

6Off High Level Alarmautomatically resets upon open circuit of high level input. High Level alarm

has 1 5 minute delay.

On I High Level Alarmcan only be reset manually. High Level Alarmhas 5 minute delay.

Mode A: Standard Configuration

Start/Stop/High Level operation. When the Pump Start input is closed contact (triggered), the Duty Pump will be turned on.

The pump will remain on until both the Pump Start and Pump Stop Inputs have turned off (Open Circuited). Upon High Level,

both pumps will run until the Pump Stop Input turns off.

In addition to this, there is a maximumidle timer, which will trigger a Pump Start condition, if either pump has not run for 4

hours, and the Stop Float Contacts are closed. The pump will continue to run until the Stop Float Contacts open. Input func-

tions are as follows:

Input

Function

Input 1 Not used

Input 2 Pump Stop

Input 3 Pump Start

Input 4 High Level

Mode B: Standard Configuration plus Low Level Alarm

As per Mode A, except it has an active Low Level input. The Low Level input must be closed, for Pump Start and Pump Stop

inputs to function. The High Level input however, will still override the Low Level and run both pumps. Input functions are as

follows:

Input Function

Input 1 Low Level

Input 2 Pump Stop

Input 3 Pump Start

Input 4 High Level

4

Você também pode gostar

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Ainda não há avaliações

- Apu B 767Documento103 páginasApu B 767gm&oAinda não há avaliações

- Monalisa Massage Bathtub User ManualDocumento15 páginasMonalisa Massage Bathtub User Manualmonalisachina50% (2)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGAinda não há avaliações

- The Forrester Wave™ - Low-Code Development Platforms For Professional Developers, Q2 2021Documento16 páginasThe Forrester Wave™ - Low-Code Development Platforms For Professional Developers, Q2 2021Daksh AnejaAinda não há avaliações

- Universal Gen Controller Manual - Digital Display, 8 Inputs, 4 RelaysDocumento21 páginasUniversal Gen Controller Manual - Digital Display, 8 Inputs, 4 RelaysBrianHazeAinda não há avaliações

- Orbit 60 Series System Datasheet 137M5182 PDFDocumento35 páginasOrbit 60 Series System Datasheet 137M5182 PDFJuan Antonio MarinAinda não há avaliações

- The ISO27k Standards: # Standard Published Title NotesDocumento8 páginasThe ISO27k Standards: # Standard Published Title NotesGiselle GirondinAinda não há avaliações

- Deh Governing-LancoDocumento35 páginasDeh Governing-LancoPRAMOD KUMAR NANDAAinda não há avaliações

- Service Manual DS-870 - DS-970 Rev CDocumento78 páginasService Manual DS-870 - DS-970 Rev CFelix Martinez PimentelAinda não há avaliações

- Turbine Operation SequenceDocumento3 páginasTurbine Operation SequenceTitas titasAinda não há avaliações

- Assembly-Line Balancing: A Valuable Tool For Increasing EfficiencyDocumento20 páginasAssembly-Line Balancing: A Valuable Tool For Increasing Efficiencyaqsa imranAinda não há avaliações

- Odoo 15 Development Essentials - 5th Ed. - 2022 - Packt PrintedDocumento548 páginasOdoo 15 Development Essentials - 5th Ed. - 2022 - Packt PrintedpablorizzoAinda não há avaliações

- Automatic Transfer Switch Panel Operation GuideDocumento23 páginasAutomatic Transfer Switch Panel Operation Guideyorgo7002100% (2)

- 1-22 PDF 20 NB Auto MPV ManualDocumento22 páginas1-22 PDF 20 NB Auto MPV ManualRagu Venkat33% (3)

- Introdution Multinet PakistanDocumento23 páginasIntrodution Multinet PakistanDemureAinda não há avaliações

- Check The OLTC Position For Startup Condition On 9 Step Position. Closed 10BBA10GS001, 10BBA10GS010, 10BBA30GS001Documento5 páginasCheck The OLTC Position For Startup Condition On 9 Step Position. Closed 10BBA10GS001, 10BBA10GS010, 10BBA30GS001jose Alberto uribe Minier100% (1)

- Jockey Pump BrochureDocumento8 páginasJockey Pump BrochuregbogboiweAinda não há avaliações

- TORNATECH JP Manual EnglishDocumento14 páginasTORNATECH JP Manual EnglishWalid AHMED MOUNIR MORSYAinda não há avaliações

- 155 17-O2 PDFDocumento152 páginas155 17-O2 PDFArshad MahmoodAinda não há avaliações

- Automatic Water Level Controller Cum IndicatorDocumento46 páginasAutomatic Water Level Controller Cum IndicatorPrasanna Dhayalamoorthy50% (2)

- Kapija BenincaDocumento5 páginasKapija BenincaMica Ivanovic100% (1)

