Escolar Documentos

Profissional Documentos

Cultura Documentos

Final Poster Presentation

Enviado por

Pinjala Anoop0 notas0% acharam este documento útil (0 voto)

210 visualizações1 páginaBehaviour of mass transfer in drying of clothes

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoBehaviour of mass transfer in drying of clothes

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

210 visualizações1 páginaFinal Poster Presentation

Enviado por

Pinjala AnoopBehaviour of mass transfer in drying of clothes

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 1

Examining the principles of heat and mass transfer in

Natural drying of clothes

CONCLUSIONS

1. The mass transfer coefficient has no dependence on the colour of the fabric

unlike the heat transfer coefficient.

2. The lesser the relative humidity of the surroundings, the faster it helps in

drying the clothes.

3. With the increase in the temperature of the surroundings, the time taken for

the clothes to dry is considerably reduced.

4. The variation in the rate of drying is not appreciable due to the colour

change as the effect of radiation heat transfer can be neglected.

IMPROVEMENTS

1. This experiment can be extended to include forced convection as well.

2. Instead of just using constant rate of drying, falling rates can be

incorporated in the drying curve.

REFERENCES

1. http://nptel.ac.in/courses/103103032/22

2. http://www.engineeringtoolbox.com/air-properties-d_156.html

3. Treybal, R. E.: Mass Transfer Operation. 2nd ed.,McGraw-Hill Book Co.,

1968

4. http://www.eattheweeds.com/how-ungreen-of-us-2/

5. http://www.conservationphysics.org/wetstuff/wetstuff01.php

6. http://www.kwangu.com/work/psychrometric.htm

MONISH BHANGALE (11110056) & ANOOP PINJALA (11110016)

AIM

The prime objective of this poster was to analyze the effect of

drying process at different temperatures varying the relative

humidity and the change in the value of the mass transfer

coefficient due the variation the relative humidity and also

effect of absorptivity of different colors on the rate of drying.

CALCULATIONS

Assumptions: Constant rate of drying and natural convection on a vertical surface.

Area and effective length of the fabric is 1.5m

2

and 0.71m respectively. The weight of

the dry fabric is 150 gm and it is assumed to be completely saturated with the liquid.

(assumed to be at wet bulb temperature).

Let the temperature of the surroundings be T

G

and the relative humidity of the air be x

%. These data can be accessed from the weather report of the area. Then the moisture

content of the air can be calculated, Y

S

. The temperature of the wet cloth would be

assumed to be equal to the wet bulb temperature of T

G

, i.e. T

S

. Moisture content at the

temperature T

S

is Y.

Amount of heat transferred, Q = heat due to convection + heat due to radiation.

Therefore, Q = h

C

A(T

G

-T

S

) + A(T

G

4

-T

S

4

).

Let h

R

= A(T

G

+T

S

) (T

G

2

+T

S

2

) and q= Q/A

q = (h

C

+ h

R

) (T

G

-T

S

). Also, let H = (h

C

+ h

R

)

q = H (T

G

-T

S

) (i)

The value of h

C

can be calculated using Dittus-Boelter/ Sieder-Tate relations by

computing the values of Reynolds number and Prandtl number of ambient air.

Rate of mass transfer, N

C

= K

Y

(Y

S

- Y) (ii)

Equating heat and mass transfer, from equations (i) and (ii), we have,

N

C

= q/ . Therefore,

K

Y

=

H(TGT

S

)

(YS Y)

.

Hence the mass transfer coefficient of the material can be found out.

