Escolar Documentos

Profissional Documentos

Cultura Documentos

Co Production

Enviado por

Suresh RamakrishnanDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Co Production

Enviado por

Suresh RamakrishnanDireitos autorais:

Formatos disponíveis

2

nd

International Conference on Engineering Optimization

September 6 - 9, 2010, Lisbon, Portugal

1

Optimization of the Operating Conditions of Production Hydrogen from Glycerol

Autothermal Reforming for fuel Cell

Giovanilton F da Silva

1

, Joclia S. Mendes

2

, Francisco A. S. Mota

2

, Andrea L. O. Ferreira

2

, Fabiano A. N.

Fernandes

2

1

IFBA, Vitria da Conquista, Brazil, giovanilton@ifba.edu.br

2

UFC-DEQ, Fortaleza, Brasil, jsousamendes@yahoo.com.br,

2

UFC-DEQ, Fortaleza, Brasil, assismota13@gmail.com

2

UFC-DEQ, Fortaleza, Brasil, andrea@ufc.br

2

UFC-DEQ, Fortaleza, Brasil, fabiano@ufc.br

Abstract

This case study focused on optimization of hydrogen production for fuel cell applications. In this case study,

glycerol was chosen as a raw material and with autothermal reforming as a process of produce hydrogen. Using a

commercial dynamic flow sheeting software, HYSYS 3.1, the process of hydrogen production was successfully

simulated. In this research, fuel processor consists of an autothermal reactor, three water gas shift reactors and a

preferential oxidation reactor was successfully developed. The purpose of this case study is to identify the effect of

various operating parameters such as air-to-fuel (A/F) ratio and steam-to-fuel (S/F) ratio to get the optimum

hydrogen production while made carbon monoxide lower than 10 %. From the results, an optimum A/F and S/F

ratio are 5.5 and 3.5, respectively to produce hydrogen 34.7 % (v/v), CO2 60% (v/v), and CO 0.02% (v/v).

Under these optimum conditions, 83.6% of fuel processor efficiency was achieved.

Keywords: glycerol, hydrogen, autothermal reforming, HYSYS.

1. Introduction

Hydrogen will play an important role as an energy carrier of the future. Hydrogen will be used as fuel in almost

every application where fossil fuels are being used today, plus the advantages of hydrogen to compare with other

fossil fuels is hydrogen fuel will not emission harmful or hazardous gas. There are three categories that been

analyzed for input or raw material for hydrogen production. The categories that had been studied was natural gas

(consist methane, ethane, propane and butane), alcohol (methanol, ethanol and glycerol) and naphtha (kerosene or

fuel jet, gasoline and diesel).

An increase in biodiesel production would decrease the world market price of glycerol. Glycerol is a waste

by-product obtained during the production of biodiesel. Biodiesel is one of the alternative fuels used to meet our

energy requirements and also carbon dioxide emission is much lesser when compared to regular diesel fuel.

Biodiesel and glycerol are produced from the transesterification of vegetable oils and fats with alcohol in the

presence of a catalyst. About 10 wt% of vegetable oil is converted into glycerol during the transesterification

process. Although glycerol is used in medicines, cosmetics, and sweetening agents, world demand is limited. As

such, when mass production of the biodiesel is realized, novel processes that utilize glycerol must be developed.

When biodiesel is produced in large quantity, it is important to find useful applications for the resulting large

quantity of glycerol in the world market. Tyson (2003) reported that glycerol markets are limited; an increase in

biodiesel production may cause glycerol prices to decline from $1/L to $0.7/L by 2010. The money invested in

purifying the glycerol would also be high (Prakash, 1998). Also, Tyson, 2003 reported that net biodiesel

production costs can be reduced from US$0.63/litre of B100 to US$0.38/litre of B100 by adding value to the

glycerol by-product.

Glycerol is a potential feedstock, for hydrogen production because one mole of glycerol can produce up to four

moles of hydrogen. Hydrogen (H2) is mostly used in refinery hydrotreating operations, ammonia production and

fuel cells (Rapagna et al., 1998). When glycerol is cracked at high temperature to produce hydrogen, it is possible

to get carbon monoxide as one of the gaseous products. Studies on the degradation of glycerol have been also

presented in previous papers, (Herai et al., Bhler et al. and Sadashiv et al.).