- ALBANY FUEL OIL PUMP OPERATIONS GUIDEDocumento26 páginasALBANY FUEL OIL PUMP OPERATIONS GUIDEMarkAinda não há avaliações

- Digital 3-phase pump controller protects pumpsDocumento10 páginasDigital 3-phase pump controller protects pumpstunmobileAinda não há avaliações

- PetroTechManual 4Documento32 páginasPetroTechManual 4jose luisAinda não há avaliações

- Kangaroo 324 - Bomba de AlimentacionDocumento11 páginasKangaroo 324 - Bomba de AlimentacionoscarledesmaAinda não há avaliações

- Pump Control EN2Documento10 páginasPump Control EN2Теодор ТодоровAinda não há avaliações

- JOBO CPP-3 Instruction ManualDocumento11 páginasJOBO CPP-3 Instruction ManualMarian TudorAinda não há avaliações

- Controller - Electric Pump YDDocumento5 páginasController - Electric Pump YDAnonymous Qv0j6jAinda não há avaliações

- BARD S8201 169 InstructionsDocumento2 páginasBARD S8201 169 InstructionsFotografias WOAinda não há avaliações

- 555 Audio Alarm ChartDocumento4 páginas555 Audio Alarm Chartnasty_beerAinda não há avaliações

- Manual FireDocumento7 páginasManual Firearyssaiman5711Ainda não há avaliações

- Digital Electric Hydraulic Control System OverviewDocumento35 páginasDigital Electric Hydraulic Control System OverviewBui Vanluong100% (1)

- ICM 450 InstallationDocumento2 páginasICM 450 InstallationRay RavelAinda não há avaliações

- WF210 ManualDocumento20 páginasWF210 ManualMarkAinda não há avaliações

- Curtis AirPLUSDocumento37 páginasCurtis AirPLUSpekawwAinda não há avaliações

- Three Phase Voltage Monitor - Ae1313Documento4 páginasThree Phase Voltage Monitor - Ae1313Ben_Yu_9137Ainda não há avaliações

- FEE 512 Tutorial 1Documento5 páginasFEE 512 Tutorial 1BILLYAinda não há avaliações

- Watermicronworld AWG-C 5,000liter Prer Day - Operation ManualDocumento16 páginasWatermicronworld AWG-C 5,000liter Prer Day - Operation ManualRobert RainmanAinda não há avaliações

- HW 01 V4Documento3 páginasHW 01 V4soulotmagic100% (1)

- PLC4Documento7 páginasPLC4Muhammad J SherwaniAinda não há avaliações

- ACA0594 GBDocumento8 páginasACA0594 GBEmi MariniAinda não há avaliações

- Advanced Hydraulic Control SystemDocumento8 páginasAdvanced Hydraulic Control SystemĐặng Trung AnhAinda não há avaliações

- Industrial RO Control Device - ROC-2313Documento10 páginasIndustrial RO Control Device - ROC-2313AmiAinda não há avaliações

- Avionic User Manual For Aircraft Esc Ver2Documento2 páginasAvionic User Manual For Aircraft Esc Ver2nopeAinda não há avaliações

- Folleto Firetrol FTA500-10 (11-28-07) - SingleDocumento4 páginasFolleto Firetrol FTA500-10 (11-28-07) - SingleTRUNAinda não há avaliações

- Control Box For Boiler & BurnerDocumento10 páginasControl Box For Boiler & BurnerSergeyAinda não há avaliações

- Vacuum System Testing & Commissioning GuideDocumento5 páginasVacuum System Testing & Commissioning GuideDong VanraAinda não há avaliações

- Reef Angel Controller (Preloade Code) Manual v1.6Documento10 páginasReef Angel Controller (Preloade Code) Manual v1.6fuzarkaAinda não há avaliações

- Automatic Flocculant Plant Control PhilosophyDocumento8 páginasAutomatic Flocculant Plant Control PhilosophyBebel VillarAinda não há avaliações

- Variador HK 18ADocumento3 páginasVariador HK 18AcachitAinda não há avaliações

- JOBO CPP-3 Manual GB V1.1 26.03.13Documento11 páginasJOBO CPP-3 Manual GB V1.1 26.03.13Marian TudorAinda não há avaliações

- Sheetline Mini-Plc Standard Application: 1.1.1 Initial ConditionsDocumento5 páginasSheetline Mini-Plc Standard Application: 1.1.1 Initial ConditionsManutenção Industrial MicroserviceAinda não há avaliações

- User Manual of AE-20A、 25A、 30A Electronic Speed Controller (ESC)Documento4 páginasUser Manual of AE-20A、 25A、 30A Electronic Speed Controller (ESC)avolaarAinda não há avaliações

