Escolar Documentos

Profissional Documentos

Cultura Documentos

Btex Buster Brochure

Enviado por

Samaneh HajipourDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Btex Buster Brochure

Enviado por

Samaneh HajipourDireitos autorais:

Formatos disponíveis

G A S

How It Works

The NATCO BTEX BUSTER is a relatively simple process that

is designed to maintain greater than 99.7%* removal of

BTEX and VOC emissions.

The vapors emitted from the glycol still column are cooled

in the natural draft air cooler to temperatures below 120 F

(49 C).

The condensed liquids are collected in a small two-

phase separator and pumped to customer storage. Non-

condensable gases from the separator are piped through

an in-line flash arrestor and then burned in the glycol

reboiler firebox to achieve an overall minimum destruction

efficiency of 99.7%* plus.

NATCO BTEX BUSTER

Removes 99.7%* of BTEX and VOC emissions from glycol reconcentrator emissions

The Simple and Cost-effective Answer to

Your Emission Compliance Problems

Camerons NATCO

BTEX BUSTER

provides a removal

efficiency greater than 99.7%*, helps recover and collect

saleable liquid hydrocarbons and prevents the loss of

expensive fuel gas from glycol reconcentrator vent

emissions.

The unit is designed using the Environmental Protection

Agency-approved Gri-Glycalc computer simulation program

with a flash-gas separator in the glycol regeneration

process. Under common operating conditions, BTEX

(benzene, toluene, ethylbenzene and xylene), as well as

other volatile organic compounds (VOCs), are emitted into

the atmosphere during the glycol regeneration process. The

rates usually are proportional to the glycol circulation rate.

The NATCO BTEX BUSTER captures those hydrocarbon

emissions.

Performance

The cost-effective system is designed to assist operators

in reducing BTEX and VOC emissions below the accepted

levels and complies with federal and state environmental

regulations.

Economics of the NATCO BTEX BUSTER show that it

can pay for itself by recovering saleable hydrocarbon

liquids and fuel gas. By condensing troublesome glycol

reconcentrator vapors and routing flash gas back to

the reconcentrator fuel gas inlet for burning, the unit

reduces emissions during glycol plant dehydration

processing.

The NATCO BTEX BUSTER incorporates field-proven

burner accessories to help prevent sooting and

backpressure on your regeneration system.

The NATCO BTEX BUSTER also features a design to

eliminate potential freeze-up problems when operating

in severe cold climates.

Cameron offers the NATCO BTEX BUSTER in standard

sizes to accommodate most customer needs. Our units

are backed by Camerons replacement parts, technical

assistance and service available 24 hours a day.

The NATCO BTEX BUSTER cold-weather design eliminates freezing

problems associated with cold climates.

BTEX BUSTER

Features Benefits

Ideal for Remote Locations Natural draft self-regulating system does not

require any moving pieces of equipment.

Environmentally Correct Meets Federal Regulation 40 CFR part 63

and meets or exceeds most stringent state

regulations LAC 111.2116 and LAC 33:111

chapter 51.

Efcient Removal efciency is greater than 99.7%*.

Reduces Operating Costs Reduces fuel gas consumption and recovers

saleable liquid hydrocarbons.

Safe Features an in-line ash arrestor, high-level

switch, pressure safety valve and gas shut-down

valves.

Designed for the Oil Field Includes eld-proven burner products, and

the pneumatic pump handles aromatic

hydrocarbons.

Designed for Cold Weather Cold-weather design eliminates freezing

problems associated with cold climates.

Camerons Services Includes experienced staff and worldwide

locations, 24 hours a day.

2013 Cameron | NATCO is a registered trademark of Cameron and BTEX BUSTER is a trademark of Cameron | 5/13 AD00535P

Built-in Safety Features

The NATCO BTEX BUSTER is engineered

with proper controls for safe operation

and long in-service life. These include

an in-line flash arrestor, separator high-

level switch, pressure safety valve and

gas shut-down valves for high reboiler

bath temperatures. It also incorporates

field-proven burner accessories that

help to prevent typical sooting and

backpressures on your regeneration

system.