One possibility is to use glycerol as a source of hydrogen, and, in this regard, steam reforming of glycerol would be

a suitable reaction. In the autothermal reforming of glycerol, synthesis gas that contains both carbon monoxide

(CO) and hydrogen (H2) is produced.

Steam-reforming is endothermic and partial oxidation is exothermic. It is possible to reaction glycerol and other

hydrocarbon fuels with a mixture of steam and oxygen or steam and air and carry out both reactions

simultaneously. The exothermic oxidation supplies the energy for the endothermic reforming. Careful control of

the oxygen content of the entering mixture is essential in these processes for maintaining proper reaction

2

temperatures. The products of these reactions are carbon monoxide, carbon dioxide, and hydrogen. The CO

requires high- and low temperature water gas shifts to oxidize it and provide additional hydrogen (Brown, 2001).

Autothermal reforming is a combination of steam reforming and partial oxidation and some other reaction that

occurred depend on the conversion of raw material, catalyst used, ratio of raw material and the temperature provide

during the process (Iwasaki et al., 2005). Lenz et al. (2005) described that autothermal reforming is known as the

simultaneous conversion of hydrocarbons with steam and oxygen. The endothermic steam reforming reaction is

generally given by four reactions:

Partial oxidation:

O H CO O O H C

2 2 3 8 3

4 3 2 (1)

Parallel Steam reforming of glycerol:

2 2 2 3 8 3

7 3 3 H CO O H O H C (2)

Series Water-gas shift reaction:

2 2 2

H CO O H CO (3)

Overall reaction:

CO H CO O O H O H C

2 2 2 2 3 8 3

9 5 2 2 (4)

2. Simulation and Optimization

2.1 Problem definition

The hydrogen production from glycerol for fuel cell was simulated using HYSYS software as a Figure 1 shows it.

Typically, the simulation process takes the following stages:

i. Preparation Stage

a) Selecting the thermodynamic model

b) Define chemical components

ii. Building Stage

a) Adding and define streams

b) Adding and define unit operations

i. Auto-thermal reforming reactor

ii. Water gas shift reactor

1. High temperature shift reactor

2. Medium temperature shift reactor

3. Low temperature shift reactor

c) Connecting streams to unit operations

d) Add auxiliary unit

i. Heater

ii. Cooler

iii. Heat exchanger

iii. Execution

a) Starting integration

b) Optimization the whole plant

Figure 1 HYSYS process flow diagram (PFD) of Reforming Glycerol plant.

3

The system considered in this study were simulated with the same basic data, show within Table 1. The

Peng-Robinson Equation of State (EOS) is used to model the thermodynamics of hydrogen production for both

steady-state.

Table 1 Steady state operating conditions.

The parameter of simulation Value

Feed flow rate of glycerol (kmol/h) 100

Reformer temperature (C) 500

Reformer pressure (250 kPa) 250

Vapor pressure ( kPa) 500

Air temperature (C) 25

The system fuel processor efficiency can be calculated by:

3 8 3 3 8 3

2 2

O H C O H C

CO CO H H

LHV n

LHV n LHV n

(5)

The lower heating value (LHV) of hydrogen, CO and glycerol are shown in Table 2.

Table 2 - Lower heating value (LHV) for hydrogen, CO and glycerol.

Component LHV (kJ/kmol)

Glycerol 1470

Hidrogen 241.83

CO 282.00

2.2 Optimization

Optimization of the autothermal reforming of glycerol was conducted searching for the operating conditions

(air-to-fuel (A/F) ratio and steam-to-fuel (S/F) ratio) that result in the highest production hydrogen. HYSYS

contains a multi-variable Steady State Optimizer. The Flowsheet has been built and a converged solution has been

obtained, it can use the Optimizer to find the operating conditions which minimize or maximize an Objective

Function. The Objective function is given by optimization of Eq. (5). For maximize of objective functions was

used the method SQP - Sequential Quadratic Programming.