For the calculation of h

C

, the following equation is used:

CL352 Chemical

Engineering Lab -3

Lab Instructors: Prof. Nitin Padhiyar

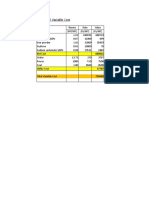

Weather conditions Time taken to dry in minutes Mass transfer coefficient (kg/m.s2) Heat transfer coefficient due to convection (W/m2.K)

Temp RH(%) Black Blue Red White Silver Black Blue Red White Silver Black Blue Red White Silver

25

40 20.02 20.02 20.03 20.03 20.03 0.821 0.821 0.820 0.820 0.820 0.0021 0.0010 0.0017 0.0007 0.0013

55 30.26 30.26 30.27 30.27 30.28 0.720 0.720 0.720 0.720 0.720 0.0024 0.0012 0.0020 0.0008 0.0016

70 52.80 52.81 52.83 52.84 52.85 0.617 0.617 0.617 0.617 0.617 0.0028 0.0013 0.0023 0.0010 0.0018

90 221.26 221.34 221.42 221.50 221.56 0.438 0.438 0.438 0.438 0.438 0.0033 0.0016 0.0027 0.0011 0.0021

35

40 15.33 15.34 15.34 15.35 15.35 0.582 0.582 0.582 0.581 0.581 0.0060 0.0029 0.0049 0.0021 0.0039

55 23.62 23.63 23.65 23.66 23.67 0.500 0.500 0.499 0.499 0.499 0.0069 0.0033 0.0057 0.0024 0.0045

70 41.87 41.90 41.92 41.95 41.97 0.419 0.419 0.419 0.419 0.418 0.0078 0.0038 0.0064 0.0027 0.0051

90 178.31 178.49 178.66 178.83 178.96 0.292 0.292 0.292 0.291 0.291 0.0091 0.0044 0.0075 0.0032 0.0059

45

40 12.19 12.20 12.21 12.22 12.23 0.405 0.405 0.405 0.404 0.404 0.0131 0.0063 0.0108 0.0046 0.0085

55 19.10 19.12 19.14 19.16 19.17 0.340 0.339 0.339 0.339 0.338 0.0151 0.0072 0.0124 0.0053 0.0098

70 34.27 34.32 34.36 34.41 34.44 0.280 0.279 0.279 0.279 0.278 0.0170 0.0082 0.0139 0.0059 0.0110

90 147.62 147.93 148.22 148.51 148.73 0.191 0.190 0.190 0.189 0.189 0.0195 0.0093 0.0160 0.0068 0.0126

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

0 1 2 3 4 5

M

A

S

S

T

R

A

N

S

F

E

R

C

O

E

F

F

I C

I E

N

T

RELATIVE HUMIDITY

1-40% 2-55% 3-70% 4-90%

VARI AT I ON OF MAS S T RANS F E R

COE F F I CI E NT F OR BL ACK WI T H CHANGE I N

RH

25C 35C 45C

Black

blue

red

White

Silver

0

5

10

15

20

25

1 2 3

T

I M

E

I N

M

I N

U

T

E

S

TEMPERATURE

1-25C 2-35C 3-45C

ME AS URI NG T I ME WI T H CONS T ANT RH( 4 0 %)

F OR VARY I NG T E MP E RAT URE S F OR

DI F F E RE NT COL OURS

INTRODUCTION

Fabrics are usually dried up for the purposes of storing or setting. Using thermal

energy to dry up and perform setting has been the most traditional and effective

method. In this study, heated air is used as a processing agent. Its physical

properties will be changed when it gains moisture and loses thermal energy. The

moisture in the fabric will be heated to form vapors after gaining energy from the air

at higher temperature to initiate a mass transfer process.

40%

55%

70%

90%

0

200

400

1 2 3

T

I M

E

I N

M

I N

U

T

E

S

TEMPERATURE

1-25C 2-35C 3-45C

VARY I NG RH AND T E MP E RAT URE F OR

BL ACK CL OT H

Black

BLue

Red

White

Silver

0

50

100

150

200

250

1 2 3 4

T

I M

E

I N

M

I N

U

T

E

S

RELATIVE HUMIDITY

1-40% 2-55% 3-70% 4-90%

T E MP E RAT URE I S CONS T ANT AND VARY I NG

T HE RH F OR DI F F E RE NT COL ORS

BLack

Blue

Red

White

Silver

0

0.005

0.01

0.015

0.02

1 2 3

D

R

Y

I N

G

R

A

T

E

( K

G

/

M

^

2

. S

E

C

)