- RHOSS, Tabela AlarmaDocumento6 páginasRHOSS, Tabela AlarmaMuhidin KozicaAinda não há avaliações

- Clarke Mechanical Engine Controller Alarm Verification ProcedureDocumento4 páginasClarke Mechanical Engine Controller Alarm Verification ProcedureChanat MeonsiAinda não há avaliações

- Manual LubDocumento25 páginasManual LubMota Guine InformaçõesAinda não há avaliações

- PLC ExperimentDocumento6 páginasPLC Experimentyttan1116Ainda não há avaliações

- Dkg-207 Amf and Remote Start Unit Installation and Operating InstructionsDocumento4 páginasDkg-207 Amf and Remote Start Unit Installation and Operating InstructionsBambang Ardiansyah SetiadyAinda não há avaliações

- Fire Fighting System Operating InstructionDocumento2 páginasFire Fighting System Operating InstructiongodwinAinda não há avaliações

- Prestige TSGDocumento30 páginasPrestige TSGningj000Ainda não há avaliações

- Fisher and Paykel SmartDrive Service Manual 053 MW053-u 2010-05-31 - 170211 - GWL - 11US - FandP - Service - ManualDocumento50 páginasFisher and Paykel SmartDrive Service Manual 053 MW053-u 2010-05-31 - 170211 - GWL - 11US - FandP - Service - Manualstkegg33% (3)

- Electronic Speed ControlDocumento3 páginasElectronic Speed ControlGaneshkumar Krishna ShettyAinda não há avaliações

- Golander Pump: Operation ManualDocumento27 páginasGolander Pump: Operation Manualjravi781043Ainda não há avaliações

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationAinda não há avaliações

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitAinda não há avaliações

- Area Length Period Elevation AverageAnnualRunoffDocumento9 páginasArea Length Period Elevation AverageAnnualRunoffvstojnicAinda não há avaliações

- Modelling Real-Time OperationDocumento1 páginaModelling Real-Time OperationvstojnicAinda não há avaliações

- Creative Genius GeniusDocumento1 páginaCreative Genius GeniusvstojnicAinda não há avaliações

- 1990 Hydrological ForecastingDocumento33 páginas1990 Hydrological ForecastingvstojnicAinda não há avaliações

- Snowy Problem Solving Process ChecklistDocumento1 páginaSnowy Problem Solving Process ChecklistvstojnicAinda não há avaliações

- 1990 Hydrological ForecastingDocumento33 páginas1990 Hydrological ForecastingvstojnicAinda não há avaliações

- Modelling - Planning & ManagementDocumento1 páginaModelling - Planning & ManagementvstojnicAinda não há avaliações

- Apesma NotesDocumento2 páginasApesma NotesvstojnicAinda não há avaliações

- The Analytic Hierarchy Process (AHP) For Decision Making: Fill-In The Yellow AreasDocumento4 páginasThe Analytic Hierarchy Process (AHP) For Decision Making: Fill-In The Yellow AreasvstojnicAinda não há avaliações

- Tecjjpiqgy Brogo and Windamere Dams: For TheDocumento1 páginaTecjjpiqgy Brogo and Windamere Dams: For ThevstojnicAinda não há avaliações

- Hec-2 For Urban Stream Corridor RestorationDocumento9 páginasHec-2 For Urban Stream Corridor RestorationvstojnicAinda não há avaliações

- The Analytic Hierarchy Process (AHP) For Decision Making: Fill-In The Yellow AreasDocumento4 páginasThe Analytic Hierarchy Process (AHP) For Decision Making: Fill-In The Yellow AreasvstojnicAinda não há avaliações

- Funny Arithmetic TestDocumento1 páginaFunny Arithmetic TestvstojnicAinda não há avaliações

- Wimmera River Hydrology, Data and ModellingDocumento6 páginasWimmera River Hydrology, Data and ModellingvstojnicAinda não há avaliações

- Sydney Water Asset Protection ReportDocumento4 páginasSydney Water Asset Protection Reportvstojnic0% (1)

- John Wolfenden - An Improved Model For Community ConsultationDocumento9 páginasJohn Wolfenden - An Improved Model For Community ConsultationvstojnicAinda não há avaliações

- 1990 Hydrological ForecastingDocumento33 páginas1990 Hydrological ForecastingvstojnicAinda não há avaliações

- A Generic Method of Design of Osd StoragesDocumento7 páginasA Generic Method of Design of Osd StoragesvstojnicAinda não há avaliações

- Solver SampleDocumento1 páginaSolver SamplevstojnicAinda não há avaliações

- 6-5 Ring Road Storage Catchment PlanDocumento1 página6-5 Ring Road Storage Catchment PlanvstojnicAinda não há avaliações