Field-proven, the NATCO BTEX BUSTER

now is available through our sales and

service locations worldwide.

Standard BTEX

Size (1)

Reconcentrator

Duty Btu/hr

Glycol Pump

gal/hr

Max Capacity

water/day (2)

Non-condensable

vapor/day (3)

Cooler Duty

Btu/hr (3)

150 75,000 40 273 7 30,000

150 150,000 40 273 10 30,000

250 250,000 90 1216 27 51,000

375 375,000 210 1807 45 76,000

550 550,000 210 2650 60 112,000

750 750,000 450 3615 100 152,000

(1) Standard BTEX

Performance of unit is based on a non-condensable vapor HHV greater than 400 Btu/cf and less than 1800 Btu/cf and a

glycol circulation rate of no more than 3 gal/lb of water removed.

(2) Maximum Capacity of Water/day

Represents the maximum capacity of water in pounds per day for each of Camerons standard reboiler size based on a

glycol circulation rate of 2 gallons of glycol per pound of water removed.

(3) Non-condensable Vapor/day

Maximum non-condensable vapor rate was calculated with the Gri-Glycalc computer simulation program with a flash-

gas separator used in the glycol regeneration process and a BTEX concentration in the inlet gas stream of no more

than 700 ppm.

Using adiabatic combustion calculations, a minimum of 99.7%* of these non-condensable vapors are destroyed.

(4) Cooler Duty Btu/hr

Cooler duty was calculated based on a prevailing windspeed of 3 mph and a maximum ambient temperature of 100 F

(38 C).

Note: Cameron is not responsible for the disposal of any condensed liquids associated with its BTEX BUSTER units.

* Certain gas streams contain more BTEX and VOCs than represented by Gri-Glycalc. Consult with Camerons engineers for system evaluation,

equipment sizing and application to ensure conversion efficiency.

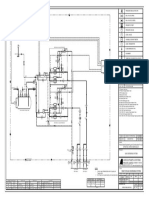

NATURAL DRAFT

AIR COOLER

CONDENSED

LIQUIDS TO

STORAGE

WILDEN M1 PUMP

NATCO BTEX BUSTER SKID UNIT

HEAT COIL

FUEL GAS SUPPLY

NON-CONDENSABLE GAS

GLYCOL REBOILER/SURGE 2 PHASE

SEPARATOR

LOCATI ONS OTHER LOCATI ONS

United States of America

11210 Equity Dr., Suite 100

Houston, TX 77041

USA

Tel 1 713 849 7500

United Kingdom

Cameron House

61-73 Staines Road West

Sunbury-on-Thames

Middlesex TW16 7AH

England, UK

Tel 44 1932 732000

Singapore

2 Gul Circle (Gate 2)

Jurong, Singapore 629560

Tel 65 6861 3355

Australia

Brazil

Canada

Colombia

France

Japan

Malaysia

Mexico

Russia

Saudi Arabia

UAE

ww. c- a- m. com

Você também pode gostar

- Natural Gas Processing from Midstream to DownstreamNo EverandNatural Gas Processing from Midstream to DownstreamNimir O. ElbashirAinda não há avaliações

- Replace Gas-Assisted Glycol Pumps with Electric for Efficiency and EmissionsDocumento11 páginasReplace Gas-Assisted Glycol Pumps with Electric for Efficiency and EmissionsAmji ShahAinda não há avaliações

- Dimensionamiento de Un Aeroenfriador de GasDocumento14 páginasDimensionamiento de Un Aeroenfriador de GasHernan Coba100% (1)

- Glycol Dehydration Instrumentation and ControlsDocumento3 páginasGlycol Dehydration Instrumentation and ControlsdndudcAinda não há avaliações

- GPA Standard 2174-93Documento15 páginasGPA Standard 2174-93marcosAinda não há avaliações

- Bulk Water SeparationDocumento1 páginaBulk Water SeparationSean MiddletonAinda não há avaliações