TEMPERATURE

1-25C 2-35C 3-45C

CONS T ANT RH( 4 0 %) F OR VARY I NG

T E MP E RAT URE S F OR DI F F E RE NT COL OURS

25C

35C

45C

0

0.01

0.02

1 2 3 4

D

R

Y

I N

G

R

A

T

E

RELATIVE HUMIDITIES

1-40% 2-55% 3-70% 4-90%

VARY I NG RH AND T E MP E RAT URE F OR BL UE

CL OT H

Black

Red

Silver

0

0.005

0.01

1 2 3 4

D

R

Y

I N

G

R

A

T

E

RELATIVE HUMIDITIES

1-40% 2-55% 3-70% 4-90%

T E MP E RAT URE I S CONS T ANT AND VARY I NG

T HE RH F OR DI F F E RE NT COL ORS

Lab experiments related to

this poster

1. Calculation of mass

transfer coefficient.

2. Absorptivity of different

surfaces

3. Drying

Latent heat

Sensible heat

Você também pode gostar

- Aeron Chairs Service InstructionsDocumento182 páginasAeron Chairs Service InstructionsMatt Wang0% (1)

- Tray Dryer Final ReportDocumento13 páginasTray Dryer Final ReportHaziq AzliAinda não há avaliações

- A Theory of Dropwise CondensationDocumento187 páginasA Theory of Dropwise CondensationJuvy A. BalbaronaAinda não há avaliações

- Lab Report CMT 450 Tray DryerDocumento3 páginasLab Report CMT 450 Tray DryerJohanAinda não há avaliações

- Bernoulli EquationDocumento6 páginasBernoulli EquationMohanadAlrofuAinda não há avaliações

- FIE Physics Lab Report 2Documento8 páginasFIE Physics Lab Report 2Sharvind Kumar Sharvind KumarAinda não há avaliações

- Formal Report - AspirinDocumento4 páginasFormal Report - AspirinMeah PachecoAinda não há avaliações

- HeatDocumento12 páginasHeatmohamedAinda não há avaliações

- Lab Report PFR PDFDocumento11 páginasLab Report PFR PDFMohd Saiful RidzuanAinda não há avaliações

- Roles & Responsibilities of An AssessorDocumento2 páginasRoles & Responsibilities of An AssessorLexJames100% (1)

- Heat TranferDocumento17 páginasHeat TranferLuis González Cos Alcocer100% (1)

- Distillation ColumnDocumento6 páginasDistillation ColumnArif HanafiAinda não há avaliações

- Data Sheet Air Foam ChamberDocumento1 páginaData Sheet Air Foam ChamberPinjala AnoopAinda não há avaliações

- Plan 53 BDocumento2 páginasPlan 53 BPinjala AnoopAinda não há avaliações

- Standard Refinery Fuel TonsDocumento2 páginasStandard Refinery Fuel TonsPinjala Anoop100% (4)

- SN398 2008-04 eDocumento4 páginasSN398 2008-04 ewasim_akp9885Ainda não há avaliações

- 5 Electricity Test AnswersDocumento4 páginas5 Electricity Test AnswersnajehAinda não há avaliações

- Integrated Cheese PlantDocumento5 páginasIntegrated Cheese PlantMohamedAinda não há avaliações

- Ex 1Documento7 páginasEx 1yad AGAinda não há avaliações

- Nitric Acid: Created By:-Aman Arya 10 A Class Roll No:-3Documento8 páginasNitric Acid: Created By:-Aman Arya 10 A Class Roll No:-3Aman AryaAinda não há avaliações

- Qasim Project Poster Final.Documento1 páginaQasim Project Poster Final.Qasim KhanAinda não há avaliações

- Bourdon GaugeDocumento4 páginasBourdon GaugeShahid Mehmud100% (1)