- Running Testing and Understanding The Hydrological Simulation Program Fortran HSPF Wang Duru HjelmfeltDocumento36 páginasRunning Testing and Understanding The Hydrological Simulation Program Fortran HSPF Wang Duru Hjelmfeltvstojnic100% (1)

- IFD Curves 20131111Documento79 páginasIFD Curves 20131111vstojnicAinda não há avaliações

- Demotivational PosterDocumento1 páginaDemotivational PostervstojnicAinda não há avaliações

- Project Management Reference Manual Part 1Documento13 páginasProject Management Reference Manual Part 1vstojnicAinda não há avaliações

- Triglav PaintingDocumento1 páginaTriglav PaintingvstojnicAinda não há avaliações

- Ways to Improve Your Writing SkillsDocumento1 páginaWays to Improve Your Writing SkillsvstojnicAinda não há avaliações

- Uputstvo Za Koriscenje Programa KanDocumento4 páginasUputstvo Za Koriscenje Programa KanvstojnicAinda não há avaliações

- 2013 JobSearchDocumento10 páginas2013 JobSearchvstojnicAinda não há avaliações

- Solver SampleDocumento1 páginaSolver SamplevstojnicAinda não há avaliações

- Bloqueo de Puertas Mazda 3Documento2 páginasBloqueo de Puertas Mazda 3Jhon ConnorAinda não há avaliações

- CBB - KB - Spec - v1 2 - 5222007Documento39 páginasCBB - KB - Spec - v1 2 - 5222007spotAinda não há avaliações

- BambuDocumento5 páginasBambuAditya Widya PranataAinda não há avaliações

- WLC D1Documento2 páginasWLC D1jvtamilanbanAinda não há avaliações

- Bahu Membahu - Job Vacancy & Talent ListDocumento18 páginasBahu Membahu - Job Vacancy & Talent ListLestari SiregarAinda não há avaliações

- Quick Start Guide InfiNet Wireless R5000Documento32 páginasQuick Start Guide InfiNet Wireless R5000Iveth Carrillo CasasAinda não há avaliações

- Xyn464032-A4695, Schematic of Cooler ControlDocumento23 páginasXyn464032-A4695, Schematic of Cooler ControlmaheshAinda não há avaliações

- Anatomy of Map Reduce Job RunDocumento20 páginasAnatomy of Map Reduce Job RunHanumanthu GouthamiAinda não há avaliações

- Cares Technical Approval TA1-A 5050: AnconDocumento14 páginasCares Technical Approval TA1-A 5050: AnconFederico.IoriAinda não há avaliações

- Klueberfluid C-F 3 ULTRADocumento2 páginasKlueberfluid C-F 3 ULTRAwajahat ali KhanAinda não há avaliações

- PLC and SCADA Lab Experiments for Instrumentation CourseDocumento4 páginasPLC and SCADA Lab Experiments for Instrumentation CourseAnonymous FKMfvCbAinda não há avaliações

- Bhoomi Project: National Informatics CentreDocumento3 páginasBhoomi Project: National Informatics CentreChoudhury Monalisa SwainAinda não há avaliações

- Seminar-Machining Centers and Machine Tool StructuresDocumento20 páginasSeminar-Machining Centers and Machine Tool StructuresniteshwanAinda não há avaliações

- The Big Problem With Renewable EnergyDocumento2 páginasThe Big Problem With Renewable EnergyDiego Acevedo100% (1)

- Lesson 2 RoboticsDocumento3 páginasLesson 2 RoboticsEzekiel DungoAinda não há avaliações

- Brand-Ventilation - Folder - Webb bs12101-2 PDFDocumento5 páginasBrand-Ventilation - Folder - Webb bs12101-2 PDFdmitar stevanovicAinda não há avaliações

- Aim: To Test Differentiator and Integrator Circuits Using Ua741op-AmpDocumento8 páginasAim: To Test Differentiator and Integrator Circuits Using Ua741op-AmpAvinash Nandakumar100% (1)

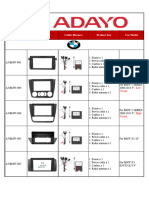

- Adayo ReplacementDocumento13 páginasAdayo Replacementkwf7yjpr26Ainda não há avaliações

- OLSR Routing Protocol in NS2Documento22 páginasOLSR Routing Protocol in NS2Hansi WijesingheAinda não há avaliações

- PBX to PBX VoIP Network (H.323Documento42 páginasPBX to PBX VoIP Network (H.323WaldirAinda não há avaliações

- 0417 m15 QP 12, JDocumento16 páginas0417 m15 QP 12, JlsorourAinda não há avaliações

- 17) Digital SignatureDocumento12 páginas17) Digital SignatureTelika RamuAinda não há avaliações

- Simple JSON REST Consumption With GSON API - CodeProjectDocumento4 páginasSimple JSON REST Consumption With GSON API - CodeProjectgfgomesAinda não há avaliações