- Cromatografo de Gas NaturalDocumento8 páginasCromatografo de Gas NaturalJinhichi Molero RodriguezAinda não há avaliações

- Design of LNG Plant Facilities.: N.Bandyopadhyay - Consulting EngineerDocumento6 páginasDesign of LNG Plant Facilities.: N.Bandyopadhyay - Consulting EngineerHoàng KakaAinda não há avaliações

- CyrogenicDocumento4 páginasCyrogenicBayu SaputraAinda não há avaliações

- Principles of Hydrocarbon Dew PointDocumento4 páginasPrinciples of Hydrocarbon Dew PointRowan BalajiAinda não há avaliações

- Operation Manual for Condensate Stabilization UnitDocumento23 páginasOperation Manual for Condensate Stabilization UnitVraja Kisori100% (1)

- PSV Load Calculation For Gas Expantion Fire Case PDFDocumento2 páginasPSV Load Calculation For Gas Expantion Fire Case PDFAnonymous V5UYBUMaAinda não há avaliações

- LPG enDocumento20 páginasLPG enrenger20150303Ainda não há avaliações

- LNG Boil-Off Re-Liquefaction Plants and Gas Combustion UnitsDocumento7 páginasLNG Boil-Off Re-Liquefaction Plants and Gas Combustion UnitsAshish SawantAinda não há avaliações

- TCVN 6486Documento14 páginasTCVN 6486Nguyen Duc Thien PhucAinda não há avaliações

- Nitrogen RejectionDocumento7 páginasNitrogen RejectionOmar TocmoAinda não há avaliações

- Electrostatic Desalter Process Data SheetDocumento10 páginasElectrostatic Desalter Process Data SheetfedemochileroAinda não há avaliações

- Storage PropaneDocumento70 páginasStorage PropaneAnonymous GfPSYi4nAinda não há avaliações

- Tank Battery Design PDFDocumento4 páginasTank Battery Design PDFdigeca100% (1)

- Procedure For Transfer of Bunkers To Vessel - ISO 13739Documento50 páginasProcedure For Transfer of Bunkers To Vessel - ISO 13739asep supriyadi100% (1)

- Varicon Pumps & Systems Private Limited: P&Id For Gas Odorizing SystemDocumento1 páginaVaricon Pumps & Systems Private Limited: P&Id For Gas Odorizing SystemDeva NaiduAinda não há avaliações

- CMPAPPP Separator Vessel and Filter Design GuideDocumento18 páginasCMPAPPP Separator Vessel and Filter Design GuideJWilson73Ainda não há avaliações

- Linde - LBPP HistoryDocumento9 páginasLinde - LBPP Historynacho_16727Ainda não há avaliações

- 245 NGL Deethanizer Capacity ExpansionDocumento1 página245 NGL Deethanizer Capacity ExpansionRafeek Emad AbdElkader0% (1)

- Teg ContactorDocumento4 páginasTeg ContactorrepentinezAinda não há avaliações

- Ground Flares - Key Considerations for LNG ProjectsDocumento8 páginasGround Flares - Key Considerations for LNG ProjectsNurul Atiqah Ahmad Kamal100% (1)

- BBS-10-W8-DS-011 - C - Glycol Surge Drum DS PDFDocumento2 páginasBBS-10-W8-DS-011 - C - Glycol Surge Drum DS PDFAdianto RahmanAinda não há avaliações

- HYSYS Simulation For Natural Gas Dehydration and SweeteningDocumento8 páginasHYSYS Simulation For Natural Gas Dehydration and SweeteningHaziq MirzaAinda não há avaliações

- BOIL OFF GAS ANALYSISDocumento8 páginasBOIL OFF GAS ANALYSISJetul PatelAinda não há avaliações

- Environmental Protection TechnologiesDocumento4 páginasEnvironmental Protection TechnologiesKostyantyn DrobotAinda não há avaliações