- Experiment 4 PDFDocumento4 páginasExperiment 4 PDFbhavesh pansuriyaAinda não há avaliações

- Coca Cola DistillationDocumento2 páginasCoca Cola DistillationSyahla Aurelya Djailani 7AAinda não há avaliações

- Experiment #01: ObjectiveDocumento10 páginasExperiment #01: ObjectiveMian GulshadAinda não há avaliações

- Plug Flow ReactorDocumento16 páginasPlug Flow ReactorN Afiqah RazakAinda não há avaliações

- Transport Process (Fluidization Beds)Documento6 páginasTransport Process (Fluidization Beds)zujishorok7Ainda não há avaliações

- Experiment Manual - Liquid-Liquid ExtractionDocumento24 páginasExperiment Manual - Liquid-Liquid ExtractionStolen RememberAinda não há avaliações

- Section 4.5 Optimization Problems 2010 Kiryl TsishchankaDocumento12 páginasSection 4.5 Optimization Problems 2010 Kiryl TsishchankaAlexis Julia CanariaAinda não há avaliações

- Heat Engines Lab ReportDocumento3 páginasHeat Engines Lab Reportapi-257546392Ainda não há avaliações

- Files 2-Experiments Homogenuous Batch ReactorDocumento6 páginasFiles 2-Experiments Homogenuous Batch ReactorS M AseemAinda não há avaliações

- Aspen Plus Biodiesel Model Aspen PlusDocumento23 páginasAspen Plus Biodiesel Model Aspen PlusLe Nguyen Phuc ThienAinda não há avaliações

- CPI LAB ManualDocumento76 páginasCPI LAB ManualFarhad Iqbal100% (2)

- Sep Lab Exp 1 LatestDocumento20 páginasSep Lab Exp 1 LatestChan Chun ChenAinda não há avaliações

- Volumetric Flow Rate Q 50 Total Volume V 2000 Concentration at Inlet C 2 Rate Constant K 0.198 Velocity V 3.8Documento9 páginasVolumetric Flow Rate Q 50 Total Volume V 2000 Concentration at Inlet C 2 Rate Constant K 0.198 Velocity V 3.8Shadow OpAinda não há avaliações

- Gas UnitDocumento4 páginasGas UnitZalina SamsuddinAinda não há avaliações

- Experiment 3: Le Châtelier's Principle: Cabajar, Jairus B., Dionisio, Nicole Anna Marie H. Group 3Documento25 páginasExperiment 3: Le Châtelier's Principle: Cabajar, Jairus B., Dionisio, Nicole Anna Marie H. Group 3twinkledreampoppiesAinda não há avaliações

- Is 1448 (P 1) 2002 Determination of Acid Number of Petroleum Products by Potentiometric TitrationDocumento17 páginasIs 1448 (P 1) 2002 Determination of Acid Number of Petroleum Products by Potentiometric TitrationMalouk CheniouniAinda não há avaliações

- 1180 Exp 04, Density and Specific GravityDocumento13 páginas1180 Exp 04, Density and Specific GravityShaniCoolestAinda não há avaliações

- UO 6 Sedimentation Study UnitDocumento8 páginasUO 6 Sedimentation Study Uniteven lee100% (1)

- CHME324-B-Lab Manual Fall 2016 (Ahmed Elkhatat)Documento99 páginasCHME324-B-Lab Manual Fall 2016 (Ahmed Elkhatat)bebsybiswezAinda não há avaliações

- Drag CoefficientDocumento5 páginasDrag CoefficientRaghav MainiAinda não há avaliações

- 333 Manual 11 T2 Armfield ManualDocumento45 páginas333 Manual 11 T2 Armfield ManualSyamim AsyrafAinda não há avaliações

- P4E2: Kinetics of Homogeneous Reaction in Batch and Continuous Stirred-Tank Reactor at Two Different TemperatureDocumento7 páginasP4E2: Kinetics of Homogeneous Reaction in Batch and Continuous Stirred-Tank Reactor at Two Different TemperaturejayaprinaAinda não há avaliações