CO should decrease because fuel cells (FC) do not tolerate excessive amounts of CO. The FC does not tolerate

more than in the order of 50ppm CO; the lower the CO concentration, the higher the efficiency of the cell.

H

2

/glycerol ratio should be increased because all glycerol would be reacted to product (H

2

).

3. Results and Discussions

Optimization for ATR was done by varying the air molar flow rate to get the best flow rate of air to be introduced

into the ATR. Two case studies were developed in order to do this optimization. The first case study was

developed to monitor the temperature at the ATR vapour stream after varying the air molar flow rate from 350

kmol/h to 800 kmol/h. The second case study was developed to monitor the molar flow rate of carbon monoxide

and hydrogen after varying air molar flow rate within the range that was chosen from first case study. The result is

shown in Figures 2 and 3.

From Figure 2, the temperature out of ATR is over 800 C only after the molar flow rate of air greater or equal 600

kmol/h. With that air molar flow rate range, the hydrogen and CO molar flow rate was monitored. From figure 3,

the flow rate of hydrogen produced by the reactor reforming of is decreasing when of air molar flow rate greater

than 550 kmol/h. Then it began constant after 750 kmol/h.

4

300 400 500 600 700 800

500

600

700

800

900

1000

1100

T

e

m

p

e

r

a

t

u

r

e

C

Air - Molar Flow (kgmole/h)

Figure 2 Temperature of reactor of reforming for varies air Feed molar flow.

300 400 500 600 700 800

0

20

40

60

80

100

120

220

240

260

280

300

320

340

CO

M

o

l

a

r

F

l

o

w

o

f

H

2

(

k

g

m

o

l

e

/

h

)

M

o

l

a

r

F

l

o

w

o

f

C

O

(

k

g

m

o

l

e

/

h

)

Air - Molar Flow (kgmole/h)

H

2

Figure 3 - Molar flow of CO and H2 effluent for varies air feed molar flow.

In Water Gas Shift Optimization , one case study was developed to optimized value of feed water molar flow to

reduce concentration of CO through water gas shift reaction. Figure 4 shows the result of case study where the

concentration of H2 and CO after water gas shift reactors was monitored.

Water molar flow rate was optimized from 2000 to 8000 kg/h. As we can see from Figure 5.8, the H

2

show an

increasing slope and the increasing is a bit slower at 7500 kg/h. The optimum water molar flow rate was taken

when hydrogen at its higher molar flow rate. So, the value of water molar flow rate that was chosen was 5500 kg/h.

At this point, H

2

produced the greatest flow rate and CO reduced the lowest flow rate.

5

2000 3000 4000 5000 6000 7000 8000

314

316

318

320

322

324

326

328

0

2

4

6

8

10

M

o

l

a

r

F

l

o

w

o

f

C

O

(

k

g

m

o

l

e

/

h

)

M

o

l

a

r

F

l

o

w

o

f

H

2

(

k

g

m

o

l

e

/

h

)

Steam - Massa flow (kg/h)

Hydrogen

CO

Figure 4 Molar flow of CO and H2 effluent for varies water feed molar flow.

In the following, the results obtained for an autothermal reforming of glycerol system are presented. With the

developed system models which are implemented in the HYSYS 3.1 process simulator, effluents from all reactors

are simulated. In this model, the air to fuel ratio is set to 5.5 and the steam to fuel ratio is set to 3.5 In these

conditions, 90% glycerol is converted to produce 34% hydrogen, 20.07% CO2 and 0.01% CO. Also, under these

conditions, oxygen is 100% consumed. As we know, WGS reaction will convert CO into CO2 and hydrogen with

the existence of steam. Therefore, the percentage of CO is decreasing, while the percentage of CO2 and hydrogen

is increasing respectively. In the same time, the percentage of steam is decreasing.

4. CONCLUSIONS

Basically, for 100 kmol/h of glycerol was inserted to the process and it produced about 327.37 kmol/h hydrogen.