- Gas Dehydration and TEG Regeneration Process OverviewDocumento60 páginasGas Dehydration and TEG Regeneration Process OverviewSuryaprakashAinda não há avaliações

- Enclosed Ground FlareDocumento4 páginasEnclosed Ground FlareAamerMAhmadAinda não há avaliações

- Smokelesss Flare - Air AssistsedDocumento19 páginasSmokelesss Flare - Air AssistsedvasuAinda não há avaliações

- Flare Gas Recovery & Zero Flare SolutionsDocumento16 páginasFlare Gas Recovery & Zero Flare SolutionsEddie TaiAinda não há avaliações

- Technical PaperDocumento6 páginasTechnical PaperCJ CHAinda não há avaliações

- De Sulfur IzationDocumento2 páginasDe Sulfur IzationngotrongthucAinda não há avaliações

- 2015 References Terminals EDocumento59 páginas2015 References Terminals EAllyson JohnsonAinda não há avaliações

- Non-exhaustive structural design criteriaDocumento22 páginasNon-exhaustive structural design criteriamarin cristian100% (1)

- Nioec SP 47 27Documento29 páginasNioec SP 47 27sgh1355Ainda não há avaliações

- Marine Vapour ControlDocumento3 páginasMarine Vapour Controlgatzbu81100% (1)

- SMR Hydrogen Generators-Technologies and Producers 2009Documento28 páginasSMR Hydrogen Generators-Technologies and Producers 2009Zoran JuricAinda não há avaliações

- Flares ImDocumento270 páginasFlares ImnelsonsenaAinda não há avaliações

- On The Design of Thermal BreathingDocumento6 páginasOn The Design of Thermal BreathingLizbeth Fiallos AvilaAinda não há avaliações

- Spray Chapter3Documento66 páginasSpray Chapter3Paijo TejoAinda não há avaliações

- Demountable Flare: Parts & Service Incinerators Flares BurnersDocumento4 páginasDemountable Flare: Parts & Service Incinerators Flares BurnersTONAinda não há avaliações

- A03 Hydrocarbon Dew Point Control Rev 07-10Documento2 páginasA03 Hydrocarbon Dew Point Control Rev 07-10Arif MokhtarAinda não há avaliações

- SulfolaneAppendices A EDocumento158 páginasSulfolaneAppendices A Erkhandelwal9604Ainda não há avaliações

- Case Study - Butadiene IncidentDocumento4 páginasCase Study - Butadiene IncidentHimat KhimaniAinda não há avaliações

- Chebeir2019 PDFDocumento16 páginasChebeir2019 PDFAndrea RodriguezAinda não há avaliações

- CATALYTIC HEATERS OVERVIEWDocumento4 páginasCATALYTIC HEATERS OVERVIEWmauricio_rrAinda não há avaliações

- Pages From Liquefied Petroleum Gas Volume 1 Large Bulk Pressure Storage and Refrigerated LPGDocumento12 páginasPages From Liquefied Petroleum Gas Volume 1 Large Bulk Pressure Storage and Refrigerated LPGAtty AttyAinda não há avaliações

- SRU UnitDocumento33 páginasSRU UnitCenk Yağız ÖzçelikAinda não há avaliações

- Pressure Relief Venting SystemsDocumento6 páginasPressure Relief Venting SystemsDaniel Puello RodeloAinda não há avaliações

- Piping Design 5 PDFDocumento9 páginasPiping Design 5 PDFSandra MArrugo100% (1)

- GAS DEHYDRATION (TEG) SYSTEMDocumento2 páginasGAS DEHYDRATION (TEG) SYSTEMJaya DevAinda não há avaliações

- 27 UnionfiningDocumento2 páginas27 Unionfiningali11111Ainda não há avaliações

- LNG - Storage - Tank - Rollover PDFDocumento7 páginasLNG - Storage - Tank - Rollover PDFchemsac20% (1)

- Pump Selection For The LNG IndustryDocumento0 páginaPump Selection For The LNG IndustryZaid Tariq AlabiryAinda não há avaliações