- Batch Distillation ExperimentDocumento8 páginasBatch Distillation ExperimentJonelou CusipagAinda não há avaliações

- Condensation in Drop and Film FormDocumento5 páginasCondensation in Drop and Film FormAshish VermaAinda não há avaliações

- Diagram/ Image:: Experiment Number: 02Documento10 páginasDiagram/ Image:: Experiment Number: 02Roshan Dhikale100% (1)

- Chap 3 - Utilities in Chem Process IndDocumento73 páginasChap 3 - Utilities in Chem Process IndAmir AzimAinda não há avaliações

- Cebu Institute of Technology - University: CHE501-V1 Group 2Documento11 páginasCebu Institute of Technology - University: CHE501-V1 Group 2Joshua ClimacoAinda não há avaliações

- SCILAB Tutorial For DSP PDFDocumento21 páginasSCILAB Tutorial For DSP PDFrichardvmorenoAinda não há avaliações

- Chap5 Design Specification Column D-101Documento10 páginasChap5 Design Specification Column D-101Liew KahJiannAinda não há avaliações

- Determination of The Heat Capacity of A CalorimeterDocumento8 páginasDetermination of The Heat Capacity of A CalorimeterVictor NyarugweAinda não há avaliações

- Mass Transfer Lab ManualDocumento29 páginasMass Transfer Lab ManualPrajwal ChavanAinda não há avaliações

- Conclusion CPP Bubble Cap DistillationDocumento2 páginasConclusion CPP Bubble Cap DistillationAhmad KhalidAinda não há avaliações

- Cre 1 IntroductionDocumento4 páginasCre 1 IntroductionEvangeline LauAinda não há avaliações

- Liquid Liquid ExtractionDocumento36 páginasLiquid Liquid ExtractionamirnimoAinda não há avaliações

- Che545 Mass Transfer Assignment 1Documento3 páginasChe545 Mass Transfer Assignment 1soapAinda não há avaliações

- Unit Operation Laboratory 2 (CCB 3062)Documento7 páginasUnit Operation Laboratory 2 (CCB 3062)Carl Erickson100% (1)

- Exp 2 Batch DistillationDocumento12 páginasExp 2 Batch DistillationSabrina AzharAinda não há avaliações

- 7405Documento8 páginas7405Ebby OnyekweAinda não há avaliações

- Distillation 3Documento36 páginasDistillation 3Renu SekaranAinda não há avaliações

- The Heat of Solution LabDocumento4 páginasThe Heat of Solution Labapi-310957734Ainda não há avaliações

- Study On Ethanol-Water Batch Distillation Tsf-1022Documento11 páginasStudy On Ethanol-Water Batch Distillation Tsf-1022Robiel GashuAinda não há avaliações

- 1982 Catalytic Air Oxidation of Propylene To AcroleinDocumento12 páginas1982 Catalytic Air Oxidation of Propylene To AcroleinChauAinda não há avaliações

- Open-Ended Problems: A Future Chemical Engineering Education ApproachNo EverandOpen-Ended Problems: A Future Chemical Engineering Education ApproachAinda não há avaliações

- Practical Chemical Thermodynamics for GeoscientistsNo EverandPractical Chemical Thermodynamics for GeoscientistsAinda não há avaliações

- Data Sheet Co2 Cylinder AssemblyDocumento2 páginasData Sheet Co2 Cylinder AssemblyPinjala AnoopAinda não há avaliações

- Inline Mixing JGS 210-120-1-72E: ConfidentialDocumento11 páginasInline Mixing JGS 210-120-1-72E: ConfidentialPinjala AnoopAinda não há avaliações

- Data Sheet Discharge NozzleDocumento1 páginaData Sheet Discharge NozzlePinjala AnoopAinda não há avaliações

- Preparation of LC and LG ArrangementDocumento13 páginasPreparation of LC and LG ArrangementPinjala AnoopAinda não há avaliações