For the first reactor that is at the reforming reactor, hydrogen that produced after the optimization was 262.65

kmol/h. Optimization had been done for every reactor whereby for the ATR reactor, we got 550 kmol/h of air for

the highest hydrogen production and the lowest CO besides temperature around 672.9 C. A number of important

observations were noted based on the analysis of conclusions:

1. The simulation of hydrogen production plant model using autothermal reforming of methanol had been

successfully developed using HYSYS 3.1.

2. The optimum A/F and S/F ratios are 5.5 and 3.5, respectively to produce hydrogen 34.7 % (v/v), CO

2

60% (v/v), and CO 0.02% (v/v).

3. With optimum parameters above, 83.6% of fuel processor efficiency was achieved.

References

[1] L.F. Brown, A Comparative Study of Fuels for On-Board Hydrogen Production for Fuel-Cell-Powered

Automobiles. International Journal of Hydrogen Energy. 26:381-397, 2001.

[2] W. E Bhler,. H.J. Dinjus, A. Ederer, C. Kruse, Ionic reactions and pyrolysis of glycerol as competing reaction pathways

in near- and supercritical water, Journal of Supercritical Fluids 22 3753, 2002.

[4] T. Hirai, N.O. Ikenaga, T. Miyake, and T. Suzuki. Production of hydrogen by steam reforming of glycerin on ruthenium

catalyst. Energy and Fuel, 9: 1761-1762, 2005.

[5] B. Lenz, and T Aicher, Catalytic Autothermal Reforming of Jet Fuel. Journal of Power Sources. 149:44-52, 2005.

[6] C.B Prakash, A Critical Review of Biodiesel as a Transportation Fuel in Canada, Report to Transportation System

Branch, Air Pollution Prevention Directorate, R gasification Biomass to produce Hydrogen Rich Gas, Int. J. Hydrogen

Energy, 23, 551-557, 1998.

[7] S. Rapagna, N. Jand and U.P. Foscolo, Catalytic Gasification Biomass to produce Hydrogen Rich Gas, Int. J. Hydrogen

Energy, 23, 551-557 1998.

[8] M. Sadashiv and M. A. Abraham, Integrated Catalytic Process for Conversion of Biomass to Hydrogen, Energy & Fuels,

20, 2616-2622, 2006.

[9] K. S Tyson, Biodiesel R & D, Montana Biodiesel Workshop, October 8, 2003.

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- IGCSE Chemistry - Acids Bases and SaltsDocumento13 páginasIGCSE Chemistry - Acids Bases and SaltsChemistryKlipz100% (11)

- Primary Health Care: Mr. John Michael M. Pitoy, B.S.N., R.NDocumento44 páginasPrimary Health Care: Mr. John Michael M. Pitoy, B.S.N., R.NJohn Michael Manlupig Pitoy100% (9)

- I. Leadership/ Potential and Accomplishments Criteria A. InnovationsDocumento5 páginasI. Leadership/ Potential and Accomplishments Criteria A. InnovationsDEXTER LLOYD CATIAG100% (1)

- Boiler Feed Water Design CalculationsDocumento4 páginasBoiler Feed Water Design Calculationsmohan100% (1)

- H2 Postion Laro S - DDocumento1 páginaH2 Postion Laro S - DSuresh RamakrishnanAinda não há avaliações

- Steam Carbon Reduction Benefit Calculation 08 - 10Documento27 páginasSteam Carbon Reduction Benefit Calculation 08 - 10Suresh RamakrishnanAinda não há avaliações

- RMP HP SD in Nov 16Documento2 páginasRMP HP SD in Nov 16Suresh RamakrishnanAinda não há avaliações

- 3247tef-2016 Sports Registration SureshDocumento4 páginas3247tef-2016 Sports Registration SureshSuresh RamakrishnanAinda não há avaliações

- 4.7 PSV DesignDocumento16 páginas4.7 PSV Designganesh82Ainda não há avaliações

- Tef - 2016 Sports & GamesDocumento4 páginasTef - 2016 Sports & GamesSuresh RamakrishnanAinda não há avaliações