- Road Map Update for Carbon Capture, Utilization, and Storage Demonstration and Deployment in the People’s Republic of ChinaNo EverandRoad Map Update for Carbon Capture, Utilization, and Storage Demonstration and Deployment in the People’s Republic of ChinaAinda não há avaliações

- Condensate Stab 2013 AIChE 91a Paper292728Documento14 páginasCondensate Stab 2013 AIChE 91a Paper292728Samaneh HajipourAinda não há avaliações

- Shiraz Festival Avant Garde Arts Performance in 1970s IranDocumento7 páginasShiraz Festival Avant Garde Arts Performance in 1970s IranSamaneh HajipourAinda não há avaliações

- My Favorite HafizDocumento57 páginasMy Favorite HafizIlaria MallardiAinda não há avaliações

- My Favorite HafizDocumento57 páginasMy Favorite HafizIlaria MallardiAinda não há avaliações

- 2009 GHG Compendium PDFDocumento807 páginas2009 GHG Compendium PDFAmpornchai PhupolAinda não há avaliações

- 2010 Subpart-W RTC Part2Documento849 páginas2010 Subpart-W RTC Part2Samaneh HajipourAinda não há avaliações

- Aspen Customization and Automation Study With Details PDFDocumento374 páginasAspen Customization and Automation Study With Details PDFAhmed D. JonjunAinda não há avaliações

- My Favorite HafizDocumento57 páginasMy Favorite HafizIlaria MallardiAinda não há avaliações

- Transportation of Petroleum LiquidsDocumento17 páginasTransportation of Petroleum LiquidsWaseem SiddiqueAinda não há avaliações

- 2014-2015 NPRI GuideDocumento63 páginas2014-2015 NPRI GuideSamaneh HajipourAinda não há avaliações

- D323 Comments From Rey Montemayor On Michael Hlavinka's E-Mail RequestDocumento3 páginasD323 Comments From Rey Montemayor On Michael Hlavinka's E-Mail RequestSamaneh HajipourAinda não há avaliações

- FlowersDocumento1 páginaFlowersSamaneh HajipourAinda não há avaliações

- 2004 Clearstone Document-Volume 1 PDFDocumento248 páginas2004 Clearstone Document-Volume 1 PDFSamaneh HajipourAinda não há avaliações

- Directive 039: Revised Program To Reduce Benzene Emissions From Glycol DehydratorsDocumento9 páginasDirective 039: Revised Program To Reduce Benzene Emissions From Glycol DehydratorsSamaneh HajipourAinda não há avaliações

- RandD Final ReportDocumento6 páginasRandD Final ReportSamaneh HajipourAinda não há avaliações

- SHV Flare System Data SheetDocumento2 páginasSHV Flare System Data SheetSamaneh HajipourAinda não há avaliações

- Directive 039: Revised Program To Reduce Benzene Emissions From Glycol DehydratorsDocumento9 páginasDirective 039: Revised Program To Reduce Benzene Emissions From Glycol DehydratorsSamaneh HajipourAinda não há avaliações

- VLE, Part 1 - An Appraisal Od Data Reduction MethodsDocumento7 páginasVLE, Part 1 - An Appraisal Od Data Reduction MethodsSamaneh HajipourAinda não há avaliações

- Pressure Sensitive Adhesive Tape ManualDocumento6 páginasPressure Sensitive Adhesive Tape ManualJurgyan IndustriesAinda não há avaliações

- Prajna YogaDocumento10 páginasPrajna YogaPrajna yogaAinda não há avaliações

- RGPH Specification Sheets PDFDocumento0 páginaRGPH Specification Sheets PDFITLHAPNAinda não há avaliações

- Cantonment Bye Law 2019 Dated 09 12 2019Documento160 páginasCantonment Bye Law 2019 Dated 09 12 2019omerumeromer100% (2)

- Closed Comminutive Fracture Middle Left Clavicle Allman Classification Group IDocumento32 páginasClosed Comminutive Fracture Middle Left Clavicle Allman Classification Group IWilliamtatokieesz Tembokrumahampebenjol-benjolAinda não há avaliações