- Data Sheet Cylinder Rack & Piping ManifoldDocumento1 páginaData Sheet Cylinder Rack & Piping ManifoldPinjala Anoop100% (1)

- Data Sheet Directional ValveDocumento1 páginaData Sheet Directional ValvePinjala AnoopAinda não há avaliações

- Tank Mixing JGS 210-120-1-66E: ConfidentialDocumento9 páginasTank Mixing JGS 210-120-1-66E: ConfidentialPinjala AnoopAinda não há avaliações

- PSA User Meet - JaipurDocumento2 páginasPSA User Meet - JaipurPinjala AnoopAinda não há avaliações

- Beacon - Corrosion Under InsulationDocumento1 páginaBeacon - Corrosion Under Insulationkave4923Ainda não há avaliações

- General Considerations: Design PracticesDocumento21 páginasGeneral Considerations: Design PracticesPinjala Anoop100% (1)

- 201906beaconenglish-Corrosion Under InsulationDocumento1 página201906beaconenglish-Corrosion Under InsulationguhadebasisAinda não há avaliações

- 2 Phase Flow OrificeDocumento14 páginas2 Phase Flow OrificePinjala AnoopAinda não há avaliações

- Points For Discussion During Training of Distillation Techniques, Operation & TroubleshootingDocumento1 páginaPoints For Discussion During Training of Distillation Techniques, Operation & TroubleshootingPinjala AnoopAinda não há avaliações

- Process DescriptionDocumento7 páginasProcess DescriptionPinjala AnoopAinda não há avaliações

- Safety Contact - Pipeline Bursted During HydrotestDocumento1 páginaSafety Contact - Pipeline Bursted During HydrotestPinjala AnoopAinda não há avaliações

- t000001864 - Filename2 - Press Tender For NHT - CCR - 24.07.2009-fDocumento88 páginast000001864 - Filename2 - Press Tender For NHT - CCR - 24.07.2009-fPinjala AnoopAinda não há avaliações

- OISD 166 GuidelinesDocumento50 páginasOISD 166 GuidelinesPinjala AnoopAinda não há avaliações

- Energy ConversionDocumento16 páginasEnergy ConversionPinjala AnoopAinda não há avaliações

- Centrifugal Compressor Surge Control Methods PDFDocumento1 páginaCentrifugal Compressor Surge Control Methods PDFPinjala AnoopAinda não há avaliações

- Standard Refinery Fuel TonsDocumento2 páginasStandard Refinery Fuel TonsPinjala AnoopAinda não há avaliações

- Fccu IiDocumento4 páginasFccu IiPinjala AnoopAinda não há avaliações

- DMS 06-04-2018Documento59 páginasDMS 06-04-2018Pinjala AnoopAinda não há avaliações

- Name: Katakam Sandeep Reddy Mobile: 9704575353: ResumeDocumento2 páginasName: Katakam Sandeep Reddy Mobile: 9704575353: ResumePinjala AnoopAinda não há avaliações

- DMS 16-12-2017Documento6 páginasDMS 16-12-2017Pinjala AnoopAinda não há avaliações

- OISD Check List - 1Documento5 páginasOISD Check List - 1Pinjala AnoopAinda não há avaliações

- QuizDocumento6 páginasQuizPinjala AnoopAinda não há avaliações

- 3-AAP Analysis ReportDocumento11 páginas3-AAP Analysis ReportPinjala AnoopAinda não há avaliações

- Iron and Steel Industry in Viet Nam: A New Phase and Policy ShiftDocumento35 páginasIron and Steel Industry in Viet Nam: A New Phase and Policy ShiftVictor GohAinda não há avaliações

- Bob Neal Overunity Compression Unit - US2030759Documento5 páginasBob Neal Overunity Compression Unit - US2030759John CarterAinda não há avaliações

- Electrical Basis of Design Standards GuidelinesDocumento19 páginasElectrical Basis of Design Standards Guidelinesessk100% (1)