- PaymentDocumento1 páginaPaymentSuresh RamakrishnanAinda não há avaliações

- SHG 37Documento15 páginasSHG 37Suresh RamakrishnanAinda não há avaliações

- Detailed Engineering Drawings, Codes and Standards: Piping & Instrumentation Diagram - Designer ChecklistDocumento3 páginasDetailed Engineering Drawings, Codes and Standards: Piping & Instrumentation Diagram - Designer ChecklistSuresh RamakrishnanAinda não há avaliações

- TEFDocumento12 páginasTEFSuresh RamakrishnanAinda não há avaliações

- PIP Accepted IdeasDocumento9 páginasPIP Accepted IdeasSuresh RamakrishnanAinda não há avaliações

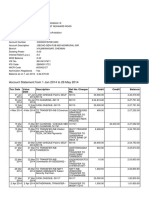

- Account Statement From 1 Jan 2014 To 26 May 2014: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalanceDocumento2 páginasAccount Statement From 1 Jan 2014 To 26 May 2014: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalanceSuresh RamakrishnanAinda não há avaliações

- Start Up PlanDocumento5 páginasStart Up PlanSuresh RamakrishnanAinda não há avaliações

- Simple CalcDocumento2 páginasSimple CalcSuresh RamakrishnanAinda não há avaliações

- Methanol Co Production EconomicsDocumento3 páginasMethanol Co Production EconomicsSuresh RamakrishnanAinda não há avaliações

- Convection Section CleaningDocumento10 páginasConvection Section CleaningSuresh RamakrishnanAinda não há avaliações

- Start Up PlanDocumento5 páginasStart Up PlanSuresh RamakrishnanAinda não há avaliações

- Qualitynet InvoiceDocumento1 páginaQualitynet InvoiceSuresh RamakrishnanAinda não há avaliações

- C 88 051 Benefit ReportDocumento1 páginaC 88 051 Benefit ReportSuresh RamakrishnanAinda não há avaliações

- 507 NeemDocumento18 páginas507 NeemSuresh RamakrishnanAinda não há avaliações

- TEF Sports Day Suresh RegiterDocumento1 páginaTEF Sports Day Suresh RegiterSuresh RamakrishnanAinda não há avaliações

- Simple CalcDocumento2 páginasSimple CalcSuresh RamakrishnanAinda não há avaliações

- On Stage Programs (Will Be Conducted On 8 May) : Event CodeDocumento4 páginasOn Stage Programs (Will Be Conducted On 8 May) : Event CodeSuresh RamakrishnanAinda não há avaliações

- RMP and Fup H Balance Report: H Production H ConsumptionDocumento1 páginaRMP and Fup H Balance Report: H Production H ConsumptionSuresh RamakrishnanAinda não há avaliações

- Steam To Carbon Ratio Calculations: InstructionsDocumento8 páginasSteam To Carbon Ratio Calculations: InstructionsSuresh Ramakrishnan100% (1)

- Start Up PlanDocumento5 páginasStart Up PlanSuresh RamakrishnanAinda não há avaliações

- Format Loop Description-BlankDocumento1 páginaFormat Loop Description-BlankSuresh RamakrishnanAinda não há avaliações

- Reformer Convection SectionDocumento7 páginasReformer Convection SectionSuresh RamakrishnanAinda não há avaliações

- Pipe Conveyor System: Effective Solutions For Long DistancesDocumento8 páginasPipe Conveyor System: Effective Solutions For Long DistancesEugenepaccelli Kolandai SamyAinda não há avaliações

- "Mode One" Author & Dating Coach Alan Roger Currie Releases Criticism of Alleged Harvey Weinstein BehaviorDocumento3 páginas"Mode One" Author & Dating Coach Alan Roger Currie Releases Criticism of Alleged Harvey Weinstein BehaviorPR.com100% (1)

- Brook Health Care Center Inc Has Three Clinics Servicing TheDocumento1 páginaBrook Health Care Center Inc Has Three Clinics Servicing Thetrilocksp SinghAinda não há avaliações

- Nutrients: Dietary Fiber, Atherosclerosis, and Cardiovascular DiseaseDocumento11 páginasNutrients: Dietary Fiber, Atherosclerosis, and Cardiovascular Diseasemichael palitAinda não há avaliações