- Estimation of Fire Loads For An Educational Building - A Case StudyDocumento4 páginasEstimation of Fire Loads For An Educational Building - A Case StudyEditor IJSETAinda não há avaliações

- UNILIA CURRICURUM VITAE - Mwayi ChirwaDocumento5 páginasUNILIA CURRICURUM VITAE - Mwayi ChirwaBRIGHT TEMBOAinda não há avaliações

- Mrs. Usha SangwanDocumento1 páginaMrs. Usha Sangwandivyakumari7414Ainda não há avaliações

- Thermal Death Kinetics of MicroorganismsDocumento6 páginasThermal Death Kinetics of MicroorganismsShubham MannaAinda não há avaliações

- Estimation of Genetic Variability and DiversityDocumento4 páginasEstimation of Genetic Variability and DiversityCharles WeslyAinda não há avaliações

- H Calculations - Enthalpy of SolutionDocumento3 páginasH Calculations - Enthalpy of SolutionArif PurwadanaAinda não há avaliações

- Opinion About The Drug WarDocumento1 páginaOpinion About The Drug WarAnonymous JusFNTAinda não há avaliações

- CH 06 Sec 03Documento12 páginasCH 06 Sec 03Verra Myza AratAinda não há avaliações

- Instrument Transformer CVT TransformerDocumento6 páginasInstrument Transformer CVT Transformerkajrare_1947Ainda não há avaliações

- Fazal Din Stock ControlDocumento30 páginasFazal Din Stock ControlPadietAinda não há avaliações

- Tecnodiesel AC350 Cummins 6LTAA9.5-G1 LS TAL 440VDocumento10 páginasTecnodiesel AC350 Cummins 6LTAA9.5-G1 LS TAL 440VJose DarioAinda não há avaliações

- Bicep Training Tips For Hypertrophy - Renaissance PeriodizationDocumento5 páginasBicep Training Tips For Hypertrophy - Renaissance PeriodizationKyle WatsonAinda não há avaliações

- Introduction to Arudha Lagna and its HousesDocumento20 páginasIntroduction to Arudha Lagna and its HousesE.n. SreenivasuluAinda não há avaliações

- Split Ac Repair Trainer: InstructionDocumento10 páginasSplit Ac Repair Trainer: InstructionSingh ShubhamAinda não há avaliações

- Onshore Knockout Drum GuidanceDocumento2 páginasOnshore Knockout Drum Guidanceneil_nhAinda não há avaliações

- CE 132 - Geotechnical Engineering 2Documento38 páginasCE 132 - Geotechnical Engineering 2hahaduAinda não há avaliações

- Facade LectureDocumento71 páginasFacade LectureYigezu YehombaworkAinda não há avaliações

- UNIT 5 - Our World - ResourcesDocumento14 páginasUNIT 5 - Our World - ResourcesVirginia CanabalAinda não há avaliações

- x2 Electric Bike ManualDocumento16 páginasx2 Electric Bike ManualwroxtarAinda não há avaliações

- ANSI AHRI Standard 850 I-P 2013Documento16 páginasANSI AHRI Standard 850 I-P 2013Sergio Motta GarciaAinda não há avaliações

- Admit Card: Instructions To The CandidateDocumento1 páginaAdmit Card: Instructions To The CandidateLavkush YadavAinda não há avaliações

- Throat PowerpointDocumento29 páginasThroat Powerpointminci sensei100% (8)

- KEYWORDS: Precipitation, Analytics, Volhard'S Method: AbstractDocumento2 páginasKEYWORDS: Precipitation, Analytics, Volhard'S Method: AbstractThania GonzlezAinda não há avaliações

- Reports On How The CovidDocumento2 páginasReports On How The CovidRama KanthAinda não há avaliações

- History Taking - Progress NotesDocumento21 páginasHistory Taking - Progress Notestwgp6pg5gh100% (1)