- Popular Woodworking 213 (September-October 2014)Documento68 páginasPopular Woodworking 213 (September-October 2014)chrix100% (2)

- Tender Document - TechnicalDocumento37 páginasTender Document - TechnicalSujithkumar100% (1)

- Assembly Manual: Thermasteel CorporationDocumento28 páginasAssembly Manual: Thermasteel CorporationSarmishtha DeAinda não há avaliações

- K 5 Premium Full Control Plus: Operating InstructionsDocumento84 páginasK 5 Premium Full Control Plus: Operating Instructionsronald DAinda não há avaliações

- Hook Pallet Capacity CalculationDocumento2 páginasHook Pallet Capacity CalculationrustamriyadiAinda não há avaliações

- FLOWTITE - Installation Guide For Buried Pipes - AWWA - Abbr. Version - enDocumento31 páginasFLOWTITE - Installation Guide For Buried Pipes - AWWA - Abbr. Version - envuqar0979Ainda não há avaliações

- Shrinkage Allowance Draft Allowance Distortion or Camber Allowance Rapping or Shaking Allowance Finishing AllowanceDocumento75 páginasShrinkage Allowance Draft Allowance Distortion or Camber Allowance Rapping or Shaking Allowance Finishing AllowanceZaheer AhamedAinda não há avaliações

- 3 Solid Waste Management 2020Documento68 páginas3 Solid Waste Management 2020Emily KarungiAinda não há avaliações

- KTC-KTCG Series ManualDocumento20 páginasKTC-KTCG Series ManualWheat State welding LLC Jeremy100% (1)

- Tipos Concavos y MantosDocumento22 páginasTipos Concavos y MantosJose Luis Atao SantiagoAinda não há avaliações

- TMMDocumento21 páginasTMMAkash LohiAinda não há avaliações

- Transmission Towers DetailingDocumento38 páginasTransmission Towers DetailingFeleki AttilaAinda não há avaliações

- Static Electricity - Shocks & How To Avoid ThemDocumento4 páginasStatic Electricity - Shocks & How To Avoid ThemDerek OngAinda não há avaliações

- Uop Polybed Psa For Gas Extraction Purification DatasheetDocumento2 páginasUop Polybed Psa For Gas Extraction Purification DatasheetRaji RauofAinda não há avaliações

- 6 Retaining WallsDocumento18 páginas6 Retaining Wallsumit2699Ainda não há avaliações

- 2 - Conservation and The Use of Secondary and Recycled Materials PDFDocumento16 páginas2 - Conservation and The Use of Secondary and Recycled Materials PDFfa_fa67Ainda não há avaliações

- BS 5896 2012 - SecuredDocumento30 páginasBS 5896 2012 - SecuredAdonis KumAinda não há avaliações

- CONTRACTING OFFICE COMPANY LTD - (CONTRACO) Saudi A 2020-05-31 10-54-23Documento68 páginasCONTRACTING OFFICE COMPANY LTD - (CONTRACO) Saudi A 2020-05-31 10-54-23Ramil LazAinda não há avaliações

- Using The Failure Assessment Diagram Method With Fatigue Crack Growth To Determine Leak-before-RuptureDocumento15 páginasUsing The Failure Assessment Diagram Method With Fatigue Crack Growth To Determine Leak-before-RuptureMohammed EljammalAinda não há avaliações

- Knurling On CNC Lathes - 275: J3 SI S5Si 5Documento63 páginasKnurling On CNC Lathes - 275: J3 SI S5Si 5Cecep Devi NugrahaAinda não há avaliações

- BD 4415 ADocumento130 páginasBD 4415 Akhx2Ainda não há avaliações

- C5210HP Technical DataDocumento9 páginasC5210HP Technical Data顏健軒Ainda não há avaliações

- MacReburBrochure WebDocumento16 páginasMacReburBrochure WebYarSakawatuAinda não há avaliações

- Project Report On GearsDocumento40 páginasProject Report On Gearsjai70% (27)