- LMA An. I-Sem 1-Engleza LEC-The Category of Aspect & Aspect 3-Reedited OnDocumento4 páginasLMA An. I-Sem 1-Engleza LEC-The Category of Aspect & Aspect 3-Reedited OnIlie IonelAinda não há avaliações

- Presentation On Dysuria 1Documento25 páginasPresentation On Dysuria 1ankur acharyaAinda não há avaliações

- CSEB Korba THERMAL POWER PLANT Mechanical Training ReportDocumento20 páginasCSEB Korba THERMAL POWER PLANT Mechanical Training Reporthaxxo24Ainda não há avaliações

- Mount Kenya University: Department: School of Social SciencesDocumento4 páginasMount Kenya University: Department: School of Social SciencesLETISIA FATUMAAinda não há avaliações

- ISO 9001: 2015 Certified Semen Freezing LaboratoryDocumento43 páginasISO 9001: 2015 Certified Semen Freezing LaboratoryShubhamAinda não há avaliações

- HC SB 61 227Documento22 páginasHC SB 61 227Hamed BarjestehAinda não há avaliações

- Basic HomeopathyDocumento2 páginasBasic Homeopathypravin216Ainda não há avaliações

- Scaffolding-Fixed and Mobile: Safety Operating ProceduresDocumento1 páginaScaffolding-Fixed and Mobile: Safety Operating Proceduresmohammed muzammilAinda não há avaliações

- July 15, 2011 Strathmore TimesDocumento24 páginasJuly 15, 2011 Strathmore TimesStrathmore TimesAinda não há avaliações

- HEM Duplex Cooling MotorDocumento4 páginasHEM Duplex Cooling MotorAbhishek Kumar Pandey1Ainda não há avaliações

- Ra Radtech Cdo July2018Documento4 páginasRa Radtech Cdo July2018Angelo MercedeAinda não há avaliações

- Lecture 16 - Bleeding Tendency DiseasesDocumento64 páginasLecture 16 - Bleeding Tendency Diseasesapi-3703352100% (1)

- EO MNC 10 June 2022Documento4 páginasEO MNC 10 June 2022LeulaDianneCantosAinda não há avaliações

- Research News: Sedimentation Velocity of Solids in Finite Size VesselsDocumento4 páginasResearch News: Sedimentation Velocity of Solids in Finite Size VesselskorangaprakashAinda não há avaliações

- Ielts ReadingDocumento7 páginasIelts ReadingTrọng Nguyễn DuyAinda não há avaliações

- Epoxy Plus Pipeline Repai Grout TG - MSDSDocumento5 páginasEpoxy Plus Pipeline Repai Grout TG - MSDSgrimaguilAinda não há avaliações

- 1402AHS Prac Manual - 2023 - FINALDocumento200 páginas1402AHS Prac Manual - 2023 - FINALRuan BritsAinda não há avaliações

- Air Compressor: TopicDocumento17 páginasAir Compressor: TopicManuel GuerreroAinda não há avaliações

- Recipes For Ceviche, Pebre and Pisco SourDocumento4 páginasRecipes For Ceviche, Pebre and Pisco SourJoaquín Rolón CarrerasAinda não há avaliações

- EP-HQ-GDL-008-00 Safety - Critical - Elements - Integrity - Management - GuidelineDocumento57 páginasEP-HQ-GDL-008-00 Safety - Critical - Elements - Integrity - Management - GuidelineAHMED AMIRA100% (5)

- Collier v. Milliken & Company, 4th Cir. (2002)Documento3 páginasCollier v. Milliken & Company, 4th Cir. (2002)Scribd Government DocsAinda não há avaliações

- Fortnightly Test For 11th NEET - 2024 - Test-03 - QP - 01!07!2023Documento19 páginasFortnightly Test For 11th NEET - 2024 - Test-03 - QP - 01!07!2023dhruvi.v91Ainda não há avaliações

- Pay & PADocumento5 páginasPay & PApujiptAinda não há avaliações